Abstract

The engine is the power plant of the vehicle hence is called as heart of the vehicles. These engines may classify as internal and external combustion engines. Usually, internal combustions engines run with the diesel and petrol fuel. Due to the scarcity of these conventional fuels, this research work has on the alternative fuels. Where the alternative fuel is microalgae methyl ester (MME). The current research has dealt with the performance characteristics compression ignition engine fuelled with MME when the piston crown was coated with ceramic material zirconium oxide of thickness 350 microns equal to 0.35 mm of thickness using plasma spray coating technique. Test samples were prepared as MME10D90 (B10), MME20D80 (B20), and MME30D70 (B30). Finally, the experimental results revealed that, at full load condition, the BSFC, BTE and volumetric efficiency of the blend MME30D70 (B30) with coated engine were improved by 3.77%, 4.29% and 2.82% respectively.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- MME

- Zirconium oxide

- Ceramic coating

- Engine performance characteristics

- Brake thermal efficiency

- Brake specific fuel consumption

1 Introduction

Biodiesel is an organic product so it is sulphur free that’s why in emission point of view which gives favourable results. But due to carbohydrate content present in the biodiesel it gives some carbon related emissions but with the help of some techniques like exhaust gas recirculation, emissions may control. So, biodiesel is gives favourable results in case of emission point view that’s why this research work is mainly focussed on the performance characterises.

As the part of literature survey under the zone of bio–diesel, many research articles, conference papers, books and some research papers are referred, and the outcome of those research are discussed in detail as given below.

Agarwal et al. [1] confined that B20 gave a optimum performance among all the other. The results indicated that percentage of difference between diesel and the blend in case of BTE at peak condition was 2.5%. Which is a very small variation that’s why biodiesel is an alternative fuel.

Avinash et al. [2] has concluded that in diesel engine characteristics wise karanja biodiesel reported the favourable spry and atomization conditions when the fuel was preheated. Tarabet et al. [3] conducted an investigation on a altered DI engine functioned with can produce eucalyptus biodiesel and natural gas under dual fuel manner and the outcome shown that the inconsiderable NOX emissions.

Demirbas et al. [4] used algae as a biofuel and conducted the experiment on the diesel engine. This experiment has given the suggested results on the biodiesel especially CO2 were less as compared with the other fuels. Chisti et al. [5] investigated on microalgae as a non-traditional source and it had been described those microalgae gave equivalent amount of biodiesel related to rapeseed or soybean crops using around 49–132 times less land.

Converti et al. [6] stated that, the lipid content of microalgae decreased from 14.7% to 5.90% when the growing temperature increased from 25 to 30 °C. Charyulu et al. [7, 8] investigated a compression ignition engine under the effect of microalgae methyl ester and diesel blends, it has been conveyed that the blend B30 formed well performance and discharge outcomes linked to that of diesel. Kumar et al. (2017) have studied the consequence of insulation with ceramic constituents on the performance, combustion, and discharge features of an engine.

The surveys revealed that the biodiesel blends can be used as substitute fuels for engines. Current study has shown that the practice of biodiesel blends can considerably growth the engine performance and diminish the emissions. So, in the existing study investigate the performance characteristics of microalgae methyl ester (MME) in the ratios 10–30% with pure diesel blends. So, the present work focussed on performance characteristics of an engine powered by the blend of diesel and MME when the piston coated with the zirconium oxide.

2 Materials and Methods

In this study, the research work done on microalgae as the feed stock for producing bio-diesel. As per the literature survey, Microalgae are auspicious substitute oil for engines. Algae can be transformed into Bio-diesel, Bio-ethanol, Bio-hydrogen, Bio-oil and Bio-methane through bio-chemical methods (Fig. 1).

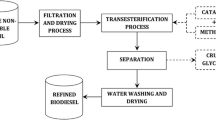

The crude oil which is extracted from the algae presented below. The major disadvantage in case of MME is viscosity content. There are different methods to reduce the viscosity but the most adopted methodology is transesterification (Fig. 2).

2.1 Transesterification

It is one of the primary mythologies to alter the unwanted fuel properties and fatty acids. This research has done on the catalytic transesterification.

The “Catalytic transesterification” procedure is the response of a triglyceride by an alcohol in the incidence of some catalyst such as sodium hydroxide or potassium hydroxide. The quantity of 1000 ml of crude algae oil is collected in flask. The measure 18 g of KOH is evaluated and 250 ml of methanol is mixed in beaker. KOH is merged with the alcohol and it is stirred while waiting for they are correctly dissolved (Fig. 3).

Micro algae oil has the fatty acid content of palmitic acid is 36.90, palmitoleic acid is11.90 margaric acid is 0.89, myristic acid is 9.10, oleic acid is 6.70 and linolenic acid is 22.30 etc. (Fig. 4).

2.2 Fuel Properties

Bio-diesel is an orgonic product. Usually, organic products contained hydro carbons due this reason it is must to verify the bio diesel properties will match or near the diesel or not. In this research work we measured main fuel properties with standard apparatus (Table 1).

2.3 Experimental Engine

The research was carried out to investigate the effect of microalgae methyl ester blends MME10D90, MME2080, and MME30D70 on performance of a diesel engine and compared to diesel fuel. The experimentation was carried out on Kirloskar make single cylinder four stroke water cooled and direct injection diesel engine (Fig. 5).

2.4 Preparation of Coated Piston

In the current study, the piston crown was treated with 0.35 mm thickness of zirconium oxide ceramic material to achieve semi LHR (Low Heat Rejection) engine which endures higher temperature in the combustion chamber that encourages the combustion. The motto of the work is to progress the performance of a diesel engine with ZrO2 treated piston by means of MME blends with several proportions fluctuating from 10 to 30% at dissimilar load situations (Fig. 6).

3 Results and Discussions

The diesel fuel was substituted with the mixtures of conventional diesel and biodiesel in the ratios 10–30% i.e., MME10D90, MME20D80, and MME30D70 by fluctuating 0–100% of load on the engine with raise of 25%. Subsequently completion of the test, now the normal piston of the engine is substituted with zirconium oxide treated piston and the above experiment is repeated in same way.

3.1 Relation Between the Brake Power and Brake Specific Fuel Consumption

Figure 7 represents the relation between the brake power (BP) and brake specific fuel consumption (BSFC) of all the test samples. It is evident from the graph that, for all the test fuels the BSFC decreased with increased brake power. Generally, brake specific fuel consumption is the measure of how the supplied fuel energy to the engine is converted into brake power and it can be defined as the amount of fuel consumed in unit time for generating kW power.

The experimental result revealed that, the BSFC of test fuels operated with coated engine was improved compared to pure diesel and base engine. Decrease in BSFC is due to the reduction in the fuel consumption and improved energy conversion rate at all loading conditions in the coated engine. This may be due to the increased temperature of the combustion chamber walls, which increase the temperature of the fuel issued from the heated fuel injecting nozzle resulting in the reduced fuel viscosity and better combustion of the fuel. At maximum load condition, MME30D70 with coated engine has registered lowest BSFC amongst all and it was improved by 9.80% compared to pure diesel and by 3.77% compared to base engine data.

3.2 Variation of Brake Thermal Efficiency with Brake Power

Figure 8 shows the variation of brake thermal efficiency (BTE) with brake power (BP) for all the test fuels. It can be noticed from the experimental results that, the BTE of all the test samples under coated engine was higher than that of base engine at all load conditions. This is due to the fact that, the thermal resistance of the piston crown which cannot allow the heat energy to coolant there by reducing the fuel consumption for the same amount of power output.

It can be observed that, at maximum load condition, the BTE of MME30D70 with coated engine is higher than that of pure diesel and base engine data. At full load condition, diesel has recorded 33.40% of BTE, MME30D70 with base engine has recorded 36.36% of BTE and with coated engine has recorded 37.92% BTE, therefore for coated engine the BTE of MME30D70 was increased by 13.54% compared to pure diesel and by 4.29% compared to base engine data.

3.3 Variation of Mechanical Efficiency with Brake Power

Figure 9 shows the variation of mechanical efficiency with brake power for all the test samples. Generally, the significance of mechanical efficiency is to measure the effectiveness of a machine in transforming from input to output by overcoming frictional losses.

It can be observed from the trend of the figure that, the mechanical efficiency was gradually increased for all the test samples from zero to maximum. As the biodiesel provides more lubrication and smooth engine operation than that of pure diesel, experimental results showed that the mechanical efficiency of the biodiesel samples operated with base engine is more than that of coated engine and pure diesel. At full load condition, among all the blends MME20D80 with base engine has registered 83.69%, MME20D80 with coated engine has recorded 82.61% and diesel has recorded 75.44% so, a little drop was found with MME30D70 with coated engine. Therefore, finally the mechanical efficiency of MME30D70 with coated engine was decreased by 2.39% compared to base engine data, and increased by 8.28% compared to pure diesel.

3.4 Variation of Mechanical Efficiency with Brake Power

Figure 10 revealed the variation of volumetric efficiency with brake power for all the test samples from zero to full load. In general, as far as the engine performance is concerned the volumetric efficiency is one of the important factors. It measures the breathing capacity of the naturally aspirated engines. It is defined as the ratio of volume of air/charge introduced into the engine cylinder during intake to the theoretical displacement volume of all the cylinders at atmospheric pressure. It can be influenced by design parameters such as intake and exhaust restrictions, valve timing, cylinder sealing, inertia of gas, speed etc., and also by some external parameters such as pressure, temperature and humidity of air.

The result shows the volumetric efficiency of each test fuel is continuously decreased from zero to full load as the brake power increases. This is because of the rise in temperature inside the engine cylinder, this was found true in case of base engine results but in case of coated engine results it was found increased instead of decreasing though it was less than that of pure diesel. At full load condition, the volumetric efficiency of MME30D70 with coated engine is higher than that of MME30D70 with base engine by 2.82% and decreased by 1.34% compared to pure diesel.

4 Conclusions

The performance characteristics of compression ignition engine powered with conventional diesel, diesel and biodiesel blend were investigated with and without piston coating. The conclusions of this investigation at full load condition are as follows,

-

In general, the brake specific fuel consumption decreases with increase in load on the engine, among all the blends, MME30D70 with coated engine has registered lowest BSFC amongst all and it was improved by 9.80% compared to pure diesel and by 3.77% compared to base engine data.

-

Diesel has recorded 33.40% of BTE, MME30D70 with base engine has recorded 36.36% of BTE and with coated engine has recorded 37.92% BTE, therefore for coated engine the BTE of MME30D70 was increased by 13.54% compared to pure diesel and by 4.29% compared to base engine data.

-

Among all the blends, MME20D80 with base engine has registered 83.69% of mechanical efficiency, MME20D80 with coated engine has recorded 82.61% and diesel has recorded 75.44% so, a little drop was found with MME30D70 with coated engine. Therefore, finally the mechanical efficiency of MME30D70 with coated engine was decreased by 2.39% compared to base engine data, and increased by 8.28% compared to pure diesel.

-

The TFC of MME30D70 with coated engine was improved by 7.81% compared to MME30D70 with base engine and by 9.92% compared to pure diesel.

-

The volumetric efficiency of MME30D70 with coated engine is higher than that of MME30D70 with base engine by 2.82% and decreased by 1.34% compared to pure diesel.

From the above conclusions it can be noticed that, as far as the performance parameters are concerned, out of all the blends MME30D70 with coated piston has showed better results and it was reported as the optimum blend with coated engine.

References

Agarwal AK, Das LM (2001) Bio-diesel development and characterization for use as a fuel in compression ignition engines. J Eng Gas Turbine Power Trans ASME 123:440–447. https://doi.org/10.1115/1.1364522

Agarwal AK, Dhar A (2010) Karanja oil utilization in a direct-injection engine by preheating. Part 1: Experimental investigations of engine performance, emissions and combustion characteristics. Proc Inst Mech Eng Part D J Automob Eng 224(1):73–84. https://doi.org/10.1243/09544070JAUTO1266

Tarabet L, Loubar K, Lounici MS, Khiari K, Belmrabet T, Tazerout M (2014) Experimental investigation of DI diesel engine operating with eucalyptus biodiesel/natural gas under dual fuel mode. Fuel 133:129–138. https://doi.org/10.1016/j.fuel.2014.05.008

Demirbas A, Fatih Demirbas M (2011) Importance of algae oil as a source of biodiesel. Energy Convers Manag 52:163–170. https://doi.org/10.1016/j.enconman.2010.06.055

Chisti Y (2007) Biodiesel from microalgae. Biotechnol Adv 25(3):294–306. https://doi.org/10.1016/j.biotechadv.2007.02.01

Converti A, Casazza AA, Ortiz EY, Perego P, Del Borghi M (2009) Effect of temperature and nitrogen concentration on the growth and lipid content of Nannochloropsis oculata and Chlorella vulgaris for biodiesel production. Chem Eng Process 48:1146–1151. https://doi.org/10.1016/j.cep.2009.03.006

Charyulu TN, Naveenchandran P (2019) The experimental features of a compression ignition engine running on pure diesel and mixtures of diesel and Manilkara zapota methyl ester. Int J Innov Technol Expl Eng 8(11):834. https://doi.org/10.35940/ijitee.K1499.0881119

Charyulu TN, Naveenchandran P (2019) The behaviour of a compression ignition engine under the influence of diesel and microalgae biodiesel blends. Int J Mech Prod Eng Res Dev 9(4):447–456. https://doi.org/10.24247/ijmperdaug201944

Charyulu TN, Naveenchandran P, Raja E, Babu RN (2020) The behavioural attributes of a compression ignition engine powered with diesel and Artocarpus heterophyllus methyl ester blends. Rasayan J Chem 13(2):876–886. https://doi.org/10.31788/RJC.2020.1325560

Agarwal D, Agarwal AK (2007) Performance and emission characteristics of Jatropha oil (preheating and blends) in a direct injection compression ignition engine. Appl Therm Eng 27:2314–2323. https://doi.org/10.1016/j.applthermaleng.2007.01.009

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Sai Babu, K., Sai Rama Krishna, B., Djana Raju, V., Rama Krisna, N. (2023). Comparative Analysis for Performance Characteristics of a Compression Ignition Engine Running on Microalgae Methyl Ester and Diesel Blends with Base Engine and Coated Engine. In: Doolla, S., Rather, Z.H., Ramadesigan, V. (eds) Advances in Clean Energy and Sustainability. ICAER 2022. Green Energy and Technology. Springer, Singapore. https://doi.org/10.1007/978-981-99-2279-6_19

Download citation

DOI: https://doi.org/10.1007/978-981-99-2279-6_19

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-2278-9

Online ISBN: 978-981-99-2279-6

eBook Packages: EnergyEnergy (R0)