Abstract

Natural methane hydrates are estimated to be the largest source of unexploited hydrocarbon fuel. However, there are many difficulties in drilling for natural gas hydrates production, among which inhibiting hydrate generation is an important issue. The conventional thermodynamic inhibitors have difficulties such as large dosages and are not environmentally friendly, while the widely used kinetic inhibitors also suffer from failure with high subcooling. Thus, it is urgent to develop new efficient hydrate inhibitors. Molecular design of hydrate inhibitor molecules using molecular simulations is one of the most common tools used. However, it is challenging to reproduce experimental-scale hydrate inhibitor fractions at the molecular scale. Thus, many studies have only investigated the effect of a minimal number of repeating units in an inhibitor on hydrate stability, leading to conclusions about the effects of various functional groups on hydrate stability. In contrast, a selection of the number of repeating units (polymerization degree, N) in the molecular structure of polymeric hydrate inhibitors has rarely been discussed. In this work, polymer PVP-N with different N was established based on NVP. The effect of a polymer molecular weight on hydrate formation was investigated. The results show that the different N in PVP has a significant effect on a diffusion coefficient of water molecules. A smaller N in PVP is more likely to inhibit hydrate formation during the phase of nucleation, but its effect is significantly weakened during the phase of formation. This study helps us to understand the effect of a polymer molecular weight on the performance of hydrate inhibitors and select an appropriate number of repeating units in molecular modeling, which dramatically reduces the difficulty of designing the molecular structures of hydrate inhibitors and other drilling fluid treatment agents, clarifies the mechanism of action of hydrate inhibitors and other drilling fluid treatment agents at the molecular scale, and is essential for developing high-performance drilling fluid treatment agents and promoting the commercial development of natural gas hydrates.

Copyright 2023, IFEDC Organizing Committee.

This paper was prepared for presentation at the 2023 International Field Exploration and Development Conference in Wuhan, China, 20-22 September 2023.

This paper was selected for presentation by the IFEDC Committee following review of information contained in an abstract submitted by the author(s). Contents of the paper, as presented, have not been reviewed by the IFEDC Technical Team and are subject to correction by the author(s). The material does not necessarily reflect any position of the IFEDC Technical Committee its members. Papers presented at the Conference are subject to publication review by Professional Team of IFEDC Technical Committee. Electronic reproduction, distribution, or storage of any part of this paper for commercial purposes without the written consent of IFEDC Organizing Committee is prohibited. Permission to reproduce in print is restricted to an abstract of not more than 300 words; illustrations may not be copied. The abstract must contain conspicuous acknowledgment of IFEDC. Contact email: paper@ifedc.org.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Natural gas hydrate is widely distributed, abundant in resources, and has minimal pollution, making it a promising and clean alternative to traditional fossil fuels in the future [1, 2]. The global proven reserves of natural gas hydrates are approximately 21 × 1015 m3, and its carbon content is roughly twice that of all fossil fuels combined, including oil, natural gas, and coal [3,4,5]. In particular, the gas hydrates are widely distributed in marine continental margin sediments and to a lesser degree in permafrost environments [6, 7].

However, it is difficult to realize commercial extraction of hydrate in the deep sea based on existing technology [8] because subsea gas hydrate is extremely sensitive to temperature and pressure. The interaction between the working fluid and gas hydrate during the drilling process, such as mass and heat transfer, can quickly induce gas hydrate decomposition in the reservoir and lead to well wall destabilization. In addition, the massive formation of hydrate in the wellbore will not only seriously affect the performance of drilling fluid but also block the wellbore [9]. Therefore, it is urgent to research high-performance hydrate inhibitors.

In recent years, molecular simulations have been introduced to study hydrate inhibitors in the expectation of discovering the mechanism of interaction between hydrate inhibitors and hydrates [6, 10, 11]. Most of the hydrate inhibitors are polymers, but in terms of molecular scale, it is very difficult to fully replicate the experimental scale molecular weight.

Polymers are long chain-like molecules obtained from many repeating units connected by covalent bonds, and molecular weight/degree of polymerization is the parameter that directly determines the chain length of the polymer molecule, which was selected more randomly in previous studies compared to the basic monomers that make up the polymer. In earlier studies, most studies for hydrate inhibitors were on small molecules, such as methanol [12], amino acids [13], and simply using dimers [14]. The polymerization of polymers was not an issue in these cases. However, in future studies of polysaccharide-based hydrate inhibitors or for the development of new inorganic polymer inhibitors, polymerization of polymers will be an inevitable issue when modeling based on molecular simulations. In particular, most of the drilling fluid treating agents are polymers, so it is necessary to investigate the effect of molecular polymerization on the simulation results during the simulation.

In this paper, the effect of the degree of polymerization of the hydrate inhibitor PVP on the simulation results was investigated based on molecular simulations, and the degree of polymerization on the MSD, hydrogen bonding, RDF, and interaction energy of water molecules was analyzed. The performance of PVP with different polymerization degrees was also tested experimentally. These results provide a reference for the future construction of macromolecular models and are essential for the development of new hydrate inhibitors.

2 Experimental and Simulation Method

2.1 Molecular Simulations

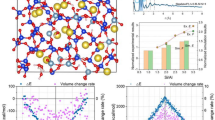

The molecular dynamics (MD) simulations were performed by using LAMMPS (Large-scale Atomic/Molecular Massively Parallel Simulator) software package under the isothermal-isobaric ensemble (NPT) and the canonical ensemble (NVT) [15]. The effect of hydrate inhibitors with different polymerization degrees on water molecules is divided into the following two steps. Firstly, the effect of hydrate inhibitors with different polymerization degrees on water molecules was analyzed at 5% and 10% mass concentrations. The constructed model is shown in Fig. 1(A), in which the number of chains of the polymer is always 1 regardless of the polymerization degree of the hydrate inhibitor, and the concentration is achieved mainly by changing the number of water molecules. This also means that the size of the simulated box is varied. Subsequently, the effect of hydrate inhibitors on water molecules was analyzed based on 10 wt% mass concentration for different polymerization degrees, in which the number of water molecules is always 3400 and the mass concentration is adjusted mainly by changing the number of chains of hydrate inhibitors, as shown in Fig. 1(B). In order to study the interaction between hydrate inhibitors of different polymerization degrees and hydrate reservoirs, we also constructed a new model shown in Fig. 1(C). The unit cell of methane hydrate used here was obtained from the available literature. A 5 × 4 × 3 supercell of SI methane hydrate was placed at the bottom of simulation box. A graphene plate was added for applying pressure while a 0.5 nm thick water box was placed between the bulk phase and the graphene plate for blocking the interaction between the hydrate inhibitor and the plate.

In our simulation, the OPLS-AA force field was used to describe methane, polymers and graphene plate. Water molecules were described using the simple point charge SPC/E mode, and the angle and the length of water molecular were 109°47 and 0.100 nm.

2.2 Experimental

The equipment used in this study was the same as in the previous study, as shown in Fig. 2 [11]. To prepare for the experiment, a reaction chamber with a volume of 1000 mL was filled with a solution containing 370 mL of pure water and various inhibitors. The chamber was then evacuated for 30 min to remove any air inside. Next, methane was introduced into the chamber to reach a pressure of 14 MPa at a temperature of 18 ℃. The pressure was maintained by periodically adding more methane to the chamber, and after 30 min the temperature and pressure had stabilized. The water bath was then gradually cooled from 18 ℃ to 0 ℃ over a period of 6 h, with a cooling rate of 3 ℃/h.

Schematic diagram of the apparatus for the formation tests of hydrate: (1) pressure transducer; (2) computer; (3) propeller; (4) water bath; (5) temperature transducer in bath; (6) magnetic coupling stirrer; (7) high-pressure needle valve; (8) snap ring; (9) temperature transducer in chamber; (10) reaction chamber; (11) windows; (12) base.

3 Result and Discussion

3.1 The Influence of Polymerization Degree of PVP on Water Molecules with Different Amounts

For hydrates, any point in a homogeneously mixed system has the potential to nucleate. The effect of the inhibitor molecule on the nucleation site of the hydrate after the addition of the hydrate inhibitor to the system is correlated with the inhibitor molecule itself. Therefore, the effect of different polymerization degrees of PVP on the transport ability of water molecules at 5% mass concentration was discussed. Also, as a control, the diffusion coefficient at 10% mass concentration was calculated, as shown in Fig. 3. Notably, the number of water molecules in this part is varied. The size of the simulated box becomes larger as the degree of polymerization of PVP increases. The statistical results show that as the polymerization degree of PVP increases, the volume of the simulated box at the same mass concentration increases, and the diffusion coefficient of water molecules gradually increases. This means that with the increase of polymerization degree, the large molecular weight of PVP has less ability to limit the behaviour of water molecules. It also means that the probability of hydrate nucleation sites appearing elsewhere in the system is significantly increased in the system. In particular, increasing the mass concentration intensifies the effect of the same degree of polymerization of PVP on water molecules and is more effective at lower degrees. Thus, the impact of the degree of polymerization of the inhibitor, or described as the molecular weight of the polymer, on water molecules cannot be neglected, and this is effectively related to its ability to inhibit hydrate production. Therefore, the mechanical of hydrate inhibitors cannot be found with a simple combination of polymers monomers alone.

The hydrogen bonding statistics between PVP and water molecules and between water molecules at different mass concentrations are shown in Fig. 4 and Fig. 5. It is evident that the number of hydrogen bonds between polymer and water molecules gradually increases from 1.42 to 45.58 at 5 wt% concentration as the polymerization degree increases, but the ratio of the number of hydrogen bonds to the polymerization degree increases from 0.71 to 0.83 and then decreases to 0.75. When the concentration increases to 10 wt%, the number of hydrogen bonds between polymer and water molecules gradually increases from 2.75 to 85.13. This means that increasing the degree of polymerization of PVP can strengthen the ability of PVP to influence the water molecules around it, but the relationship between the degree of polymerization and the strengthening of hydrogen bonds is not positively correlated. This may be due to the curling or folding of the molecular weight of PVP at a high polymerization degree, which reduces its interaction area with water molecules and thus causes some waste. Although increasing the mass concentration can increase the hydrogen bonding between PVP and water molecules, the gain is also not linear. Moreover, in agreement with the previous description, it is an obvious conclusion that the hydrogen bonding between water molecules is increased with increasing polymerization degree since large polymerization degree values imply more water molecules in the simulation system.

In addition, we also paid attention to the variation of RDF between water molecules at different degrees of polymerization, as shown in Fig. 6. It is clear that when the mass concentration is 5 wt%, the peak of RDF of water molecules in the system increases from 2.689 to 2.803, 2.817, and then decreases to 2.813, 2.797, 2.803, 2.794 with the increase of PVP polymerization degree. Although the addition of PVP changed the spatial distribution around the water molecules, there was little relationship between this and the degree of polymerization of PVP. Meanwhile, when the mass concentration of PVP increased to 10 wt%, the peak of the RDF of water molecules in the system increased to around 2.935, and the difference between different degrees of polymerization of PVP was much smaller.

3.2 The Influence of Polymerization Degree of PVP on Water Molecules with Fixed Amounts

To further investigate the effect of the degree of polymerization of PVP on water molecules, the variation of the diffusivity coefficient of water molecules at 10 wt% mass concentration under the same number of water molecules was also investigated, and the results are shown in Fig. 7. It is clear that the intervention of PVP seriously affects the diffusion of water molecules, and the diffusion coefficient of water molecules decreases from 217.98 to 189.64, while the diffusion coefficient of water molecules gradually decreases from 189.64 to 189.42, 183.38, and 177.54 as the polymer of water molecules increases from N = 2 to N = 23. However, although the diffusion coefficient of water molecules increases when the polymerization degree of the polymer increases to 35, the diffusion coefficient of water molecules increases to 178.60, but the increase is slight. This also means that in systems with a certain number of water molecules, when the mass concentrations of PVP with different polymeric degrees are the same, the numerical advantage of PVP with a low polymerization degree compensates for its lack in polymerization degree. In particular, when the degree of polymerization increased from N = 2 to N = 35, the change in the diffusion coefficient of water molecules was only 5.8%. Thus, in systems with multiple polymer chains, the effect of the polymerization degree of the polymer on the water molecules becomes insignificant.

Similarly, we also investigated the number of hydrogen bonds in different systems, and the results are shown in Table 1. From the results, it is clear that the increase of polymerization degree of PVP at the same mass concentration does not significantly change the average number of hydrogen bonds between PVP and water and water molecules.

This means that in the same mass concentration system, the hydrogen bonding between different PVP and water molecules does not differ significantly depending on the degree of polymerization. Therefore, when the synthesized products are large molecular polymers, the polymerization degree, as well as the concentration of the polymer, should be increased appropriately when exploring the effect of functional groups on hydrate generation, and more apparent results may be obtained.

Figure 8 presented the results of RDFs between water molecules with different polymerization degree of PVP. It is clear that the peak of RDF of water molecules in the system increases significantly with the effect of PVP with different polymerization degree. In particular, the increase in PVP aggregation did not significantly change the peak and the position of the peaks of RDFs, which corresponded well with the previous results.

3.3 He Interaction Between PVP and Methane Hydrate

Based on the above results, the variation of the total and average interaction energy between PVP and hydrate with different polymerization degrees at 10 wt% mass concentration was also investigated, as shown in Fig. 9(a). From the results, it can be seen that the total interaction energy between PVP and hydrate reservoir is −239.53 kcal/mol when N = 2, while the total interaction energy between PVP and hydrate reservoir decreases significantly when the N value increases. This may be because PVP with large values of N is more likely to collide or fold in space, affecting their adsorption on the hydrate surface. In order to elaborate more clearly on the interaction between PVP with different polymerization degrees and hydrate reservoir, we also calculated the average interaction energy between PVP and reservoir for different N values in the system, as shown in Fig. 9(b). It is obvious that the average interaction energy between PVP and methane hydrate is the strongest when N = 23, and the average interaction energy is -35.91 kcal/mol. Therefore, PVP with a smaller polymerization degree may be more easily adsorbed on the hydrate surface. Further, it can be speculated that the optimal molecular weight of PVP should be 2558.33.

3.4 Experimental Verification

Experiments based on macroscopic scales to accomplish results on the molecular scale are difficult, especially for experimental replication of chemical synthesis based on specific degrees of polymerization. Therefore, experimental comparisons were limited to currently available PVP of different molecular weights, and the results of the temperature and pressure curves during the experiments are shown in Fig. 10. From the results, it can be seen that there is no significant change in torque and pressure of the system during hydrate generation, but the hydrate generation time under the action of PVP-K10 is 305.81 min, while the hydrate generation time under the effect of PVP-K20, PVP-K30, and PVP-K90 is gradually decreasing to 299.02 min, 260.34 min, and 247.97 min. Therefore, on the macroscopic scale, the smaller the molecular weight of PVP, the stronger its hydrate inhibition performance.

4 Conclusion

There are differences in the properties of polymers with different degrees of polymerization, so the degree of polymerization of the simulated polymer should be as close as possible to the molecular weight of the actual product. When the degree of polymerization of PVP is small, the concentration in the model should be increased appropriately to reduce the error. When the degree of polymerization should be greater than 10, the error generated by the simulation may be reduced. Based on the simulation results, the optimum molecular weight of PVP with strong inhibitory properties is presumed to be 2558.33. In contrast, the experimental results show that the PVP-K10 sold has the best inhibitory effect.

References

Liao, B., Wang, J.T., Han, X.P., Wang, R., Lv, K.H., Bai, Y.J., et al.: Microscopic molecular insights into clathrate methane hydrates dissociation in a flowing system. Chem. Eng. J. 430, 133098 (2022)

Yang, L., Guan, D., Qu, A., Li, Q., Ge, Y., Liang, H., et al.: Thermotactic habit of gas hydrate growth enables a fast transformation of melting ice. Appl. Energy 331, 120372 (2023)

Ning, F., Zhang, K., Wu, N., Zhang, L., Li, G., Jiang, G., et al.: Invasion of drilling mud into gas-hydrate-bearing sediments. Part I: effect of drilling mud properties. Geophys. J. Int. 193(3), 1370–1384 (2013)

Wu, N.Y., Li, Y.L., Wan, Y.Z., Sun, J.Y., Huang, L., Mao, P.X.: Prospect of marine natural gas hydrate stimulation theory and technology system. Nat. Gas Ind. B 8(2), 173–187 (2021)

Wang, R., Wang, C., Long, Y., Sun, J., Liu, L., Wang, J.: Preparation and investigation of self-healing gel for mitigating circulation loss. Adv. Geo-Energy Res. 8(2), 112–125 (2023)

Wang, J., Sun, J., Wang, R., Cheng, R., Liao, B., Qu, Y., et al.: Mechanisms of synergistic inhibition of NaCl and glycine mixtures on methane hydrate formation: experimental and molecular dynamic simulation. Gas Sci. Eng. 110, 204880 (2023)

Wang, R., Liao, B., Wang, J.T., Sun, J.S., Wang, Y.D., Wang, J.L., et al.: Microscopic molecular insights into methane hydrate growth on the surfaces of clay minerals: experiments and molecular dynamics simulations. Chem. Eng. J. 451, 138757 (2023)

Jager, M.D., Sloan, E.D.: The effect of pressure on methane hydration in pure water and sodium chloride solutions. Fluid Phase Equilib. 185(1–2), 89–99 (2001)

Pei, J., Wang, Z., Zhang, J., Zhang, B., Ma, N., Sun, B.: Prediction model and risk analysis of hydrate deposition and blockage in reduced-diameter pipelines. Fuel 337, 127071 (2023)

Wang, J.L., Sun, J.S., Wang, R., Lv, K., Wang, J.T., Liao, B., et al.: Mechanisms of synergistic inhibition of hydrophilic amino acids with kinetic inhibitors on hydrate formation. Fuel 321, 124012 (2022)

Liao, B., Wang, J.T., Sun, J.S., Lv, K.H., Liu, L., Wang, Q., et al.: Microscopic insights into synergism effect of different hydrate inhibitors on methane hydrate formation: experiments and molecular dynamics simulations. Fuel 340, 127488 (2023)

Su, Z., Alavi, S., Ripmeester, J.A., Wolosh, G., Dias, C.L.: Methane clathrate formation is catalyzed and kinetically inhibited by the same molecule: two facets of methanol. J. Phys. Chem. B 125(16), 4162–4168 (2021)

Li, S.X., Lv, R.J., Yan, Z.S., Huang, F., Zhang, X.R., Chen, G.J., et al.: Design of alanine-rich short peptides as a green alternative of gas hydrate inhibitors: dual methyl group docking for efficient adsorption on the surface of gas hydrates. ACS Sustain. Chem. Eng. 8(10), 4256–4266 (2020)

Yun, S., Jo, I., Go, W., Kim, Y., Kim, K.-S., Seo, Y.: Water-soluble cellulose as a new class of green CH4 hydrate inhibitors: insights from experiments and molecular dynamics simulations. ACS Sustain. Chem. Eng. 11(16), 6153–6162 (2023)

Thompson, A.P., Aktulga, H.M., Berger, R., Bolintineanu, D.S., Brown, W.M., Crozier, P.S., et al.: LAMMPS - a flexible simulation tool for particle-based materials modeling at the atomic, meso, and continuum scales. Comput. Phys. Commun.Commun. 271, 108171 (2022)

Acknowledgments

The project is supported by the National Natural Science Foundation of China (No. 52274025 and 51991361), the National Key Research and Development Program of China (2021YFC2800803), the CNPC’s Major Science and Technology Projects (No. ZD2019-184-003), the Key R & D Program of Shandong Province (No. 2020ZLYS07), and the China Scholarship Council (award to Bo. Liao for one year’s study abroad at the University of Calgary). Also, we greatly acknowledge the computational support provided by the Research Computing Services group at the University of Calgary.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Liao, B. et al. (2024). The Effect of Polymerization Degree of Hydrate Inhibitor on Hydrate Formation: Molecular Dynamics Simulations and Experiments. In: Lin, J. (eds) Proceedings of the International Field Exploration and Development Conference 2023. IFEDC 2023. Springer Series in Geomechanics and Geoengineering. Springer, Singapore. https://doi.org/10.1007/978-981-97-0268-8_22

Download citation

DOI: https://doi.org/10.1007/978-981-97-0268-8_22

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-97-0267-1

Online ISBN: 978-981-97-0268-8

eBook Packages: EngineeringEngineering (R0)