Abstract

In this chapter, a discussion on the use of various inorganic nanoparticles such as silver nanoparticles, titanium dioxide, silicon dioxide, zinc oxide, iron oxides, and others is made with relevant application in edible food packaging. Further, the effectiveness of inorganic nanoparticles in preventing foodborne diseases is also discussed, where the inorganic nanoparticles can release biocide into food products. The inorganic nanomaterials are used in addition to polymer composites to improve the efficiency of the packaging materials in terms of fortified food products and nutraceutical-added food products. Further, these inorganic nanoparticles also increase the functional properties of edible bionanocomposite films. The chapter is also focused to discuss the updated knowledge in recent research on edible nanocomposites-based packaging with multiple inorganic nanofillers.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

8.1 Introduction

The non-biodegradable food packaging materials have created enormous environmental pollution and credit most of the plastic-based environmental concerns all across the world. In the present scenario, consumers as well as the complete fraternity of scientists and industrialists associated with packaging materials demand biodegradable materials as a replacement of non-biodegradable materials. Recycling of such non-degradable plastics has not shown much efficacy in terms of both economic and performance aspects. There are several available biopolymers which are used as packaging materials to preserve food products [1]. Certain compostable polymers like poly(lactic acid) (PLA) need more of industrial composting environment to degrade it completely. In that case, the collection and segregation of these biodegradable plastics from non-degradable one, is highly important for safe material processing and is a serious matter of concern for industries as well as composting of these material. Compostable polymers which are frequently termed as biodegradable polymers may or may not shrink environmental pollutions, as these polymers hardly assimilate under non-simulated condition, i.e., under natural conditions. Hence, the biodegradation could be a criterion to boost up the awareness on environmental concern, but cannot completely nullify the environmental pollution. Very recently, scientific research on edible and biodegradable packaging using inorganic nanomaterials has taken tremendous space particularly in food packaging applications. End-of-life of such edible food packaging films is not associated with any separate post-service composting condition or treatment to knock it down to the environment.

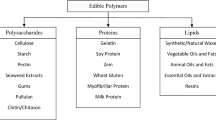

As similar to other synthetic, non-biodegradable food packaging materials, these edible food packaging films based on inorganic nanostructured materials are capable to provide additional activities related to carrying out biodegradation under simulated or non-simulated condition. Though the terms “edible film” and “edible coating” have different meaning in terms of its applicability; herein this book, they are used interchangeably. These edible packaging films are not only able to prevent moisture loss as well as oxygen and carbon dioxide penetration but also effectively retain the aromas and prevent solute transport [2]. As like conventional packaging materials, these inorganic nanomaterials-based edible films are able to retain the quality and stability of packaged food products over extended time period by controlling the exchange of gases, moisture, flavor, aroma, lipids, and other organic compounds between environment and food. Also, these films resist microbial attack on food products. Besides the above-mentioned characteristics, some of these films are capable to provide safety from physical damages. It is obvious that these edible films cannot replace conventional packaging materials completely. The edible films in food packaging applications are more commonly derived from natural sources and are considered as the waste or by-products [3]. The frequently used materials for the production of edible films include plant and animal-based proteins, lipids, polysaccharides, and large possible mixture of these materials. It is also the common trend to incorporate different types of additives into these edible materials in order to enhance various functional properties of resulting films. The inherent film-forming ability of different biomaterials like cellulose, starch, chitosan, pectin, alginate, pullulan, kefiran, etc., makes it more popular for the specified application as edible films in food packaging. Based on the type of food to be protected, the barrier as well as other properties of edible films can further be tailored by the incorporation of multiple food-grade additives. As for example, plasticizers are added to reduce the brittleness of films, inorganic fillers in nanoforms are included for a variety of purposes into the edible films during the processing step.

In this chapter, we are primarily discussing on the effect of various types of inorganic nanofillers as functional additive in edible food packaging materials. The structure–property relationship and functionality of these nanofillers are also discussed in detail. Also, advantages and limitations of different inorganic nanofillers are thoroughly discussed in order to give a broader sense of understanding on its applicability in different edible biopolymer films. Most commonly used inorganic nanoparticles as additive in edible biopolymer films for food packaging application are silver nanoparticles, zinc oxide nanoparticles, silicon oxide nanoparticles, titanium oxide nanoparticles, iron nanoparticles, etc. In the subsequent section of this chapter, we are going to discuss on various functional properties of different inorganic nanoparticles in particular to food packaging applications.

8.2 Inorganic Nanofillers in Edible Films

Edible films are mostly made up of fruits and vegetable extracts that are basically some biopolymers and act as the matrix of the films. Such biopolymers are hydrophilic in nature and possess poor mechanical strength, abrasion resistance, thermal degradation stability, as well as oxygen, carbon dioxide and moisture barrier properties in comparison with conventional polymers. Any material with poor performance in above-mentioned properties is generally not competent enough to be used in food packaging applications. One of the most feasible strategies to tackle this technical limitation of such edible food packaging materials is to inclusion of fillers into the matrix material. Addition of fillers into the biopolymers leads to formation of modified form of material called biocomposites. Further, as the fillers come within the range of nanometer then the resultant material is called bionanocomposites. There are a range of nanofillers available that can add up multiple benefits to the base polymer matrix. In particular, inorganic nanofillers are capable to enhance various physical, mechanical, and thermal properties of the edible polymeric films. Depending upon the factors such as good polymer–fillers, interfacial interactions, uniform nanofiller dispersion within the polymer matrix, certain changes in behavior at molecular level occur, which results in dramatic improvement in thermal stability and mechanical strength of the edible films. High surface area of the added filler available for interaction with polymer matrix is essential to increase the mentioned factors in a polymer biocomposite system. Moreover, a greater surface area of the nanofillers can be achieved through improving the aspect ratio of the fillers. A high aspect ratio of fillers (length/diameter ratio), fine particle diameter, and presence of holes enhances the surface area of fillers to interact with the polymer matrix. Further, as part of smart packaging, the edible biopolymers are filled with certain inorganic nanofillers that provide functionalities including antimicrobial, antifungal, antioxidant, ultraviolet (UV) resistance property, etc., to the edible films. However, the various available inorganic nanomaterials (zinc, silicon oxide, titanium oxide, magnesium oxide, iron oxide, silver, and others), their functionality in biopolymer nanocomposites (increase filler–matrix interaction, nanofunctionality, nanopreservatives, texture enhancers, enhanced nutritional value, inhibit foodborne pathogens), and targeted food packaging applications (active packaging, smart packaging, edible films/coatings, conventional packaging, biobased packaging, and others) have been mentioned in Fig. 8.1.

8.2.1 Zinc Nanoparticles

Zinc is an essential element for defensive mechanism (immune system) of human body. It also plays important roles in cell division and cell growth in injuries, and helps healing at faster rate. It is the integral element that is found in every cell of human body. Often due to inappropriate diet, deficiency in zinc causes multiple health problems. In those cases, zinc supplement can be fulfilled upon using zinc-based nanoparticles as functional filler in biopolymer of edible films. Other than its nutritional values, zinc oxide nanoparticle (ZN) is multifunctional inorganic nanoparticles that is recognized by the US Food and Drug Administration (USFDA) as safe to human consumption. Hence, instead of making zinc as monofunctional food additive, ZN can be used in edible food packaging for multiple applications such as antimicrobial activity and antifungal activity. The nutritional value including texture, flavor, and storage properties of food products is improved using zinc nanoparticles.

8.2.2 Silicon Oxide Nanoparticles

Silicon oxide nanoparticle in amorphous phase is authorized as food additive by the European Union (EU) and is found to be completely safe for consumption after several long-term experiments in animals. Further, these nanomaterials impart great advantages in edible packaging films like improvement in mechanical strength of the films, antimicrobial properties, enhancing shelf life of packaged food products, generating high gas barrier properties, etc. Silica is most abundant mineral on earth and mostly exists in the form of its oxides in nature. Hence, oxides of silicon are relatively easy to prepare at low cost. Other than improvement in mechanical properties in the edible biopolymer films, these nanoparticles are capable of improving moisture barrier property of films effectively. Further, these nanoparticles have gained tremendous application in commodity food packaging areas, primarily due to its functional properties at cheaper price that impart great advantages in the edible films.

8.2.3 Titanium Oxide Nanoparticles

Titanium dioxide nanoparticles are functional fillers used mostly in variety of food products including medicines. It is the most explored nanomaterial in the area of food and edible food packaging due to its non-toxic, photostable, antibacterial, high thermostability, and inclusion of TiO2-N resists growth of microorganisms in food products. Other than improving functional properties, TiO2-N has attained extensive attention owing to its low cost and high antimicrobial activity.

8.2.4 Magnesium Oxide Nanoparticles

Magnesium oxide is a naturally available mineral that is colorless and crystalline material and is produced economically on large scale. It is also used in food and in edible food packaging materials and is also certified as safe in food applications by USFDA. It also exerts great improvement in mechanical strength, opacity that provided safety to food products from UV rays, gas barrier property, etc., to be used as edible biopolymers like chitosan films.

8.2.5 Iron Oxide Nanoparticles

Iron is the most essential and basic requirement of human body as it constitutes the hemoglobin. Hence, inclusion of iron-based compounds into edible films for food packaging will be advantageous as it will be providing nutrition. A hybrid nanostructure of magnetic ferro or ferric oxide nanoparticles coated on graphene oxide nanosheet provides better barrier property even higher than aluminum films [4]. The nanocomposites of Fe3O4-NPs with starch, cyclophosphamide, and glycerine show superior property related to its application as edible food packaging materials [5]. Hence, other than nutritional values, iron oxide nanoparticles also provide safeguard to food products from UV rays, thereby increasing the shelf life.

8.3 Effectiveness of Inorganic Nanomaterials of Packaging Properties

8.3.1 Mechanical Property

As referred earlier, mechanical properties of the edible films do not fully comply with the standards required for food packaging applications. Due to this limitation, these edible films may be used as complement to conventional food packaging material. The use of reinforcing agents to the edible polymeric matrix with nanomaterial served the purpose by increasing the mechanical strength of the films. In this respect, silver nanoparticles (AgNPs) have attained maximum attention toward the specific applications [6]. The biopolymer-assisted synthesis of AgNPs gives rise to improve the stability and dispersion of the nanoparticles in the polymer matrix of films that leads to development of final structural stability of films [7]. For in situ technique of preparation of edible biocomposite films, the biopolymer acts as dispersing medium of the already synthesized nanoparticles [8]. In a nanocomposite film of biopolymer with AgNPs, van der Waals force of attraction exists between the hydroxyl group of biopolymer and partial positive charge of the metal nanofiller surfaces. Chitosan-based edible packaging films showed significant improvement in mechanical resistance upon incorporation of AgNPs [9]. Also, the improvement in mechanical strength upon incorporation of the nanoparticle was significant in case of edible film based on konjac glucomannan–chitosan and cassava starch blend system as well as hydroxylmethyl cellulose/bacterial cellulose nanocrystals [10, 11]. Further, the incorporation of AgNPs in pectin film causes slight increment in mechanical strength while overall change in mechanical property was insignificant [21]. This mild increment in the mechanical strength is due to the formation of hydrogen bond between the pectin polymer and the nanoparticle surface as evident from the chemical analysis of nanocomposite samples. In case of bionanocomposite films of carrageenan with minor amount of AgNPs, the increased mechanical strength was attributed to existence of interfacial interaction between the two components [12]. However, a linear decrease in mechanical strength with increasing the nanofiller loading can also be found due to increased aggregation in nanoparticle at higher concentration in base matrix. Further, in case of starch film, a decreasing value in the mechanical strength and elastic modulus was observed, while retaining the percentage elongation at break value of the bionanocomposite films [13]. Similar observation on deteriorated mechanical strength with containment in toughness values was reported for agar-based, corn starch-based, and beeswax-based edible films [14, 15]. However, in case of agar/banana powder-based biopolymers and most other edible films, addition of AgNPs caused significant increment in toughness at the cost of mechanical strength [16, 17]. The hydroxypropyl methylcellulose based edible films containing AgNPs of different sizes provide increase in tensile strength, which is associated with decrease in percentage elongation at break [18]. The effect was found to be more prominent in case of nanoparticles with smaller size.

It can be realized from the above discussion that metal nanoparticles like AgNPs are capable to act as reinforcing inorganic fillers of several biopolymers. In a composite system, reinforcement is a phenomenon that exists only if physical or chemical interaction exists between the polymer matrix and the nanoparticle fillers. Depending upon the nature of biopolymer matrix, different types of inter- and intramolecular interaction occur between the biopolymer chains and the nanoparticle surfaces. Among different interactions, weak van der Waals force of attraction between the polar hydroxyl groups of biopolymer matrix and the partial positive charge of nanoparticle surface exists. In certain cases, the presence of phenolic compounds, different types of proteins, carbohydrates, celluloses, hemicelluloses, etc., may take part in developing bonding between the two phases of composites. The improvement in the interfacial bonding between the nanoparticle and the biopolymer matrix causes effective stress transfer from the biopolymer matrix to filler, which leads to improvement in tensile strength. Uniform dispersion of the nanofillers within the biopolymer matrix is the result of good adhesion between the two components, and this is another factor that contributes in improving mechanical property [19]. Besides the nature of adhesion between the two phases, the concentration of nanoparticle loading also affects the final properties of bionanocomposites. Further, the processing condition has a tremendous impact in determining final properties of biocomposite films. Most commonly, in situ synthesis of AgNPs within the matrix of biopolymers, where the biopolymer reacts with the precursor or reactants and finally produces the nanoparticles, shows better mechanical performance compared to ex situ technique. These inorganic reinforcing nanoparticles may be beneficial in edible food packaging applications considering other advantages, e.g., antimicrobial effect, enhanced shelf life, etc.

8.3.2 Barrier Property

Starch is used for developing edible films, and it can bind with electropositive transition metals like silver (Ag) through electrostatic force of attraction and stabilizes the AgNPs during its synthesis. Inclusion of clay along with AgNPs in starch-based edible films caused significant increment in mechanical as well as gas barrier properties. The clay particles as well as the AgNPs are easily complexed by the huge amount of free hydroxyl groups of the starch [20]. Extensive research indicates significant improvement in moisture barrier property of various edible biopolymer films of celluloses, banana powder, agar, chitosan, gelatine etc., upon incorporation of AgNPs. The reduction in water vapor permeability of several edible films on addition of AgNPs is primarily attributed to the uniform dispersion of nanoparticles in the polymer matrix that increases tortuosity in path of water molecules that passes through the film, which caused decreasing tendency in diffusion of water molecules through the edible films. However, contradictory results can also be expected as the water vapor permeability increases upon addition of AgNPs to carrageenan films, agar, gelatin, and pectin-based edible films [21]. Additionally, nanotitanium dioxide (TiO2-N) can improve the moisture barrier property in certain edible films. Incorporating TiO2-N in chitosan–starch blend caused significant decrease in water vapor permeability (WVP), and the effect can be attributed to high degree of hydrophobicity of the infilled nanoparticles. Further, such water-resistant nanoparticle added to the matrix gives rise to tortuosity in the pathway for moistures. As a result, the permeability of moisture decreases sharply.

Nanosilicon dioxide (nano-SiO2)-based starch edible films show decrease in water vapor transmission rate (WVTR). The morphology indicates highly compact structure of the films upon the addition of the nanoparticles with different sizes. Hydrogen bond forms between the oxygen atom of nano-SiO2 and the hydroxyl groups of starch molecules. Other than the physical barrier incurred by the incorporated nano-SiO2 particles, the increased degree of crystallinity in the starch film caused significant reduction in the WVT rate when nano-SiO2 (100 nm) incorporated. Smaller the size of the nanoparticle, better is the dispersion, thereby causing remarkable decrease in moisture permeability [22]. However, there are differences in the trend that can be observed based on the nature of the biopolymer matrix. Zinc oxide nanoparticle (ZN) upon addition to kefiran matrix causes significant reduction in the WVP rate, and it is attributed to the fact that kefiran forms hydrogen bond with the oxygen atom of ZN and thereby makes it a strong structure that inhibits diffusion of water molecules through it. Further, the hydrophobicity of ZN and the increased degree of crystallinity resist the moisture permeation through the film. Further, inorganic nanomaterials are also used in non-edible food packaging also to deliver improved packaging property. In this regard, magnesium oxide nanoparticles (MgO-NPs) when incorporated in PLA show improvement in oxygen barrier and tensile strength of the resultant nanocomposite films. Further, it also provides antimicrobial property to the films. Similarly, it also adds functional benefits to different biopolymer-based edible films [23]. Addition of MgO-NPs in chitosan biopolymer films increases mechanical property, film thickness, film opacity, reduced moisture barrier property, and swelling in certain solvents [24].

In other words, the addition of inorganic nanoparticles in an optimized proportion in edible films based on biopolymer matrix can provide certain characteristics including functional properties. There are several factors that are associated with the nanoparticles that dictate the final functional properties like barrier properties of bionanocomposite film. Besides the inherent hydrophobicity of the incorporated inorganic nanofillers, its interaction with the biopolymer matrix, the processing technique for the fabrication of the composite films, nucleation capacity of the nanoparticles within the biopolymer matrix, degree of crystallinity under the influence of the nanoparticles, etc., are some of the essential factors that determined the barrier property of the films. Further, the concentration of the nanoparticles in biopolymer matrix, the size and shape of the nanoparticles, and the uniformity in dispersion of the nanoparticles within biopolymer matrix have great degree of influence upon the barrier property of the bionanocomposite films.

8.3.3 Optical Properties

Optical property of edible films are primarily related to the optical transparency, the aesthetic and gloss of films, and the resistance to UV light, while UV light causes great alteration in the nutritional value of food products through developing certain chemical reaction in food products. Large amount of compounds related to phenolic compounds are present in certain food products that show sensitivity toward UV radiation. Hence, dark color in edible films is beneficial; however, transparency in films along with good aesthetic of food should also be considered. Bionanocomposites of starch-based edible films with nano-SiO2 in different sizes ranging from 200 to 800 nm are capable to resist UV light from penetrating and falling onto the food products. Only 30% UV light could pass through the 100-nm films at 600-nm wavelength, which impart great protection to the food products. Further, uniform distribution of these nanoparticles is much required characteristics in the films. Zinc oxide nanoparticles at 1wt% concentration are able to provide high UV stability in kefiran-based edible bionanocomposite films. The concentration of added nanoparticles and size of the nanoparticles have great impact on the final optical property of the films. For example, at higher concentration of ZN, the film opacity increases. Titania nanoparticles at lower concentration cause transparency, whereas at higher concentration of titania nanoparticle leads to increase in the opacity.

8.4 Case Studies on Inorganic Nanomaterials in Edible Food Packaging

As discussed earlier, the inorganic nanofillers used for the fabrication of edible films and coatings include titanium dioxide, silica, nanozinc oxide, silver nanoparticle, etc [25, 26]. As discussed earlier, the properties of edible food packaging can be modified using the mixed organic and inorganic materials for developing nanocomposites [27]. The inorganic nanomaterials have obtained a great interest in fabricating the edible food packaging (edible films/edible coatings). In this regard, the use of various available inorganic nanomaterials in the development of edible food packaging for attaining tailor-made properties has been represented in Table 8.1.

8.4.1 Application of Titanium Dioxide in Edible Food Packaging

As discussed earlier, the nanoparticle titania or titanium dioxide has many beneficial properties to be used in developing edible food packaging such as non-toxicity, cost-effectiveness, photocatalytic disinfection (antimicrobial activity/antibacterial property), and abundant [28,29,30]. Titanium dioxide is used widely to develop edible films or coatings with antimicrobial property to deliver ready-to-eat food products with controlled food property and quality. The edible films based on sweet potato starch, lemon waste-based pectin, and titanium oxide nanoparticles are considered as potential edible biodegradable packaging materials [31]. The starch, pectin, and TiO2 (0, 0.5, 1,2,3, and 4% w/w of total solid)-based composite edible films can provide improved properties, where the incorporation of nanoparticle provides rough and uneven surface. Additionally, by increasing the nanofiller concentration, the surface of the starch–pectin and titanium dioxide-based composite edible films provide discontinuous phases. The specified edible films have an ability to provide tunable mechanical property, barrier property, physicochemical property by varying the concentration of the nanoparticle. In the starch/pectin/titanium oxide-based edible films, the increased concentration of TiO2 (0.5–4% wt) has a tendency in decreased moisture content, moisture uptake, and solubility of the film materials. The low conc. of TiO2 provides improved moisture barrier properties, mechanical properties, etc. In 2011, Li et al. have developed edible films based on the whey protein isolate and TiO2-based composites, where 0.1% (a low concentration) TiO2 concentration has many beneficial properties such as (i) improved tensile strength and reduced ability of UVC absorption. On the other hand, a high concentration of TiO2 provides increased size and crystallization degree, reduced tensile strength, reduced water vapor permeability, etc. However, the UV absorption ability of the composite films is influenced by the presence of the nanoparticle [32]. Thus, the above-mentioned composite films have a tunable transmittance, tensile strength, water vapor permeability properties, etc. The nanoparticle percentage in the composite films (whey protein isolate and TiO2) is 0, 0.1, 0.25, 0.5, 1.00, and 2%, where the percentage of the nanoparticle in the composite films plays a crucial role in providing the tailor-made properties of the composite-based edible films. The water vapor permeability of the neat WPI films and 2 w% reinforced WPI films are ~3.19 × 10−10 g s−1 m−1 Pa−1 and ~2.92 × 10−10 g s−1 m−1 Pa−1, respectively. The moisture contents of the neat WPI films and 2 w% reinforced WPI films are ~32.40% and ~33.75%, respectively. Additionally, the titanium dioxide and clove oil improve the property of chitosan–starch films, where the nanotitanium dioxide improves the tensile strength, physicochemical property, antimicrobial property, and biological property [33]. Further, the edible nanocomposite films for lamb meat based on whey protein isolate, cellulose nanofiber, rosemary essential oil, and TiO2 nanoparticles have an ability in improving the product life by 12–15 days [34]. The materials can be used to preserve sensory qualities and are very effective in reduced growth of microorganisms such as Escherichia coli, L. monocytogenes, and S. aureus. Rosemary essential oil (REO) is used for food preservation for having antimicrobial, antioxidant, anticancer properties, etc. However, the edible packaging materials based on titanium dioxide nanoparticle-dispersed soy protein isolate can also be used for enhanced shelf life of food products [35].

8.4.2 Application of Zinc Oxide Nanoparticle in Edible Food Packaging

The zinc oxide nanoparticles, being a multifunctional inorganic nanomaterial, have a strong antimicrobial property and are another kind of inorganic nanomaterials which have attained a remarkable interest in developing edible coatings. The zinc oxide nanoparticles are used to fortify food products as zinc is considered as a necessary component for many cellular functions, hormonal and enzyme activities. Further, zinc oxide particles have a GRAS status by USFDA. In this way, zinc oxide nanoparticle is used to develop active edible coating materials. A research reports the study of ultrasound treatment and nanozinc oxide coating on fresh-cut kiwifruits to obtain improved shelf life of the cut fruit [26]. In this study, the fresh kiwifruits are given a combined treatment of nanozinc coating and ultrasound treatment and further stored at 4 °C for 10 days to study the storage life. The sample preparation is done via (i) control: dipping in NaClO solution, hand peeling, slicing, and storage study; (ii) US: combined treatment of whole kiwifruit is dipping in NaClO solution and ultrasound treatment, hand peeling, slicing, and storage study; (iii) 0.8 NZ: combined effect of NaClO solution dipped (whole fruit) and cut into slices and coating with nano-ZnO (0.8 g/L) coating solution; (iv) US + 0.4 NZ: combined effect of NaClO solution (dipping of whole fruit), ultrasonic treatment, and nano-ZnO coating (0.4 g/L); (v) US + 0.8 NZ: combined effect of NaClO solution (dipping of whole fruit), ultrasonic treatment, and nano-ZnO coating (0.8 g/L); and (vi) US + 1.2 NZ: combined effect of NaClO solution (dipping of whole fruit), ultrasonic treatment, and nano-ZnO coating (1.2 g/L). The storage condition (vi) provides improved quality of cut kiwifruits with 7.87 N texture, 0.46% water loss, 1.86 mLkg−1h−1 of ethylene production at the end of storage life. The effect of the combined treatment on ethylene production and carbon dioxide production during storage of fresh-cut kiwifruits depends on various factors. The development of zinc oxide nanoparticle-reinforced chitosan-based edible films has an antibacterial activity against E. coli and provides thermal stability, etc. [36]. Interestingly, zinc oxide nanoparticles are also used to develop ready-to-eat poultry meat, where zinc oxide nanoparticles are effective against foodborne pathogens [37]. The development of edible coating on fresh-cut mango cv. Arumanis utilizing nanocomposite of cassava starch, ZnO nanoparticle, stearic acid helps to maintain postharvest life [38]. A research reported the development of bilayer edible films containing bilayer of cellulose and chitosan–zinc oxide-based composite films containing nisin [39]. The film can be used for the active packaging of ultrafilter white cheese. The use of biosynthesized zinc oxide nanoparticle (from spinach leaves) for coating fig fruit can improve the shelf life by maintaining the keeping qualities such as weight loss, ripening, color changes, and firmness [40].

8.4.3 Application of Silver Nanoparticle in Edible Food Packaging

Silver nanoparticles are very effective against gram-positive bacteria, gram-negative bacteria, protozoa, fungi, etc [41,42,43]. There are many reports available which reports the use of silver nanoparticle-based edible coating on food products such as sausages, asparagus, tomato, and ladies finger [43,44,45,46]. The application of silver nanoparticles as edible coating to sausages has an ability to inhibit the growth of lactic acid bacteria for 30 days, where the silver nanoparticles are fabricated following a green route utilizing starch and glucose [43]. The use of silver nanoparticle-based coating also provides improved texture property, which may be obtained due to the interactions between silver and the components of proteins such as phosphorus and sulfur. Further, application of alginate and nano-Ag-based edible coating on shiitake mushroom (during cold storage) helps in maintaining tissue firmness, reduced the mesophile count, and further provides enhanced shelf life [45]. Further, Mohammed Fayaz and coworkers have developed biogenic silver nanoparticles-reinforced sodium alginate films as an antibacterial edible coating for fruits and vegetables for improved quality which are also suitable for the preservation of fruits and vegetables [47]. Additionally, iron oxides, nanosilicon dioxide, and others are also used for edible food packaging materials in terms of edible coating and films for improved shelf life of food products. However, nanosilicon dioxide is used as an anticaking agent, as a carrier for flavors, to thicken pates, etc. Further, iron-fortified food products can be developed by edible coating the fruits and vegetables [48].

8.5 Conclusion

The chapter provides the readers a basic understanding on the importance of adding various inorganic nanoparticles on edible films for targeted food packaging applications. Some of these nanoparticles not only are capable of synergizing nutritional and antimicrobial properties, but add value to mechanical, thermal stability, water, and other gas barrier properties, which are very essential for the mentioned application. Further, these nanoparticles are non-toxic both to human and to the environment. These nanoparticles are cost-effective and easy to produce via multiple processes making it more convenient to use at a broader sense. In overall aspects, inorganic nanoparticles are capable to enhance multiple properties in edible food packaging.

Bibliography

Persin Z, Stana-Kleinschek K, Foster TJ, van Dam JEG, Boeriu CG, Navard P (2011) Challenges and opportunities in polysaccharides research and technology: the EPNOE views for the next decade in the areas of materials, food and health care. Carbohydr Polym 84(1):22e32. http://dx.doi.org/10.1016/j.carbpol.2010.11.044

Aider M (2010) Chitosan application for active bio-based films production and potential in the food industry: review. LWT-Food Sci Technol 43(6):837e842. http://dx.doi.org/10.1016/j.lwt.2010.01.021

Kim KM, Son JH, Kim SK, Weller CL, Hanna MA (2006) Properties of chitosan films as a function of pH and solvent type. J Food Sci 71(3):E119eE124. http://dx.doi.org/10.1111/j.1365-21.2006.tb15624.x

Ren P-G, Wang H, Yan D-X, Huang H-D, Wang H-B, Zhang Z-P, Xu L, Li Z-M (2017) Ultrahigh gas barrier poly(vinyl alcohol) nanocomposite film filled with congregated and oriented Fe3O4@GO sheets induced by magnetic-field. Compos Part A-Appl Sci Manuf 97:1–9

Shariatinia Z, Fazli M (2015) Mechanical properties and antibacterial activities of novel nanobiocomposite films of chitosan and starch. Food Hydrocoll 46:112–124

Mihindukulasuriya SDF, Lim L-T (2014) Nanotechnology development in food packaging: a review. Trends Food Sci Tech 40:149–167

Islam MS, Yeum JH (2013) Electrospun pullulan/poly(vinyl alcohol)/silver hybrid nanofibers: preparation and property characterization for antibacterial activity. Colloid Surf A Physicochem Eng Asp 436:279–286

Plaza H (2015) Antimicrobial polymers with metal nanoparticles. Int J Mol Sci 16:2099–2116

Kadam D, Momin B, Palamthodi S, Lele SS (2019) Physicochemical and functional properties of chitosan-based nano-composite films incorporated with biogenic silver nanoparticles. Carbohydr Polym 211:124–132

Nair SB, Alummoottil N, Moothandasserry SS (2017) Chitosan-konjac glucomannan-cassava starch-nanosilver composite films with moisture resistant and antimicrobial properties for food-packaging applications. Starch 69:1600210

George J, Kumar R, Sajeevkumar VA, Ramana KV, Rajamanickam R, Abhishek V, Nadanasabapathy S (2014) Hybrid HPMC nanocomposites containing bacterial cellulose nanocrystals and silver nanoparticles. Carbohydr Polym 105:285–292

Roy S, Shankar S, Rhim J-W (2019) Melanin-mediated synthesis of silver nanoparticle and its use for the preparation of carrageenan-based antibacterial films. Food Hydrocoll 88:237–246

Ortega F, Giannuzzi L, Arce VB, García MA (2017) Active composite starch films containing green synthetized silver nanoparticles. Food Hydrocoll 70:152–162

Ji N, Liu C, Zhang S, Xiong L, Sun Q (2016) Elaboration and characterization of corn starch films incorporating silver nanoparticles obtained using short glucan chains. LWT-Food Sci Technol 74:311–318

Bahrami A, Mokarram RR, Khiabani MS, Ghanbarzadeh B, Salehi R (2019) Physico-mechanical and antimicrobial properties of tragacanth/hydroxypropyl methylcellulose/beeswax edible films reinforced with silver nanoparticles. Int J Biol Macromol 129:1103–1112

Orsuwan A, Shankar S, Wang L-F, Sothornvit R, Rhim J-W (2016) Preparation of antimicrobial agar/banana powder blend films reinforced with silver nanoparticles. Food Hydrocoll 60:476–485

Kanmani P, Rhim JW (2014) Physicochemical properties of gelatin/silver nanoparticle antimicrobial composite films. Food Chem 148:162–169

De Moura MR, Mattoso LHC, Zucolotto V (2012) Development of cellulose-based bactericidal nanocomposites containing silver nanoparticles and their use as active food packaging. J Food Eng 109:520–524

Kurhade Ankeeta, Patil Sonal, Sonawane Sachin K, Waghmare Jyotsna S, Arya Shalini S (2016) Effect of banana peel powder on bioactive constituents and microstructural quality of chapatti: unleavened Indian flat bread. J Food Meas Charact 10(1):32–41

Abreu AS, Oliveira M, de Sa A, Rodrigues RM, Cerqueira MA, Vicente AA, Machado AV (2015) Antimicrobial nanostructured starch based films for packaging. Carbohydr Polym 129:127–134

Shankar S, Tanomrod N, Rawdkuen S, Rhim J-W (2016) Preparation of pectin/silver nanoparticles composite films with UV-light barrier and properties. Int J Biol Macromol 92:842–849

Zhang R, Wang X, Cheng M (2018) Preparation and characterization of potato starch film with various size of nano-SiO2. Polymers 10(10):1172

Swaroop C, Shukla M (2018) Nano-magnesium oxide reinforced polylactic acid biofilms for food packaging applications. Int J Biol Macromol 113:729–736

Sanuja S, Agalya A, Umapathy MJ (2014) Studies on magnesium oxide reinforced chitosan bionanocomposite incorporated with clove oil for active food packaging application. Int J Polym Mat Polym Biomater 63(14):733–740

Bakhy EA, Zidan NS, Aboul-Anean HED (2018) The effect of nano materials on edible coating and films’ improvement. Int J Pharm Res Allied Sci 7(3):20–41

Meng X, Zhang M, Adhikari B (2014) The effects of ultrasound treatment and nano-zinc oxide coating on the physiological activities of fresh-cut kiwifruit. Food Bioprocess Technol 7(1):126–132

Zambrano-Zaragoza ML, González-Reza R, Mendoza-Muñoz N, Miranda-Linares V, Bernal-Couoh TF, Mendoza-Elvira S, Quintanar-Guerrero D (2018) Nanosystems in edible coatings: a novel strategy for food preservation. Int J Mol Sci 19(3):705

Gautam RB, Kumar S (2017) Development of protein based films with nanoparticle as strengthening material for biodegradable packaging—a review. Int J Agri Innov Res 5(5):791–805

Foster HA, Ditta IB, Varghese S, Steele A (2011) Photocatalytic disinfection using titanium dioxide: spectrum and mechanism of antimicrobial activity. Appl Microbiol Biotechnol 90(6):1847–1868

Scuderi V, Buccheri MA, Impellizzeri G, Di Mauro A, Rappazzo G, Bergum K, Privitera V (2016) Photocatalytic and antibacterial properties of titanium dioxide flat film. Mater Sci Semicond Process 42:32–35

Dash KK, Ali NA, Das D, Mohanta D (2019) Thorough evaluation of sweet potato starch and lemon-waste pectin based-edible films with nano-titania inclusions for food packaging applications. Int J Biol Macromol 139:449–458. https://doi.org/10.1016/j.ijbiomac.2019.07.193

Li Y, Jiang Y, Liu F, Ren F, Zhao G, Leng X (2011) Fabrication and characterization of TiO2/whey protein isolate nanocomposite film. Food Hydrocolloids 25:1098–1104. https://doi.org/10.1016/j.foodhyd.2010.10.006

Li W, Zheng K, Chen H, Feng S, Wang W, Qin C (2019) Influence of nano titanium dioxide and clove oil on chitosan–starch film characteristics. Polymers 11(9):1418. https://doi.org/10.3390/polym11091418

Sani MA, Ehsani A, Hashemi M (2017) Whey protein isolate/cellulose nanofibre/TiO2 nanoparticle/rosemary essential oil nanocomposite film: its effect on microbial and sensory quality of lamb meat and growth of common foodborne pathogenic bacteria during refrigeration. Int J Food Microbiol 251:8–14

Malathi AN, Kumar N, Nidoni U, Hiregoudar S (2017) Development of soy protein isolate films reinforced with titanium dioxide nanoparticles. Int J Agri Environ Biotechnol 10(1):141–148. https://doi.org/10.5958/2230-732x.2017.00014.6

Bajpai SK, Chand N, Chaurasia V (2010) Investigation of water vapor permeability and antimicrobial property of zinc oxide nanoparticles-loaded chitosan-based edible film. J Appl Polym Sci 115(2):674–683

Akbar A, Anal AK (2014) Zinc oxide nanoparticles loaded active packaging, a challenge study against Salmonella typhimurium and Staphylococcus aureus in ready-to-eat poultry meat. Food Control 38:88–95

Iuliani S, Wardana AA, Meindrawan B, Edhi N, Muchtadi TR (2018) Nanocomposite edible coating from cassava starch, stearic acid and ZnO nanoparticles to maintain quality of fresh-cut mango cv. Arumanis. Annals of the University Dunarea de Jos of Galati. Fascicle VI-Food Technology 42(2):49–58

Divsalar E, Tajik H, Moradi M, Forough M, Lotfi M, Kuswandi B (2018) Characterization of cellulosic paper coated with chitosan-zinc oxide nanocomposite containing nisin and its application in packaging of UF cheese. Int J Biol Macromol 109:1311–1318

Lakshmi SJ, Roopa Bai RS, Sharanagouda H, Ramachandra CT, Nadagouda S, Nidoni U (2018) Effect of biosynthesized zinc oxide nanoparticles coating on quality parameters of fig (Ficus carica L.) fruit. J Pharmacognosy Phytochem 7(3):10–14

Fabrega J, Fawcett SR, Renshaw JC, Lead JR (2009) Silver nanoparticle impact on bacterial growth: effect of pH, concentration, and organic matter. Environ Sci Technol 43(19):7285–7290

Logeswari P, Silambarasan S, Abraham J (2015) Synthesis of silver nanoparticles using plants extract and analysis of their antimicrobial property. J Saudi Chem Soc 19(3):311–317

Marchiore NG, Manso IJ, Kaufmann KC, Lemes GF, de Oliveira Pizolli AP, Droval AA, Bracht L, Goncalves OH, Leimann FV (2017) Migration evaluation of silver nanoparticles from antimicrobial edible coating to sausages. LWT-Food Sci Technol 76:203–208. https://doi.org/10.1016/j.lwt.2016.06.013

Ragunathan R, Kumar RR, Tamilenthi A, Johney J (2015) Green synthesis of chitosan silver nanocomposites, its medical and edible coating on fruits and vegetables. Int J Biol Pharm Res 6:129–136

Jiang T, Feng L, Wang Y (2013) Effect of alginate/nano-Ag coating on microbial and physicochemical characteristics of shiitake mushroom (Lentinus edodes) during cold storage. Food Chem 141(2):954–960

An J, Zhang M, Wang S, Tang J (2008) Physical, chemical and microbiological changes in stored green asparagus spears as affected by coating of silver nanoparticles-PVP. LWT-Food Sci Technol 41(6):1100–1107

Mohammed Fayaz A, Balaji K, Girilal M, Kalaichelvan PT, Venkatesan R (2009) Mycobased synthesis of silver nanoparticles and their incorporation into sodium alginate films for vegetable and fruit preservation. J Agric Food Chem 57(14):6246–6252

Ghosh T, Teramoto Y, Katiyar V (2019) Influence of nontoxic magnetic cellulose nanofibers on chitosan based edible nanocoating: a candidate for improved mechanical, thermal, optical, and texture properties. J Agric Food Chem 67(15):4289–4299

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Bhagabati, P., Ghosh, T., Katiyar, V. (2021). Inorganic Nanomaterials in Edible Food Packaging. In: Nanotechnology in Edible Food Packaging. Materials Horizons: From Nature to Nanomaterials. Springer, Singapore. https://doi.org/10.1007/978-981-33-6169-0_8

Download citation

DOI: https://doi.org/10.1007/978-981-33-6169-0_8

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-33-6168-3

Online ISBN: 978-981-33-6169-0

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)