Abstract

The power consumption, capacity, speed of rotation, separation precision and the centrifugation time are essential technical parameters of the centrifuge device, and hence their reliability may affect the system reliability and productivity. The modified period of velocity profile model (spinning period) which leads to decreasing the power consumption of laboratory centrifuge devices is derived. Based on the centrifugation time model, a fuzzy controller is proposed for the laboratory centrifuge device. The proposed controller design will produce high reliability by selecting various separation efficiencies, evaluating the separation efficiency period precisely, and reduction of separation power consumption. Based on the derived model, a low-cost controller modification leads to a shorter blood test time and lower power consumption while improving the separation efficiency to greater than 95 %.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

The centrifugal devices can use in a variety of medical and industrial applications. Typically, the power consumption, capacity, speed of rotation, separation precision and the centrifugation time are essential technical parameters of the centrifuge device, and hence their reliability may affect the system reliability and productivity. For this reason, centrifugation process is often obeying to developments and improvements continuously.

Continuing from our previous research [1], we derived a modified period of velocity profile model (spinning period) which leads to decreasing the power consumption of laboratory centrifuge devices. The new model has ability to estimate the power consumed for pre-defined separation efficiency.

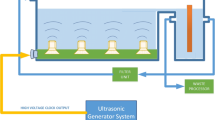

Laboratory diagnosis of blood depends on separation efficiency which is done by means of centrifugal force and the spinning time for the blood sample. The current method of separating contents of a blood sample is not accurate in terms of centrifugation force and time. These variables are evaluated based on sedimentation theory, which calculates the sedimentation time based on higher particle density (red blood cells) and depth of sedimentation [2]. Therefore, about 0.5 ml volume of a 1 ml blood sample, the current centrifugation time is 5 min (also as recommended by the centrifuge device recommended manufacturer). To minimize or eliminate such uncertainties (due to damage of some red blood cells) from the process, we have developed a new technique that accurately predicts the required time for the separation then control the velocity profile period of centrifuge device. This technique is based on measuring the attenuation of the wave propagated through liquid its density varies with time of spinning [3, 4]. Separation efficiency of blood and plasma is evaluated empirically by percentage count for the red blood cells, white blood cells, HCT, and platelets in a sample using blood analyzer device (cell-dyne 1800). Experimental data was used to calculate the power consumption during the time taken for accurate separation. The schematic diagram of experimental attenuation measurements is shown in Fig. 1. Human blood was drawn from 84 healthy volunteers, 23 women and 61 men; their HCT values ranged from 21 to 53.7 %; age range, 21–50 years. Samples of plasma were prepared using a serum separator tube (EDTA (K2); Demophorius Ltd, Cyprus, EU, UK). This method can also be applied to other purpose of centrifugal device, such as measurements of solid contents in liquid and sedimentation measurements [5]. Since the installation of additional measurement sensors may be costly and the sensors can also reduce the device reliability, they are not always the most cost-effective solution for the separation percentage monitoring of a centrifuge device. For this reason, the centrifuge velocity profile controller must be modified according to new mathematical model.

Based on the centrifugation time model, a fuzzy controller is proposed for the laboratory centrifuge device, Fig. 2. The proposed controller design is based on the separation efficiency and maximum spinning speed, which will produce high reliability by selecting various separation efficiencies, evaluating the separation efficiency period precisely, and reduction of separation power consumption. The design of the proposed fuzzy controller is divided into two parts, the linear velocity profile generator and the fuzzy logic controller, as illustrated in greater detail in the following sections.

2 Separation Efficiency

The various organs, tissues and cells throughout the body require oxygen from the blood. Other bodily elements also require carbon dioxide, which also depends on the cycling of blood effective techniques for separating; concentrating and accumulating one or more of the components of blood will improve our ability to understand the properties of blood ascertain the state of an individual’s health and treat bodily diseases. Therefore, accuracy in separating blood-plasma has advantages in various fields of scientific research, diagnostic testing and therapeutic treatment [6].

The separation efficiency S e is a key factor for evaluating the performance of blood-plasma separation. It can be defined as

where C B is the cell concentration in the blood sample, and C P is the cell concentration in the plasma, which is generated by the centrifugation process. For C P = 0, the optimum separation process for plasma is present (S e = 100 %). In next sections, a relationship between power consumption of centrifuge device, separation period and separation efficiency are derived.

3 Linear Velocity Profile Generator

The proposed centrifugation velocity profile controller was designed based on the optimisation spinning time model. This model calculates the spinning time as a function of the separation efficiency. The mathematical model for the optimisation of the centrifugation time includes the acceleration and deceleration period because the blood sample is subjected to accelerated centrifugal force during the acceleration period and vice versa for the deceleration period [7].

These forces contribute the main centrifugal force (at 3,000 rpm) to separate the blood cells from the plasma. The need for a long acceleration and deceleration period (approximately 13 s) is observed because the blood cells encounter a high centrifugal force, which may cause damage. Therefore, to prevent this problem, the centrifugation speed gradually increases until it reaches a maximum (long settling time). The current periods of acceleration and deceleration are identical and equal to 13.6 s as a rapid mode operation. For this reason, as shown in Fig. 2, the FLC design begins with a ramp (linear) velocity profile generator, which is fed by the required spinning speed and separation efficiency percentage value. This generator consists of a Separation Efficiency (S e ) to Separation Period converter, a timer, an initial condition function and a speed limiter [8–10].

4 Experimental Setup

The Mathematical Model of the shorter separation process time and the separation efficiency greater than 95 % of 0.35 ml plasma, evaluated based on the mathematical model of ultrasound attenuation measurements in our previous research [1]. Utilize of attenuation measurements of wave propagate through a sample of blood during centrifugation process, is to calculate the separation efficiency of blood-plasma. In this research we divided the mathematical model into two models, first is the time duration of centrifugation as a function of separation efficiency model, while the second model is device power consumption as a function of time duration centrifugation technique, Fig. 3 summarize the derivative power consumption model.

The tools used in the experimental setup, as shown schematically in Fig. 1, consisted of a blood tube, the ultrasound pulser, Gampt–Echo Scan as a receiver, switch, and software analysis, while Fig. 4 shows the experimental procedure steps for evaluate the mathematical model. The transducer with center frequencies of 2 MHz was attached to the outside of the vessel. In the attenuation measurements reported here, data was obtained for the 2 MHz transducer, which gave the required detection depth and sufficient level of clarity of the separation efficiency measurements of the blood plasma. Table 1 was filled follow same procedure mentioned in our previous research for evaluating the optimization time for centrifugation process. Therefore the two part of mathematical model can be derived.

5 Centrifugation Period Model

The Separation Efficiency to Separation Period block is programmed with a Matlab package based on the optimisation centrifugation time model, which evaluates the time period required to achieve the predefined separation efficiency. The rest time in the velocity profile is determined by the time optimisation model (2) as a constant speed period. Figure 5 shows the velocity profile for 20 % separation efficiency, where the total period (T) of 20 % separation is approximately 55 s, calculated using (2) [11].

6 Centrifugation Power Consumption Model

Power consumption is one of the most important measurement parameters for the design of a successful controller. The power consumption of the proposed controller can be evaluated based on the operation period of the centrifuge device.

As mentioned in the previous section, the constant speed period (t c ) is limited by the separation efficiency value in (1). In addition, using rapid mode, the acceleration and deceleration periods are equal to 13.6 s. Therefore, the total spinning time changes based on predefined separation efficiency (t c ). Figure 6 shows the spinning period for various separation efficiencies. According to the experimental results, to obtain a volume of 0.35 ml with greater than 95 % plasma concentration, the appropriate time is 3 min. Therefore, the total centrifugation time is a 3.45 min. The electrical power consumption can be easily calculated using the following formula:

where \(T_{PC}\) is the total power consumption, \(D_{PC}\) is the device power consumption and \(O_{t}\) is the operation time period which can be formulate as:

Thus, the power consumption can be rearranged as function of separation efficiency;

The power of the laboratory centrifuge device (Kubota corporation model 2420) used is 180 W. An evaluation of the separation efficiency and power consumption over a 5-min interval using a 180-W centrifuge device is shown in Table 1. The classical spinning time required to separate 0.35 ml of plasma from 1 ml blood with a separation efficiency greater than 95 % is 5 min according to the manufacturer’s recommendations, while for proposed method, the time is 3.453 min, as shown in Fig. 6 [12].

7 Conclusions

Based on the mathematical model of the optimisation time for the centrifugation process, a mathematical of centrifugation process power consumption is derived. The centrifugation speed profile is linear, and it consists of the acceleration and deceleration period because the blood sample is subjected to an accelerated centrifugal force during the acceleration and deceleration period. These forces contribute the primary centrifugal force (at 3,000 rpm) for the precipitation of blood cells from plasma. Based on the derived model, a low-cost controller modification leads to a shorter blood test time and lower power consumption while improving the separation efficiency to greater than 95 %. In addition, increases the reliability of the centrifuge device for estimating the centrifugation period for predefined separation efficiency.

The relationships between the power consumption of the device and the centrifugation time and the plasma separation efficiency are linear, as shown in Figs. 7 and 8, respectively. As a result, the power consumption relative to the specific separation efficiency for any centrifuge device wattage can be estimated. The mathematical model of the centrifugation time derived based on attenuation measurements successfully conserved 18 kWh monthly when the device is used 100 times daily, Table 2. Figure 9 shows that the difference in the power consumption of the classical and proposed controller increases with the time of operation of the device per day in addition to the wattage of the device itself.

Additionally, the power consumption of a 180-W centrifuge device using the proposed controller is approximately equal to that of a 300-W centrifuge device using a classical controller.

References

Salim MS, Abd Malek MF, Heng RBW, Sabri SN, Juni KM (2011) A new measurement method of separation percentage for human blood plasma based on ultrasound attenuation. IJPS 6(30):6891–6898

Theory of sedimentation and centrifugation (2009) www.bbka.org.uk/local/iceni/bm~doc/pollensuspension-2.pdf

Greenwood MS, Adamson JD, Bamberger JA (2006) Long-path measurements of ultrasonic attenuation and velocity for very dilute slurries and liquids and detection of contaminates. Ultrasonics 44:461–466

Bain BJ (2006) Blood cells: a practical guide. Blackwell Publishing, Malden, 476p

Bamber JC (2004) Attenuation and absorption. In: Hill CR, Bamber JC, ter Haar GR (eds) Physical principles of medical ultrasonics. Wiley, Chichester, pp 93–166

Edward RT (2001) An investigation of centrifugal blood-cell separation. Ph.D. thesis, New Jersey Institute of Technology, Department of Chemical Engineering

Acarnnley PP (1982) Stepping motors guide to modern theory and practice. Peter Peregrinus Ltd, London

Ramu K (1998) Electronic control of machines. ECpE 4324, A-1 Copies, Blacksburg (From the forthcoming book electronic control of machines, Prentice-Hall, USA)

Leonard W (1985) Control of electric drives. Springer, Berlin

Chung S et al (1994) A robust speed control of brushless direct drive motor using integral variable structure control with sliding mode observer. Conference record of IAS annual meeting, vol 1, IEEE, Piscataway, NJ, pp 393–400

Salim MS, Abd Malek MF, Sabri N, Noaman NM, Juni KM (2013) Novel: time optimization model for centrifugation process: application in human blood-plasma separation. Measurement. http://www.sciencedirect.com/science/article/pii/S0263224113002741

Kubota Corporation–Laboratory Centrifuge Catalogue (2010) http://www.centrifuge.jp/product/2420/index.html

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer Science+Business Media Singapore

About this chapter

Cite this chapter

Salim, M.S., Abd Malek, M.F., Sabri, N. (2015). Reduction of Power Consumption for Centrifugation Process Using Separation Efficiency Model. In: Gaol, F., Shrivastava, K., Akhtar, J. (eds) Recent Trends in Physics of Material Science and Technology. Springer Series in Materials Science, vol 204. Springer, Singapore. https://doi.org/10.1007/978-981-287-128-2_16

Download citation

DOI: https://doi.org/10.1007/978-981-287-128-2_16

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-287-127-5

Online ISBN: 978-981-287-128-2

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)