Abstract

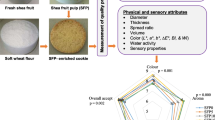

For many people living in urban regions, fresh fruits and vegetables are practically a fantasy in the contemporary circumstances due to time constraints and the risks inherent in procuring them. To profoundly boost human nutritional value, the inclusion of abundantly produced healthy fruits and vegetables in the region and as ready-to-eat snacks is certainly desired. Squash or Chayote (Sechium edule) is prevalent in mountainous regions of India and can be found throughout the year. The people of Northeast India extensively use this vegetable in a variety of forms, despite the fact that the peel is nothing more than a waste product containing rich nutrients. Dried squash powder can be used to improve the nutritional value of a wide range of dishes. Cookies that contain little or no gluten are becoming increasingly popular. It is possible to bake gluten-free treats using sugar-snap cookies, which are heavy in fat and sugar. Squash pulp and peel powder can serve as a good substitute to wheat flour for those with gluten sensitivities. In the current study, rice flour and varied proportions of squash pulp powder were combined to achieve squash-based cookies after analysing their functional properties and proximate properties. In comparison to fresh samples, dried powdered samples were found to considerably improve the nutritional characteristics such as ash, crude fibre content, fat, carbohydrate, and protein. The squash pulp and peel powder can be utilized for baked goods. This is evident in their functional characteristics such the capacity to absorb water and oil, the lowest gelatinization temperature, and the lowest concentration of gelation. Cookies were analysed for their sensory properties by utilizing a 9-point hedonic scale and fuzzy logic analysis. It was observed that the squash-based cookies with a rice:wheat ratio of 3:1 and 30% squash pulp powder substitution were the most preferred. With greater substitution of squash pulp powder, the amount of crude fibre and vitamin C increased while the amount of fat lowered. With greater substitution of squash pulp powder, the TPC values and antioxidant activity also increased.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Belonging to the Cucurbitaceae gourd family, the edible plant Sechium edule (commonly known as chayote), bears green, pear-shaped fruits and tough tendrils that distinguish the perennial herb from other climbers. The ideal conditions for Chayote to thrive are mild temperatures, high relative humidity, evenly distributed annual rainfall, and 12 h of daylight [1]. It is easy to grow squash (chayote) due to its excellent ability to acclimatize to an extensive choice of environmental surroundings. As one of the cheapest vegetables in India, the prominent home garden crop in Northeast India, is also widely cultivated for both commercial and personal consumption [2]. Squash is an excellent source of fibre, protein, fat, minerals, and vitamins, especially vitamins A and C [3]. Due to its fragile flesh's short shelf life and severe perishability, it has a substantial negative impact on productivity. In the recent years, the fruits of this tree, which are becoming increasingly popular in the world as a vegetable, have been exported.

Any perishable vegetable or fruit that is being exported can be dried to reduce its water content and enhance its shelf life. Additionally, drying prevents microbial attack-related breakdown, giving dried goods with an extended storage life. Such dried items can hence be available in the entire year without losing their nutritional composition. For such drying, a wide variety of drying methods can be deployed, including sun, tray, oven, shadow drying etc. As a thumb rule, shadow drying takes a long time, whereas sun drying is detrimental to the preservation of vegetable nutritional values. Heat treatment and drying environments can adversely affect several nutritional components. As a result, it's important to adapt a drying process that effectively preserves nutritional content of the fruit at a lower cost. For the Northeast India, horticultural produce drying in a hot air oven or a tray dryer would be a feasible inexpensive option to reduce their water content. Dried vegetable powders can be used to serve as key constituents in several food products, including bakery and confectionary items.

Due to their high nutritional value and low cost, cookies are popular. Rapid population expansion, enhanced influence of the Western countries habitat in food consumer products, the emergence of a female working population, and changing eating patterns have all contributed to enhanced cookie and biscuit production. Due to a rise in health awareness of foods, a strong demand exists for healthier cookie products. In the recent years, consumer interest in wheat-free meals (Triticum aestivum) has steadily increased to reduce the risk of celiac disease and associated disorders that is still largely unknown [4]. Since wheat flour contains gluten, patients with celiac disease cannot eat baked treats or other dishes cooked with it. A variety of flours can be used to supplement gluten, which significantly influence and determine the cookie's processability and end productivity.

Sensorial assessment process is a scientific strategy for eliciting, measuring, assessing, and interpreting the product's sensory reactions. The five sense organs of the human beings generally respond to the associated stimuli and reactions [5]. On a scale of 9 that corroborate to “like highly” and “dislike excessively,” a hedonic scale rating test is often utilized to assess upon the degree of pleasurable and unpleasurable cookie consumption experience. For this purpose, evaluation form is provided to experienced panelists with a number ranking system that contained several sensory criteria and scoring options. In due course of evaluation, the panelist data is averaged and tabulated. Taste, texture, colour, appearance and general acceptability have all been considered in due course of the sensory analysis-based rating of the cookies. Also, basic fuzzy logic approaches can be as well followed to establish an experiment's truthfulness using its fuzzy sets. In the recent research endeavours, fuzzy notions have been used along with hedonic scale-based sensory evaluation.

Existing research in this field has been devoted towards the nutritional analysis of squash fruit, squash pulp and peel flour and sensory analysis of squash cookies. The existing literature is fairly suggestive to this area of research. The moisture content of squash was found to be about 89–95 g/100 g by few authors [6]. Chayote always consists of good quantity of moisture (89.3–94.2%) but has lower protein constitution (0.77–1.05%). The extracted fruit juice has abundant constitution in vitamin C (22.3%). Additionally, the fruits of the S. edule plant have significant amounts of ash content (0.245–0.321%), crude fibre (4.88–5.89%), and carbohydrate (4.12–4.98%) [7]. The protein content varies from 0.82 to 1.74 g per 100 g, while the starch ranges from 0.20 to 1.56 g per 100 g, and the fat content varies as from 0.10 to 0.30 g per 100 g [8]. Also, ash content has been evaluated to be about 0.40–3.60% dry weight in the vegetables. Mineral content of the vegetable refers to 125–338 mg/100 g (potassium), 12–25 mg/100 g (calcium), 12–15.4 mg/100 g (magnesium) and 4–60 mg/100 g (phosphorus) [9]. The immature uncooked fruits of several squash varieties have high vitamin C (7.7–20 mg/100 g) on dry weight basis. The peel portion of the vegetable contains 8.31% (dry weight) ash, which predominantly constitutes 307 mg/100 g of calcium, 196 mg/100 g of phosphorus and iron (6.72 mg/100 g) [9]. Fruit, peel and leaves of the vegetable have ample quantity of vitamin C and carotenoids such as lutein and carotene (β).

Till date, only one article devoted towards the development of squash enriched wheat-based cookies [10]. However, researchers investigated the nutritional and functional aspects of several squash pulp powders [11]. The water, fat, protein, total carbohydrate and energy contents of squash powder were found to be in the range of 10.65–12.5%, 0.8–2.19%, 2.92–4.76%, 73.76–77.39%, and 324.87–333.75 kcal respectively for the chayote flour-based biscuits. The micronutrient constitution in terms of total carotenoid, vitamin C, phosphorus, calcium, iron, potassium, zinc levels have been 6.38–23.30 mg/100 g, 14.58–20.54 mg/100 g, 13.75–26.45 mg/100 g, 39.60–60.98 mg/100 g, 0.55–0.97 mg/100 g, 102.56–119.65 mg/100 g, 0.34–0.56 mg/100 g respectively [12]. These findings demonstrate that the nutrition-based analysis of the average proximate parameters (carbohydrate, fat, protein, water, and inorganic mineral or ash content) have been as 57.66, 19.39, 16.99, 6.68, and 5.28 g/100 g respectively. In the vegetable, the maximum vitamin C content has been 13.97%, followed by vitamin E (0.11%) and vitamin A (0.041%). Highest mineral content corresponded to 3,902 mg/100 g for potassium, followed by sodium (861.0 mg/100 g) and calcium (665.6 mg/100 g) [11]. Water absorption, water retention, and oil absorption capabilities of squash powder have been estimated to vary as 7.50–9.13, 3.35–6.05 and 1.02–2.04 respectively [11]. The thermal properties and the particle size analysis of squash pulp and peel powder have not been analysed. Till date, the nutritional parameters of squash peel powder have not been investigated.

Cookies with 90:10 wheat:squash constitution have been reported to have 75% acceptance by a set of panellists. Similarly, the researchers investigated squash-based culinary items [10]. The authors targeted variant squash constitution in the prepared items. The best sensory scores formulations for making squash cookies use various quantity of squash. There were 7.58, 7.69, 7.62, 7.46, 7.67 and 7.60 for taste, colour, aroma, texture, appearance and weighted mean score respectively. Upon storage in airtight jars, the squash-based cookies possessed a shelf life of nine days [10]. Fuzzy logic has been a useful technique for analysing unclear and ambiguous data and drawing critical conclusions about food approval, refusal, rating negative and positive features. Language variables (for example not satisfactory, acceptable, exceptional etc.) are often used in fuzzy clustering to build correlations between independent (such as appearance, aroma, flavour, texture, accessibility, etc.) and dependent (such as acceptability, denial, rating, good and bad food qualities) variables [13]. Fuzzy sets can be used to analyse sensory data instead of using the average scores approach to compare the qualities of the samples. This is due to the reason that they are not constrained to a predetermined value and are advantageous in sensory evaluation as human expressions on how we feel about food are fuzzy rather than predictable [13]. For judging and ranking food products, the created fuzzy computing models do an impressive job [14]. In fuzzy logic control, a subject can be represented by a series of elements and the degrees to which they are members of the two sets without membership [15]. The fuzzy sets have been proven to provide mathematical approaches for the analyzation of the complexity of human perception [16]. These methods have studied well with mango beverages [17], dahi [18] and instant green tea powder [19]. Cookies made with squash were made in accordance with the earlier study [10], although without the correct composition modification. Not many attempts were reported to determine the sensory qualities of the various squash pulp flours. Cookies made with squash have not yet been determined to have any nutritional benefits. Therefore, the current research focused on the developing squash-based cookies with the best sensory properties (for both 9 point hedonic and fuzzy logic scale). In order to accomplish this, the nutritional, functional, and physical attributes of squash pulp and peel flours were assessed and utilised in the development of the cookies.

2 Materials and Methods

2.1 Procurement of Raw Materials and Sample Preparation

From Kamrup (Shingimari area), Assam, India, raw squash vegetables were bought (26.2205 °N; 91.6241 °E). During transportation, polyethylene bags were used. Thereafter, the vegetables were washed several times with running water to get rid of any dirt or debris that could have been on them. Later, the squash was peeled. The peeled squash was then sliced into 0.5 mm thick slices with a slicer and the uneven pieces were removed. The vegetable samples were dried on trays in a laboratory-scale oven (Make: REICO) for five hours at 60 °C.

2.2 Preparation and Baking of Cookies

The cookies were developed with several ingredients such as wheat flour, sugar, butter, baking powder, vanilla essence, rice flour, and squash pulp flour. To do so, firstly, squash pulp powder was substituted in 10, 30, and 50% weight proportions in the flour constitution. For the rice and wheat based flour constitution, the squash pulp was kept at 30% and rice was varied from 1 to 3 in proportions (dry weight basis) and with reducing wheat flour proportion in the corresponding formulation. Also, same rice: wheat flour formulations were used to bake few cookies without squash constitution. The proportions of sugar, butter, and baking powder were kept constant and as 19, 34 and 2% respectively. The cookies were cut using a cookie cutter of diameter 6 cm and height of 1 cm. The baking temperature and time were varied as 150–170 °C and 15–20 min respectively. Thereby samples (A–J) with the altered constituents were obtained.

2.3 Chemicals

Anthrone, DPPH (extra pure), indophenol sodium salt and sodium bicarbonate were acquired from the manufacturing company SRL Pvt. Ltd., India; Anthrone, Anthrone extra pure, sodium bicarbonate were purchased from Rankem and Sigma Aldrich, India respectively. Merck India supplied pellets of sodium hydroxide, oxalic acid (dehydrate), petroleum ether, 98% sulfuric acid, dextrose, methanol (absolute).

2.4 Determination of Proximate Characteristics

Moisture content (Moc): The moisture content of the squash was calculated using a prior art-based technique (AOAC, 2010). For this, squash sample was kept at 105 ± 5 °C for overnight. Thereafter, the sample was allowed to reach room temperature without absorbing moisture and was evaluated by weighing. The following equation was used to assess Moc (AOAC, 2010) of the sample:

where Moc = moisture content, \({w}_{1}\) and \({w}_{2}\) are taken as the weights of the squash specimen and the squash (bone dried) sample respectively.

Ash-content: The AOAC, 2010 method was employed to measure the ash-content. For this, in duplicate, a constant amount of squash sample was placed inside a muffle furnace for 6 h at 550 °C. The ash residue was weighed after desiccated storage. The ash content has been calculated with the expression:

where \({w}_{3}\) and \({w}_{4}\) are taken as the weight of ash and squash (dehydrated) taken respectively.

Crude-fibre: The crude-fibre content was determined using the method delineated by Sadasivam and Manikam's (1992) method [14]. For this, firstly, 1 g dried sample with 1.25% H2SO4 was stirred with a setup of magnetic plate for 30 min. The acid was subsequently removed from the sample by filtering it through a cotton cloth and washing it in hot water at boiling stage. Then the residual portion was exposed to 1.25% NaOH and filtered. The residue was rinsed with H2SO4 (1.25%), along with water (50 mL) and alcohol (25 mL). The residual portion was washed thoroughly and a crucible was used for keeping the residue for 2 h at 130 °C. The sample was burnt in a muffle furnace for 30 min at 600 °C after cooling and weighed it. The sample was subsequently weighed after cooling to ascertain its quantity of crude fibre using the following formula.

where \({w}_{5}\) and \({w}_{6}\) are the weight loss at 600 °C (during ignition in a muffle furnace) and the sample taken initially respectively.

Fat content: The AOAC (2010) method was used to determine the amount of fat in the vegetable sample. A specific amount of the dried material had to be put into a thimble before being extracted with petroleum ether in a Soxhlet apparatus. After evaporating petroleum ether, the fat content was determined using the formula below:

where \({w}_{7}\) and \({w}_{8}\) correspond to the weight of treated and initial sample respectively.

Soluble-protein: To quantify the amount of soluble-protein in the squash sample, Bradford's method was applied [15]. For this, firstly 100 mL of distilled water was used to dissolve about 100 mg of dried material. After performing the extraction, 5 mL of Bradford's reagent was added. The absorbance of the mixture was measured at 595 nm using a BSA standard and a UV–Visible spectrophotometer (Model No. UV-2600, Make: Shimadzu, Singapore).

Carbohydrate-content: The Clegg anthrone technique was used to determine the carbohydrate content [16]. The following is a summary of the involved steps. First, 10 mL of distilled water and 1 g of the substance were well combined. After adding 62% of perchloric acid (13 mL), the mixture was agitated for 20 min. Subsequently, the liquid was diluted to 250 mL and filtration was performed. With 100 mL of distilled water and 5 mL anthrone reagent solution, the filtrate was diluted. With 5 mL of anthrone reagent and 1 mL of distilled water, a blank sample was created. Following that, both samples were kept at 100 °C for 12 min. At 630 nm, the samples’ absorbance was finally measured. Applying the following formula, its carbohydrate content was determined [16].

where \({A}_{1}\) and \({A}_{2}\) are the diluted sample and standard (blank) absorbances respectively.

2.5 Bioactive Compounds

Vitamin C content: The method outlined by Sadasivam and Manickam (1992) was used to calculate the sample's vitamin C. To begin with, dried sample of 0.1 g were extracted with 4% oxalic acid (10 mL). Centrifugation and subsequent harvesting of the sample in another media was the next step. 10 mL of oxalic acid (4% concentration by volume) and the supernatant of 5 mL were added together. The indophenol dye (2,6-dichlorophenol) solution was added to titrate the mixture. As a result, vitamin C was calculated using the following equation:

where \({v}_{3}\) and \({v}_{4}\) are the volume of standard (ascorbic acid) and sample extract consumed and \({w}_{9}\) corresponds to the sample weight.

TPC and TFC: The FCR method was used to estimate the TPC [18]. The TPC content of the samples was expressed as mg of gallic acid equivalents (GAE)/g weight of the corresponding samples (mg/g sample) using a calibration curve made with gallic acid. The TFC of the samples was evaluated using the AlCl3 technique [18]. The TFC of the sample was calculated as mg of QE/g weight of the sample. The absorbance of the samples was measured at 517 nm for TFC and 750 nm for TPC.

Antioxidant activity: The 2,2-diphenyl-1-picrylhydrazyl (DPPH) assay methods described by the authors [19] with methanol were taken to assess the activity of antioxidants of the vegetables. The samples were then incubated in the dark for half an hour. Finally, at 517 nm, the absorbance of the samples was measured with a UV spectrophotometer. The antioxidant activity of the samples was evaluated using the expression utilising measured absorbance values and the measured absorbance values [19].

where \(\text{AnO}\) is the Anti-oxidant activity and \({A}_{4}\) and \({A}_{3}\) resemble to the absorbance of sample and control case respectively.

2.6 Functional Attributes of Flours

Water absorption capacity (WAC, %), oil absorption capacity (OAC, %), temp. of gelatinization (GT, °C), least concentration of gelatinization (LGC, %), and bulk density (g/cc) were used to analyse the functional qualities of flours.

Water absorption capacity (WAC): The WAC of the flours was determined by the prior art method [20]. For this, 1 g of sample and 10 mL of distilled water were combined with and kept to rest for 30 min at room temperature. The mixture was then exposed to centrifugation for 30 min at 2000 g or 3000 rpm. In terms of g of water bound per g of flour, the WAC was measured.

Oil absorption capacity (OAC): OAC was calculated using the prior art methods [20]. For this, 10 mL of soybean oil with a specific gravity of 0.9092 was combined with 1 g of the sample and left to stand for 30 min at room temperature. The mixture was then centrifuged for 30 min at 2000 g or 3000 rpm. In terms of g of oil bound per g of flour, oil absorption was measured.

Least-gelation concentration (LGC): LGC was assessed with minimal adjustments and with the prior art reported approach [21]. In 5 mL of distilled water, flour dispersions with variation from 2 to 30% (w/v) samples were made. They were then cooked in a water bath at 90 °C for one hour. The samples were then cooled using tap water and maintained at 10 °C for 2 h. The concentration that corresponds to the sample that did not fall from an inverted tube was chosen as the one with the least amount of gelation.

Least-gelatinization temperature: Gelatinization temperature was determined as per the reported prior art method [22]. In order to do so, a 1 g quantity of flour was precisely weighed in triplicate and placed into 20 mL screw-capped tubes. Then, each sample received 10 mL of water. The samples were then gradually cooked in a water bath until they solidified. Thereby, the respective temperature for complete gel formation was noted and reported as gelatinization temperature.

Packed Bulk density: To evaluate the parameter, 100 g of flour was weighed into a 250 mL measuring cylinder. Thereafter, the cylinder was tapped on a wooden plank until there was no discernible volume loss. The apparent (bulk) density was then computed using the weight and volume [23].

2.7 Flour-Thermal Properties

Using a differential scanning calorimeter, the squash samples’ thermal characteristics were examined (Make: DSC Sirious). In order to do so, 5–7 mg of the sample were placed on the DSC pan for thermal analysis at temperature range and heating rate of 30–350 °C and 10 °C/min, respectively.

2.8 Average Particle Size and Poly-diserpsity Index

The particle size (average) and PDI of the squash samples were evaluated using particle analyser [Make: Beckman Coulter Model: Delsa Nano C] and with dynamic light scattering method. To do so, 0.1 g sample and 20 mL water was mixed properly with 10 min sonication and was thereafter transferred into a cuvette for analysis at 25 °C and 170° scattering angle. For these experiments, the deployed diluent water possessed a refractive index of 1.3328 and viscosity 0.8818 cP respectively.

2.9 Functional Group Analysis Using Fourier Transform Infrared Spectroscopy

Fourier transform-infrared spectrophotometry (FTIR; Shimadzu; Japan; IR Affinity1) (4000–400 cm−1 wavenumber range) was conducted to determine the existence of functional groups in raw and dried squash peel and pulp. Thereby, relevant interactions have been analysed.

2.10 Physical Properties of Cookies

The average of the highest and minimum values of the measured thickness was used to calculate the thickness of a cookie. The ratio of the baked round diameter to thickness was used to compute the spread factor. The weight reduction was calculated as a percentage of the cookie's final weight to its initial weight [24]. Such measurements were based on six repetitions.

2.11 Sensory Analysis

A panel of sixteen semi-trained panellists (senior research scholars) evaluated the sensory features of cookies. The samples had been coded with alphabets ranging from A to J for this purpose. Prior to organoleptic evaluation, the panellists were instructed on the hedonic 9-point scale and fuzzy scale-based rating. The attributes being evaluated were flavour, colour, texture, breakability, taste, crunchiness, after taste and overall acceptance. A 9-point hedonic scale was utilised, with 1 representing dislike strongly, 5 representing neither like nor dislike, and 9 representing like extremely. Samples being analysed with 70% of the scores in the ‘like range’ (6–9) of the hedonic region for various attributes were considered to be acceptable. Panellists were asked to provide ratings in the form of NS (Not Satisfactory), F (Fair), Medium (M), Good (G), and Excellent (E) for samples, and NI (Not Important), SI (Somewhat Important), I (Important), HI (Highly Important), and EI (Extremely Important) for the entire product for fuzzy logic analysis. These were recorded with a fuzzy linguistic score sheet [25]. Excel 2016 (Microsoft Inc. 2016, United States) was applied in this study to analyse sensory assessment data of squash-based cookies using a fuzzy logic technique. The individuals were given water to rinse their mouths between evaluations. Thereby, they were allowed comfort if they did not wish to swallow the samples.

3 Results and Discussion

3.1 Nutritional Characteristics

Moisture content: Fresh squash pulp had a moisture content of 96% while squash peel had a moisture content of 94.41%. Similarly, the authors [6] found that the moisture content of fresh squash fruit was in the range of 89–95%. The dried squash pulp powder has a moisture % of 8.68 whereas for dried squash peel powder, it was found to be 12.24%. Similarly, the prior art reported 10.65–12.5% moisture content in squash pulp powder [11]. In cookies, the range of moisture was determined to be about 0.9–8.48%. Among various samples, the cookies with 1:1 rice:wheat formulation possessed the lowest moisture content (0.9%) and control cookies possessed the highest moisture content (8.48%). The moisture content for cookies with 3:1 rice: wheat and 30% squash constitution was 2.68%. Similar results were reported by a research group [12] for chayote powder-based biscuits (6.68% moisture content).

Ash content: For fresh samples, it was observed that the squash pulp's ash concentration was higher (0.075%) than that of the squash peel (0.013%). Similarly, researchers [7] reported that the ash content varied as 0.245–0.321% for the chayote fruits. For dried powdered samples, the ash content was comparatively higher for squash peel (3.415%) than for the squash pulp (1.345%). The ash content of papaya powder has been reported to be 4.42%. The cookies’ ash content ranged from 1.015 to 1.956%. The highest ash content was for the cookies with no substitution and for 1:1 rice:wheat formulation, the value was assessed to be lowest. The ash content of chayote based biscuits (5.28%) was reported in the relevant literature [12].

Crude fibre: For fresh samples, the crude fibre content was found to vary as 1.7–1.8%. The literature confirmed that the crude fibre content of the chayote fruit varied as 4.88–5.89% [7]. For powdered samples, the crude fibre content has been in the range of 4.4–9.7% and the highest value has been for the squash peel. For papaya peel powder, a crude fibre content of 0.65% has been reported [26]. The crude fibre content for cookies has been in the range of 0.5–1.8%. The highest fibre content of 1.8% was obtained for the formulation with 30% squash flour and 3: 1 rice to wheat ratio while the lowest was for the control cookies (0.5%). However, for the control sample, crude fibre content is found to be lowest. The crude fibre content of the papaya pulp based cookies was reported to be 3.48% [27].

Fat content: The fat content of fresh squash pulp and fresh squash peel were 0.1 and 0.048% respectively. Few authors, reported that the fat content in fresh squash fruit varied as 0.1–0.3% [17]. The squash pulp powder and squash peel powder possessed fat content of 3.3–5.47%. For squash pulp powder, the fat content of 0.8–2.19% has been reported by few authors [11]. For cookies, the fat content was in the range of 31–38.44%. For the control cookie samples, the fat content of 38.44% was obtained. Comparatively, for the 30% squash constituted 3:1 rice to wheat formulated cookies, the fat content was 31%. The fat content of chayote-based cookies was reported to be 19.39% [12].

Carbohydrate: For fresh samples, the carbohydrate content was 5.09 and 5.39% for squash pulp and peel respectively. Similarly, in the literature, researchers reported carbohydrate content of the chayote fruit to vary as 4.12–4.98% [7]. The carbohydrate content of squash pulp and squash peel powder have been in the range of 41.1–52.6%. Among both, the squash peel had lower carbohydrate content. In the literature, few authors found that the carbohydrate content of squash pulp powder varied as 73.76–77.39% [11]. For cookies, the carbohydrate content was 51.91% for control samples and was 54.4% cookies with 30% squash constitution and 3:1 rice to wheat ratio. For the literature reported cookies, the carbohydrate content was about 56.6% [12].

Vitamin C content: The vitamin C content of fresh squash pulp and fresh squash peel was found to be 7.142 and 14.28 mg/100 g respectively. Similarly, the literature reported vitamin C content of the chayote fruit varied as 7.7–20 mg/100 g [9]. The squash pulp powder and squash peel powder possessed vitamin C content in the range of 71.42–142.8 mg/100 g. The vitamin C content of squash powder as per literature varied as14.58–20.54 mg/100 g [11]. For control cookie sample, it varied as the vitamin C content was nil and was 142.85 mg/100 g for 1: 1 rice to wheat constituted cookies with 30% squash content. For chayote powder, the literature reported a vitamin C content of 139.7 mg/100 g [12].

Soluble protein: The protein content of fresh squash pulp and squash peel samples have been in the range of 0.7–1.5%. The literature reported the protein content of squash fruit to vary as 0.7–1.05% [7]. The protein content of squash pulp powder varied as 5.454–5.677%. For the squash peel powder it varied as 6.171–6.430%. The literature confirmed that the protein content of squash powder to vary from 2.92 to 4.76% [11]. The cookies possessed protein content in the range of 1.77–1.98%. The literature reported protein content of cookies was about 16.99% [12].

Total Phenolic Content (TPC) and Total Flavonoid Content (TFC): For fresh squash pulp and fresh squash peel samples, the TPC were 1.89 and 1.31 mg GAE/g respectively. The fresh pulp and fresh squash peel samples possessed TFC of 4 mg of QE/g and 4.05 mg of QE/g respectively [28]. The TPC values for squash fruits have been reported in the literature to vary as 1.02–6.18 mg GAE/g [9]. Corresponding TFC varied as 1.5–60.1 mg QE/g [9]. The dried samples of squash pulp and squash peel possessed TPC of 0.912 and 1.18 mg GAE/g respectively. Corresponding TFC values for the samples were 3.85 and 6.2 mg QE/g respectively. For pumpkin slice powder, the reported TPC in the literature was 11.13 mg GAE/g [29]. For butternut squash powder, the reported TFC was 1.32 mg GAE/g [30]. The cookies with 3:1 rice to wheat and 30% squash constitution had highest TPC of 0.97 mg GAE/g. On the other hand, TPC was lowest for 1:1 rice to wheat ratio cookies and was 0.27 mg GAE/g. The control sample possessed a TPC of 0.66 mg GAE/g. With respect to the TFC, the control samples had the highest value (5.5 mg QE/g) and the lowest was for cookies with 1:1 rice to wheat ratio (3 mg QE/g). However, the TFC value for cookies with 3:1 rice to wheat ratio and with 30% substitution of squash was 5 mg QE/g.

Antioxidant activity: The antioxidant activity of fresh squash pulp and squash peel samples were found to be about 7.68 and 43.19% respectively. The dried samples reported an antioxidant activity of 18.83% for squash pulp powder and 35.5% for squash peel powder. For the cookies, the highest antioxidant value has been obtained for samples prepared with 3:1 rice to wheat ratio and 30% squash constitution (62.84%) and the lowest was for the control samples (15.24%). Incidentally, the antioxidant activity of the cookies with 1:1 rice to wheat constitution was 18.51%.

3.2 Functional Properties

Water absorption capacity and oil absorption capacity: While water absorption capacity was maximum for the squash peel fine powder (7.98 g water/g sample), it was lowest for the squash pulp finer powder (4.8 g water/g sample). The coarser squash pulp powder had a water absorption capacity of 6.12 g water/g sample. The oil absorption capacity of squash pulp fine powder, squash pulp coarse powder and squash peel fine powder were 1.26, 1.23 and 1.44 oil/g sample respectively. In the literature, the reported water absorption and oil absorption capacities varied as 7.50–9.13 g water/g sample and (1.02–2.04 g water/g sample) respectively [11]. These have been summarized in Table 1.

Least gelatinization temperature and least gelation concentration: The least gelatinization temperature for squash pulp powder and squash peel powder were 97 and 94 °C respectively. The least gelation concentration of squash pulp powder and squash peel powder were 12 and 14% respectively.

Bulk density: The packed bulk density of squash pulp powder and (g/mL) squash peel powder were 0.606 and 0.59 g/mL respectively.

3.3 Thermal Properties

For squash pulp powder, the glass transition onset temperature was 56.2 °C and the end temperature was 182.0 °C. The peak glass transition temperature has been 98.6 °C and the specific heat (CP) was (0.622 J/(g °K)). For squash peel powder, the glass transition onset temperature was 63.2 °C, end temperature was 201.1 °C and peak temperature was 89.3 °C. The specific heat capacity (CP) was 0.475 J/(g oK) for the squash peel powder (Fig. 1).

3.4 Average Particle Size

The average particle size of fine (F) squash pulp powder was 3747.1 nm and its polydispersity index was 0.946 (Fig. 2). The coarse (C) squash pulp powder sample had an average particle size of 4295.6 nm and polydispersity index of 0.509. For the squash peel powder sample, the average particle size was 2282.2 nm and the polydispersity index was found to be 0.660 respectively (Table 2).

3.5 Fourier Transform Infrared Spectroscopic Analysis

The raw pulp spectra exhibited hydrogen bonded normal polymeric OH stretch (peak at 3307.33 cm−1), Alkenyl C=C stretch (peak at 1636.99 cm−1), methyl asymmetric bend (peak at 1440.84 cm−1), CN stretch (primary amine) with (at 1029.71 cm−1), aliphatic C–I stretch Iodo compounds peak at 564.19 cm−1. Apart from these functional groups in raw squash pulp, the squash peel spectra confirmed the aliphatic bromo compound with a peak at 608.96 cm−1. For the coarse squash pulp powder sample, most mentioned functional groups of the fresh pulp existed. Along with these, a methylene C–H asymmetric stretch related peak was observed at 2926.81 cm−1. However, the methyl asymmetric bend was absent and a carboxylate group can be confirmed with a peak at 1406.45 cm−1. For the fine squash pulp powder, aliphatic chloro compounds with a peak at 774.7 cm−1 and aryl group having C–H 1,4 di substitution (para) peak at 818.59 cm−1 can be analysed in addition to the other groups being observed for the coarse squash pulp powder. The squash peel powder spectra confirmed similar functional groups that exist in the coarse squash pulp powder sample (Figs. 3 and 4).

3.6 Physical Properties of Cookies

For the control cookie sample, the spread ratio was 9.375. Similarly, for the squash enriched cookies with 10, 30 and 50% squash constitution, the spread ratio varied as 10.41–10.71. For cookies with 1:1, 1:2 and 1:3 rice to wheat ratio, the spread ratio was 14.5, 17.6 and 27.14 respectively. Thus, the spread ratio increased with rice inclusion in the wheat flour. The squash enriched cookies along with rice and wheat flour having 30% squash substitution and rice: wheat in ratio (1:1), (2:1) and (3:1) spread ratio possessed values of 14.11, 11.18 and 13.84 respectively. The squash inclusion reduced the spread ratio of cookies with rice and wheat flour. The weight reduction for control (only wheat) and wheat cookies with 10, 30 and 50% squash constitution was 11.66, 11.11, 10.67 and10.1% respectively. For cookies with rice to wheat ratio of 1:1, 2:1 and 3:1, these were 10.13, 10.23 and 10.9% respectively. The squash enriched cookies with 30% substitution and rice to wheat ratio of 1:1, 2:1 and 3:1 possessed a spread ratio of 8.03, 8.56 and 9.1% respectively.

3.7 Sensory Analysis

The overall sensory score based on 9-point hedonic scale for control cookie samples was 8.45. However, the score reduced with the addition of squash pulp powder 10, 30 and 50 proportions and as 7.88, 6.81 and 6.46 respectively. However, the score was above 6 even for 50% squash substituted samples and were hence considered to be acceptable. For sample with rice to wheat ratio of 1:1, 2:1 and 3:1, the overall sensory scores were 7.91, 7.79 and 7.59 respectively. It is evident that with an increase in rice constitution, the sensory score reduced. The cookies with 30% squash constitution and rice to wheat ratio of 1:1, 2:1 and 3:1constitution possessed as overall sensory scores of 6.63, 6.81 and 7.51 respectively (Table 3). These scores convey that with an increase in rice constitution along with squash pulp powder, the overall sensory score increased for the cookies. The quality features of the cookies were graded based on fuzzy logic in the order of decreasing importance as taste, flavour, after taste, crunchiness, overall acceptability, texture, breakability and colour. According to fuzzy logic sensory scale, the control cookies with only wheat flour have been rated to be very good (0.79) followed with wheat cookies substituted with 10% squash (also rated to be very good with 0.74 sensory score). The wheat cookies with 30% and 50% squash constitution were rated as good (0.7) and satisfactory (0.75). For control cookie samples with rice to wheat ratio of 1:1, 2:1 and 3:1, these sensory ratings were very good (0.71), very good (0.69) and good (0.69) respectively. The cookies with 30% squash pulp powder constitution and with rice to wheat ratio 1:1, 2:1 and 3:1 possessed these ratings as good (0.74), good (0.72) and very good (0.71).

4 Conclusions

Since squash pulp flour and squash peel flour possessed significant amount of WAC constitution, they can be inferred to be useful for various bakery products such as cookies. Similar to the polysaccharides, good water absorption characteristics confirm upon the existence of compounds with higher presence of more hydrophilic groups. In baked products, oil holding capacity is an essential property to influence the texture-flavour-taste qualities of the product. Due to their improved absorption of oil in comparison with wheat, the squash pulp and peel can be used as alternate the gluten-free flour in the formulation of cookies. An increment in oil absorption capacity of squash flour has been probably due to the binding of non-polar side chain of the flour with the hydrocarbon side chain of the oil. Compared to wheat (56.22 °C), least gelatinization temperatures have been high for squash pulp and peel flours and they indicate lower constitution of starch. Least gelation concentration (LGC) defines lowest protein concentration that can be used as an index of gelation capacity. Wheat flour has lower gelation concentration (LGC) of about 8 g/100 mL in comparison to squash pulp and peel flours that exhibit an LGC of 12–14 g/100 mL [31].

Compared to the fresh samples, the nutritional parameters such as ash, crude fibre, fat, carbohydrate and protein have been found to significantly higher in dried powdered samples. This infers that such dried powders can be applied to enhance the nutritional qualities of various food materials. Vitamin C content was found in greater constitution in dry powders such as 71.42 mg/100 g for squash pulp powder and 142.85 mg/100 g for squash peel powder in comparison with the fresh pulp and peel. A similar trend existed for the followed for the antioxidant activity. It was analysed that the antioxidant activity of dried powders was 18.83% for squash pulp and 35.5% for squash peel powder and these were greater than the values obtained for fresh squash pulp and fresh squash peel. From thermal stability perspective, both squash flours (pulp and peel) were found to be stable for baking temperatures upto 182–201 °C. The average particle size of the squash pulp and peel (2282.2–4295.6 nm) was comparable to that of the wheat flour. Additional methylene C–H asymmetric stretch (at 2926.81 cm−1 peak) and carboxylate group (peak at 1406.45 cm−1) did exist in case of powdered squash pulp and peel in comparison with the fresh squash pulp and peel. Only control and squash substituted wheat cookies (10–50%) did not confirm upon any significant change in terms of spread ratio. However, only for wheat and rice constituted cookies without squash flour, a huge variation in spread ratio was observed. This confirms that the rice flour has a significant influence on the parameter. According to the findings of the current study, incorporating squash greatly decreased the spread ratio and increased the thickness of the cookies to a desired level. Spread ratio and thickness of cookies are often inversely proportional to one another and do have a crucial role in consumer acceptability. In general aspect, cookies with lower thickness and higher spread ratio are less preferred by the consumers.

The 9-point hedonic scale-based sensory evaluation confirmed the highest overall sensory score for wheat based samples control (8.45) followed by rice:wheat 1:1 rice to wheat ratio cookies, wheat flour substituted with 10% squash pulp flour and rice to wheat 3:1 ratio and with 30% squash pulp powder. The corresponding overall sensory scores were 7.91, 7.88 and 7.51 respectively. According to fuzzy logic-based sensory evaluation, all three samples (control, 1:1 rice to wheat ratio sample and sample with 3:1 rice to wheat ratio and 30% squash pulp flour) confirmed very good score. The quality attributes of cookies were classified on the basis of fuzzy logic and in the order of reducing significance of taste, flavour, after taste, crunchiness, overall acceptability, texture, breakability and colour. The substitution of squash pulp powder did enhance the nutritional parameters of the cookies. The fibre content (crude) of the samples (1.8%) was higher than that of the only wheat-based cookies. The fat content of squash based cookies with 30% squash content and 3:1 rice to wheat ratio was lesser than that of the control cookie samples. Marginal enhancement in carbohydrate content (about 3%) was observed in squash-based cookies. For the squash-based cookies, the vitamin C content enhanced to 142.85 mg/100 g sample from 0 mg/100 g in control cookies. The TPC values of squash-based cookies were higher (0.97 mg GAE/g) than the TPC values of control wheat cookies. The antioxidant activity of squash-based cookies (58.94–66.75%) was higher in conjunction with the control cookies with only wheat. Henceforth, the incorporation of squash peel powder and pulp in wheat and wheat and rice-based cookies will be an important choice for the development of various bakery products. The enhancement of squash pulp flour in cookies through an alteration in the suggested formulations can further promote the application of squash as a gluten-free alternative in bakery products.

References

Lira Saade, R.: Chayote, Sechium edule (Jacq.) Sw., Promoting the Conservation and Use of Underutilized and Neglected Crops (1996)

Sahoo, K.U., Rocky, P., Vanlalhriatpuia, K., Upadhyaya, K.: Structural diversity and functional dynamism of traditional home gardens of North-East India. The Bioscan 1, 159–171 (2010)

Sanwal, K.S., Yadav, K.R., De, C.L.: Exploring underutilized vegetables of north-eastern region. Indian Hortic. 52(1), 18 (2007)

Lovis, J.L.: Alternatives to wheat flour in baked goods. Cereal Foods World 48(2), 61 (2003)

Singh-Ackbarali, D., Maharaj, R.: Sensory evaluation as a tool in determining acceptability of innovative products developed by undergraduate students in food science and technology at the University of Trinidad and Tobago. J. Curric. Teach. 3(1), 10–27 (2014)

Shiga, M.T., Peroni-Okita, G.H.F., Carpita, C.N., Lajolo, M.F., Cordenunsi, R.B.: Polysaccharide composition of raw and cooked chayote (Sechium edule Sw.) fruits and tuberous roots. Carbohydr. Polym. 130, 155–165 (2015)

Mishra, K.L., Das, P.: Nutritional evaluation of squash (Sechium edule) germplasms collected from Garo Hills of Meghalaya-North East India. Int. J. Agric. Environ. Biotechnol. 8(4), 971 (2015)

Coronel, O., León-García, E., Vela-Gutiérrez, G., Medina, R.V.G., García, H.: Chayote (Sechium edule (Jacq.) Swartz), fruit and vegetable phytochemicals. Chem. Hum. Health 979–992 (2017)

Vieira, F.E., Pinho, O., Ferreira, M.I., Delerue-Matos, C.: Chayote (Sechium edule): a review of nutritional composition, bioactivities and potential applications. Food Chem. 275, 557–568 (2019)

Valencerina, L.D.R.: Formulation and quality shelf life evaluation of squash food products. Asian J. Multidiscip. Stud. 1(3), 80–82 (2018)

Adelaïde, M.D., Vanissa, A., Vanessa, G.B., William, A.D., Fabien, F.D.D., Inocent G.: Evaluation of nutritional and functional properties of squash pulp powder from cameroon and squash base biscuit. J. Sci. Res. Rep. 1–13 (2021)

Sakung, M.J., Nurmayanti, Y., Fitra, H.: Nutritional evaluation of chayote flour-based biscuits (Sechium Edule). Indian J. Public Health Res. Dev. 11(3) (2020)

Das, H.: Sensory Evaluation Using Fuzzy Logic, Food Processing Operations Analysis, pp. 384–402 (2005)

Sadasivam, S., Manickam, A.: Biochemical Methods for Agricultural Sciences. Wiley Eastern Limited (1992)

Bradford, M.M.: A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal. Biochem. 72(1–2), 248–254 (1976)

Okonwu, K., Enyinnaya, A.: Comparative phytochemical studies and proximate analysis of five commonly consumed vegetables of Southern Nigeria. Asian J. Biol. 1(2), 1–7 (2016)

Anjali, M.K., Singh, N., Pal, K.: Effect of sulphur dioxide on plant biochemicals. Int. J. Pharma Prof. Res. 3(2), 627 (2012)

Tharasena, B., Lawan, S.: Phenolics, flavonoids and antioxidant activity of vegetables as Thai side dish. APCBEE Proc. 8, 99–104 (2014)

Barimah, J., Yanney, P., Laryea, D., Quarcoo, C.: Effect of drying methods on phytochemicals, antioxidant activity and total phenolic content of dandelion leaves. Am. J. Food Nutr. 5(4), 136–141 (2017)

Sosulski, F., Humbert, S.E., Bui, K., Jones, D.J.: Functional properties of rapeseed flours, concentrates and isolate. J. Food Sci. 41(6), 1349–1352 (1976)

Abbey, W.B., Ibeh, O.G.: Functional properties of raw and heat processed cowpea (Vigna unguiculata, Walp) flour. J. Food Sci. 53(6), 1775–1777 (1988)

Chavan, D.U., Shinde, G.B., Kadam, S.S., Amarowicz, R.: Isolation and Characterization of Starch from Horse Gram (2010)

Steinberg, L.S., Kluitenberg, G.J., Jones, S.B., Daidzic, N.E., Reddi, L.N., Xiao, M., Alexander, J.I.D.: Physical and hydraulic properties of baked ceramic aggregates used for plant growth medium. J. Am. Soc. Hortic. Sci. 130(5), 767–774 (2005)

Maeda, S., Kimora, H., Hayashi, T., Maeno, M., Yano, T.: Study on the micro silicas. Part 2 (the correlation between the properties of the spherical silicas and the properties or the SBR compounds). Kyujo silica no seijo to gomu bussei tono kanren ni tsuite Nippon Gomu Kyokai-Shi. J. Soc. Rubber Ind. Jpn. 64(10) (1991)

Jaya, S., Das, H.: Sensory evaluation of mango drinks using fuzzy logic. J. Sens. Stud. 18(2), 163–176 (2003)

Mate, B.A., Kotecha, P.M., Patil, R.M., Titkare, G.A., Chavan, D.U.: Studies on Utilization of Papaya Peel Powder in the Preparation of Cookies (2021)

Varastegani, B., Zzaman, W., Yang, A.T.: Investigation on physicochemical and sensory evaluation of cookies substituted with papaya pulp flour. J. Food Qual. 38(3), 175–183 (2015)

Fidrianny, I., Hartati, K.: Evaluation of antioxidant activities of fruit extracts of chayote (Sechium edule [Jacq.] Swartz) grown in different sites in Java-Indonesia. Asian J. Pharm. Clin. Res. 9(4) (2016)

Wijewardane, R., Nawarathne, B.S., Wikramasinghe, I., Gunawardane, R.C., Thilakarathne, B.: Effect of Dehydration Methods on Chemical Properties and Antioxidants in Dehydrated Powdered Vegetables (2015)

Gündoğdu, B., Süfer, Ö., Simsek, M.: Effect of different drying methods on the phenolic extraction from butternut squash pomace. GIDA/J. FOOD 46(4) (2021)

Chandra, S., Singh, S., Kumari, D.: Evaluation of functional properties of composite flours and sensorial attributes of composite flour biscuits. J. Food Sci. Technol. 52(6), 3681–3688 (2015)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Ethics declarations

Data Availability Statement

Not applicable.

Funding Statement

This work received no outside funding.

Disclosure of Any Conflicts of Interest

The authors declare that they have no potential conflicts of interest.

Ethical Clearance Statement

None of the authors conducted any studies with human subjects or animals for this work.

Permission to Reproduce Material from Other Sources

Not applicable.

Contribution of the Authors

All authors contributed to the study's idea and design. Paushali Mukherjee and Rushikesh Kudave prepared the materials, collected data, and analysed the results. Paushali Mukherjee wrote the first version of the manuscript, and all contributors provided feedback on prior revisions. The final versions were read and approved by all authors.

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Mukherjee, P., Kudave, R.R., Uppaluri, R.V.S. (2023). Formulation and Characterization of Squash Enriched Cookies. In: Uppaluri, R.V., Das, C., Goud, V., Anandalakshmi, R. (eds) Agro and Food Processing Technologies. NERC 2022. Springer, Singapore. https://doi.org/10.1007/978-981-19-9704-4_13

Download citation

DOI: https://doi.org/10.1007/978-981-19-9704-4_13

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-9703-7

Online ISBN: 978-981-19-9704-4

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)