Abstract

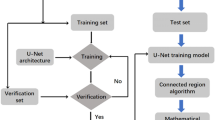

Accurate segmentation of phases is an extremely crucial part of phase quantification and identification. In this paper, an efficient image segmentation process has been proposed using watershed techniques. The proposed image processing method has been applied to public datasets of ultra-high carbon steel (UHCS) scanning electron microscopy (SEM) microstructure images. The experimental results clearly show the phase segmentation of images with fine, blocky structures, and significant foreground and background differences. The detection of grains appears to be credible for images with reasonable foreground and background differences. However, detective efficiency is relatively poor in the case of images that can’t differentiate between foreground and background. In most instances of compositional range, heat treatment, and magnification, the proposed image processing technique shows promising results in UHCS SEM images.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Bhavsar P, Safro I, Bouaynaya N, Polikar R, Dera D (2017) Machine learning in transportation data analytics. In: Chowdhury M, Apon A, Dey K (eds) Data analytics for intelligent transportation systems. Elsevier, pp 283–307 (Chapter 12). https://doi.org/10.1016/B978-0-12-809715-1.00012-2

DebRoy T, Mukherjee T, Wei HL, Elmer JW, Milewski JO (2021) Metallurgy, mechanistic models and machine learning in metal printing. Nat Rev Mater 6(1):48–68. https://doi.org/10.1038/s41578-020-00236-1

Choudhury A, Kannur T, Chattopadhyay PP, Pal S (2019) Structure prediction of multi-principal element alloys using ensemble learning. J Eng Comput Emerald Insight 37(3):1003–1022

Cherian RP, Smith LN, Midha PS (2000) A neural network approach for selection of powder metallurgy materials and process parameters. Artif Intell Eng 14(1):39–44. https://doi.org/10.1016/S0954-1810(99)00026-6

Luengo J et al (2022) A tutorial on the segmentation of metallographic images: taxonomy, new MetalDAM dataset, deep learning-based ensemble model, experimental analysis and challenges. Inf Fusion 78:232–253. https://doi.org/10.1016/j.inffus.2021.09.018

Otsu N (1979) A threshold selection method from gray-level histograms. IEEE Trans Syst Man Cybern 9(1):62–66. https://doi.org/10.1109/TSMC.1979.4310076

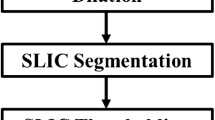

Gupta S, Sarkar J, Banerjee A, Bandyopadhyay NR, Ganguly S (2019) Grain boundary detection and phase segmentation of SEM ferrite–pearlite microstructure using SLIC and skeletonization. J Inst Eng (India) Ser D 100(2):203–210. https://doi.org/10.1007/s40033-019-00194-1

Choudhury A (2020) The role of machine learning algorithms in materials science: a state of art review on industry 4.0. Arch Comput Methods Eng 28:3361–3381

Choudhury A, Naskar R, BasuMallick A, Pal S (2019) Computer vision approach for phase identification from steel microstructure. J Eng Comput Emerald Insight 36(6):1913–1932

Dillencourt MB, Samet H, Tamminen M (1992) A general approach to connected-component labeling for arbitrary image representations. J ACM 39(2):253–280. https://doi.org/10.1145/128749.128750

Choudhury A (2022) Prediction and analysis of mechanical properties of low carbon steels using machine learning. J Inst Eng India Ser D. https://doi.org/10.1007/s40033-022-00328-y

Ganesh N, Jain P, Choudhury A, Dutta P, Kalita K, Barsocchi P (2021) Random forest regression-based machine learning model for accurate estimation of fluid flow in curved pipes. Processes 9(11):2095

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Jain, M., Jain, V., Choudhury, A., Ghosh, M. (2023). Phase Segmenting Process in Ultra-High Carbon Steels Using Deep Vision Approach. In: Tiwari, S., Trivedi, M.C., Kolhe, M.L., Singh, B.K. (eds) Advances in Data and Information Sciences. Lecture Notes in Networks and Systems, vol 522. Springer, Singapore. https://doi.org/10.1007/978-981-19-5292-0_17

Download citation

DOI: https://doi.org/10.1007/978-981-19-5292-0_17

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-5291-3

Online ISBN: 978-981-19-5292-0

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)