Abstract

Research on using biodiesel and bioethanol as fuels for internal combustion engine is necessary to solve the shortage of fossil fuels and environmental pollution. This paper presents the performance and emissions of a 4-cylinder, naturally aspirated diesel engine fueled by diesel and blends of diesel, ethanol and biodiesel. The blends included DE10 (90% diesel-10% ethanol), DB5 (95% diesel-5% biodiesel), DE10B5 (85% diesel-10% ethanol-5% biodiesel). The engine torque, specific fuel consumption and emissions were compared, the number of particles in the exhaust gas when the engine operated with diesel and fuel blends were also considered. The engine was tested at full load condition.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The rapid depletion of oil reserves and environmental pollutions created an incentive to study and evaluate alternative fuels. Biofuels, such as ethanol and biodiesel, have had a significant role in improving the sustainability of transport sector. They can be used to partly subsitute for fossil fuel, reduce toxic emissions. Biodiesel and ethanol are potential alternative fuel because they come from renewable bio-based resource and they have high oxygen content, there by possible to improve the exhaust gas emissions. Ethanol has been used normally as commercial fuel in term of blending with gasoline to use for gasoline engines [1, 2]. Beside that ethanol might also be blended with diesel to use as fuel for diesel engine. However, ethanol-diesel blend has not been commercially used due to the difference in chemical and physical properties between ethanol and diesel fuel. At present, some investigations of the potential application of diesel - ethanol (DE) and diesel - biodiesel (DB) and diesel - ethanol - biodiesel (DEB) fuel blends on diesel engine have been carried out. Huang et al., investigated the engine performance and exhaust emissions of diesel engine when using 10%, 20%, 25% and 30% ethanol blended diesel fuels [3]. In that study, the results showed that the brake thermal efficiencies decreased with increasing amount of ethanol in the blended fuels. Rakopoulos et al., studied the effects of ethanol blends with diesel fuel, with 5% and 10% (by volume) on the performance and emissions of a turbocharged direct injection diesel engine [4]. The results showed that increasing the ethanol content in the fuel blend increased the brake specific fuel consumption and decreased the brake thermal efficiency. Besides ethanol, biodiesel which basically has very similar properties as fossil diesel is another kind of biofuel. Although biodiesel fuel can be used by itself for diesel engine, it is more commonly used as a blend component with conventional diesel. Biodiesel has lower heating value, higher oxygen content, higher cetane number, higher viscocity, lower compressibility, higher density as compared to fossil diesel that may effect on diesel engine performance and emissions [5, 6]. In general, biodiesel-diesel blends do not change much engine power, especially at low percentage of biodiesel [7], and brake specific fuel consumption can increase up to 14% or maybe higher with pure biodiesel used [6, 8, 9]. Combining ethanol and biodiesel as blend components with conventional diesel is also one more solution to promote the use of biofuels replacing mineral fuel. Nadir Yilmaz testing blends of 45% biodiesel - 10% ethanol - 45% diesel and 40% biodiesel - 20% ethanol - 40% diesel on a direct injected diesel engine pointed out that higher brake specific fuel consumption, higher CO and HC emissions, but lower NO emissions and no significant different in exhaust gas temperature when fueling the blends as compared to diesel [10]. All studies above provide the ability to use blends of ethanol, biodiesel and diesel as fuel for diesel engine. However, the effect of blends on engine performance and emissions depends on engine operating conditions as well as engine configuration and fuel properties. This paper investigates the performance and emission characteristics of an in-use diesel engine fueled by blends of 10% ethanol - 90% diesel (DE10), 5% biodiesel - 95% diesel (DB5), 10% ethanol - 5% biodiesel - 85% diesel (DE10B5) by volume.

2 Exprimental

2.1 Experimental Apparatus

The test engine was a four-stroke, 4 cylinder, non-turbocharged diesel engine commonly used on 1.25 ton Hyundai truck in Vietnam. The engine specifications are shown in Table 1.

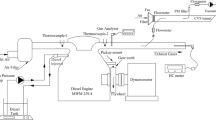

The engine was coupled to an electrical dynamometer to provide brake load, and equipped with the instrumentation for its control (Fig. 1). The consumption of fuel and air was measured by Fuel Balance AVL 733S and Air Flow Meter Sensy Flow P. The cooling water temperature, oil temperature and pressure, cylinder pressure, intake and exhaust gas temperatures and lambda value were also measured or monitored by sensors. For emission analysis, an AVL Combustion Emission Bench (CEB II) and a Smoke Meter AVL 415 were installed and sampled the raw exhaust gas at the tail pipe. The CEB II comprises all analysers for HC, CO and NOx measurements.

Moreove, the Research Center for Engines, Fuels and Emissions at Hanoi University of Science and Technology (HUST, Vietnam) has developed a dilution system for particle number measurement. Based on the requirement of Particle Measurement Program (PMP) [11], a such dilution system shall comprise a first dilution stage at which the sample gas is heated to 150°C, an evaporation tube that heat sample gas to 300–400°C, and a second dilution stage which cool the sample gas down to about 30°C (Fig. 2). In this study experiments, an ejector was used for first dilution stage in which clean compressed air produced an under pressure at the nozzle that drew the sample gas. The second diluter was the mixer in which sample gas and clean air were mixed. Dilution factors of the first diluter and the second diluter were defined by measuring related flow rates. The overall dilution factor of the system was product of two dilution factors mentioned above. A Miniature Diffusion Size Classifier (DiSCmini) manufactured by Testo was used to determine the particle number. The DiSCmini can detect particle number concentration up to 106 #/cm3 with the size in the range of 20–700 nm with the sampling flow rate of 1l/min. Although this particle counting system had not been calibrated and validated by PMP method, but the results of comparative measurement could provide useful information of the change in particle number in exhaust gas when using the different fuels.

2.2 Test Fuels

The test was conducted in order to assess engine performance and emission characteristics when using blends 90% diesel - 10% ethanol (DE10), 95% diesel -5% biodiesel (DB5) and 10% ethanol - 5% biodiesel - 85% diesel (DE10B5) by volume. Properties of the diesel fuel that has 0.05% sulfur available in Vietnam market according to TCVN 5689-2005 and properties of the ethanol are provided in Table 2. The ethanol and diesel fuels were mixed together without any additive by an agitator. Right after blending, the blends were fueled to engine for testing.

2.3 Test Modes

In order to assess the effect of fuels on maximum engine torque, specific fuel consumption, emissions, lambda values and the number of particles in the exhaust gas. The test was carried out at full load condition at which the speed varied from 1000 rpm to 3500 rpm with an increment of 500 rpm were measured with diesel, DE10, DB5 and DE10B5 fuels in turn. The engine was not modified or adjusted throughout the test.

3 Results and Discussion

3.1 Engine Performance

The variation of engine torque and specific fuel consumption at full load with all test fuels is plotted versus engine speed (Figs. 3 and 4). When using diesel-ethanol blends DE10, DB5, DE10B5 the engine torque decreased by 6.9%, 2.02% and 1.1%, fuel consumption increased by 6.9%, 1.96% and 1.1% on average over speed range, respectively, as compared to conventional diesel. This is attributed to the lower heating value of ethanol which is 26.8 MJ/kg as compared to 43 MJ/kg that of diesel and also the lower density of ethanol which may reduce the mass of fuel injected per cycle. However, this reduction can be negligible when 5% biodiesel was added, maybe due to the improvement of cetane number and lubricity of the blends.

In case of DE10, DB5 and DE10B5 the lambda values increased by 10.69%, 6.40% and 9.87% due to high oxygen content in ethanol (Fig. 5).

3.2 Engine Emissions

Emissions including CO, HC, NOx and smoke were measured at each test mode (Fig. 6, 7, 8, and 9). The measured emissions are compared between all the test fuels at full load while the speed varies from 1000 rpm to 3500 rpm.

For CO emissions, ethanol and biodiesel has about 34% and 8.4% of oxygen, so that DE10, DB5, DE10B5 blends contain amount of oxygen which can enhances the complete combustion, that lead to the reduction in CO emissions. The lower C content in blends that diminishes the CO formation may also be another reason. On average, CO reduced by 36.61%, 26.60% and 34.40%.

HC reduced by 37.16%, 32.26% and 43.33% and smoke reduced by 45.66%, 24.11% and 29.45% with DE10, DB5, DE10B5 respectively. DE10, DB5, DE10B5 have a smaller C/H ratio than conventional diesel that may be another reason leading to the results above.

On average, over speed range at full load NOx emissions increased by 7.39%, 2.13% with DE10, DB5 blends and reduced by 4.6% with DE10B5 by the diesel fuel. The formation of NOx emissions is mainly due to the peak temperature and the availability of oxygen in combustion chamber during combustion process. Adding small amount of ethanol and/or biodiesel to diesel, on one hand, supplement a little oxygen content into the blended diesel that may lead to increase in the NOx emissions. However, in the other hand, ethanol has higher latent heat of vaporization (840 kJ/kg) than diesel (270 kJ/kg) that may cause the lower combustion temperature in the cylinder for the ethanol blended diesel, and as a result preventing the NOx formation. Besides that, lower heating value and lower cetane number of the ethanol and/or biodiesel blended diesel fuels may be other reasons of lower combustion temperature and reduce the NOx.

3.3 The Number of Particles in the Exhaust Gas

The number of particles in the exhaust gas wasmeasured at each mode with all fuels. It showed that DE10, DB5, DE10B5 produced lower particle number than diesel fuel in most cases. On average, the particle number decreased by 28.70%, 42.85% and 19.26% with DE10, DB5, DE10B5 compared to diesel fuel (Fig. 10). This result agrees with the reduction of smoke mentioned above and one more time it shows that the combustion process with DE10, DB5, DE10B5 is better than that with conventional diesel.

4 Conclusions

The influences of the blends including DE10, DB5, DE10B5 on performance and emission characteristic of the diesel engine had been studied by carrying out the experiments on the engine test bed. The results showed that DE10, DB5, DE10B5 reduced engine torque averagely by 6.9%, 2.02% and 1.1% at full load as compared to the diesel fuel. On the aspect of emissions, fueling these blends reduced quite clearly HC, CO and smoke emissions. The highest reduction in CO, HC and smoke could be up to 36.61%, 43.33% and 45.66%. Moreover the number of particles in the exhaust gas decreased by 28.70%, 42.85% and 19.26% with DE10, DB5, DE10B5 compared to diesel fuel over the speed range. However, NOx emissions increased by 7.39%, 2.13% with DE10, DB5 but decreased by 4.6% with DE10B5. These results demonstrate the initial possibility of application of ethanol and biodiesel blended diesel as fuels for diesel engine without any engine modification.

References

Barry, D.S., Justin, R.B., Kathleen, E.H.: Grain and cellulosic ethanol: history, economics, and energy policy. Biomass Bioenerg. 31(6), 416–425 (2007)

Regina Delgado, Y.C.O.B., Antonio Araujo, S., Fernandes, Jr., V.J.: Properties of Brazilian gasoline mixed with hydrated ethanol for flex-fuel technology. Fuel Process. Technol. 88(4) 365–368 (2007)

Huang, J., Wang, Y., Li, S., Roskilly, A.P., Hongdong, Y., Li, H.: Experimental investigation on the performance and emissions of a diesel engine fuelled with ethanol–diesel blends. Appl. Therm. Eng. 29(11–12), 2484–2490 (2009)

Rakopoulos, D.C., Rakopoulos, C.D., Kakaras, E.C., Giakoumis, E.G.: Effect of ethanol–diesel fuel blends on the engine performance and emissions of heavy duty DI diesel engine. Energy Convers. Manag. 49(11), 3155–3162, 525 (2008)

Borhanipour, M., Karin, P., Tongroon, M., Chollacoop, N., Hanamura, K.: Comparison Study on Fuel Properties of Biodiesel from Jatropha, Palm and Petroleum Based Diesel Fuel. SAE Technical Paper 2014-01-2017 (2014). https://doi.org/10.4271/2014-01-2017

Lapuerta, M., Armas, O., Fernández, J.R.: Effect of biodiesel fuels on diesel engine emissions. Progr. Energy Combust. Sci. 34, 198–223 (2008)

Tuyen, P.H., Tuan, L.A., Lan, H.L.: The influences of waste cooking oil derived biodiesel on diesel engine characteristics. In: Proceedings of the 5th South East Asian Technical University Consortium (SEATUC), Hanoi, pp. 542–545 (2011). ISSN 1882-5796

Labeckas, G., Slavinskas, S.: The effect of rapeseed oil methyl ester on direct injection diesel engine performance and exhaust emissions. Energy Convers. Manag. 47, 1954–1967 (2006)

Subbaiah, G.V., Raja Gopal, K., Hussain, S.A.: The effect of biodiesel and bioethanol blended diesel fuel on the performance and emission characteristics of a direct injection diesel engine. Iran. J. Energy Environ. 1(3), 211–221 (2010). ISSN 2079-2115

Yilmaz, N.: Comparative analysis of biodiesel - ethanol - diesel and biodiesel - methanol -diesel blends in a diesel engine. Energy 40, 210–213 (2012)

Andersson, J., Giechaskiel, B., MuñozBueno, R., Sandbach, E., Dilara, P.: Particle Measurement Programme (PMP) Light-duty Interlaboratory Correlation Exercise (ILCE_LD), Final Report of Institute for Environment and Sustainability (2007)

Acknowledgments

We would like to thank Hung Yen University of Technology and Education and Hanoi University of Science and Technology for supporting this research.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Van, N., Minh, T., Huu, T. (2022). The Effect of Biodiesel-Ethanol-Diesel Blends on Performance and Emissions of a Diesel Engine. In: Le, AT., Pham, VS., Le, MQ., Pham, HL. (eds) The AUN/SEED-Net Joint Regional Conference in Transportation, Energy, and Mechanical Manufacturing Engineering. RCTEMME 2021. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-1968-8_38

Download citation

DOI: https://doi.org/10.1007/978-981-19-1968-8_38

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-1967-1

Online ISBN: 978-981-19-1968-8

eBook Packages: EngineeringEngineering (R0)