Abstract

Finishing is an integral part of textile processing which augments the performance of the fabrics and adds functional properties as well. According to AMCA (The American Mosquito Control Association), mosquitoes are responsible for more than one million deaths per year worldwide. Many studies have been undertaken to develop mosquito repellent textiles using chemical and natural sources. Due to the negative effects of synthetic mosquito repellents, people are switching to herbal and natural plant-based mosquito repellents. The present study is an endeavour in this direction and is aimed at developing a mosquito repellent finish for textiles using neem oil extract. The formulation was developed in different concentrations for the optimization of the recipe. The shelf life of the formulation was assessed. The developed formulation was applied to different types of cotton fabrics using two methods of application. The efficacy of formulation was evaluated by conducting cage tests for the finished fabrics at NIMR (National Institute of Malaria Research, Delhi). The effect of storage time period of the finished fabric on mosquito repellency was also studied. The neem oil formulation gave promising results as it was effective against mosquitoes and could be applied as a household finish to various textiles.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

The textile finishing industry is accountable for the consumption and discharge of huge quantities of chemicals and substances that are perilous to our environment. Furthermore, finishing is liable for creating the highest volumes of wastewater amidst all other stages of textile processing. Consumers in present times have inexhaustible expectations from textile products with sustainability as a prerequisite. There is a need to shift to practices that are eco-friendly and use raw materials that are non-hazardous to the environment.

Protective textile is one of the upcoming areas of technical textiles with mosquito repellence as one of its most desirable attributes. There are various ways in which mosquito repellents are used in the form of mats, lotions, creams, coils, patches, etc. Incorporating mosquito repellent formulation into the fabric is one of the revolutionary steps taken in the advancement of the textile finishing industry. The textiles with mosquito-repelling features can drive the mosquito away from the treated textile, or knock down the mosquitoes when it is in contact with the treated textiles. The addition of repellent properties to textile material can help to reduce the statistics of vector disease cases without having any side effects on the wearer.

It has been found that the use of synthetic repellents have various negative effects on the health of the people as they cause headache, dizziness, sore throat, nausea, vomiting, stomach pain and drowsiness, and can sometimes lead to asphyxiation and suffocation. DEET (N, N-diethyl-m-toluamide) and permethrin are the predominant synthetic mosquito repellents and permethrin has been used for finishing textiles since the advent of mosquito repellent textiles. Many studies have been undertaken to make advancements in this area since then. Permethrin is a pyrethroid-based insecticide similar to pyrethrins, a natural insecticide extracted from chrysanthemum flowers. Military uniforms for the soldiers working in areas where they are vulnerable to attack by various insects are constructed with permethrin incorporated textiles. Studies have been conducted to improve the longevity of finish efficacy on cotton textiles by employing techniques like micro- and nano-encapsulation of limonene and permethrin [1].

As DEET applied to textiles does not have wash fastness even for one cycle, trials have been made to synthesize its derivatives and coupling with different naphthols to get dyed cotton fabric, imparted mosquito repellent finish by combining the steps of dyeing and finishing into a single process [2]. The application of chemical-based repellents for prevention from insects and arthropods has given rise to various concerns as they are not eco-friendly and are precarious for human beings, animals and aquatic species [3]. Due to the negative effects of synthetic mosquito repellents, people are switching to more herbal and natural plant-based mosquito repellents. The easy availability of these plant-based repellents has made these repellents preferential over synthetic ones.

There are many plants having mosquito repellent properties such as neem, basil, catnip, marigold, rosemary, clove, eucalyptus, citronella, sweet orange, etc. [4]. Many studies have been conducted to see the effectiveness of various plants as mosquito repellents. Development of mosquito repellent cotton fabric using eco-friendly mint [5], castor oil [6], marigold petals [7, 8], sweet basil and eucalyptus [9, 10], citronella [11] and different medicinal natural plants [12] was investigated and they were found to be effective as mosquito repellents though they were poor in wash fastness.

Researchers have been investigating different methods for the application of these plant and chemical-based finishes on textiles to boost their performance. Four methods that are employed to impart these finishes include absorption (padding/dipping/spraying), incorporation, polymer coating and microencapsulation [13]. Microencapsulated citronella oil [14] and other herbal oils like lemongrass [15] were found to have improved mosquito repellence longevity.

The innumerable researches administered to utilize the non-hazardous herbal plant sources clearly stipulate their applicability as mosquito repellent finishes for textiles. Though there are some limitations like the durability of finishes, they could be condoned owing to our concerns for sustainability. Efforts should be made to modify the techniques used to impart finishes to the textiles for enhancing their durability.

In this study, an attempt was made to develop a formulation based on neem oil which can impart mosquito repellence to textiles and can be used both at commercial and household levels. This formulation can be used by people who are vulnerable to mosquito bites like people working in forest areas and children who usually spend the major part of their day outside. Application of such formulation on apparel and home textiles makes it easy and effective without having a need to carry mosquito repellents separately in the forms like creams, sprays, lotions, etc. In addition, it can be used after laundering every time like other blueing or starching agents which will overcome the problem of lack of durability, the most obvious concern with respect to herbal mosquito repellent finishes.

This chapter gives an overview of the methodology followed for developing mosquito repellent formulations from Neem oil and evaluation of the shelf life of the formulation. This chapter includes the details of the application of the developed formulation to the fabric samples and the evaluation of the samples. The pad-dry and spraying techniques used for the application of the formulation to the fabrics have been discussed. Performance of the finished fabrics with respect to various factors like mosquito repellency, toxicity, mosquito repellency after storage and after laundering as well as the change in colour of the fabric after the application of finish have been discussed.

2 Methodology

This study involved the preparation of neem oil formulation for finishing textiles to obtain mosquito repellence properties. The finished fabric was evaluated for its mosquito repellence properties using the cage test. The effect of laundering on the durability of formulation on finished fabric was studied. The shelf life of the formulation was also assessed. The research design of the study comprised of two phases:

2.1 Phase I: Preparation of Mosquito Repellent (MR) Formulation and Assessment of Its Shelf Life

The formulation based on neem oil was prepared in various compositions and the shelf life of the final formulation was assessed with and without stabilizers.

-

A.

Preparation of the formulation. The first and foremost step was to prepare the formulation of neem oil using an emulsifier. The composition of the formulation is given in Table 1

Table 1 Basic composition of Neem oil mosquito repellent formulation -

B.

Assessment of shelf life of Mosquito Repellent formulation. Shelf life is a period during which a good remains effective and free from deterioration, and thus saleable in the given standard conditions. The shelf life of the formulation was evaluated by observing it for any signs of deterioration or fungal growth for a period of time.

The assessment was carried out by keeping the formulation at room temperature for 1–12 weeks. Also, the effect of sodium benzoate as a preservative on the mosquito repellent formulation was studied. The formulation was divided into two parts. In one part sodium benzoate was added and the other part did not contain any preservative. The shelf life of both the formulations was studied for 12 weeks.

2.2 Phase II: Application and Evaluation of Mosquito Repellent Formulation

This phase comprised the application of the Neem Oil formulation to two types of fabrics and the evaluation of their efficacy against mosquitoes. Various physical parameters of the finished fabrics were also evaluated.

-

A.

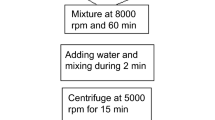

Application of formulation: The formulation prepared was applied to two different fabrics, namely cambric and casement, using two different techniques, i.e. Pad-Dry technique (2 dips-2 nips) and Spray technique. The formulation was applied in three different concentrations (10, 20 and 30%) by mixing with the required quantities of water on the selected fabrics, i.e. cambric and casement.

-

B.

Evaluation of the finished fabrics. The following test was performed on the finished fabrics.

Assessment of mosquito repellence activity: The mosquito repellency properties were studied using a standard cage test which was performed at the National Institute of Malaria Research, Dwarka, New Delhi.

-

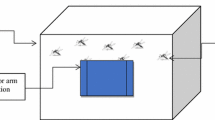

Cage test is also known as Arm-in-cage test, which is a standard test method for investigating the efficacy of mosquito repellent formulations. Cage tests are quick and cost-effective ways to determine the mosquito-repelling qualities of treated textiles. The repellence test of the samples was done on the basis of the standard as certified by WHO with some modifications that were thought to be important for the study.

The repellence test was done by preparing a cage (Fig. 1) and rearing 30 mosquitoes ((laboratory reared Anopheles stephensi, 3 days old). The 40 cm × 40 cm ferrous frame cage was covered with muslin cloth and its front was covered with a nylon net. The samples were inserted into the cage without inserting the forearms of the volunteer and cotton soaked in glucose was placed in the cage to confuse mosquitoes of the human blood smell. While the mosquitoes were inserted into the cage with a suction tube, they tend to sit/rest on the wall of the cage and not on the ground where the samples were kept. So, the testing method was modified by placing the treated samples on the wall of the cage and the number of mosquitoes that arrived on the treated samples was counted and recorded for four hours. The cage was covered with a black colour cloth ensuring that there is no light entering the cage. Also, mosquitoes settle on a place where they sit first (when it is convenient for them), they may not fly to the other place. So, the cage was shaken each 10 min to disturb the mosquitoes. The number of mosquitoes found sitting on the fabric after every hour were counted. The observation was done for up to four hours.

Protection % was calculated as follows:

$${\text{Protection\;\% }} = \frac{{\begin{array}{*{20}c} {{\text{No.}}\;{\text{of}}\;{\text{mosquitoes}}\;{\text{on}}} \\ {{\text{control}}\;{\text{sample-no}}\;{\text{of}}\;{\text{mosquitoes}}\;{\text{on}}} \\ {{\text{treated}}\;{\text{sample}}} \\ \end{array} }}{{{\text{No}}.\;{\text{of}}\;{\text{mosquitoes}}\;{\text{on}}\;{\text{control}}\;{\text{sample}}}} \times 100 $$ -

Effect of storage time on mosquito repellence of treated fabrics: Effect of storage time on mosquito repellent efficiency of the treated fabrics was studied using the cage test. The effectiveness of the formulations on the fabrics was evaluated within 24 h and after 15 days.

-

Effect of laundering on mosquito repellence of treated fabrics: The treated fabric samples were washed in a launderometer according to the conditions given in Table 2. After washing, the fabric samples were tested again for their mosquito repellence properties using the cage test to check whether the finish is durable or not.

Table 2 Conditions for washing treated fabric samples -

Cone bioassays test-For this, the rim of the cone was fixed to the treated fabric samples fastened with a rubber band. The cones were fixed randomly with fabrics treated with different concentrations of finish. One fabric sample from each concentration and one control sample was taken. Ten mosquitoes were introduced into each of the plastic cones through an orifice and the orifice was plugged with a cotton ball. Two exposures were made for three minutes on two flaps of the treated fabric and the control. The number of mosquitoes knocked down at the end of the three minutes were recorded and the mosquitoes were transferred to plastic containers with a nylon net fastened with a rubber band. Mosquitoes were provided with the sugar-soaked cotton ball placed on the top of the net. The plastic container was placed preferably in an unsprayed room maintained at standard temperature (27 ± 2 °C) and relative humidity (60–70%). If it is not feasible to maintain temperature and humidity, a moist chamber can be used as described in WHO (1981). Mosquitoes are considered to be alive if they can both stand upright and fly in a coordinated manner. Mosquitoes that are moribund or dead are classified and recorded as knocked down at 60 min and as dead at 24 h. A mosquito is moribund if it cannot stand (e.g. has one or two legs), cannot fly in a coordinated manner or takes off briefly but falls immediately. A mosquito is dead if it is immobile, cannot stand or shows no sign of life. Per cent mortalities are determined after 24 h of holding from the alive and dead mosquitoes. Results are expressed as overall persistence against the given dose of insecticide.

$$\% {\text{Mosquito}}\;{\text{Mortality}}\;{ = }\;\frac{\begin{gathered} {\text{No}}{.}\;{\text{of}}\;{\text{mosquitoes}} \hfill \\ {\text{knocked}}\;{\text{dead}} \hfill \\ \end{gathered} }{\begin{gathered} {\text{Total}}\;{\text{no}}{.}\;{\text{of}}\;{\text{mosquitoes}} \hfill \\ {\text{introduced}} \hfill \\ \end{gathered} } \times 100$$

3 Results and Discussion

3.1 Preparation of Formulations and Evaluation of Their Shelf Life

The formulation was prepared using four ingredients, viz. Sodium Lauryl Ether Sulphate, Neem oil, Sodium Benzoate and water. Sodium lauryl ether sulphate works as an emulsifier which helps in making an emulsion of essential oil and water, whereas sodium benzoate acts as a preservative. To check the shelf life, neem oil formulation was divided into two parts. In one formulation, sodium benzoate was added and the other was left as it is for the time period of a minimum of four months. There was no sign of fungal growth or deterioration in both cases (with and without sodium benzoate) even after 4 months of storage at room temperature. Hence. this formulation can be used for apparel and upholstery in houses and can be kept for long periods. The only precaution which should be kept in mind is that the shaking of the formulation is important before use.

3.2 Evaluation of the Finished Fabric Samples

Mosquito repellency of the finished fabrics was determined at the National Institute of Malaria Research, Dwarka, New Delhi, using Cage test methods. The results are discussed below.

Cage test. The test was done for a duration of 4 h. The number of mosquitoes landing on the test samples was counted after every hour for up to four hours and the total number of mosquitoes was then calculated. The effectiveness of the sample was evaluated on the basis of the number of mosquitoes attracted on the finished and control fabric samples The test was done on the Casement and Cambric samples finished with different application methods-Pad-Dry method and Spraying method. The finished fabrics were tested within 24 h of the treatment and after 15 days of the treatment to study the change in efficacy on storage, if any.

Results for samples tested within 24 h of application of finish: The mosquito repellency results of cage test (within 24 h) of the Cambric and Casement fabric treated with neem oil formulation by padding method are given in Tables 3 and 4.

The finished cambric fabric showed a significant increase in mosquito repellency with an increase in the concentration of the finish. On application of 10% concentration of formulation, approximately 60% protection was achieved which significantly increased to 72% on increasing the application concentration to 20%. With 30% concentration, almost 84% of mosquito repellency could be achieved.

10% concentration was not used for further experiments as it showed very poor results.

As can be seen from Table 4, the mosquito repellency seen on treated casement fabric is slightly less than that on cambric fabric, however, the difference is not very significant.

Tables 5 and 6 show the results of samples which were treated by spray method and were tested within the time period of 24 h.

The results on both the fabrics show that there is an increase in protection percentage as the concentration of oil increases but the protection achieved by spraying method is much lower than that obtained by padding technique. This could be due to lesser amount of finish being received by the fabric as a significant amount of the finish may get lost in the air during spraying. In spite of this limitation, 65–70% protection could be achieved when 30% formulation was applied. The casement fabric gave better results for mosquito repellence than the cambric fabric when the finish was applied by spraying technique.

This technique can be very beneficial when one wants to impart mosquito repellency to textile products, which are difficult to treat by pad-dry method, such as upholsteries, curtains, carpets, mattresses, etc.

Effect of storage time on mosquito repellence properties of the treated fabric. A cage test was used to see the efficacy of the treated fabrics after 15 days of storage which gave an idea about the efficacy of formulation on the fabrics on storage. The results of cambric and casement fabrics treated with mosquito repellent formulation and tested after 15 days of application are given in Table 7.

In both the fabrics, there was a considerable reduction in the mosquito repellency, the protection percentage reduced to around 60% for fabrics treated with 20% concentration and to 70% in the case of 30% formulation.

3.3 Effect of Laundering on Mosquito Repellency of Treated Fabric

The efficacy of mosquito repellent formulation was determined after washing the treated fabrics. For this, the treated fabric samples were washed and tested again to check whether the finish is durable (Table 8).

It was observed that after washing, the protection of treated fabric reduced significantly in both cambric and casement. However, cambric fabric showed a greater reduction in the protection percentage than the casement fabric.

Overall, casement fabric, among the two fabrics used for the study, gave better results, which means it showed a better protection percentage than cambric fabric at all the concentrations.

3.4 Cone Bioassays Test

To evaluate the toxicity of the finished fabric, the cone bioassays test was used. The toxicity of the formulation was evaluated on the basis of mortality reported after 24 h of feeding glucose to the knock down mosquitoes (Table 9).

It was observed that the treated fabrics were not toxic to mosquitoes. The formulation applied on the fabrics only repels the mosquitoes through unwanted smell without killing them.

3.5 Effect of Formulation on the Colour of the Treated Fabrics

The change in colour due to the application of the finish was studied by testing the fabrics on a spectrophotometer. The results were assessed on the basis of K/S, L* C* h* values, Whiteness Index and Yellowness Index (Table 10).

The K/S values obtained for all the treated samples were higher as compared to the control samples irrespective of the fabric type, concentration of formulation and method of application of finish as shown in the results above (Table 10).

The whiteness index and the yellowness index also indicate that there is yellowing of all the treated samples. The whiteness index of the treated samples is lower as compared to that of the control sample and an increase in the concentration of formulation resulted in further lowering of the whiteness index. The yellowness index of treated fabrics is higher as compared to control samples for all the variations. The fabrics given spraying treatment showed more yellowness.

4 Conclusion

The results of the study show that neem oil formulation can be used as a mosquito repellent finish for textiles effectively. This formulation being an alternative to synthetic mosquito repellents like DEET, permethrin, etc. will reduce the environmental impact of harmful chemicals which are hazardous for health and the environment. The only limitation it poses is the slight yellowing of white fabrics which makes this finish better suited for coloured fabrics. It can be used easily as a household finish for textiles like upholstery or home furnishings, especially at public places (hospitals, etc.). The main strength of this finish would be its ease of application by common consumers on a variety of fabrics as per the requirement.

References

Türkoğlu GC, Sarıışık AM, Erkan G, Yıkılmaz MS, Kontart O (2020) Micro- and nano-encapsulation of limonene and permethrin for mosquito repellent finishing of cotton textiles. Iran Polym J 29(4):321–329. https://doi.org/10.1007/s13726-020-00799-4

Teli MD, Chavan PP (2017) Dyeing of cotton fabric for improved mosquito repellency. J Text Inst 109(4):427–434. https://doi.org/10.1080/00405000.2017.1351066

Raja A, Kawlekar S, Saxena S, Arputharaj A, Patil PG (2015) Mosquito protective textiles—A review. Int J Mosq Res 2:49–53

Agarwal A (2015) Development of mosquito repellent wet wipes. Unpublished Master Dissertation, Department of Fabric and Apparel Science, Lady Irwin College, University of Delhi

Gupta A, Singh A (2017) Development of mosquito repellent finished cotton fabric using eco friendly mint. Int J Home Sci 3:155–157

Tseghai GB (2016) Mosquito repellent finish of cotton fabric by extracting castor oil. Int J Sci Eng Res 7:873–878

Rastogi A (2014) Eco-friendly Dyeing of Juco fabrics using waste Marigold (Tagetes Erecta) flowers for development of home textiles. Unpublished Master Dissertation, Department of Fabric and Apparel Science, Lady Irwin College, University of Delhi

Gupta A, Singh A (2016) Development of eco friendly mosquito repellent cotton fabric. Int J Curr Res 9(07):53434–53435

Kantheti P, Rajitha I, Padma A (2020) Natural finishes on textiles to combat the mosquitoes: a pilot study. J Entomol Zool Stud 8:30–33

Gogia M (2013) Application of Dye extracted from Eucalyptus Citridora leaves on selected synthetic fabrics. Unpublished Master Dissertation, Department of Fabric and Apparel Science, Lady Irwin College, University of Delhi

Kakaria R (2019) Mosquito repellent formulations from eucalyptus and citronella oil: a comparative study. Unpublished Master Dissertation, Department of Fabric and Apparel Science, Lady Irwin College, University of Delhi

Mia R, Sajib MI, Banna BU, Chaki R, Alam SS, Rasel A, Islam T (2020) Mosquito repellent finishes on textile fabrics (woven & knit) by using different medicinal natural plants

Anuar AA, Yusof N (2016) Methods of imparting mosquito repellent agents and the assessing mosquito repellency on textile. Fash Text 3(1). https://doi.org/10.1186/s40691-016-0064-y

Specos MM, García JJ, Tornesello J, Marino P, Vecchia MD, Tesoriero MV, Hermida LG (2010) Microencapsulated citronella oil for mosquito repellent finishing of cotton textiles. Trans R Soc Trop Med Hyg 104(10):653–658. https://doi.org/10.1016/j.trstmh.2010.06.004 PMID: 20673937

Thite AG, Gudiyawar DM (2015) Development of microencapsulated ecofriendly mosquito repellent cotton finished fabric by natural repellent oils. Int J Sci Technol Manag 4(11):166–174

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Rastogi, D., Jain, A., Negi, A. (2022). Development of Mosquito Repellent Finish for Textiles Using Neem Oil: An Eco-Friendly Approach. In: Muthu, S.S. (eds) Sustainable Approaches in Textiles and Fashion. Sustainable Textiles: Production, Processing, Manufacturing & Chemistry. Springer, Singapore. https://doi.org/10.1007/978-981-19-0538-4_9

Download citation

DOI: https://doi.org/10.1007/978-981-19-0538-4_9

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-0537-7

Online ISBN: 978-981-19-0538-4

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)