Abstract

Chloride ingress is among the principal causes of corrosion in reinforced concrete (RC) bridge decks, impairing their durability and serviceability. Climate change is expected to alter the environmental factors (e.g., temperature and relative humidity) that are known to influence the corrosion process, creating additional uncertainties in the long-term performance of RC decks. This study aims to tackle this issue by quantifying the corrosion-induced damage under a changing climate. To accomplish this objective, a spatial time-dependent reliability method is used to calculate the probability and extent of corrosion-induced cover cracking to RC bridge decks. Random field method and Monte Carlo simulation (MCS) are used to model the spatial variability of structural and material parameters, and exposure conditions of the bridge deck, as well as the inherent randomness associated with deterioration. The proposed methodology is then illustrated using a numerical example that calculates the corrosion-induced damage for bridge decks, in terms of probability of corrosion initiation, and the probability and extent of concrete surface cracking on the top of the deck. Analysis results are compared for historical and future climate scenarios and for two Canadian cities characterized by different weather and exposure conditions (an inland area with cold winter and a coastal area, where chlorides come from de-icing salts and salt spray, respectively). Compared to the case with climate change effects incorporated, using historical climate data results in an overestimation of up to 14.3, 13.7 and 10.8% for the time to corrosion initiation, time to crack initiation, and service life, respectively.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

1 Introduction

The 2019 Canada Infrastructure Report Card makes it clear that the rapid aging of Canada’s bridges is alarming [5]. Chloride-induced corrosion is among the principal causes of RC bridge deterioration in Canada due to the extensive use of de-icing salts in winter. Corrosion results in a reduction in reinforcement section, cracking and spalling of concrete cover, which creates a risk for the serviceability and safety of the structure and further leads to increased maintenance and repair costs [13]. Climate change is expected to accelerate the corrosion-induced deterioration, creating additional uncertainties in the long-term performance of RC bridges. The annual cost directly due to corrosion in highway bridges is over $900 million in Canada [22], and this cost will likely increase under a changing climate.

In the past decades, there has been a concerted effort to understand the mechanism of chloride-induced corrosion. A number of empirical or mechanistic models were proposed to predict the deterioration state of RC structures [6, 30, 31]. However, the majority of the current corrosion models were developed for a constant climatic condition [4]. In reality, the climate condition is fluctuating over time and the evidence of climate change is increasingly alarming. Observations gathered worldwide indicate an overall increase in the near surface air temperature on a global scale and continuous growth could be expected in the coming decades. At the same time, many regions in Canada are becoming not only warmer but also wetter [14]. Previous studies have shown that the corrosion process can be greatly influenced by the weather conditions at the surrounding environment, particularly in the long term [2, 28].

Projected climate change, including higher temperature, increased relative humidity, and higher carbon concentrations in the atmosphere all lead to an increased rate of corrosion-induced deterioration. Reference [3] proposed a stochastic approach to model the weather conditions under warming effects with the objective of characterizing the effect of global warming on chloride ingress into RC structures. The results indicated that climate change could cause a 2% to 18% reduction in the time to corrosion initiation of RC structures. Reference [16] studied the prediction of chloride ingress into concrete under realistic weather conditions by using mathematical models to simulate the temporal variations of temperature and relative humidity. [18] investigated carbonation-induced deterioration of RC structures constructed in China under a changing climate by using a spatial time-dependent reliability method to account for spatial variability of material properties and dimensions. The results showed that a changing climate could increase the extent of damage by up to 6% for RC structures in inland areas of China. Reference [9] utilized a probabilistic model to analyze the effects of global warming and sea-level rise on the service life of coastal concrete structures. Their research showed that the service life decreased by about 5% after considering the effects of global warming and sea-level rise. In addition, [22] studied how uncertainties associated with climate change projections would affect the prediction of RC bridge deck service life under chloride attack by utilizing an ensemble of climate models. They found that the predictions could be highly influenced by the selection of climate models. Reference [10] investigated the effect of climate change on RC bridge decks with different designs under corrosion attack. It was found that the extent to which the service life of a bridge deck would be influenced by a changing climate was strongly dependent on the durability design of the bridge deck.

Although recent research recognizes the necessity and challenge of integrating climate change effects into the prediction of RC structure deterioration due to chloride ingress, relatively less research has simulated the multi-phased deterioration process over the design-service life of RC bridge decks. Further to this, the effects of spatially varying material properties and exposure conditions remain a less studied yet critical issue for corrosion damage modeling under chloride attack in a changing climate. This study aims to address these gaps and quantify the corrosion-induced damage and subsequent reduction in serviceability of RC decks in the face of climate change. The complete deterioration process including three key phases (i.e., corrosion initiation, crack initiation and crack propagation) is modeled to predict the timing and extent of different damage levels of bridge decks. Climate change projections are obtained using the Canadian Regional Climate Model (CanRCM4). A spatial time-dependent reliability method is used to calculate the probability and the extent of damage for RC bridge decks under chloride ingress. Random field method and Monte Carlo simulation (MCS) are used to model the spatial variability of structural and material parameters, and exposure conditions of the bridge deck, as well as the inherent randomness associated with deterioration. The findings could support effective decision-making on the maintenance and proactive protection of concrete bridge decks subjected to a changing climate.

2 Chloride-Induced Deterioration Models

Corrosion due to chloride ingress can be characterized in three key phases: ‘corrosion initiation’, ‘crack initiation’ and ‘crack propagation’ [17], as presented in Fig. 1. At first, chloride ions that come from the surrounding environment gradually diffuse through the protective concrete cover and then accumulate on the surface of steel bars. For RC bridge decks, the sources of chloride ions mainly include salt spray in coastal areas and de-icing salts used in inland cities with cold winter. The time to corrosion initiation (T1) is determined as the time it takes for the chloride concentration near steel bars reaches a critical threshold value. Next, an electrochemical reaction starts, followed by a reduction in bar diameter and the formation of rust. Because the volume of corrosion products is usually several times that of the consumed ferrite, the rust layers around the bar could cause considerable pressure on the surrounding concrete. The time required for the internal stress caused by corrosion to exceed the cracking strength of concrete is referred to as T2. These cracks continue to propagate from the steel bar to the concrete surface and cause severe cracks to the concrete cover. This is referred to as the serviceability limit state for bridge decks. Time from crack initiation to serviceability limit state (i.e., severe cracking) (T3) is dependent on the allowable crack width. In this study, the maximum allowable crack width of 0.3 mm is used according to AASHTO LRFD Specifications [1]. Chloride-induced corrosion induces both uniform corrosion and pitting corrosion to steel bars. Reference [15] found that pitting corrosion and uniform corrosion produced similar cover cracking patterns when there was no external load applied. For this reason, only a uniform corrosion process is the consideration for this study. It should be noted that intensive pitting corrosion may result in different cracking behaviour.

Figure 1 presents the models that are used to simulate the three key corrosion phases in this study. These models feature the capability of incorporating the effects of environmental factors into deterioration modeling. Fick’s second law of diffusion is used to describe chloride ingress based on the assumption that ionic diffusion is the dominant transport process of chloride into concrete. The chloride diffusion coefficient \(D\) is determined as the multiplication of the reference diffusion coefficient (\({D}_{ref}\)) and a series of modification factors, as shown in Eq. 1. The reference diffusion coefficient (\({D}_{ref}\)) is obtained for a given environmental condition (i.e., temperature and humidity) [9] (Eq. 2). The modification factors \(f\left(T\right)\), \(f\left(h\right)\) and \(f\left(t\right)\) are set to account for the effects of temperature, relative humidity, and concrete age, respectively, and their mathematical expressions are presented in Eqs. 3–6 [13, 20, 23].

where \(w/c\) is the water-cement ratio of concrete, \(E\) is the activation energy for the diffusion process (\(KJ/mol\)); \(R\) is the gas constant (\(8.314 J/mol.^\circ K\)); \({T}_{ref}\) and \({t}_{ref}\) are the reference temperature (\(293K\)) and the reference time (\(28 days\)) at which the reference diffusion coefficient \({D}_{ref}\) has been evaluated respectively; \({h}_{c}\) is critical humidity (0.75); \(m=0.2\) and \({t}_{lim}\) is 30 years.

For the corrosion propagation phase, a thick-walled cylinder model proposed by [7] is used to represent the relationship between the degree of corrosion and the pressure excreted on the surrounding concrete, for the purpose of predicting the time from corrosion initiation to crack initiation. This model is selected because it shows good accuracy when comparing with the experimental results. An empirical crack propagation model which was developed by [15] based on a series of corrosion experiments is used to estimate the time from crack initiation to the maximum allowable crack width. To account for the dependence of corrosion rate on temperature and relative humidity, the constant corrosion rate used in both models is modified according to Liu and Weyers’s time-variant corrosion rate model [12] in the present study.

3 Climate Scenarios and Cities Considered

Two climate scenarios are considered in this study to investigate the effect of climate change on RC deck deterioration under chloride attack: (1) Historical Climate Database: this climate scenario uses the climate data (daily temperature and relative humidity) of a historical period (1991–2020); (2) Climate Change Projection: this climate scenario uses the climate change projections of a future period (2021–2100). Climate data is obtained from the Canadian Regional Climate Model (CanRCM4) developed by the Canadian Centre for Climate Modeling and Analysis [21]. This study intends to take into account the climate change effects for the worst scenario, therefore the projected climate change (temperature and relative humidity) is characterized using CanRCM4 driven by the Second Generation Canadian Earth System Model (CanESM2) under the RCP8.5 scenario.

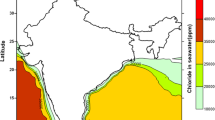

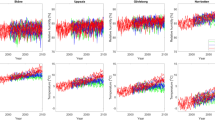

Two Canadian cities—Toronto and Victoria—are included for analysis to represent different climate configurations (Temperate Continental Climate and Temperate Mediterranean Climate, respectively) [11] and different exposure conditions (an inland area with cold winter and a coastal area, where chlorides come from de-icing salts and salt spray, respectively). Figure 2 presents near-surface air temperature and relative humidity in these two cities for the abovementioned two climate scenarios considered. It can be seen that the average temperature in a long-term period has a distinctly growing trend in both cities, while this is not obvious for relative humidity.

4 Deterioration Modeling of RC Bridge Deck

4.1 Bridge Deck Design

The RC bridge deck considered for the illustrative numerical example is \(10\mathrm{ m}\times 10\mathrm{ m}\), hence the total area is \(100 {\mathrm{m}}^{2}\). The water-cement ratio of concrete is assumed to be 0.5 (characteristic concrete compressive strength \({f}_{c}^{\mathrm{^{\prime}}}=33MPa\)). To consider the inherent randomness associated with the deterioration process, a probabilistic approach (MCS with probabilistic model inputs) is used in this study. Distributions for the probabilistic inputs used in the MCS are shown in Table 1.

4.2 Spatial Time-Dependent Reliability Method

Concrete strength, dimensions and exposure conditions usually vary spatially over an RC deck due to many influential factors including material properties, workmanship as well as the environment [26]. In this study, the spatial variability of concrete cover, concrete compressive strength and surface chloride concentration are considered by using random field analysis. In a random field analysis, the RC bridge deck is discretized into a number of elements of size \(\Delta\) and a random variable is used to represent the random field over each element. These random variables are statistically correlated and the correlation between them can be defined by correlation functions. The mid-point method is selected for this study to model the random fields, meaning that the value at the centroid of each element represents the entire element. The Gaussian correlation function is used to define the spatial correlation between elements (Eq. 7):

where \({\tau }_{x}\) and \({\tau }_{y}\) are the distances between the centroid of correlated elements in the \(x\) and \(y\) directions, respectively; \({d}_{x}={\theta }_{x}/\sqrt{\pi }\) and \({d}_{y}={\theta }_{y}/\sqrt{\pi }\) where \({\theta }_{x}\) and \({\theta }_{y}\) are the scales of fluctuation in the \(x\) and \(y\) directions, respectively, referring to the distance within which correlation exists in the random field. In this study, an element size \(\Delta =0.5\mathrm{m}\) is chosen based on the state-of-practice bar spacing in bridge decks, creating a total of 400 deck elements. The scales of fluctuation for concrete cover, surface chloride concentration and concrete compressive strength are taken as \(2\mathrm{m}\), \(2\mathrm{m}\) and \(1\mathrm{m}\) respectively based on prior studies [19].

At the element level, the deterioration state of each element is predicted at each time interval. Accordingly, the extent of corrosion initiation, cracking initiation, and severe concrete cracking at the top surface of the deck is quantified at daily time increments for a design life span of 80 years. The climate data for 1991–2020 is repeated multiple times to cover a time duration of 80 years. For each MCS run, the extent of RC deck elements that have been corrosion damaged at a given time t can be calculated using Eq. 8:

where \(k\) is the total number of elements and \(T\) denotes the time required for corrosion initiation (\(T1\)) or crack initiation (\(T1+T2\)) or severe cracking (\(T1+T2+T3\)).

4.3 Results

One Monte Carlo realization for the bridge deck in Toronto under climate scenario ‘Historical Climate Database’ is used to illustrate the spatially distributed chloride-induced corrosion process (seen in Fig. 3). The time to reach each phase of corrosion is predicted for each element, and then the areas where corrosion initiated, crack initiated and severely cracked are calculated for every 20 years. The corrosion damage severity of the deck increases over time. The deck exhibits a quite different corrosion progression in space. The variability of deck progression in space is very high, reflecting the high uncertainties of the stochastic deterioration process. Some elements are already severely cracked when the service time of the bridge has not reached 20 years, while some elements are even not corrosion initiated when the time exceeds the 75-year design service life of the bridge. Moreover, the deterioration states of adjacent elements show a spatial correlation due to the usage of random field modeling. According to the results of a number of Monte Carlo realizations, the corrosion progression of each simulation is quite different from one another in both time and space. Based on a convergence analysis, 100 simulations are adopted for each time steps since the improvement in the accuracy of the prediction results is negligible once the number of MCSs exceeds 100.

5 Influence of Climate Change on RC Bridge Deck Performance

The deterioration states of RC decks in both Toronto and Victoria under two climate scenarios (i.e., Historical Climate Database and Climate Change Projection) are predicted at every time interval utilizing the spatial time-dependent method (presented in Sect. 4.2). The percent of the deck area deteriorated is plotted over the 80-year period to produce a cumulative damage plot, as shown in Fig. 4. In general, climate change leads to increased corrosion damage risks for both Toronto and Victoria. As a result of climate change, the percentage of bridge deck area that suffer corrosion initiation, crack initiation, and severe concrete cracking in the year of 40 increases by 3.5%, 3.8%, and 5.5%, respectively, for Toronto and by 8.8%, 9.3%, and 11.2%, respectively, for Victoria. This is mainly because the increased temperature leads to a larger chloride diffusion coefficient and corrosion rate, thereby accelerating both corrosion initiation and corrosion propagation (i.e. concrete cracking formation and propagation). Comparing the predicted results for Toronto and Victoria, it is also demonstrated that the climate change impact varies between locations due to their different weather and exposure conditions.

Based on the spatial time-dependent analysis results, the deck service life under each climate scenario is calculated and presented in Fig. 5. The service life of a deck can be defined as the time when the percentage of areas with cracking width greater than the maximum allowable limit prescribed by AASHTO (0.3 mm) exceeds 30% [8, 27]. For consistency, the time to corrosion initiation and the time to crack initiation are defined as the time when 30% of deck areas are corrosion initiated and crack initiated, respectively. The time to corrosion initiation (\(T1\)) is much longer than the time from corrosion initiation to crack initiation (\(T2\)) and the time from crack initiation to severe concrete cracking (\(T3\)). The duration of the first corrosion phase ranges from 11.5 to 16.8 years whereas the time to first cracking occurs less than 2 years after corrosion initiation and the time needed from crack initiation to severe cracking ranges from 4.3 to 5.2 years. This further demonstrates the findings of [27] that the prediction of the time to failure of RC structures is dominated by the accuracy of the time to corrosion initiation. For both the ‘Historical Climate Database’ scenario and ‘Climate Change Projection’ scenario, the bridge deck in Toronto is more vulnerable to corrosion damage, as compared to that in Victoria. This is mainly due to the larger surface chloride concentration for deck exposed to de-icing salts in Toronto than for deck exposed in a coastal atmospheric environment in Victoria.

Compared to the case with climate change effects incorporated, using a historical climate condition results in an overestimation of up to 14.3, 13.7 and 10.8% for the time to corrosion initiation (\(T1\)), time to crack initiation (\(T1+T2\)), and service life (\(T1+T2+T3\)), respectively. In other words, the RC bridge deck under the future climate tends to deteriorate more severely than ever before. This finding highlights the importance of taking into account climate effects for service life modeling. The location of bridge decks also plays a role in determining the extent to which the corrosion damage of bridge decks is affected by climate change. For example, the overprediction in the service life of bridge decks in Toronto and Victoria due to the use of historical climate data varies between 9.5 and 10.8%, indicating that the climate change impact is more significant for bridges in Victoria than Toronto. This may be due to the lifespan of decks is generally longer in Victoria, which enables the deck to be affected by climate change for a longer time period.

6 Conclusions

This paper focuses on RC bridge deck deterioration caused by chloride-induced corrosion and investigates how the corrosion damage risks will be affected by climate change. The complete deterioration process including corrosion initiation, crack initiation and crack propagation is simulated to assess the lifetime serviceability of the RC deck. A spatial time-dependent reliability method is incorporated with deterioration modeling to calculate the probability and extent of the damage for RC decks under both historical and future climate scenarios. Two Canadian cities—Toronto and Victoria—are selected for analysis to cover different exposure and weather conditions. The major conclusions are listed as follows:

-

Analysis results demonstrate the negative impacts of climate change on RC deck serviceability. The projected changes in environmental conditions (temperature and relative humidity) lead to an increase of up to 8.8, 9.3 and 11.2% in the percentage of bridge deck area that suffers corrosion initiation, crack initiation, and severe concrete cracking, respectively, for Year 40.

-

Compared to the case with climate change effects incorporated, using a historical climate condition results in an overestimation of 9.5 and 10.8% for the service life of decks in Toronto and Victoria, respectively.

-

The extent to which the corrosion-induced damage of the RC deck will be affected by climate change varies between different locations of the bridge. A complementary project is ongoing at McMaster to extend the simulation to other Canadian cities for a holistic spatial assessment.

References

AASHTO (American Association of State Highway and Transportation Officials) (2017) AASHTO LRFD bridge design specifications. 8th ed., Washington, DC, USA

Balafas I, Burgoyne CJ (2010) Environmental effects on cover cracking due to corrosion. Cem Concr Res 40:1429–1440

Bastidas-Arteaga E, Chateauneuf A, Sanchez-Silva M, Bressolette P, Schoefs F (2010) Influence of weather and global warming in chloride ingress into concrete: a stochastic approach. Struct Saf 32:238–249

Bastidas-Arteaga E, Stewart MG (2014) Damage risks and economic assessment of climate adaptation strategies for design of new concrete structures subject to chloride-induced corrosion. Struct Saf 52:40–53

Canadian Infrastructure Report Card (2019) Monitoring the state of Canada’s core public infrastructure. http://canadianinfrastructure.ca/downloads/canadian-infrastructure-report-card-2019.pdf

Du YG, Clark LA, Chan AHC (2005) Residual capacity of corroded reinforcing bars. Mag Concr Res 57(3):135–147

El Maaddawy T, Soudki K (2007) A model for prediction of time from corrosion initiation to corrosion cracking. Cement Concr Compos 29(3):168–175

Englund S, Sorensen JD, Sorensen B (1999) Evaluation of repair and maintenance strategies for concrete coastal bridges on a probabilistic basis. ACI Mater J 96(2):160–166

Gao XJ, Wang XY (2017) Impacts of global warming and sea level rise on service life of chloride-exposed concrete structures. Sustainability 9:460. https://doi.org/10.3390/su9030460

Guest G, Zhang JY, Atadero R, Shirkhani H (2020) Incorporating the effects of climate change into bridge deterioration modeling: the case of slab-on-girder highway bridge deck designs across Canada. J Mater Civ Eng 32(7):04020175

Kottek M, Grieser J, Beck C, Rudolf B, Rubel F (2006) World map of the Köppen-Geiger climate classification updated. Meteorol Z 15(3):259–263

Liu T, Weyers RW (1998) Modeling the dynamic corrosion process in chloride contaminated concrete structure. Cem Concr Res 28(3):365–379

Martin-Perez B, Pantazopoulou SJ, Thomas MDA (2001) Numerical solution of mass transport equations in concrete structures. Comput Struct 79:1251–1264

Mekis E, Vincent LA (2011) An overview of the second generation adjusted daily precipitation dataset for trend analysis in Canada. Atmos Ocean 49(2):163–177

Mullard JA, Stewart MG (2011) Corrosion-induced cover cracking: new test data and predictive models. ACI Struct J 108(1):71–79

Nguyen PT, Bastidas-Arteaga E, Amiri O, EI Soueidy C (2017) An efficient chloride ingress model for long-term lifetime assessment of reinforced concrete structures under realistic climate and exposure conditions. Int J Concr Struct Mater 11(2):199–213

Nickless K, Atadero RA (2018) Mechanistic deterioration modeling for bridge design and management. J Bridg Eng 23(5):04018018

Peng LZ, Stewart MG (2014) Spatial time-dependent reliability analysis of corrosion damage to RC structures with climate change. Mag Concr Res 66(22):1154–1169

Peng LZ (2015) Spatial time-dependent reliability analysis of carbonation induced corrosion damage to RC structures under a changing climate and cost-benefit analysis of climate adaptation strategies. Doctoral dissertation, The University of Newcastle, Australia

Saetta AV, Scotta RV, Vitaliani RV (1993) Analysis of chloride diffusion into partially saturated concrete. ACI Mater J 90(5):441–451

Scinocca JF, Kharin VV, Jiao Y, Qian MW, Lazare M, Solheim L, Flato GM (2016) Coordinated global and regional climate modeling. J Clim 29(1):17–35

Shirkhani H, Zhang JY, Lounis Z (2020) Ensemble analysis of climate change impacts on design-service life of reinforced concrete bridge decks across Canada. Nat Hazard Rev 21(3):04020030

Song HW, Shim HB, Petcherdchoo A, Park SK (2009) Service Life prediction of repaired concrete structures under chloride environment using finite different method. Cement Concr Compos 31:120–127

Stewart MG (1995) Workmanship and its influence on probabilistic models of concrete compressive strength. ACI Mater J 92(4):361–372

Stewart MG (1996) Serviceability reliability analysis of reinforced concrete structures. J Struct Eng 122(7):794–803

Stewart MG (2006) Spatial variability of damage and expected maintenance costs for deteriorating RC structures. Struct Infrastruct Eng 2(2):79–90

Stewart MG, Mullard JA (2007) Spatial time-dependent reliability analysis of corrosion damage and the timing of first repair for RC structures. Eng Struct 29(7):1457–1464

Stewart MG, Wang X, Nguyen MN (2011) Climate change impact and risks of concrete infrastructure deterioration. Eng Struct 33(4):1326–1337

Vu KAT, Stewart MG (2000) Structural reliability of concrete bridges including improved chloride-induced corrosion models. Struct Saf 22:313–333

Xi YP, Bazant ZP (1999) Modeling chloride penetration in saturated concrete. J Mater Civ Eng 11:58–65

Zhang JY, Lounis Z (2006) Sensitivity analysis of simplified diffusion-based corrosion initiation model of concrete structures exposed to chlorides. Cem Concr Res 36:1312–1323

Acknowledgements

This research was supported by the Faculty of Engineering at McMaster University. The results, conclusions and opinions given in this paper are the ones of the authors and do not necessarily reflect the views of the funding agencies and the parties acknowledged.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 Canadian Society for Civil Engineering

About this paper

Cite this paper

Xu, M., Yang, C. (2023). Corrosion-Induced Serviceability Risks for Bridge Decks in a Changing Climate. In: Walbridge, S., et al. Proceedings of the Canadian Society of Civil Engineering Annual Conference 2021 . CSCE 2021. Lecture Notes in Civil Engineering, vol 241. Springer, Singapore. https://doi.org/10.1007/978-981-19-0511-7_42

Download citation

DOI: https://doi.org/10.1007/978-981-19-0511-7_42

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-0510-0

Online ISBN: 978-981-19-0511-7

eBook Packages: EngineeringEngineering (R0)