Abstract

When exposed to persistent moisture fluctuations, expansive clayey soil is mostly impermeable and has a dual tendency (swelling/shrinkage). The heave motion causes such clayey soils to lose volumetric and mechanical strength and is difficult to regulate the differential settlement. The current study focuses on the stability of black expansive clayey soil (BES) using alkaline-activator binders (ABs) reinforced with natural and artificial fibers instead of standard cement-based binders. The effects of different concentrations of ABs at varying curing durations are examined by conducting a series of index and shear strength property tests on treated BES. The treatment improves the geoengineering behavior of BES and helps to increase the unconfined compressive strength (UCS) values by regulating the heave and void ratios effectively. Mineral alteration caused by BES treatment with AB is responsible for reducing volumetric swelling and plasticity index. This study could be very useful in developing a cost-effective solution to the problem associated with BES.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Because of the unique character of expansive clayey soil, it has limited volumetric constancy when there is a moisture imbalance, which causes considerable damage to roadways, airport paved surfaces, and lightweight structures built on top of it. The active occurrence of montmorillonite and other smectite-related clay minerals is primarily responsible for periodic swell-shrinkage activity due to a high retain moisture tendency, resulting in significant distress when the load is applied [1, 2]. The major issues of this type of soil (especially at the subgrade layer) are formed the desiccating cracking, which typically impacts the performance against the rutting and fatigue failures of the asphalt or concrete layers. If these clayey soils are not adequately treated before constructing a substructure, it may lead to natural hazards resulting in millions of dollars in restorations and rehabilitation costs [3, 4]. The annual losses caused by construction on expansive soil are estimated to reach $9000 million in the United States, $1000 million in China, and 500 million in the United Kingdom. The overall annual loss increased by nearly 141% between 1970 and 2000, with 4000 million USD in lightweight structures alone in America [5, 6]. Before any construction is built on top of the soil, chemical stabilization can significantly increase the interfacial bonding and mechanical qualities. Lime and cement are calcium-based chemical binders that efficiently limit soil swelling potential and compressibility through pozzolanic and hydration processes. Nevertheless, the production of these cementitious binders has a substantial environmental impact by releasing carbon dioxide (CO2) and other greenhouse gases. By 2050, demand for traditional binders will have increased by up to 200% globally [7, 8]. Due to the quick sulfate reaction, excessive levels of lime/cement in the soil can induce carbonation shrinkage fractures and make it impossible to achieve the desired geomechanical strength without the admixture inclusions.

Alkaline-activator Binders (ABs) have recently acquired popularity as an alternative cement binder for soil stabilization, particularly in expansive clayey-type soils. ABs is a low carbon emission alkaline agent with a long-chain polymeric sodium aluminosilicate compound upon the activation of pozzolanic precursors. The high performance of alkaline activation in organic clay (geopolymerization) generated from silica (SiO2) and alumina (Al2O3) has proven to be an effective ground improvement approach. Using an environmentally safe alkaline binder has dual advantages: it eliminates the need for traditional cement binders on the one hand, and it avoids the cost of dumping fly ash/slag into landfills (Provis & Deventer, 2014). It surpasses PC-based binders in terms of mechanical strength, workability, and durability while emitting up to 75–80% less carbon dioxide and having a 70–75% lower global warming potential. Although alkaline mixed clayey soil effectively strengthened the peak compressive strength, it exhibited poor flexural and tensile forces resistance. In the subgrade layer, where this type of clayey soil is likely to shrink in the peak summer season, the occurrence of linear shrinkage, tensile and flexural cracking is a critical concerned [9]. The use of high tensile and stiffness-bearing fiber reinforcement in soft soil mixtures is a well-known geoengineering technique for regulating the width and number of cracks that propagate. Several studies have shown the effectiveness of discrete fiber (artificial/natural) reinforcement in chemically stabilized soil and considered good earth reinforcing material [10,11,12,13,14,15,16].

In the proposed stabilization procedure, fly ash and slag are used as binding ingredients on a poor subgrade soil surface. After China and the United States, India is the world’s third-largest coal-fired power producer. According to a study by India’s central electrical regulator, power stations produce around 200 million tonnes of fly ash each year. More than 75% of the ash is very fine in nature. Also, every year 20% of fly ash goes unused. Moreover, India has 60 thousand acres of fly ash and other pond ash, with production estimated to reach 230 million tonnes by the end of 2022 [14]. Furthermore, toxic elements mobilized in deposited fly ash-slag have the potential to damage surface and groundwater, soil, and vegetation. The cost of producing alkaline binder is less than Portland cement, although most plants donate fly ash and slag. India is the world’s second-largest producer of fiber. In alkaline soils, these fibers (synthetic and chemically treated fibers) are unaffected by salts and can function at high temperatures with negligible biodegradation. The use of alkaline soil fly ash, slag, and fibers in combination will provide a green and long-term solution for addressing the subgrade’s inferior characteristics.

This research focused on using green and sustainable industrial by-products as an alternative to traditional cement binders for soil stabilization. The primary goal of this research is to determine the optimal AB dose for different water to solid (w/s) ratios and aluminosilicate precursors in the alkaline mixture. According to the literature study, considerable research on the effectiveness of fiber reinforcing (type, size, and quantity) with conventional binders on soil subjected to geomechanical strength has been undertaken. However, the effect of a combination of pozzolanic precursors and discrete fibers (natural/manufactured) in an alkaline binder on expansive clayey soil performance against linear shrinkage and tensile cracking has not been adequately studied. The major purpose of this study is to determine the geotechnical reaction of an alkaline binder mixed clayey soil reinforced with a random inclusion of synthetic and chemically treated fibers at the varying proportion of fly ash and slag.

2 Materials and Experimental Methodology

2.1 Materials

Soil.

The black expansive clayey soil (BES) utilized in this study was gathered at a depth of a minimum of 10 cm below the surface level in the Kazipet region of the Warangal district of Telangana, India, to prevent the collecting of stems and vegetation along with the soil. The soil is dark brownish in color and has an in-situ moisture content of around 20%. The collected soil is categorized to a compressible clay (CH) according to the Unified Soil Classification System (USCS), with about 20–25% of the fine content being smaller than 75 μ. The high silica content detected in the expansive clayey soil and can be a prime chemical modification requirement before mechanical load application. The basic geoengineering (both physical and chemical) properties of soil are presented in Table 1. The main crystalline phases of clayey soil detected from X-ray diffraction (XRD) are Quartz (Q), Montmorillonite (M), and Muscovite (Ms).

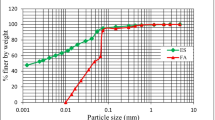

Fly Ash and Slag.

The national thermal power plant (NTPC) Ramagundam, Telangana, India, provided Class F (low calcium) fly ash for this investigation, conforming to ASTM C618-17a. JSW Cement Ltd. in Andhra Pradesh supplied the blast furnace slag (conforming to ASTM C989). X-ray fluorescence analysis (XRF) is used to determine the chemical composition of fly ash and slag. In fly ash, the principal constituents are aluminum oxide (Al2O3), silicon dioxide (SiO2), ferric oxide, and magnesium oxide (MgO). Slag attained a high amount of calcium oxide (CaO) and another element (Al2O3, MgO, and SiO2) compounds. The amount of heavy metals leaching from the mixture of fly ash and slag is found to be negligible.

Fiber.

As reinforcing agents of geopolymerized expansive soil, two different kinds of fibers, polypropylene (PF) and glass (GF), and two forms of natural fibers, hemp (HF) and coir (CF), are used. Kanaka Durga Industries in Hyderabad and Go-green Industries in Tamil Nadu, respectively, provide a consistent length of 12 mm for polypropylene (PF), glass (GF), and 24 mm for hemp (HF) and coir (CF) fiber. PF and GF with a length of 12 mm have greater soil-fiber interaction with good frictional bonding, improved interlocking, and a high tendency to regulate surface cracking when compared to other synthetic fibers. Due to their length and diameter, natural fibers (coir and hemp) significantly impact the soil reinforcing mechanism. It’s also worth noting that fiber lengths below 10 mm and greater than 40 mm have a low contact area with the soil, making higher pullout intensity difficult during loading. As a result, the ideal fiber lengths in the AB-soil mixture are 12 mm (PF and GF) and 24 mm (CF and HF). Before being used as a sustainable soil reinforcing material, cellulose and hemicellulose-rich natural fibers are thoroughly treated by using sodium hydroxide (NaOH-solution), maintaining 10M [13, 17, 18].

Alkaline-Activator Binder (AB).

The alkaline binder is prepared by mixing the activating solution (consisting of sodium silicate, sodium hydroxide, and water) and a dry pozzolanic precursor (Class F fly ash/slag). Both chemicals (NaOH pellets and Na2SiO3 solution) are obtained from Hychem Laboratories, Hyderabad. The food-grade of NaOH pellets with 99% purity and the industrial-grade Na2SiO3 contained 29.5% SiO2 and 14.7% Na2O by weight is maintained. The mass ratio of 1.057:12.9:40.00 to NaOH, Na2SiO3, and slag-fly ash precursors are utilized for binder preparation [13,14,15, 19]. The amount of water in the alkaline mixture is varied from 0.3 to 0.5 as water to solid ratios (w/s). The different slag and fly ash percentages are applied in the alkaline solution to obtain the optimum mix.

2.2 Experimental Methodology

Microstructural Characterization.

A series of X-ray diffraction (XRD), Fourier transform infra-red (FTIR), scanning electron microscopy (SEM/EDS) are carried out on BES, alkaline mixed clayey soil, and fiber mixed AB soil at different slag-fly ash doses. These tests are carried out to quantify the phases and morphological changes due to cementitious formation in both unreinforced alkaline and fiber-reinforced soil. Moreover, the microstructure of a material (particle size, molecular bonding, element, and mineral compositions) can strongly influence soil mechanical properties, such as shear strength, volumetric stability, and bearing capacity. Microstructural studies allow full recognition of fiber-soil interaction, soil surface crack propagation, and their stiffness behavior on a macro-scale.

Powder XRD examination is carried out on a RIGAKU Ultima IV diffractometer with a 2θ value spanning from 0o to 80°. The CuK rays were generated at 40 mA with 40 kV at 0.02 step of 2θ values and integrated at a rate of 2 s for evaluating the samples. The transmittance spectroscopy was performed using a JASCO FTIR 4200 setup. K.Br pellets are used to coat samples, and wavelengths are kept between 4000 and 400. Thermo Scientific Apreo SEM machines are used at varying magnifications to analyze the surface morphological behavior of soil before and after fiber reinforcement.

Geoengineering Characterization.

Detailed geotechnical tests such as compaction, consistency limit, linear shrinkage, consolidation, and swelling characteristics are performed on expansive untreated soil and alkaline mixed clayey soil at varying proportions of fly ash-slag content. The findings of these tests are used to evaluate the effectiveness of stabilizers in controlling volumetric strain and cracking behavior in expansive soil. All proportions of alkaline-soil mixes based on fly slag were prepared at their MDD/OMC values and tested according to ASTM standards. Soil linear shrinkage test is measured in a semi-cylindrical shrinkage mold of 25 cm in length with a radius of 1.25 cm as per the Australian standard (AS-1289.C4-1). Indirectly, this linear shrinkage can help estimate the shrinkage properties of clayey soil, especially in road construction materials. It is defined as the ratio of soil length specimen in a bar mold oven drying to its original length before drying. The soil samples are kept at room temperature followed by oven drying at 110 ℃ for 24 h, and the size of dried specimens is determined. The linear shrinkage LS (%) is given by

where Li and Lf are the initial and final lengths of soil samples, respectively (Fig. 1).

The 1D-Oedometer test is used to evaluate the compressibility and swell properties of expansive soil supplemented with various alkaline binder dosages at various w/s ratios and fly ash slag content, according to ASTM D-2435. Both untreated and alkaline treated clayey soil is compacted in a cylindrical consolidation metal ring with a diameter of 6 cm and a height of 2 cm. For all samples, swell percentages are calculated using a seating pressure of 6.25 kPa, and the e-log (p) curves are approximated for each load increment. All composite soil undergoes multiple UCS testing following ASTM D-2166. Before testing, different dosages of the fibers-fly ash-slag mixture in alkaline mixed soil specimens are stored for 30 min in an airtight vacuum desiccator to confirm maturation. The compression machine is a strain-controlled automatic compression machine with a maximum capacity of 20 KN and a fixed strain rate of 1.25 mm/min.

3 Results and Discussions

3.1 Microstructural Characterization

X-Ray Diffraction (XRD).

XRD tests are carried out on both untreated clayey soil and fiber mixed alkaline clayey soil in order to: (1) examine mineralogical changes in the soil structure owing to the presence of the alkaline stabilizing agent, and (2) evaluate the formation of crystalline pozzolanic products during geopolymerization. Montmorillonite (M), the major clay mineral in the expansive soil, is detected around 2θ = 19.7°, 27.1°, 36.2°, and 60.8° values, which mainly affects the volumetric stability behavior. Around 26.1°, 27.6°, and 59.4°, a minor amount of Muscovite (Ms) is also be found. The sharp crystalline peaks indicate the presence of Quartz (Q) around the 2θ values of 27.3°, 36.1°, and 61°. The diffractogram patterns reveal that different percentages of alkaline binder and cure times result in noticeable changes in the crystalline structure of the soil. As seen in Fig. 2(a–b), the peak intensity of Montmorillonite (M) decreases while the crystallinity of Quartz (Q) remains unchanged.

The diffraction pattern of alkaline mixed soil samples shows slag as one of the pozzolanic components in the soil matrix, as shown in Fig. 2b. In the 10% slag-based AB-clay mixture, a new crystalline pozzolanic reaction material, Augite (A), was identified at 22.9° and 36.3°. Interestingly, after 20% fly ash replacement with slag in the alkaline binder, ion participation improves significantly. The addition of slag is beneficial from the fact that as the amount of slag concentration in the alkaline soil increases, another notable crystalline peak Gehlenite (G) is identified at around 2θ values of 28.8°, and 39.1°, which also correspond to pozzolanic activity [20]. The rapid emergence of pozzolanic reactions in the soil also indicates active cementitious compound formation. Furthermore, the new cementitious compound calcium silicate hydrate (CSH) has been identified as a 30% slag substitute. These minerals may form due to rapid flocculation and vigorous cation exchange occurrence in silica-rich soil. As shown in Fig. 2b, the simultaneous mixing of alkaline binder and fiber reinforcement in clayey soil samples did not affect the mineralogical crystalline pattern. Flatter portions of the diffractogram indicate the amorphous phases in the hardened paste of alkaline binders.

Fourier Transfer Infra-Red (FTIR) Spectroscopy.

The FTIR technique measures the transmittance spectroscopy of chemical bonds that vibrate independently at distinctive wavelengths. The molecular vibration spectrum curve in untreated soil is widely employed by montmorillonite with a strong band at 3640 cm−1 as O-H stretching in Portlandite [Ca(OH)2]. After alkaline treatment, there is a slight drop in montmorillonite peak intensity (O-H stretch bond), as shown in Fig. 3a. The C = O carbonyl bond is seen about 1740 cm−1 in slag-based AB mixture and fiber-reinforced alkaline soil containing (fly ash replacement with slag) followed by the bending vibration of the = CH2 group (carbonation reaction) broadband in the region of 1470 cm−1. An excess of Na in the alkaline solution may be associated with the cause of this carbonation reaction. Both alkaline mixed and untreated soil show a strong band at 1050 cm−1, which corresponds to the asymmetric vibration of the Si(Al)-O group. As the w/s ratio in the AB mixture fraction grows, the intensity of the different band’s increases due to a greater extent of polymerization reaction between the fly ash and alkali-activating solution [9, 19, 21]. The weaker peaks between 880 cm−1 and 600 cm−1, ascribed to Si–Al in-plane bending vibration, are attributed to amorphous silica. Apart from that, Si-O-Al bending vibrations are identified with a wavenumber of nearly 540 cm−1. Thus, the spectra peaks from untreated and alkaline mixed soil exhibit identical linkage with a chemical shift of about 20 cm−1.

Scanning Electron Microscope (SEM)

An SEM image of untreated clayey soil at 40 µm resolution displays a flaky microstructure that mostly corresponds to smectite groups [22, 23]. The micrograph of the AB-soil samples showed better homogeneity after 20% slag content in the alkaline binder. Slag is beneficial in the AB-soil because it effectively binds the clay particles and produces silicate hydrates surrounding the clay particles in a cement paste coating, leading to reduced fluidity (low moisture affinity) and swelling [24, 25]. Thus, the dissolution of precursors can easily attribute to forming the dispersed gel around the clay particles, resulting in a more compact matrix with increased strength and stiffness. The surface morphology of polypropylene fiber (PF) reinforced alkaline mixed soil at 100 µm, and 500 µm resolution is shown in Figs. 4(a–b). A series of discrete polypropylene fiber (PF) reinforcement bounded by pozzolanic material enhances the bond strength in an alkaline clay matrix [13]. Furthermore, by interlocking the clayey particles, the combined inclusions of the PF-AB mixture act as a spatial groove network, thereby regulating the shrinkage crack propagation. The addition of glass fibers (GF) in the alkaline soil mixture appears like a rod-like ettringite needle structure (Figs. 4c–d), contributing to achieving higher interfacial bonding and soil stiffness by enhancing frictional resistance [16, 26]. By retaining the soil around the fiber surfaces, the discrete GF serves as a thread network, overcoming the soil’s brittle nature. As a result, the PG-GF-AB soils serve as a complex bracing network, generating efficient bonding and interfacial friction between soil-fiber matrixes and increasing mechanical stress resistance.

Similarly, Figs. 4(e–h) show the coir (CF) and hemp (HF) fiber-reinforced alkaline soil mixture at 100% and 60% fly ash dosages. The simultaneous presence of HF-AB in the soil results in forming a bridge fabric network that effectively limits the number and size of linear shrinkage fractures, as seen in Figs. 4(e–f). The spatial groove matrix is formed when the rough surface of hemp fiber is tightly encircled by the dense cementitious gel layers surrounding it. In the alkaline soil, the discrete HF is intertwined and operates as a spatial stress network that enhances the reinforced soil’s stiffness and tensile strength. When a relative displacement trend arises between one fiber in the network and soil particles under external load, the other nearby fibers help to restrict that displacement. As a result, the external strain is shared by all nearby threads, thereby increasing the total strength of the reinforced soil [13,14,15]. Figures 4(g–h) show a 500 µm resolution micrograph of the coir alkaline sample reinforced chemically treated fiber in alkaline soil. A strongly compacted micrograph exists in a bar-like wire construction with several coir fibers confined with cementitious materials around the clay minerals [27]. Furthermore, isolated coir fiber-connected in alkaline soils enhances interlocking friction and penetration resistance by increasing interfacial bonding and preserving the clay pocket around their surfaces [17, 18]. As a result of the increased mobilization of interfacial friction formed around the fiber surfaces, the combined fly ash-slag-based alkaline binder with fiber reinforcement in the expanding soil effectively improves compressive shear, flexure, and stiffness resistance outcome.

3.2 Geotechnical Characterization

Linear Shrinkage.

The linear shrinkage results for PF-AB-soil with different quantities of fly ash and slag in the fiber-alkaline-soil mixture are shown in Fig. 5. The linear shrinkage and shrinkage limit of expansive untreated soil was calculated to be 15% and 24%, respectively, indicating significant shrinkage. After adding a fly ash-based alkaline binder, the expansive clayey soil’s linear shrinkage was reduced from 24 to 14%, attributed to the production of pozzolanic compounds. The shrinkage behavior improved as the slag substitution increased in the alkaline mixture; this improvement could be caused by poor liquidity and capillary forces hastening the pozzolanic process. Furthermore, the fiber-AB paste containing 100% fly ash reduced linear shrinkage percentages significantly, indirectly lowering the plasticity index. As a result, the pure fly ash-based alkaline soil attains less shrinkage compared to based mixed AB-soil.

Consolidation.

The results of a series of e-log p and heave curves are shown in Fig. 6(a–b). The apparent correlation of soil volumetric stability behavior was demonstrated in the slope of void ratio curves. In comparison to alkaline mixed soils, untreated clayey soil showed the highest heave height. The presence of a montmorillonite-illite group and a large specific surface area of clay particles impaired the interfacial particle bonding, resulting in substantial swelling [28]. As the amount of slag in the soil grew, the compressibility of the alkaline soil fell significantly. The active multivalent cationic generation between the clay particles lowered the void ratio after replacing it with slag. In addition, the active dissolution of pozzolanic compounds in silica-rich soil activates the aluminum silicate hydrate gel, affecting soil heaving behavior [26]. When the soil specimen was unloaded, the cementitious agents enwrapped the volumetric particle activity [21].

The change in heave rate for untreated and alkaline treated soil at various dosages of fly ash-slag was displayed in Fig. 6b. The highest heave for untreated soil under the seated load was 2.78 mm in 3 days. The findings revealed that when different quantities of aluminosilicate precursors were used, the heave in alkaline soil was dramatically reduced. The usage of a pure fly ash-based AB mixture in the soil helped to preserve heave effects (from 2.78 mm to 1.88 mm), which could be attributed to an improvement in clay composition and morphology (due to rapid cementitious reaction activation) [29]. The volumetric expansion of the alkaline binder decreased considerably as the slag content increased. It’s also worth noting that replacing up to 40% of the fly ash in AB soil mixtures with an alkaline solution reduces the void ratio and swelling. The addition of slag to the alkaline solution aided the rate of geopolymerization reaction created around the clay matrix. As a consequence, the soil compressibility results showed that using alkaline binder as a cementitious additive can successfully improve interlocking particle density by preventing substantial soil settlement.

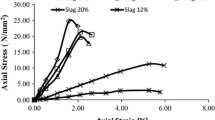

Unconfined Compressive Strength.

The UCS of four various types of fiber reinforcement with different slag-fly ash content in the alkaline binder mixed soils is shown in Figs. 7(a–b). It was discovered that in silica-rich expansive soil, combining fiber reinforcing with an aluminosilicate-based alkaline binder had a considerable impact on shear strength behavior. UCS growth percentages increased with fiber doses in both figures regardless of fly ash-slag proportions and fiber type. Fiber-AB soil achieved a higher UCS value than the fly ash alone (F100S0) alkaline-fiber matrix and slag (F60S40). The low silica and alumina reactivity with fly ash in the alkaline solution compared to rapid slag hydration could explain these large variations in shear resistance. Similar findings on the improvement of expansive soil shear strength behavior reinforced with polypropylene fibers in cement and lime were reported [16, 30, 31].

The alkaline soil combination’s interlocking bonding and frictional resistance rose as the slag and fiber content increased. As a result, the fibers restricted the relative shifting of their position from one step to another, enhancing shear resistance during loading [9]. The compressive shear strength of coupled polypropylene fiber and AB inclusions increased significantly more than glass fiber-AB inclusions. The PF-AB mixed UCS values also rose by roughly 26% as compared to the GF-AB matrix. This increase may be related to the increased frictional bonding resistance [18]. Fiber added to alkaline soil mixes (both natural and synthetic) improved confinement density and interfacial bonding during loading. Excessive fiber inclusion (more than 0.6% for synthetic and 0.8% for natural) mixed with alkaline biner-soil attained difficulty to compact, influencing stiffness behavior by forming smooth textures, weakening the particle holding efficacy. The flexible nature of fibers may indirectly dominate the resisting power of shear strength when a large amount of fiber is introduced to the soil. As a result, the fiber-reinforced alkaline soil reached its highest density between 0.6 and 0.8% fiber content.

4 Conclusions

The present study examines the geotechnical and microstructural characteristics of untreated expansive clayey soil, alkaline mixed soil, and fiber-reinforced-AB soil with varying fiber and AB doses in the soil mixture. After 28 days of curing, XRD and FTIR measurements demonstrate the creation of new mineralogical phases and chemical vibrational bonding in the alkaline soil mixed with various slag-fly ash concentrations. At a minimum of 0.4 w/s ratios, a fiber-reinforced alkaline soil micrograph demonstrates a high interfacial bonding interaction around the soil-fiber matrix. With enough friction and stiffness, the fiber bridge effect can effectively transform brittle soil behavior to ductile. Furthermore, the physical surface morphology of fiber-AB-treated soil tightly encircling the clay particles surrounding the fiber.

The combined effect of an alkali activator with four kinds of fiber reinforcements on expansive soil treated at different fractions of aluminosilicate precursors in the alkaline solution is also investigated. The results of the experiments revealed that soil fiber reinforcement may effectively control shrinkage fractures. In pavement geotechnics, the combination of fiber-slag-fly ash as an envirosafe alkaline additive in geopolymer stabilized subgrade soil was innovative and noteworthy. Laboratory studies were used to assess the viability of fly ash-slag proportions, and fiber dosage in the alkaline stabilized material as a bonded pavement material. At various slag-fly ash proportions and fiber doses, geomechanical investigations revealed that PF and HF-AB-soil had stronger penetration, compressive shear, tensile cracking resistance, interlocking density, and stiffness than GF and CF-AB-soil. However, it may be noted that mixing beyong 0.8% of fibers with clay resulted in minor segregation of the fibers. Overall, the proposed envirosafe alkaline binder can be used as a subgrade stabilizer with reduced carbon emissions from industrial by-products.

References

Ackroyd, L.W., Husain, R.: Residual and lacustrine black cotton soils of north-east Nigeria. Géotechnique 36(1), 113–118 (1986). https://doi.org/10.1680/geot.1986.36.1.113

Chen, F.: Foundations on Expansive Soils, p. 280. Elsevier Scientific Publishing Company, New York (1975)

Nelson, D., Miller, D.J.: Book Review: Expansive Soils - Problems and Practice in Foundation and Pavement Engineering, p. 17 (1993)

Puppala, A., Hoyos, L., Viyanant, C., Musenda, C.: Fiber and fly ash stabilization methods to treat soft expansive soils, pp. 136–145 (2008). https://doi.org/10.1061/40552(301)11

Jalal, F.E., Xu, Y., Jamhiri, B., Memon, S.A., Graziani, A.: On the recent trends in expansive soil stabilization using calcium-based stabilizer materials (CSMs): a comprehensive review. Adv. Mater. Sci. Eng. (2020). https://doi.org/10.1155/2020/1510969

Saride, S., Puppala, A.J., Chikyala, S.R.: Swell-shrink and strength behaviors of lime and cement stabilized expansive organic clays. Appl. Clay Sci. 85(1), 39–45 (2013). https://doi.org/10.1016/j.clay.2013.09.008

Taylor, M., Tam, C., Gielen, D.: Energy efficiency and CO2 emissions from the global cement industry. In: IEA-WBCSD Workshop. Energy Efficiency and CO2 Emission Reduction Potentials and Policies in the Cement, pp. 4–5 (2006)

Gartner, E.: Industrially interesting approaches to “low-CO2” cements. Cem. Concr. Res. 34(9), 1489–1498 (2004). https://doi.org/10.1016/j.cemconres.2004.01.021

Pourakbar, S.: Application of alkali-activated agro-waste reinforced with wollastonite fibers in soil stabilization. J. Mater. Civ. Eng. 29(2), 04016206 (2016). https://doi.org/10.1061/(asce)mt.1943-5533.0001735

Bordoloi, S., Garg, A., Sekharan, S.: A review of physio-biochemical properties of natural fibers and their application in soil reinforcement. Adv. Civ. Eng. Mater. 6(1), 20160076 (2017). https://doi.org/10.1520/acem20160076

Consoli, N.C., Arcari Bassani, M.A., Festugato, L.: Effect of fiber-reinforcement on the strength of cemented soils. Geotext. Geomembr. 28(4), 344–351 (2010)

Park, S.S.: Unconfined compressive strength and ductility of fiber-reinforced cemented sand. Constr. Build. Mater. 25(2), 1134–1138 (2011). https://doi.org/10.1016/j.conbuildmat.2010.07.017

Mazhar, S., GuhaRay, A.: Effect of fiber reinforcement on mechanical behaviour of alkali activated binder treated expansive soil: a reliability-based approach. Int. J. Geomech. 20(12), 04020225-1-14 (2020). https://doi.org/10.1061/(ASCE)GM.1943-5622.0001871

Mazhar, S., GuhaRay, A.: Effect of natural fiber reinforcement on strength response of alkali activated binder treated expansive soil: experimental investigation and reliability analysis. Constr. Build. Mater. 273(1), 121743 (2021). https://doi.org/10.1016/j.conbuildmat.2020.121743

Mazhar, S., GuhaRay, A., Goel, D.: Strength characterisation of fiber reinforced expansive subgrade soil stabilised with alkali activated binder. Road Mater. Pavement Des. (2021). https://doi.org/10.1080/14680629.2020.1869062

Tang, C., Shi, B., Gao, W., Chen, F., Cai, Y.: Strength and mechanical behavior of short polypropylene fiber reinforced and cement stabilized clayey soil. Geotext. Geomembr. 25(3), 194–202 (2007). https://doi.org/10.1016/j.geotexmem.2006.11.002

Anggraini, V., Asadi, A., Farzadnia, N., Jahangirian, H., Huat, B.B.K.: Reinforcement benefits of nanomodified coir fiber in lime-treated marine clay. J. Mater. Civ. Eng. 28(6), 1–8 (2016). https://doi.org/10.1061/(ASCE)MT.1943-5533.0001516

Sudhakaran, S.P., Sharma, A.K., Kolathayar, S.: Soil stabilization using bottom ash and areca fiber: experimental investigations and reliability analysis. J. Mater. Civ. Eng. 30(8), 1–10 (2018). https://doi.org/10.1061/(ASCE)MT.1943-5533.0002326

Gupta, S., GuhaRay, A., Kar, A., Komaravolu, V.P.: Performance of alkali-activated binder-treated jute geotextile as reinforcement for subgrade stabilization. Int. J. Geotech. Eng. 15(3), 299–312 (2018). https://doi.org/10.1080/19386362.2018.1464272

Sekhar, D.C., Nayak, S.: Utilization of granulated blast furnace slag and cement in the manufacture of compressed stabilized earth blocks. Constr. Build. Mater. 166, 531–536 (2018). https://doi.org/10.1016/j.conbuildmat.2018.01.125

Miao, S., Wei, C., Huang, X., Shen, Z., Wang, X., Luo, F.: Stabilization of highly expansive black cotton soils by means of geopolymerization. J. Mater. Civ. Eng. 29(10), 04017170 (2017). https://doi.org/10.1061/(asce)mt.1943-5533.0002023

Al-Mukhtar, M., Khattab, S., Alcover, J.F.: Microstructure and geotechnical properties of lime-treated expansive clayey soil. Eng. Geol. 139–140, 17–27 (2012). https://doi.org/10.1016/j.enggeo.2012.04.004

Sivapullaiah, P.V., Prasad, B.G., Allam, M.M.: Effect of sulfuric acid on swelling behavior of an expansive soil. Soil Sedim. Contam. 18(2), 121–135 (2009). https://doi.org/10.1080/15320380802660289

Mohammadinia, A., Arulrajah, A., Sanjayan, J., Disfani, M.M., Win Bo, M., Darmawan, S.: Stabilization of demolition materials for pavement base/subbase applications using fly ash and slag geopolymers: laboratory investigation. J. Mater. Civ. Eng. 28(7) (2016). https://doi.org/10.1061/(asce)mt.1943-5533.0001526

Zhang, Y., Johnson, A.E., White, D.J.: Laboratory freeze-thaw assessment of cement, fly ash, and fiber stabilized pavement foundation materials. Cold Reg. Sci. Technol. 122, 50–57 (2015). https://doi.org/10.1016/j.coldregions.2015.11.005

Rios, S., Cristelo, N., Viana da Fonseca, A., Ferreira, C.: Structural performance of alkali-activated soil ash versus soil cement. J. Mater. Civ. Eng. (2016). https://doi.org/10.1061/(ASCE)MT.1943-5533.0001398

Lekha, B.M., Goutham, S., Shankar, A.U.R.: Evaluation of lateritic soil stabilized with Arecanut coir for low volume pavements. Transp. Geotech. 2, 20–29 (2015). https://doi.org/10.1016/j.trgeo.2014.09.001

Sharma, A.K., Sivapullaiah, P.V.: Swelling behaviour of expansive soil treated with fly ash–GGBS based binder. Geomech. Geoeng. 12(3), 191–200 (2017). https://doi.org/10.1080/17486025.2016.1215548

Ouhadi, V.R., Yong, R.N., Amiri, M., Ouhadi, M.H.: Pozzolanic consolidation of stabilized soft clays. Appl. Clay Sci. 95, 111–118 (2014). https://doi.org/10.1016/j.clay.2014.03.020

Moghal, A.A.B., Chittoori, B.C.S., Basha, B.M.: Effect of fibre reinforcement on CBR behaviour of lime-blended expansive soils: reliability approach. Road Mater. Pavement Des. 19(3), 690–709 (2018). https://doi.org/10.1080/14680629.2016.1272479

Moghal, A.A.B., Chittoori, B.C.S., Basha, B.M., Al-Shamrani, M.A.: Target reliability approach to study the effect of fiber reinforcement on UCS behavior of lime treated semiarid soil. J. Mater. Civ. Eng. 29(6), 04017014 (2017). https://doi.org/10.1061/(asce)mt.1943-5533.0001835

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

GuhaRay, A., Syed, M. (2022). Performance of Expansive Soil Treated with Fiber Reinforced Alkaline-Activator Binder for Pavement Subbase Applications. In: Zhu, HH., Garg, A., Zhussupbekov, A., Su, LJ. (eds) Advances in Geoengineering along the Belt and Road. BRWSG 2021. Lecture Notes in Civil Engineering, vol 230. Springer, Singapore. https://doi.org/10.1007/978-981-16-9963-4_10

Download citation

DOI: https://doi.org/10.1007/978-981-16-9963-4_10

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-9962-7

Online ISBN: 978-981-16-9963-4

eBook Packages: EngineeringEngineering (R0)