Abstract

Globally, bio-lubricants are getting attention as these are sustainable, environment friendly, having good lubricity and can easily be extracted from vegetable oils. This study focused on the formulation of TMP based bio-lubricant from renewable cotton seed oil and measuring of its tribological characteristics to evaluate its potential for replacing petroleum-based lubricants. Coefficient of friction and wear for cylinder liner-piston ring combination was measured on HFRR and four-ball. SEM, EDX and surface morphology also described the wear nature and their surface roughness. SAE-40 was studied as a reference commercial lubricant for comparison purposes. It is concluded that pure cotton bio lubricant (CBL-100) gives good lubricity with low COF but higher wear than SAE-40. So, cotton bio lubricant with suitable anti-wear additives package has great potential to be used in global lubricant market instead of mineral based lubricants.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The depletion of mineral reservoirs along with health and environmental concerns have led to a greater focus on bio-lubricants. Most of the engine parts and engineering equipment used lubricants to overcome frictional losses and reduced wear. Mostly non-biodegradable and toxic petroleum-based lubricants are available in the global market, which creates health, water, and environmental issues [1].

So, it is necessary to increase the synthesis of bio-lubricants from renewable vegetable oils. Bio-lubricants are biodegradable, non-toxic renewable than mineral lubricants and their spillage is not harmful to the environment. Some bio-lubricants have bad oxidative stability and poor cold flow properties that can be improved by TMP-based transesterification of vegetable oils [2,3,4,5].

Tribological investigation of pure TMP-based bio-lubricants derived from palm oil showed very poor anti-wear characteristics with high COF as compare to ordinary lubricants [6].

TMP lubricant of Calophyllum inophyllum showed good anti-frictional characteristics (COF) due to its different fatty acids composition but poor anti-wear characteristics [7]. While automotive IC engines are demanding more efficient bio-lubricants, so researchers are finding ways to enhance the tribological characteristics of engine oils. Improvements in tribological characteristics will increase oil changing service interval resulting decrease in maintenance costs.

This study focuses on the formulation of renewable and environment-friendly bio-lubricant from cottonseed oil and evaluation of wear and frictional behavior of cotton bio-lubricant and SAE-40 on cylinder-liner piston ring.

2 Materials and Methods

Cottonseed oil based TMP-bio lubricant (CBL-100) was synthesized by transesterification process as described in earlier research [8], SAE-40 (Castrol brand) was purchased from the local market of Malaysia. High-frequency reciprocating rig and four-ball tribo tester were used for evaluation of tribological behavior. Grey-cast iron plates (developed from cylinder liner material), and Riken piston ring. AISI 52100 steel balls.

3 Results and Discussion

3.1 Physiochemical Properties

Density (15 °C) and viscosities (40 °C and 100 °C) were calculated by SVM-3000 (Anton Paar) viscometer according to ASTM-D7042 (Table 1).

3.2 High Frequency Reciprocating Rig (HFRR)

A cylinder-liner piston ring combination was used on HFRR (DUCOM: Model # TR-281-M8) for estimating tribological behavior of commercial lubricant (SAE-40) and cotton bio lubricant (CBL-100) in IC engines.

Experiments were conducted with cylinder liner-piston ring combination on HFRR for 1 h at 50 N load, 75 ℃ temperature, 50 rh humidity with 6 mm stroke length, 10 Hz frequency and 2 Hz frame rate.

3.2.1 Coefficient of Friction

The average COF calculated for SAE-40 and CBL-100 were 0.105269 μm and 0.04454 μm respectively. Cotton-bio lubricant showed less COF than commercial lubricant (SAE-40) because ester group of long-chain saturated fatty acids of cotton bio lubricant have affinity with metal surfaces so help in developing effective lubricating film between the sliding surfaces [9, 10]. COF during running-in-time and steady state are presented in Fig. 1.

3.2.2 Wear Characteristics

SAE-40 showed more COF than cotton bio lubricant for all intervals of time but less wear rate under same operating conditions. Wear rate of cotton bio lubricant is high because oxygen present in TMP-esters that chemically reacts with metal surface and make their oxides (metallic soap). These metallic soap layers have very low share strength so formed and removed continuously by sliding motion of piston ring on the plate, thus removed nonreactive materials increases the wear [7, 11]. SAE-40 showed less wear as compared to cotton-bio lubricant because it contains anti-wear additives as cleared from Fig. 2. YU FU XU et al. also showed that pure bio-oils caused the more corrosion of rubbing surfaces and engine parts than mineral based lubricants thus increasing corrosive wear mechanism [12].

3.2.3 SEM and EDX Analysis

Furthermore, surface analysis of cylinder-liner plates was performed by SEM and EDX, results are presented in Fig. 3. As SAE-40 contains anti-wear additives and metallic inorganic oxides (Fe3O4, Fe2O3 as appeared by dark colors) that protect the rubbing surfaces and reduces wear. Abrasive wear (scratches) appears on the surface due to corrosive oxidation. N.W.M. Zulkifli finding also showed that TMP-palm bio lubricant showed more wear than ordinary and paraffin lubricant in IC engines [6, 13]. While almost no protective film developed between rubbing surfaces with CBL-100 and causes severe adhesive wear and cracks due to the high concentration of wear debris and EDX analysis also confirmed the presence of many other metals removed by the severe wear between cylinder liner and piston ring.

Surface roughness of both plates was also measured with the help of ALICONA machine and values are compared in Fig. 4. Cotton bio lubricant has little bit more roughness (average roughness Ra, Rq, and Rz) than SAE-40 due to the presence of nonreactive detergents (removed particles) from metallic soap layers that developed and removed continuously by the sliding motion between cylinder liner-piston ring.

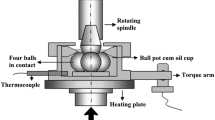

3.3 Four-Ball

Tribological properties of pure cotton bio-lubricant (CBL-100) and SAE-40 were also tested by using 4-ball tribo tester (DUCOM brand: with ±1% accuracy). Working Conditions set for four-ball were temperature = 27 ℃, speed = 1770 rpm, time = 10 s with constant load of 785 N (80 kg). COF, wear scars diameters and microscopic images of worn surfaces of balls tested with cotton bio lubricant are also shown in Table 2 and Fig. 5.

CBL-100 gives low COF but high WSD in comparison of SAE-40. Microscopic images of CBL-100 also showed material removal/adhesive wear.

4 Conclusion

Tribological analysis of cylinder liner-piston ring combination from HFRR and four ball showed that presence of TMP-ester group in pure cotton bio lubricant (CBL-100) is very good for lubricity that gives low COF but have more wear than SAE-40. So, cotton bio lubricant can be used as alternative renewable potential bio lubricant for IC engines with suitable anti-wear additive packages. There is also needed to explore suitable anti-wear additives in TMP-based-cotton bio lubricant or to use CBL as an additive in commercial lubricants. So that with better lubricity, wear rate can also be enhanced.

References

Rudnick, L.R.: Synthetics, Mineral Oils, and Bio-Based Lubricants: Chemistry and Technology, 3rd ed. CRC Press (2020). https://doi.org/10.1201/9781315158150

Heikal, E.K., et al.: Manufacturing of environment friendly biolubricants from vegetable oils. Egypt. J. Petrol. 26(1), 53–59 (2017). https://doi.org/10.1016/j.ejpe.2016.03.003

Mobarak, H.M., et al.: The prospects of biolubricants as alternatives in automotive applications. Renewable Sustainable Energy Rev. 33, 34–43 (2014). https://doi.org/10.1016/j.rser.2014.01.062

Kim, H., et al.: Immobilized lipase-catalyzed esterification for synthesis of trimethylolpropane triester as a biolubricant. Renewable Energy 130, 489–494 (2019). https://doi.org/10.1016/j.renene.2018.06.092

Gul, M., et al.: A review: role of fatty acids composition in characterizing potential feedstock for sustainable green lubricants by advance transesterification process and its global as well as Pakistani prospective. BioEnergy Res. 13(1), 1–22 (2019). https://doi.org/10.1007/s12155-019-10040-7

Zulkifli, N.W.M., et al.: Wear prevention characteristics of a palm oil-based TMP (trimethylolpropane) ester as an engine lubricant. Energy 54, 167–173 (2013). https://doi.org/10.1016/j.energy.2013.01.038

Habibullah, M., et al.: Tribological characteristics of Calophyllum inophyllum-based TMP (trimethylolpropane) ester as energy-saving and biodegradable lubricant. Tribol. Trans. 58(6), 1002–1011 (2015). https://doi.org/10.1080/10402004.2015.1025934

Gul, M., et al.: RSM and artificial neural networking based production optimization of sustainable Cotton bio-lubricant and evaluation of its lubricity and tribological properties. Energy Rep. 7, 830–839 (2021)

Reeves, C.J., et al.: The influence of fatty acids on tribological and thermal properties of natural oils as sustainable biolubricants. Tribol. Int. 90, 123–134 (2015). https://doi.org/10.1016/j.triboint.2015.04.021

Gul, M., et al.: Effect of TMP-based-cottonseed oil-biolubricant blends on tribological behavior of cylinder liner-piston ring combinations. Fuel 278, 118242 (2020). https://doi.org/10.1016/j.fuel.2020.118242

Jayadas, N.H., Nair, K.P., Ajithkumar, G.: Tribological evaluation of coconut oil as an environment-friendly lubricant. Tribol. Int. 40(2), 350–354 (2007). https://doi.org/10.1016/j.triboint.2005.09.021

Xu, Y.F., et al.: Friction and wear behaviors of a cylinder liner–piston ring with emulsified bio-oil as fuel. Tribol. Trans. 56(3), 359–365 (2013). https://doi.org/10.1080/10402004.2012.754532

Zulkifli, N.W.M., et al.: Lubricity of bio-based lubricant derived from different chemically modified fatty acid methyl ester. Tribol. Int. 93, 555–562 (2016). https://doi.org/10.1016/j.triboint.2015.03.024

Acknowledgement

Authors would like to thank all the members of CES, Faculty of Engineering, University of Malaya, Malaysia for their support through the research grant no FP142-2019A under the Fundamental Research.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Gul, M., Kalam, M.A., Zulkifli, N.W.M., Masjuki, H.H., Mujtaba, M.A. (2022). The Comparison of Tribological Characteristics of TMP Based Cotton-Bio Lubricant and Commercial Lubricant for Cylinder Liner-Piston Ring Combination. In: Samion, S., Abu Bakar, M.A., Kamis, S.L., Sulaiman, M.H., Mohd Zulkifli, N.W. (eds) Proceedings of the 3rd Malaysian International Tribology Conference. MITC 2020. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-16-9949-8_4

Download citation

DOI: https://doi.org/10.1007/978-981-16-9949-8_4

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-9948-1

Online ISBN: 978-981-16-9949-8

eBook Packages: EngineeringEngineering (R0)