Abstract

With the transition from planned maintenance to condition-based maintenance, it is essential to strengthen the effective management of labor costs. This paper takes the integration of business and finance as a guiding ideology. First of all, we compare condition-based maintenance’s business status and labor cost with planned maintenance’s business status and labor costs. Then we establish a set of labor costs analysis model which is in line with condition-based maintenance’s characteristics of railway freight cars. We hope this model will guide railway freight car enterprises to standardize and strengthen labor costs management. At the same time, enhance the competitiveness of railway freight car enterprises.

Foundation item: Research on Comprehensive Economic Benefit of Condition Based Maintenance (CBM) (SHGF-17-56-14).

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

China’s railway freight car maintenance system is mostly preventive daily inspection and regular maintenance that is planned maintenance. With the continuous upgrading of vehicle technical equipment, vehicle parts’ service life and reliability have been greatly improved. Therefore, according to the original maintenance operation standards, excessive maintenance often occurs. In recent years, the “system cost” of railway freight cars remains high. On the one hand, it’s resulted from high vehicle operation costs, that is to say maintenance costs. For example, because of the limited means of vehicle fault monitoring, a large number of train inspection operation fields have been set up, which lead to huge labor costs of train inspection. On the other hand, it is related to the low transportation efficiency. The vehicles that cannot be put into use due to maintenance seriously hinder the improvement of vehicle utilization rate, and the frequent shunting operations seriously restrict the passing capacity of stations. Driven by the demand of reducing maintenance costs and improving transportation efficiency, railway freight car companies are pushing the reform from planned maintenance to condition-based maintenance.

Since 2013, China’s demographic dividend era has gradually come to an end. With labor costs’ continuous rigid growth, labor costs are growing faster than GDP and have become a relatively large part of enterprise costs. Nowadays the labor costs’ input-output competitiveness has become one of the important factors that affects product market competitiveness and enterprises’ sustainable development. As for Railway freight car maintenance enterprises, they are much more dependent on human capital. Given labor costs not only affect products competitiveness and enterprise profits, but also affect employees’ interests and work enthusiasm. Railway freight car enterprises need strengthen labor costs’ effective management to improve enterprises’ core competitiveness, and improve employees’ enthusiasm and creativity by attracting and retaining talents. In this way, human resources in railway freight car enterprises will be allocated more reasonably and human resource management will be more scientific and effective. Therefore, how to establish a set of scientific labor cost analysis model that accords with the industry characteristics and adapts to enterprises’ development strategy is a new and important topic for railway freight car enterprises.

In order to promote labor costs’ optimization and control, taking the reform of railway freight car maintenance system as opportunity, we do some research on railway freight car maintenance. Based on the Integration of business and finance, this paper makes a comparative study on condition-based maintenance labor costs and planned maintenance labor costs. Accordingly, a labor costs analysis index system is constructed based on study. We hope to put forward the thinking of labor costs control by using the labor costs analysis model.

2 Literature Review

China’s definition of labor cost is the sum of all direct and indirect costs paid by enterprises in the process of production, operation and provision of labor services in a certain period of time. It includes total wages, social insurance expenses, welfare expenses, education expenses, labor protection expenses, housing expenses and other labor costs. This definition comes from the No. 261 document (1997) of original Ministry of labor, which is also widely used in academic circles. Labor cost is of great significance to the market economy, which is not only related to the market competitiveness and economic benefits of enterprises, but also related to the economic income of workers. Labor cost can be interpreted from different perspectives. From the perspective of workers, labor cost is the sum of the expenses that workers get equivalent to their own labor value. From the perspective of enterprises, labor cost is the expenses that enterprises need to bear in order to obtain human resources through recruitment, training, admission, management, assignment, medical treatment, insurance and other purposes. In fact, it is the remuneration the enterprise must pay in the process of enterprise operation when human resources create value for the enterprise (Zheng 2015).

The research on labor cost analysis has made some achievements in academic circles. Xiao (2016) systematically analyzed the current situation of labor cost of Wu Gang Co. Ltd and calculated the financial indicators related to labor cost, by combining with the employee structure and market situation. Wang et al. (2014) innovated the labor cost management of power grid enterprises according to the idea of flexible control and benchmarking management, and established a set of analysis, early warning and evaluation system in line with the characteristics of power grid enterprises. Many scholars have incorporated cost analysis into the cost control system and constructed the labor cost analysis and control system covering labor cost budget, implementation and control, cost accounting, cost analysis, cost evaluation and other aspects (Liu 2015; Chen 2015). According to the existing literature, the indicators of labor cost analysis are mainly divided into three categories: the first is the total labor cost index, which reflects the total level of enterprise labor cost; the second is the structural index of labor cost, which refers to the proportion of each component of labor cost; the third is the benefit index of labor cost, which is the common core index of labor cost analysis.

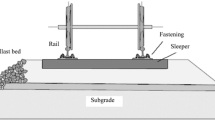

At present, China’s railway freight cars adopt the preventive planned maintenance mode of combining “daily inspection and regular maintenance”. The daily inspection includes station repair and operation repair. The regular inspection includes depot repair and overhaul. The maintenance contents are respectively implemented in the existing regulations for railway freight cars. The maintenance cycle is mainly based on time management. Other lines are mainly based on actual mileage. According to the state repair schedule of railway freight cars of National Energy Group, it can be divided into online repair and state repair. According to the different technical status of the whole train, state repair can be divided into four repair levels, namely state one repair, state two repair, state three repair and state four repair, which are respectively referred to as “Z1 repair”, “Z2 repair” and “Z3 repair” “Z4 repair” and “Z4 repair”. Online repair is mainly aimed at the treatment of individual vehicles with poor technical status, while condition repair is mainly aimed at the targeted repair of regular faults of the whole train. Under the condition-based maintenance mode, the repair process is no longer judged by the mileage and time of vehicles, but by the co mprehensive judgment model based on the “parts score - device score - vehicle score - train set score”.

Currently, there are many researches on labor cost analysis in academic circles, but there are few researches combined with enterprise business. In view of this, this paper focuses on the research of the labor cost of condition-based maintenance of railway freight cars. On the basis of the comparative analysis of planned maintenance business and planned maintenance finance, it constructs the labor cost analysis system of condition-based maintenance, and thus forms a three-step analysis model of “Business Analysis and Comparison - Labor Cost Calculation - Labor Cost Analysis”.

3 The Construction of Model

As a typical processing and manufacturing enterprise, railway freight car maintenance company’ business captures market demand and technological environment changes at the front end, and then drives financial function. At the same time, guided by financial cost objectives, it puts forward requirements for business development through the process of budget, control, accounting, analysis and assessment. The construction of the labor cost analysis model of condition-based maintenance is divided into three parts. The first part is business analysis and comparison, which provides business basis for labor cost analysis by comparing condition-based maintenance business with planned maintenance business. The second part is labor cost calculation, which provides the labor cost calculation model of condition-based maintenance according to the calculation of labor cost of planned maintenance. The third part is the analysis of the labor cost of condition-based maintenance, which constructs the analysis index system of the labor cost of condition-based maintenance of railway freight cars. In this way, the three-step model can help enhance the analysis and management of the labor cost of condition-based maintenance, promote the further improvement of the business, and realize the optimization of the labor cost.

3.1 Business Analysis and Comparison

Driven by the demand of reducing maintenance costs and improving transportation efficiency, railway freight car companies implement the maintenance mode reform. At present, technical breakthroughs have been achieved in the aspects of breakdown maintenance opportunity, parts detection content, flaw detection inspection opportunity, maintenance limit, maintenance process, etc. The innovation of maintenance technology leads to the optimization of five systems’ maintenance business, and the workload of condition-based maintenance is significantly reduced compared with the existing maintenance. Through the optimal allocation of human resources such as decomposition, cleaning and rust removal, appearance inspection, flaw detection, detection, processing, assembly and test, maintenance efficiency can be greatly improved, which will improve labor productivity, reduce the labor cost of single vehicle, and realize the optimization of labor cost (Figs. 1, 2).

3.2 Labor Cost Calculation

The cost of planned maintenance and condition-based maintenance both include material cost, labor cost, equipment cost, management cost and other costs. The current planned maintenance mainly carries out operation according to the time span. Taking C80 freight car as an example, depot repair is carried out once every two years, and overhaul is carried out once every eight years. There are nine depot maintenance and two or three overhaul in the whole life cycle. Condition-based maintenance is carried out according to the running mileage. Similarly, taking C80 freight car as an example, state two repair and state three repair is carried out once every 400,000 km, state four repair is carried out once every 1,600,000 km. In the whole life cycle, state two repair is carried out six times, state three repair is carried out three times, state four repair is carried out two times. Table 1 shows the labor cost calculation model of the whole life cycle under the two maintenance systems.

3.3 Labor Cost Analysis

Labor cost analysis adopts monthly statistical system and quarterly and annual analysis system. Through regular labor cost analysis meetings, problems can be found in time to realize the normalization of daily analysis and improvement. For the workshops with more labor cost overruns, the operation department, labor department and financial department will go deep into the site, focus on the analysis and put forward rectification suggestions. For the workshops with more labor cost savings, the experience will be summarized and promoted. The main content of labor cost analysis includes the production and operation situation of each workshop, the employment situation, the comparison between the actual labor cost and the budget progress, the comparison between the labor cost of this period and the same period of last year, the evaluation and analysis of labor cost input-output index, typical experience and practice, the main existing problems and rectification objectives, and the proposed measures. Referring to the existing labor cost analysis index system, the labor cost analysis indexes of condition-based maintenance are mainly divided into three categories: total index, structure index and input-output index, as shown in Table 2.

-

1)

Comparative Analysis of State Repair: Through the use of the total index of labor cost of condition-based maintenance, the data are compared with the previous data of the enterprise vertically and with the planned maintenance data horizontally. Then we can find out the differences and analyze the reasons.

-

2)

Structure Analysis of State Repair. Labor cost content of condition-based maintenance reflects the absorption degree of material transformation labor by living labor. In addition, it can also analyze the changes of each component and each level of maintenance in the total labor cost of condition-based maintenance through wage rate of labor cost and other indicators.

-

3)

Input-Output Analysis of State Repair. By calculating the profit rate of labor cost, personnel cost rate and labor distribution rate, analyze the input and output of labor cost.

4 Conclusion

The labor cost analysis and management of railway freight car enterprises is a relatively professional and complex work, which is directly related to the economic benefits of enterprises. In the labor cost analysis of railway freight car enterprises, the three-step analysis model of “Business Analysis and Comparison - Labor Cost Calculation - Labor Cost Analysis” constructed in this paper can be used to improve the management level of labor cost control.

References

Zheng, H.: Analysis of problems and countermeasures in labor cost management. Enterp. Reform Manag. (02), 22 (2015)

Xiao, Y.: Labor cost analysis and influencing factors of Wu Gang Co. Ltd. Account. Township Enterp. China (03), 111–114 (2016)

Wang, L., Lou, J., Ding, D.: Labor cost analysis of power grid enterprises based on elastic control theory. East China Electr. Power 42(04), 775–778 (2014)

Liu, G., Zhang, S., Li, Y.: Construction of labor cost management system in Chinese petroleum enterprises. J. China Univ. Petrol. (Soc. Sci. Ed.) 31(03), 12–16 (2015)

Chen, q.: Analysis of the establishment of labor cost analysis and control system in state owned enterprises. Chinese Foreign Entrepreneurs, (16), 180–181 (2015)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Gao, J., Cui, Y., Li, X., Sun, Y. (2022). Research on Labor Costs Analysis Model for Condition-Based Maintenance of Railway Freight Cars Based on the Integration of Business and Finance. In: Shi, X., Bohács, G., Ma, Y., Gong, D., Shang, X. (eds) LISS 2021. Lecture Notes in Operations Research. Springer, Singapore. https://doi.org/10.1007/978-981-16-8656-6_18

Download citation

DOI: https://doi.org/10.1007/978-981-16-8656-6_18

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-8655-9

Online ISBN: 978-981-16-8656-6

eBook Packages: Business and ManagementBusiness and Management (R0)