Abstract

Biodiesel are produced from plant derivatives and are highly potent in usage instead of diesel in diesel engines due to their low emissions which significantly reduce the environmental impacts and can use as fuel for diesel engines deprived of any alterations. The major drawback of biodiesel is associated with NOx and smoke reduction. Emulsified fuels are known to have high potent in reducing harmful emissions into atmosphere. Nitrogen oxides (NOx) and smoke are the major pollutants released through diesel combustion. Using water emulsions in biodiesel reduces the nitrogen oxide and smoke emissions. Span 80 is used as surfactant during emulsion to stabilise the whole blend. Nanoparticles increases the combustion rate and provides the combustion stability. Water is mixed with biodiesel in different proportions to study the emulsion stability, characteristics and performance. Water in biodiesel emulsion contains water range of about 5–15%. By literature survey and experimental analysis, we found that 5% water emulsion in biodiesel blend.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Nowadays, pollution is becoming as major threat to the environment and life on the planet. This is due to release of materials and energy released into atmosphere which effects environment eventually leads to show a potent effect on human life, animal life, natural resources and eco-system [1,2,3,4,5]. Air pollution is recorded as major environmental threats for life. In developing countries like India more than 90% of children under 5 years age are exposed to toxic air [6, 7]. A World Health Organisation (WHO) study states that in 2016 over one lakh children in India are dead due to air pollution. Atmosphere is mainly composed of toxic gases and dust particles [8,9,10,11]. These are mainly produced due pollutants released by automobiles. Diesel is majorly used as a fuel for of automobiles. Diesel engines are necessary but their emissions and its impacts on environment drives us to search for an alternate fuel which can be used instead of diesel which facilitates the lower emissions and low environmental impacts [12,13,14,15,16,17].

Biodiesel is emerged as an alternate fuel for diesel due to its low emissions compared to diesel and can be manufactured easily. This reduces the urge for fossil fuels and stops the extinction of fossil fuels [18,19,20,21,22,23]. This provides fossil fuel conversation for future use. The main drawback of biodiesel is its inability to reduce the NOx and smoke. This drawback can be overcome by mixing a tiny amount of water in biodiesel. By using water emulsions in biodiesel, the peak temperature during the combustion process is reduced this is because a part of heat during combustion is utilised by water to vaporise [24,25,26,27,28,29]. This ultimately reduces the NOx generation because the NOx is generated at higher temperatures, addition of water decreases the peak temperature rise in cylinder. Generally, water and diesel are both immiscible liquids. Both the liquids get separated within no time. Hence, a surfactant named SPAN 80 is used for proper emulsion [30,31,32,33,34]. This surfactant makes the water molecules to get binded against the diesel molecules. This provides proper emulsion stability. We blended the surfactant and biodiesel blend using ultrasonic sonicator [35,36,37,38].

Here flaxseed oil extract is used for biodiesel preparation. Flaxseed oil is also known as linseed oil. Flaxseed oil consists of high amount of linoleic acid (40–60%). Various researchers have researched on reduction of exhaust emissions. When the emulsion ratio increases NOx and smoke decreases [39]. Because the water content absorbs the heat and gets vaporised resulting in lower peak temperature in cylinder and provides enhanced mixing by micro-explosions [40,41,42,43]. Balanced water emulsified fuel creates lower BSFC compared with the non-water emulsified fuels. The best results for water emulsified fuels are found at 5% compared to all the remaining concentrations. Using nanoparticles like aluminium oxide nanoparticles are one of the most competent catalysts. When added these increases the combustion speed and combustion stability [44,45,46,47,48], this facilitates complete combustion. Thus, aluminium oxide nanoparticles helps in reducing the smoke emission rates.

2 Preparation of Biodiesel Blend

In this experiment, we extracted oil from flaxseed and the obtained flaxseed oil is converted into biodiesel in the presence of catalyst to form methyl esters. The obtained biofuel is mixed in diesel to form a biodiesel blend (B20) of composition 20% flaxseed biofuel + 80% diesel. This blend preparation is done in ultrasonic homogeniser. The resulting biodiesel blend properties are identified and are shown below.

By comparing the biodiesel blend and diesel properties, we found that the properties of both the properties are almost similar and the flaxseed biodiesel can be used as an alternate fuel for diesel engines.

The resultant biodiesel blend water is added in different proportions with 3% surfactant (SPAN 80) to provide a homogeneous mixture. The water composition is varied from 5%, 10%, 15%, whereas the span 80 remains constant at 3% for all the three samples (Table 1). 25 ppm of aluminium oxide nanoparticles are added to each sample. The aluminium oxide acts as catalyst and provides combustion stability. NOx and smoke emissions are scaled down by using water emulsions in fuels. After preparation of various samples, the properties of each sample are then identified.

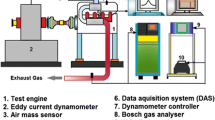

3 Experimental Setup

The variable compression ratio (VCR) is a four-stroke diesel engine consists of single cylinder (Fig. 1). To this engine, an eddy current type dynamometer is connected to facilitate the electric start motion. We can change the compression ratio even without stopping the engine this is because of specially designed tilting chamber block arrangement. The engine specifications are listed in Table 2.

4 Results and Discussion

Various tests were conducted to evaluate the Engine characteristics at different flaxseed biodiesel blends. Fuel samples such as diesel and bio diesel were fuelled in different proportions in a VCR diesel engine. CO, CO2, O2, NOX and HC emissions were measured as the loads varied. Samples of bio diesel were compared and analysed.

4.1 Specific Fuel Consumption

Figure 2 shows the comparison between the specific fuel consumption (SFC) and brake power (BP) of various blends of biodiesel and pure diesel. From the graph, we noticed that pure diesel has the low SFC compared to all the blends. The SFC for the for the flaxseed biodiesel blend (B20) is higher than diesel. SFC is of an engine is going on increase with increase in water content of the biodiesel blend. Flaxseed biodiesel blend with 15% water shows the highest SFC compared to all the blends [49,50,51,52].

4.2 Brake Thermal Efficiency

Figure 3 shows the graph comparison of brake thermal efficiency (BTHE) with BP. At beginning, the BTHE for all the sample blends remains similar as the load increases, the BTHE varies differently for different blends. Here pure diesel has the highest BTHE compared to all the blends. BTHE is reduced gradually upon the increase of water content in biodiesel blend. 10% water emulsified biodiesel blend shows the least BTHE performance. This lowering of BTHE than pure diesel is because of heat utilisation of water content present in biodiesel blends. Due to water, a part of heat is lost for vaporisation. In general, brake thermal efficiency refers to the ratio of heat input to heat produced by the fuel during combustion [53,54,55]. Due to this loss of heat nearly 19% of heat is lower than pure diesel for 5% water emulsified biodiesel blend.

4.3 Nitrogen Oxide (NOx)

Figure 4 shows the comparison graphs for nitrogen oxide (NOx) and BP for all the different concentrations of water emulsions in flaxseed biodiesel blend, flaxseed biodiesel blend (B20), pure diesel. From the above graph, it is absorbed that the NOx emission is reduced as the water content in the blend gets increases. The flaxseed biodiesel blend (B20) shows an increase in NOx production than the pure diesel while adding water to the same flaxseed biodiesel blend (B20) shows a drastic difference in reducing the NOx production. Here 15% water emulsified biodiesel B20 shows least NOx production compared to all the blends shown above. There is an effective reduction of 27% NOx (ppm) with 15% water emulsified biodiesel blend than pure diesel [56, 57]. This effective reduction is because of water content present in biodiesel blend and aluminium oxide nanoparticles because water content helps in reducing the peak temperature rise and aluminium nanoparticles acts as catalyst and facilitates smooth and fine combustion.

4.4 Hydrocarbon

Figure 5 shows a graphical comparison between hydrocarbon (HC) and BP with the blends of biodiesel. Here pure diesel has the least HC emission compared to all the blends. The blends other than diesel shows a drastic increase in HC emissions compared to pure diesel emissions [58,59,60]. The above graph clearly shows that with addition of water the HC emission percentage gets increased and has a maximum HC emission at 15% water emulsion + B20 in the above graph, 5% water emulsion in flaxseed biodiesel (B20) shows a minimum HC emission among all the biodiesel blends.

4.5 Carbon Dioxide

Figure 6 shows the graphical comparison with carbon dioxide (CO2) emission and BP for various blends of biodiesel and pure diesel. From the above graph, it is clearly stated that with addition of water content the CO2 emission is increased because of micro-explosion phenomenon of water molecules which facilitate the more homogeneous mixing of fuel and air and facilitate the smooth and complete combustion process. Nanoparticles also show major factor influencing the CO2 emission because of its ability to perform smooth and faster combustion rates. Here 10% water emulsified flaxseed biodiesel blend shows a higher CO2 emission compared to all the blends above while pure diesel shows a least CO2 emission. This increase in CO2 emission is nearly 30% higher than the pure diesel. But gets decreased upon addition of more water because of lowering the temperature during the combustion. So optimum usage of water should be used for increasing smooth combustion [61, 62].

4.6 Smoke Opacity

Water emulsified fuels show the continuous reduction in Fig. 7 and show the variation of brake power with smoke. Pure diesel emissions of smoke are less than blended biodiesel (B20). Increase the water micro-emulsion in blended biodiesel the smoke emission is decreased gradually. We can conclude that 5, 10, 20% composition water emulsion with biodiesel blend is lesser than the pure diesel and blend 20 (b20). But blend 20 is increase smoke emission then pure diesel. This reduction smoke is nearly 10, 13 and 15% by using 5, 10 and 15% water emulsions with blend (B20). The aluminium nanoparticles help in smooth and complete combustion of the resultant blend.

5 Combustion Analysis

5.1 Crank Angle Versus Pressure

Figure 8 describes various peak pressure rise of various samples with respect to crank angle. Here 5%, 10%, 15% water emulsified fuels are taken and are tested for their peak pressure rise. Here blend 20 shows a higher peak pressure than any other sample at full load. It shows nearly 15% pressure rise than any other sample. On the other hand, 15% water emulsified fuel shows a higher peak pressure than other samples it shows nearly 10% higher than other water emulsions with biodiesel blend. The pressure rise of diesel is higher than other samples.

5.2 Net Heat Release

Figure 9 describes the net heat release of various samples with respect crank angle. Here various samples with different water emulsified biodiesel blends are taken and are tested for determining the net heat release of each sample. In above graph, blend 20 shows a maximum heat release than other samples. It is approximately 20% more heat is released than other samples at full load. This is because the heat released during the combustion process is utilised by water molecules for its vaporisation. This results in lower net heat release of water emulsified biodiesel blends. This lower net peak heat rise results in lowering the NOx emissions because NOx is generally produced at higher temperatures. So by using water emulsified fuels the NOx production is reduced to a greater extent. Here the net heat release of blend 20 is higher than any samples, and it is nearly 50% more than the pure diesel.

6 Conclusion

By using water emulsions in flaxseed biodiesel, we obtained the emission and performance results through VCR single cylinder engine and AVL smoke meter for various compositions of water emulsions (5, 10 and 15%) in flaxseed-based biodiesel blend.

-

1.

Water emulsions cut down the peak temperature rise while combustion because, a part of heat is consumed by the water molecules for vaporisation. Generally, NOx gases are produced at very higher temperatures. So, the NOx generation is reduced.

-

2.

Aluminium oxide nanoparticles are one of the most competent catalysts. When added these increases the combustion speed and combustion stability. This facilitates complete combustion. Thus, aluminium oxide helps in reducing the smoke emission rates.

-

3.

From the results, we can say that 5% water emulsion in flaxseed biodiesel blend shows a better reduction in NOx and smoke emissions.

-

4.

Water emulsion in biodiesel results in reduction of smoke. This is because upon addition of water, during combustion micro-explosions takes place. Due to micro-explosions, the complete mixing of air fuel mixture takes place.

References

Eng. Dan, Dunarea de Jos of Galati Diesel-water emulsion, an alternative fuel to reduce diesel emissions. A review, Romania Machines, Technologies, ISSN 1313–0226. ISSUE 7/2013

Javier M (1996) Ballester, Norberto Fueyo and C6sar Dopazo combustion characteristics of heavy oil-water emulsions. Fuel 75(6):695–705

Rathinam S, Sajin JB, Subbiah G, Rajeev A, Prakash S, Christopherselvam D (2020) Assessment of the emission characteristics of the diesel engine with nano-particle in neem biodiesel 2019. Energ Sources Part A: Recovery Utilization Environ Eff 42(21):2623–2631

Sujesh G, Ganesan S, Ramesh S (2020) Effect of CeO2 nano powder as additive in WME-TPO blend to control toxic emissions from a light-duty diesel engine—an experimental study. Fuel 278:118177

Hemanandh J, Ganesan S, Devaraj R, Venkatesan SP, Ramprakash G (2020) Robust design approach for intake manifold of the 1 litre turbo charger intercooler diesel engines. Int J Ambient Energ 41(11):1214–1226

Padmanabhan S, Vinod Kumar T, Chandrasekaran M, Ganesan S (2020) Investigation of Sapindus seed biodiesel with nano additive on single cylinder diesel engine. Int J Ambient Energ 41(10):1106–1109

Rangabashiam D, Rathinam S, Subbiah G, Jb S, Sb S (2019) Emission behaviour studies on the cause of ZnO nanoparticle inclusion in neat biodiesel. Energ Sources Part A: Recovery Utilization Environ Effects 42(16):1989–1996

Devarajan Y, Munuswamy D, Nagappan B, Ganesan S (2020) Detailed study on the effect of different ignition enhancers in the binary blends of diesel/biodiesel as a possible substitute for unaltered compression ignition engine. Petroleum Sci 17(4):1151–1158

Sidheshware RK, Ganesan S, Bhojwani VK (2020) Experimental analysis of magnetic field effects on compressor energy saving cooling system. In: 2020 E3S web of conferences, p 170. https://doi.org/10.1051/conf/202017001020

Devarajan Y, Beemkumar N, Ganesan S, Arunkumar T (2020) An experimental study on the influence of an oxygenated additive in diesel engine fuelled with neat papaya seed biodiesel/diesel blends. Fuel 268

Rajasekar R, Ganesan S, Marynishanthi W (2020) Performance and emission characteristics of biodiesel derived from coconut acid oil 2018. Int J Ambient Energ 41(6):627–630

Venkatesan SP, Ganesan S, Devaraj R, Hemanandh J (2020) Design and analysis of exhaust manifold of the spark ignition engine for emission reduction. Int J Ambient Energy 41(6):659–664

Ganesan S, Padmanabhan S, Mahalingam S, Shanjeevi C (2020) Environmental impact of VCR diesel engine characteristics using blends of cottonseed oil with nano additives 2019. Energ Sources Part A: Recovery Utilization Environ Effects 42(6):761–772

Mahalingam S, Ganesan S (2020) Effect of nano-fuel additive on performance and emission characteristics of the diesel engine using biodiesel blends with diesel fuel. Int J Ambient Energ 41(3):316–321

Ganesan S, Mahalingam S, Raj RA, Rajesh S (2020) Effects of nano additives on performance and emission characteristics of Mentha longifolia biodiesel. Int J Ambient Energ 41(3):322–325

Ganesan S, Senthil Kumar J, Hemanandh J (2020) Optimisation of CI engine parameter using blends of biodiesel by the Taguchi method. Int J Ambient Energ 41(2):205–208

Ganesan S, Sridhar Raja KS, Senthil Kumar J (2020) Effects of MgO as an additive in canola oil–an experimental study. Int J Ambient Energ 41(1):1–4

Rajasekar R, Ganesan S, Logesh U, Prraveen NS, Javed M Effects of antioxidant additives on biodiesel/diesel performance and emission characteristics of ci engine. Indian J Environ Protect 40(3): 235–242

Rangabashiam D, Narayanaperumal KB, Subbiah G, Arumugam R (2020) Experimental study on utilizing peel oil, diesel and ignition-enhancer blends as fuel for diesel engine. Energy Sources Part A: Recovery Utilization Environ Effects. https://doi.org/10.1080/15567036.2020.1808743

Hemanandh J, Ganesan S, Puneeth C, Manikankata Tejesh G (2020) Vehicle emission analysis by using refined sunflower oil as alternate fuel and varying the injection timing in diesel engine. Int J Veh Struct Syst 12(1):65–69

Sidheshware RK, Ganesan S, Bhojwani V (2020) Enhancement of internal combustion engine efficiency by magnetizing fuel in flow line for better charge combustion. Heat Transf Res 21(5):419–431

Venkatesan SP, Ganesan S, Prabhahar JJ, Kaveti VR, Anoop A, Andrew A (2020) Performance and emission test on diesel engine using Prosopis juliflora seed oil. Int J Ambient Energ, pp 1–4. https://doi.org/10.1080/01430750.2020.1719887

Sujesh G, Ganesan S, Ramesh S (2020) Effect of compression ratio on the performance, combustion and emission of a single cylinder diesel engine using multi blended second generation biofuel. Int J Mech Prod Eng Res Dev 10(1):133–144

Hemanandh J, Ganesan S, Fiaz AS, Gunasekar P (2020) Investigation of Papaya seed methyl ester blended diesel for emission reduction in direct injection engines. Int J Vehicl Struct Syst 11(4):366–368

Devarajan Y, Munuswamy D, Nagappan B, Subbiah G (2019) Experimental assessment of performance and exhaust emission characters of a diesel engine fuelled with Punnai biodiesel/butanol fuel blends. Petrol Sci 16(6):1471–1478

Selvaraj M, Subbiah G (2019) The influence of injection parameters on the performance and emission characteristics of a DI diesel engine using biofuel-blended-pure diesel fuel. Int J Ambient Energ 40(8):800–803

Ganesan S, Rajasekar R (2019) Impact of dodecenyl succinic anhydride on performance and emission analysis of canola oil in direct injection variable compression ratio diesel engine. Indian J Environ Prot 39(11):985–988

Senthil Kumar J, Ganesan S, Sivasaravanan S (2019) Impact of nano additive on engine characteristics using blends of thyme oil with diesel. Int J Ambient Energ 40(7):768–774

Ganesan S, Hemanandh J, Sriharsh M, Anish M Experimental investigation on Di diesel engine with blends of black jamun seed oil using taguchi based optimization. In: AIP conference proceedings. vol 2161

Rangabashiam D, Logesh K, Yashvanth U, Ganesan S, Christopher Selvam D (2019) Detailed study on the effect of nano-particle size on emission characteristics of diesel engine. Petrol Sci Technol 37(18):2018–2024

Rathinam S, Sajin JB, Ganesan S, Yuvarajan D (2019) Performance and emission study on the effect of oxygenated additive in neat biodiesel fueled diesel engine. Energ Sources Part A: Recovery Utilization Environ Effects 41(16):2017–2027

Senthil Kumar J, Ramesh Bapu BR, Ganesan S, Krishnan L (2019) Evaluation of performance and emission behaviour of DI diesel engine powered by biofuel. Int J Ambient Energ 40(6):566–570

Rathinam S, Balan KN, Subbiah G, Sajin JB, Devarajan Y Emission study of a diesel engine fueled with higher alcohol-biodiesel blended fuels. Int J Green Energ 16(9):667–673

Sridhar Raja KS, Ganesan S, Senthil Kumar J (2019) Performance and emission characteristics of biodiesel from black pepper oil. Int J Ambient Energ 40(5):463–466

Senthil Kumar J, Ganesan S, Raja KSS (2019) Experimental analysis of the effects of cerium oxide nanoparticles on a single-cylinder diesel engine using biofuel blended with diesel as fuel. Int J Ambient Energ 40(5):490–493

Devarajan Y, Nagappan B, Subbiah G (2019) A comprehensive study on emission and performance characteristics of a diesel engine fueled with nanoparticle-blended biodiesel. Environ Sci Pollut Res 26(11):10662–10672

Mahalingam S, Ganesan S, Krishna GS, Perumalsamy V (2019) To study use of rubber seed oil blends diesel fuel at various injection pressures. Indian J Environ Prot 39(3):233–238

Rajasekar R, Ganesan S, Kumar MS (2019) Noise and emission characteristics of biodiesel used in multi-cylinder diesel engine. Indian J Environ Prot 39(10):924–927

Mathalai Sundaram C, Balam KN, Arunkumar T, Ganesan S, Rameshbabu A Emission study on the outcome of DMC on neem biodiesel ignited diesel engine. Part A: Recovery Utilization Environ Effects. https://doi.org/10.1080/15567036.2019.1691683

Rangabashiam D, Jayaprakash V, Ganesan S, Christopher D (2019) Investigation on the performance, emission and combustion pattern of research diesel engine fueled with higher alcohol and pongamia biodiesel blends. Energ Sources Part A: Recovery Utilization Environ Effects. https://doi.org/10.1080/15567036.2019.1670760

Rangabashiam D, Jayaprakash V, Ganesan S, Nagaraj M, Rameshbabu A (2019) Emission, performance, and combustion study on nanoparticle-biodiesel fueled diesel engine. Energy Sources Part A: Recovery Utilization Environ Effects. https://doi.org/10.1080/15567036.2019.1677

Ganesan S, Padmanabhan S, Hemanandh J, Venkatesan SP Influence of substrate temperature on coated engine piston head using multi-response optimization techniques. Int J Ambient Energ. https://doi.org/10.1080/01430750.2019.1653988

Sidheshware RK, Ganesan S, Bhojwani V Experimental investigation on the viscosity and specific volume of gasoline fuel under the magnetisation process. Int J Ambient Energ. https://doi.org/10.1080/01430750.2019.1653987

Rajasekar R, Ganesan S (2018) Experimental analysis of engine performance and emission characteristics using biodiesel obtained from winter green oil. Indian J Environ Protect 38(12):998–1003

Mahalingam S, Ganesan S, Krishna GS, Perumalsamy V (2018) Comparative analysis of performance and emission characteristics of thermal barrier coated diesel engine using biodiesel fueled with diesel fuel. Indian J Environ Prot 38(10):848–852

Padmanabhan S, Pradeep B (2018) Influence of cerium oxide additive and aloe vera biodiesel on a CI engine. Int J Ambient Energ 39(5):516–520

Ganesan S, Karthikayan S, Krishna GS, Reddy GVR (2018) Investigation on performance and emission characteristics of diesel engine with the blends of rosemary oil with magnesium oxide. ARPN J Eng Appl Sci 13(1):386–390

Padmanabhan S, Rajasekar S, Ganesan S, Saravanan S, Chandrasekaran M (2017) Performance and emission analysis on ci engine using soapnut oil as biofuel. ARPN J Eng Appl Sci 12(8):2491–2495

Padmanabhan S, Chandrasekaran M, Ganesan S, Khan Patan MN, Navakanth P (2017) Optimal solution for an engineering applications using modified artificial immune system, iop conference series: materials science and engineering. 183(1)

Karthikayan S, Ganesan S, Vasanthakumar P, Sankaranarayanan G, Dinakar M (2017) Innovative research trends in the application of thermal barrier metal coating in internal combustion engines. Mater Today: Proc 4(8):9004–9012

Senthil Kumar J, Ganesan S, Sivasaravanan S, Padmanabhan S, Krishnan L, Aniruthan VC (2017) Effects of nano additives in engine emission characteristics using blends of lemon balm oil with diesel. In: IOP conference series: materials science and engineering 197(1)

Ganesan S, Padmanabhan S, Senthil Kumar J, Polina N, Kumar SK (2017) Influence of MgO on performance and emissions of di engine using blends of castor oil. In: 2017 IOP conference series: materials science and engineering 197(1)

Padmanabhan S, Ganesan S, Jeswin Arputhabalan J, Chithrala V, Ganesh Bairavan P (2017) Performance test on compression ignition engine by blending ethanol and waste plastic pyrolysis oil with cetane additive. In: IOP conference series: materials science and engineering 197(1)

Sundararajan K, Ganesan S, Gomathinayakam S (2016) Emission estimation of neat paradise tree oil combustion assisted with superheated hydrogen in a 4-stroke natural aspirated DICI engine. Thermal Sci 20:S1137–S1144

Ganesan S, Elango A (2015) Analysis of emission characteristics on direct injection engine using biodiesel with MgO. Int J Appl Eng Res 10(9):13704–13713

Ganesan S, Elango A, Krishna EV, Balaji A (2013) Influence of nano catalyst on emission characteristics of di diesel engine with blends of lemon grass oil using taguchi approach. Int J Appl Eng Res 9(21):9941–9949

Ganesa S, Elango A (2013) Influence of nano catalyst in the performance of direct injection CI engine using blends of castor oil, ICANMEET, pp 723–725

Padmanabhan S, Ganesan S, Chandrasekaran M, Srinivasa Raman V (2010) Gear pair design optimization by genetic algorithm and FEA. In: Proceedings of the international conference on frontiers in automobile and mechanical engineering, pp 301–307

Ganesan S, Padmanabhan S, Vihaari V, Krishna Kumar S, Yamini P (2017) Influence of MgO on emissions of DI engine using blends of biodiesel. ARPN J Eng Appl Sci 12(6):1792–1795

Mangesh VL, Padmanabhan S, Ganesan S, Prabhudevrahul D, Kumar Reddy TD (2017) Prospects of pyrolysis oil from plastic waste as fuel for diesel engines: a review. In IOP conference series: materials science and engineering 197(1)

Dhanasekaran R, Ganesan S, Rajesh Kumar B, Saravanan S (2019) Utilization of waste cooking oil in a light-duty DI diesel engine for cleaner emissions using bio-derived propanol. Fuel 235:832–837

Badran O, Emeish S, Abu-Zaid M, Abu-Rahma T, Al-Hasan M, Al-Ragheb M (2011) Impact of emulsified water/diesel mixture on engine performance and environment. Int J Thermal Environ Eng 3(1):1–7

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Ganesan, S., Hemanandh, J., Venkatesh, S., Kumar, P. (2023). Combustion, Performance and Emission Analysis of VCR Diesel Engine Using Water Emulsion in Flaxseed-Based Biodiesel Blend. In: Edwin Geo, V., Aloui, F. (eds) Energy and Exergy for Sustainable and Clean Environment, Volume 2. Green Energy and Technology. Springer, Singapore. https://doi.org/10.1007/978-981-16-8274-2_8

Download citation

DOI: https://doi.org/10.1007/978-981-16-8274-2_8

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-8273-5

Online ISBN: 978-981-16-8274-2

eBook Packages: EnergyEnergy (R0)