Abstract

Middle East has one of the largest numbers of oil storage worldwide. Most of the tank farms have been built along coastlines of Arabian Gulf and Gulf of Oman. Commonly, the tanks shallow foundations were seated on very dense gravelly gabbro fills, which was laid above a layer of dynamic-compacted calcareous (natural) sand. It has been observed for several cases that different settlements beneath tank bottom annulus after 10-year operation exceeded acceptable limited as per API standard [1].

In this paper, the long-term settlement of large oil tanks on shallow foundation was investigated using both in-situ tests and laboratory tests. In laboratory, creep of calcareous sand was measured using triaxial cell. Effects of oil tank filling and emptying on foundation settlement was also evaluated. 100 loading cycles under drained conditions were applied on the gravel extracted underneath one of the tank foundations. The loading frequency was relatively slow, 120 min per cycle, to simulate the long-term tank loading operation. The accumulative residual settlement and soil stiffness vs. loading cycles were used to explain the settlement phenomenon of the tank.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Middle East has one of the largest numbers of oil storage facilities in the world. Tank farms are mostly located at ports along coastlines of the Arabian Gulf, where calcareous sand is prevailing, and flexible steel storage tanks having diameters up to 100 m and heights up to 30 m has been constructed.

Differential settlement, measured at adjacent points along the perimeter of the tank, is of the greatest concerns, as high settlement and/or high differential settlement beyond the acceptable limits affect the walls verticality and tank performance. To evaluate the tank performance after constructed, the tank was undergone a hydrostatic test, in which the tank is incrementally filled with water up to the highest pressure. The water is then emptied to achieve a permanent settlement. During the operation lifetime, the subsequent foundation settlements are assumingly inconsiderable hence ignored.

In this paper, we present a geotechnical investigation and assessment to understand the reasons and mechanism to cause the relatively large settlements observed in four oil fixed cover, flexible steel oil – storage tanks. The tank diameters are from 33 m to 40 m, and the tank height is 19 m, constructed in 2008 (Fig. 1). After more than 10 years of operation, the tanks experienced relatively large settlement. Tank settlement inspection as per API-653 [2] reported that the accumulative settlement has exceeded 50 mm (Fig. 2). The excessive settlement can be observed at various locations along the annular plate seating area. The annular plate itself was also deformed, hence the tanks were emptied, and remediation was required.

The recorded “permanent” settlement at eight monitoring points, evenly distributed along the perimeter of each tank, due to hydrostatic test conducted in 2008, were from 20 mm to 25 mm. This relatively low settlement resulted from the hydrostatic test was well confirmed by the results of our finite element (FE) model of the tank subjected to an incremental uniform static load of 200 kPa, which is higher than the peak pressure applied in the hydrostatic test. This indicates that the soils beneath the foundation were sufficient stiff. The predicted settlement, that could occur further during operational lifetime of the tanks due to cycles of compression and uplift and a long-term creep of foundation on sand [5, 6] as estimated and given in the foundation design report was less than 15 mm.

The causes of the excessive settlement were not known. We believe that it could be linked to the factual time dependent creep, which can be higher than the estimated value, and/or the accumulated cyclic settlement caused by cycles of loading and unloading during tank operation. Therefore, we undertook a geotechnical investigation including in-situ tests, Non-destructive geophysical survey, and advanced laboratory tests to verify the above hypothesis, to understand the mechanism of the settlement, and also to support the design of remediation works. Due to confidential reasons, the name and location of the tanks investigated cannot be disclosed.

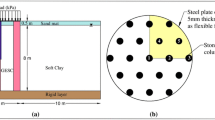

2 General Tank Foundation and Ground Condition

Figure 3 shows a tank foundation seated on dense crushed rock embankment over well compacted granular engineered fill with a total thickness up to 5.0 m. The tank shallow foundation was designed as per API Standard 650 [2]. Beneath the granular engineered fill is a layer of natural calcareous sand, with the thickness up to 10 m. The natural calcareous sand, underlain eventually by sedimentary rock, was compacted by mean of vibro-compaction or dynamic compactionFootnote 1.

We reassessed the sand density based on the available data obtained from CPT tests conducted previously and also the shear wave velocity measured using MASW technique in this study (presented below). The sand can be classified as medium dense to dense fine to coarse calcareous SAND, with loose/medium dense thin localities. Bedrock of extremely weak sandstone at the site is found at the depth of 15 m below the ground level (bgl). The ground water table at the site is at about 5 m (bgl) with an approximately seasonal fluctuation in range of ±0.5 m (Fig. 4).

3 Assessment in Situ Soil Density and Stiffness

Three trial pits with 2 m depth around the tank perimeter were excavated to assess the quality and compactness of engineered fill. At the bottom of trial pits, some in-situ tests i.e. in-situ density using sand replacement [7], manually operated dynamic penetration test [8], and dynamic plate loading test [9] were conducted. The measured in-situ dry density varies from 2.01 to 2.19 T/m3. The in-situ test results suggested that the engineered fill was very well compacted with the dry density from 2.01 to 2.19 T/m3 and the degree of compaction more than 95%–100%. Multichannel analysis of surface waves (MASW) was conducted to evaluate the stiffness of the foundation soils up to 28 m (bgl) as shown in Fig. 5.

4 Settlement Evaluation Using Laboratory Tests

4.1 Measurement of Creep for Calcareous Sand Using Triaxial Test

A representative sample of calcareous sand was collected and tested in triaxial cell to investigate the time depended creep. Triaxial tests were preferred selected over Oedometer tests due to the relatively larger in size (e.g. triaxial sample height is more than 8 time thicker than oedometer sample thickness). The sand was moistly tamped in a split mould in five equal layers to achieve a uniform specimen at 80% relative density, which represents the average in-situ relative density of the sand. The sample were saturated until Skempton’s B value was greater than 0.95.

Initially, the samples were isotopically consolidated at the overburden effective stress of 145 kPa, representing average depth of the sand layer. Then it was anisotropically consolidated to the deviator stress of 190 kPa as detailed in Table 1, to mimic the pressure applied during the hydrostatic test. The effective stress conditions were maintained constantly for a sufficient period of time i.e. 18 days and the vertical deformation of the specimen was monitored using an external LVDT.

From the trendline for the most linear part of the cure (Fig. 6), the derived creep rate (α) for the calcareous sand is 0.095% per logarithmic cycle. The total creep strain measured in laboratory after 18 days was approximately 0.19% (Fig. 3). The settlement was almost ceased after that as shown by the plateau at the end of the statement curve. This level of vertical strain induced will correspond to 19 mm settlement for a 10 m layer of sand in the field. This measured creep settlement was higher than the value estimated in design of 15 mm. It should be noted that the stress level of 190 kPa applied in triaxial cell is higher than the possible maximum oil pressure during operation (about 170 kPa). The results obtained from the creep test suggest that (i) creep of calcareous sand could contribute to the settlement of the tank under a constant load, however, (ii) creep may not be the major factor causing the tank large settlement.

4.2 Assessment of Cyclic Foundation Settlement

Triaxial tests in drained conditions were conducted to simulate the cyclic loading of both granular engineered fill and calcareous sand to study the deformation behaviour of the materials. The associated residual deformation from such cyclic loading is typically ignored in common designing practice. Similar to test procedure applied for the creep test above, the samples were prepared and anisotropically consolidated in triaxial cell to the deviator stress of 190 kPa to simulate the pressure applied during the hydrostatic test. The specimens were then unloaded to the tank deadload (Table 1) prior to the cyclic loading stage. A number of 100 cycles of loading and unloading were applied to the specimen in drained condition to mimic the processes of filling and emptying of oil tank during the last 10 years, with an average of one cycle per month. The peak-to-peak deviator stress amplitude applied was 170 kPa (Fig. 7), which is as same as the possible highest oil filling pressure. The loading frequency was sufficiently slow i.e. 0.00014 Hz or 120 min/cycle, allowing water to be drained freely without any EPWP.

During the cyclic load application, the strain gradually accumulated as shown in Fig. 7 and Fig. 8, and the soils became stiffer thanks to the effects of draining conditions. The residual strain accumulated vs. number of cycles were plotted in Fig. 7. It is observed that when the number of loading cycles exceeded 75 (for granular fill) and 95 cycles (for calcareous sand), the accumulated strains were almost constant, meaning that the settlement could be no longer taking place in the future.

The total accumulative cyclic vertical strain induced was about 0.2% for granular fill and 0.3% for sand (Fig. 8). These cyclic strains are equivalent to 10 mm settlement for 5.0 m thickness of granular fill, and 30 mm settlement for 10 m thickness of calcareous sand. The total permanent cyclic settlement therefore was up to 40 mm, which was significantly higher than the creep settlement under static load measured above. It should also be noted that the level of accumulated vertical strains illustrated in this study by no meant can be deemed as representatives for all calcareous sands in UAE. The accumulated settlement appeared to be terminated after a larger number of cycles for sand compared to granular fill. This can be attributed to the lower relative density and particle crushability of the calcareous sand.

5 Concluding Remarks and Recommendations

-

The process of filling and emptying tank during its operation caused the major excessive settlement with time. This was observed for both dense calcareous sand and very dense granular engineering fill.

-

For the studied tanks, it is likely that no further settlement could be taken place in the granular fill and in calcareous sand after 75 and 95 loading cycles, respectively, thanks to the stiffening effects in fully drained condition under cyclic load.

-

Creep under constant static load could partially contribute to the settlement but does not represent the actual loading mode of the tanks, and it underestimated the long-term settlement of the tank.

-

The creep rate of dense calcareous sand measured in the laboratory under effective stress of 190 kPa, was 0.095% per logarithmic time cycle, which exceeds the estimates made by empirical relations (e.g. [5, 6]) for 10 years period, whereas residual vertical strain resulted from cyclic loading and unloading is much higher.

-

Settlement monitoring results of a typical tank performance during operational service if available will be very valuable to establish the rate of time – dependent settlement and tank loading condition.

-

It is recommended to conduct specialist laboratory tests, in which sand relative density, and the in-situ stress history shall be considered, i.e. cyclic tests to determine the residual settlements caused by various loading modes and creep monitoring under a constant pressure. These cyclic settlement and creep measured shall be then appropriately considered in the design of oil-tanks foundation.

References

API Standard 653: Tank Inspection, Repair, Alteration, and Reconstruction, 3rd edn. American Petroleum Institute Washington DC (2003)

API Standard 650: Welded Tanks for Oil Storage, 12th edn. American Petroleum Institute Washington DC (2013)

Al-Homoud, A.S., Wehr, W.: Experience of vibrocompaction in calcareous sand of UAE. Geotech. Geol. Eng. 24, 757 (2006)

Kirsch, K., Kirsch, F.: Ground Improvement by Deep Vibratory Methods, 2nd edn. CRC Press (2019)

Burland, J.B., Burbidge, M.C.: Settlement of foundations on sand and gravel. Proc. Inst. Civil Eng. 1(78), 1325–1381 (1985)

Schmertmann, J.H.: Static cone to compute static settlement over sand. J. Soil Mech. Found. Div. ASCE 96(SM3), 1011–1043 (1970)

ASTM D1556/D1556M - 15e1: Standard Test Method for Density and Unit Weight of Soil in Place by Sand-Cone Method. ASTM, PA, USA (2018)

ASTM D6951/D6951M – 09: Standard Test Method for Use of the Dynamic Cone Penetrometer in Shallow Pavement Applications. ASTM, PA, USA (2015)

ASTM E2835 – 11: Standard Test Method for Measuring Deflections using a Portable Impulse Plate Load Test Device. ASTM, PA, USA (2015)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Sharif, E., Bui, M. (2022). Investigation of Long-Term Settlement of Flexible Steel Oil Storage Tanks on Calcareous Sand in UAE. In: Huynh, D.V.K., Tang, A.M., Doan, D.H., Watson, P. (eds) Proceedings of the 2nd Vietnam Symposium on Advances in Offshore Engineering. VSOE2021 2021. Lecture Notes in Civil Engineering, vol 208. Springer, Singapore. https://doi.org/10.1007/978-981-16-7735-9_12

Download citation

DOI: https://doi.org/10.1007/978-981-16-7735-9_12

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-7734-2

Online ISBN: 978-981-16-7735-9

eBook Packages: EngineeringEngineering (R0)