Abstract

Based on the convolution neural network (CNN) technology, and the use of video monitoring equipment, an intelligent safety monitoring system for nuclear power plant is designed and developed, to realize the continuous monitoring of regional fire situation and whether the personnel wearing safety helmet or not. This paper introduces the framework of the system, the principle of convolution neural network and the feature recognition strategy, and describes the process of system training data acquisition and model training in detail. The 6-month continuous measurement in nuclear power plant shows that this system is stable, accurate and timely, and can effectively improve the efficiency of field monitoring.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

At present, more than 30 countries in the world have nuclear power plants, and the nuclear power accounts for more than 15% of the total power generation. China has 47 operating nuclear power units, 15 nuclear power units under construction, and 18 nuclear fuel cycle facilities. The total number of nuclear power units ranks the second in the world, and the number of units under construction ranks the first in the world. Nuclear power has become an important part of China’s energy structure.

Safety is the most important basis of nuclear power development. According to the statistical result, more than 90% of all kinds of accidents in nuclear power plants are caused by unsafe state of objects and unsafe behaviors of people. And the highest proportion of unsafe behaviors is un-wearing safety helmet, which often leads to serious injury or death accidents. Among various accidents of nuclear power plant, the frequency of fire accidents is much higher than that of nuclear accidents. According to the statistical result of American Electric Power Research Institute, the frequency of nuclear power plant fires is about 0.14/ (plant year).

This paper proposes an intelligent safety monitoring system for nuclear power plant based on the convolution neural network technology and video monitoring equipment, to realize the continuous monitoring of regional fire situation and whether personnel wearing safety helmet or not, which can be helpful for the safe and stable operation of nuclear power plant.

2 System Framework Design

2.1 A Subsection Sample

Based on the image analysis and convolution neural network technology, using the monitoring equipment installed in the nuclear power plant and according to the background system analysis results, the intelligent safety monitoring system for nuclear power plant can monitor continuously the fire situation and the wearing of safety helmet in the monitoring area, so as to ensure the safe and stable operation of the nuclear power plant. The intelligent security monitoring system is mainly composed of front end equipment, video storage and forwarding equipment, alarm processing and displaying equipment and linkage control equipment. The specific system framework is shown in Fig. 1.

Front end equipment: including camera, video coding equipment, accessories and other equipment, mainly used for video signal acquisition.

Video storage and forwarding equipment: including network switch, video storage device and other equipment, used for video storage and forwarding.

Alarm processing and displaying equipment: including video analysis server, client server, display, alarm output and other equipment. The server connects with the video storage device through ethernet, extracts the video signal, analyzes the status of personnel wearing helmet and fire situation in the area in real time, then outputs the alarm signal.

Linkage controller: used to realize the whole alarm linkage control function of nuclear power plant through receiving the system alarm signal.

By using the convolutional neural network, and integrating the computer vision technology and deep learning technology, the system analyzes, locates, identifies and tracks the image sequence of the camera without human intervention. Then on this basis the data are analyzed to realize the timely acquisition, response and processing of specific conditions, and to monitor the status of personnel wearing helmet and fire situation in the area.

3 System Technical Principles

3.1 Convolution Neural Network

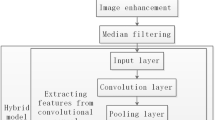

The convolution neural network is a multi-layer neural network using back-propagation algorithm for feature training, and its core is the convolution layer. Compared with other intelligent neural networks, it avoids the complex feature extraction process, reduces the complexity of network model, and is widely used in artificial intelligence [1], text processing, image recognition and other aspects. The basic convolution neural network is usually composed of convolution layer, pooling layer and fully connected layer.

Features extracted by the convolutional neural network can be divided into three levels: low level, middle level and high level. The low level layer is used for extracting low-level features; middle level layer is used for extracting middle-level features; and high-level layer is used for extracting high-level features [2]. The basic structure of the convolution neural network is shown in Fig. 2.

The convolution layer is used for extracting the features of input data. It contains multiple convolution kernels, and is the core of the convolutional neural network [3]. The input data is extracted and compressed repeatedly by convolution kernel, and the high-level feature of the data is finally obtained, which can be used for recognition, analysis and processing. Its mathematical expression is shown in formula (1).

In formula (1), \( f\left( x \right)\) is the activation function, \(\omega^{n,m}\) is the corresponding weight of convolution kernel, \(N\) and \(M\) are the size of convolution kernel, \(u\) is the upper output feature, and \(b\) is the offset value.

In the development process, the activation function \( f\left( x \right)\) uses the linear rectification unit (Rectified Linear Unit, ReLU), which is the nonlinear function, and its mathematical expression is shown in formula (2).

In formula (2): \({{\upvarphi }}\) is the output of ReLU, and \(\omega_{i}\) is the i-layer weighted, \(\alpha_{i}\) is i-layer input.

The system trains the convolutional neural network to extract target features through preprocessing image data set, and detects image features combining with DARKENT network model, and trains various image feature extraction under the support of multi GPU based on Yolo v3 [4].

After feature extraction in the convolution layer, the output feature maps will be transferred to pooling layer for feature selection and information filtering. The pooling process is shown in Fig. 3. The initial characteristic sample size is 20 × 20, and the sampling window size is 10 × 10. After repeated sampling, the final sampling is 2 × 2. The data dimension is reduced by down sampling, but the feature statistical attributes can still reflect the image characteristics, and can effectively avoid the problem of over fitting.

3.2 Realization of Feature Recognition

Based on the multiscale strategy, the DARKENT network structure uses three feature maps (13 × 13, 26 × 26, 52 × 52) to predict smoke, flame and helmet wearing. Three frames are predicted for each grid cell. The tensor dimension of the final output is \(N \times N \times \left[ {3 \times \left( {4 + 1 + 80} \right)} \right]\). Where \(N\) is the length and width of the feature map, 3 is the three predicted borders, 4 is the \(tx,ty,tw,th\), 1 is the confidence level of the predicted borders, and 80 is the number of categories. The 9 anchor sizes on coco dataset are (10 × 13), (16 × 30), (33 × 23), (30 × 61), (62 × 45), (59 × 119), (116 × 90), (156 × 198), (373 × 326).

There are three branch outputs predict all kinds of features in yolov3, the feature map of output is 13 × 13, 26 × 26, 52 × 52, and each feature graph uses three anchors.

-

(1)

The 13 × 13 feature map uses (116 × 90), (156 × 198), (373 × 326).

-

(2)

The 26 × 26 feature map uses (30 × 61), (62 × 45), (59 × 119).

-

(3)

The 52 × 52 feature map uses (10 × 13), (16 × 30) and (33 × 23).

In yolov3, there are six anchors, which are (10, 14), (23, 27), (37, 58), (81, 82), (135169), (344319). Finally, the yolov3-tiny has two branches for prediction, and the size of feature map is 13 × 13 and 26 × 26. Each feature map uses three anchors for prediction.

4 Data Acquisition and Model Training

The intelligent safety monitoring system mainly monitors the two status of fire and helmet wearing, so it is necessary to collect data samples for these two states respectively [5].

4.1 A Subsection Sample

According to the results of hazard analysis of nuclear power plant, different fire pictures are selected as data sets from three aspects of combustible type, scale size and smoke type. And the types of combustible materials can be divided into: gasoline, diesel oil, lubricating oil, natural gas (simulating hydrogen explosion), wooden pile, tire, cable electrical, etc. The scale size can be divided into: small size (first level sensitivity), medium size (second level sensitivity), large size (third level sensitivity). The smoke type can be divided into: thin smoke, white smoke, black smoke, smoke under low illumination, etc. 100,000 images including smoke or flame were collected, and 50,000 images of which were used as training data set together with 5,000 other interference images, and the remaining 50,000 images were used as test data set.

The images of all training data sets and test data sets are preprocessed, and then the convolution neural network is used for training and learning. Each image in the dataset contains the corresponding classification label. An example of a dataset sample is shown in Fig. 4.

4.2 Safety Helmet Wearing Data Set

Safety helmet can be divided into general safety helmet, electric safety helmet, antistatic helmet, cold helmet and helmet with goggles. Combined with the field application in nuclear power plant, the samples of universal safety helmet and safety helmet with goggles are mainly collected. Taking all kinds of safety helmets distributed in a nuclear power plant in recent five years as the basic samples, about 20,000 frames of monitoring video stream are intercepted, and about 30,000 pictures of safety helmet wearing are collected through the Internet to form the basic sample data set; then the samples are classified according to the size of the pictures and the complexity of the background [6]. In the basic sample data set, 30,000 images were randomly selected and 1,000 other hat interference images were collected as the training data set, and the remaining 20,000 images were used as the test data set. An example of a dataset sample is shown in Fig. 5.

4.3 Model Training

After the training data set is obtained, the data set is trained by deep learning network model, and the training process can be observed and analyzed by visual tools, which is the change trend of loss function in the training process [7], and 200,000 iterations have been carried out in the training process of various monitoring items. The training results are shown in Fig. 6.

In the safety helmet monitoring, when reaching 120,000 iterations, the loss tends to be stable. In the fire monitoring, after 160,000 iterations, the loss tends to be stable, and the training process basically meets the expectation. By increasing the number of GPUs, the parallel operation can greatly shorten the training time.

5 System Test

5.1 Simulation Test

The fire test set and helmet test set are used to test and analyze the system, and the detection accuracy of the two monitoring items is calculated [8].

In formula (2): \({\updelta }\) is the accuracy rate; \(\rho\) is the number of wrong inspection; \(\sigma\) is the number of missed inspection; \(N\) is the number of test samples.

Taking the intersection over union (IOU) of predicted bounding box and ground truth bounding box as the matching basis [9], the result matching method is shown in Table 1.

In the fire model test, 50000 samples are used as the test data set, and the detection accuracy rate reaches 92.73%; in the safety helmet model test, 20000 samples are used as the test data set, and the detection accuracy rate reaches 94.27%.

5.2 Field Test

The actual fire monitoring experiments under different environments are carried out, and the experimental data are shown in Table 2.

The fire monitoring field test status is shown in Fig. 7.

The safety helmet wearing monitoring experiments under different environments are carried out, and the experimental data are shown in Table 3.

The safety helmet wearing status field test status is shown in Fig. 8.

Through the simulation experiment and field measurement, the system has a good monitoring effect on far and near distance, indoor and outdoor flame, smoke and safety helmet under different conditions. The recognition accuracy and timeliness of the system fully meet the practical requirements. After testing, the intelligent safety monitoring system was deployed on site in a nuclear power plant and continuously monitored for 6 months. The system was stable in operation, and found once grade 0 fire accident and 3 times of un-wearing safety helmet. At the same time, it can effectively ensure the operation safety of nuclear power plant.

6 Conclusion

The intelligent safety monitoring system based on the convolution neural network can realize 24-h continuous monitoring of fire risk and the status of safety helmet wearing, by using existing camera equipment in the nuclear power plant. The field application results show that this system runs stably, monitors accurately and responds timely, which can improve the monitoring efficiency and be helpful for the stable operation of nuclear power plant. And this system can also be used in other special places, and provides new ideas for development of the other monitoring system.

References

Qi, Z.: The Research of Automatic Image Recognition Technology Based on Forest Fire Video Monitoring. School of Computer Science & Engineering, Chengdu (2017)

Jie, F.: Application and Research of Image Recognition Technology in the Monitoring System. North China Electric Power University, Baoding (2010)

Zhang, C.-Z., Gu, X.-T., Zhang, Y.-M.: Gesture recognition based on deep convolutional neural network. Radio Eng. 49(7), 587–591 (2019)

Shi, H., Chen, X.-Q., Yang, Y.: Safety helmet wearing detection method of improved YOLO v3. Comput. Eng. Appl. 55(11), 213–220 (2019)

Zhang, J., Sui, Y., Li, Q., et al.: Fire video image detection based on convolutional neural network. Appl. Electr. Tech. 45(4), 34–38, 44(2019)

Duan, S.-L., Gu, C.-L.: Research on the detection method based on the optimized BP neural network for the visual fire flame recognition. J. Changzhou Univ. (Nat. Sci. Edn.) 29(2), 65–70 (2017)

Koppe, G., Guloksuz, S., Reininghaus, U., et al.: Recurrent neural networks in mobile sampling and intervention. Schizophrenia Bull. 45(2), 272–276 (2019)

Yi, X., Bei-Bei, L., Wei, S.: Research on improved deep belief network classification algorithm. J. Front. Comput. Sci. Technol. 13(4), 596–607 (2019)

Zhang, R.-H., Tian, Z.-Z., Hu, J.-M., et al.: Target recognition in infrared imagery using convolutional neural network. In: International Conference on Artificial Intelligence Techniques and applications, pp. 170–178 (2016)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Bai, XT., Sun, DD., Zhang, XC., Sun, BC. (2021). Intelligent Safety Monitoring System for Nuclear Power Plant Based on the Convolution Neural Network. In: Xu, Y., Sun, Y., Liu, Y., Gao, F., Gu, P., Liu, Z. (eds) Nuclear Power Plants: Innovative Technologies for Instrumentation and Control Systems. SICPNPP 2020. Lecture Notes in Electrical Engineering, vol 779. Springer, Singapore. https://doi.org/10.1007/978-981-16-3456-7_70

Download citation

DOI: https://doi.org/10.1007/978-981-16-3456-7_70

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-3455-0

Online ISBN: 978-981-16-3456-7

eBook Packages: EnergyEnergy (R0)