Abstract

Large rotating machinery is very extensive and important equipment in nuclear power plant. It is necessary to carry out on-line vibration monitoring and effective fault diagnosis, which are also the basic application characteristics of intelligent nuclear power plant system. Support vector machine (SVM) can be applied to the fault diagnosis of large rotating machinery in nuclear power plant because it can achieve better classification effect with less training samples and no prior knowledge of fault classification. Therefore, firstly, an online vibration monitoring system for large rotating machinery in nuclear power plant is constructed to extract fault features. Then, according to the simulation data of vibration test-bed and the fault data of actual equipment operation, SVM algorithm is used to simulate. By comparing with the actual fault, the diagnosis result is better, which verifies the effectiveness of the method, and is intelligent for the software platform of vibration monitoring device Diagnostic function development provides support.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The essence of fault diagnosis is a pattern recognition problem. The problems of judging whether the standby operation state is normal or abnormal, and determining the fault form and the specific location of the fault can be attributed to the problem of pattern recognition, which is simply a classification problem [1]. At present, one of the difficulties in the realization of intelligent fault diagnosis of nuclear power plant equipment is the lack of typical fault data sample data, the other is the problem of fault feature knowledge discovery, which restrict the application of intelligent fault diagnosis in nuclear power plant. Some commonly used intelligent diagnosis methods, such as fuzzy diagnosis, expert system and artificial neural network, need a large number of fault data samples or prior knowledge, and it is difficult to guarantee the generalization performance of the methods when the training samples are limited. Support vector machine (SVM) can achieve ideal classification results in the case of few training samples, so it is a promising method for intelligent equipment fault diagnosis [2].

2 Multi Class Classification Algorithm Based on 2-support Vector Machine

At present, the multiclass classification algorithms of support vector machine (SVM) can be roughly divided into two types: firstly, based on the theory of the two types of support vector machines, the objective function is improved directly, the multi value classification model is reconstructed, and the k-class support vector machine is established. By optimizing the new objective function, the multiclass classification can be realized at one time. The objective function of this algorithm is complex, the number of variables is large, and the training speed and classification accuracy are not high. Multiclass classification is realized by combining a series of two class support vector machines, which are mostly used in fault diagnosis. This algorithm can be divided into the following branch algorithms:

2.1 One Against One Classification

In all k-class training samples, a SVM classifier is constructed between all two kinds of samples, so that a total of K (k − 1) / 2 two class classifiers can be constructed. When a new sample is classified, each classifier classifies its category and adds one vote to the corresponding category. The category with the most votes is the category to which the new sample belongs. Its disadvantage is that the number of training samples increases with the number of classes K, and the generalization error is unbounded. If a single classifier is not standardized, the whole k-class classifier will tend to over learn.

2.2 One Against All Classification

For the k-class problem, a total of K two-class SVM classifiers are constructed. The i-svm classifier uses the training samples in class I as a large class and all the other samples as another large class. In the classification, the new samples are classified into the one with the largest output. The disadvantages are that the number of training samples is large, the training is difficult, and the generalization error is unbounded [2].

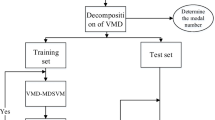

2.3 Linear Binary Tree Classifications

The k − 1 class of K class is regarded as a large class, and the remaining class is regarded as another large class. A two class SVM classifier is established for classification. Then in the k − 1 class, take (k − 1) − 1 class as a large class, and regard the remaining class as another large class, and establish another two class classifier for classification. And so on until the last two classes, as shown in the following figure. For k-class problems, a total of k − 1 SVM classifiers need to be constructed. This algorithm has fewer classifiers and fewer samples for repeated training, so the speed of training and classification can be improved [3] (Fig. 1).

In the test, the samples are input into the first classifier first. If the output is class 1, the sample class is determined as the fault category corresponding to classifier 1, and the test is finished. If not, the next classifier is used until the test sample belongs to the category. Compared with the one-to-one and one to many methods, this serial structure greatly reduces the number of repeated calculation of training samples, and eliminates the inseparable regions existing in one-to-one and one to many methods, and improves the efficiency of classification training.

2.4 Selection of Kernel Functions

The commonly used kernel functions include linear kernel function, Gaussian radial basis function, polynomial kernel function and exponential radial kernel function [4].

-

(1)

The kernel function in polynomial form, the corresponding SVM is a q-order polynomial classifier \(K\left( {x,x_{i} } \right) = \left[ {\left( {x^{T} x_{i} } \right) + 1} \right]^{q}\).

-

(2)

The kernel function in the form of radial basis function, the corresponding SVM is a radial basis function classifier \(K\left( {x,x_{i} } \right) = \exp \left\{ { - \frac{{\left\| {x - x_{i} } \right\|}}{{\sigma^{2} }}^{2} } \right\}\).

-

(3)

S kernel function, Then SVM realizes a two-layer perceptron neural network, only here, not only the weight of the network, but also the number of hidden layer nodes of the network is automatically determined by the algorithm [5] \(K\left( {x,x_{i} } \right) = \tanh (v(x^{T} x_{i} ) + c)\).

3 SVM Classification Training and Application

For the vibration fault of large-scale rotating machinery in nuclear power plant, the typical failure modes are unbalance, misalignment, rub impact, bearing pedestal looseness and rotor bending. With the application of intelligent diagnosis function, the platform can automatically realize the fault mode diagnosis output through modeling and classification training.

3.1 Vibration Test Device and Fault Feature Extraction

The data used are from ZT-3 rotor vibration simulation test-bed, which can effectively reproduce a variety of vibration phenomena produced by large-scale rotating machinery. By changing the rotor speed, shafting stiffness, mass imbalance, friction or impact conditions of bearings and the type of coupling, the running state of rotating equipment is simulated. The experimental platform is driven by DC shunt motor. The motor shaft directly drives the rotor through the coupling. The rated current of the motor is 2a and the maximum output power is 250 W. By adjusting the output voltage manually, the steeples speed regulation of the motor in the range of 0–10000 RPM can be realized, and the speed up can reach 800 RPM/min. The vibration measuring device used in the experiment is rvm1000 vibration monitoring system based on embedded application, which is self-developed by national heavy industry laboratory. The collector integrates signal conditioning and data acquisition, and is equipped with wireless signal transmission. The monitoring software realizes time and frequency domain analysis and application (Fig. 2).

Five kinds of faults, such as original unbalance, misalignment, rub impact, bearing pedestal looseness and rotor bending, are simulated in turn on the test-bed. The spectrum data of the five faults are calculated in the following eight frequency bands (0.01–0.39) F1, (0.4–0.49) F1, 0.5f1, (0.5–0.99) F1, F1, 2F1, 3f1, >3f1 (F1 is power frequency) [6], and the sum of the amplitudes of each spectrum segment is calculated and normalized The ratio of and is used as the characteristic parameter in frequency domain (Fig. 3).

3.2 Characteristic Value of Ascending and Descending Speed Trend

When the vibration fault occurs, the fault itself has its own occurrence and development process. Most of the conventional diagnosis methods only use the characteristics of the fault time; however, the approach of different vibration fault characteristics of the unit will lead to misjudgment [7]. On the other hand, there are considerable differences in the development process of different faults over time. For example, when the dynamic and static rub impact of the unit, the local temperature of the rotor will rise and bend, which will change the original rotor mass imbalance, resulting in vibration amplitude and 1-fold frequency phase fluctuation; the generation of steam induced vibration is often due to the change of unit load or thermal parameters, which leads to the rotor shaft being affected Under the action of tangential force, the instability will occur gradually, which will be reflected in the time-varying trend of the axis orbit. Practice has proved that the time trend information of characteristic quantity plays an important role in fault diagnosis.

When the vibration fault occurs, the fault itself has its own occurrence and development process. Most of the conventional diagnosis methods only use the characteristics of the fault time; however, the approach of different vibration fault characteristics of the unit will lead to misjudgment. On the other hand, there are considerable differences in the development process of different faults over time. For example, when the dynamic and static rub impact of the unit, the local temperature of the rotor will rise and bend, which will change the original rotor mass imbalance, resulting in vibration amplitude and 1-fold frequency phase fluctuation; the generation of steam induced vibration is often due to the change of unit load or thermal parameters, which leads to the rotor shaft being affected Under the action of tangential force, the instability will occur gradually, which will be reflected in the time-varying trend of the axis orbit. Practice has proved that the time trend information of characteristic quantity plays an important role in fault diagnosis (Tables 1 and 2).

3.3 Fault Sample Data Collection

The 18 dimensional symptom feature vector is constructed by combining the frequency domain feature with the ascending and descending speed trend feature. The original unbalance, misalignment, rub impact, bearing pedestal looseness and rotor bending five kinds of faults, 20 samples are taken from each fault, and 100 sample data are obtained from the test bench, of which 10 of each kind of fault constitute the training samples, and the other 10 are the test samples. Through the model training results, 10 groups of test sample data are tested, and the classification test results are obtained.

3.4 Fault Classification Test Based on SVM

Firstly, the samples are numbered, and the original unbalance, misalignment, rub impact, bearing pedestal looseness and rotor bending are numbered 1–5 in sequence. Proceed as follows.

Step 1: using the linear binary tree classification structure, establish four support vector machine second class classifiers. SVM1_ 2345, SVM2_ 345, SVM3_ 45, SVM4_ 5, respectively represents two types of classifiers, i.e. class 1 and 2345, class 2 and 345, class 3 and 45, and class 4 and 5.

Step 2: the radial basis function is selected from the kernel functions of the four classifiers, \(K\left( {x,x_{i} } \right) = \exp \{ - \gamma \left\| {x - x_{i} \left. {} \right\|} \right.^{2} \}\), and define γ = 0.5.

Step 3: Input the learning samples into each class II classifier according to the topological structure shown in the above figure for sample learning, and then classify the test samples. The classification results are shown in Table 3.

3.5 Test and Results

Through fault simulation, sample collection and feature extraction, fault samples for learning and testing are obtained. Based on the two class classification model, the application model of one to many classification algorithm is constructed. According to the training of sample data, five kinds of faults can be distinguished. At the same time, it shows that the number of SVM samples is small, but the fault recognition rate is high; at the same time, it can be misclassified according to the expectation The number of samples is used to reduce the value range of kernel function γ [8].

4 Conclusion

According to the vibration signal of the acquisition equipment, the spectrum is drawn, and the fault signal is analyzed from the frequency domain. After verification, SVM can classify the normal signal and fault signal successfully, and there are few wrong samples. Therefore, the application of support vector machine in intelligent fault diagnosis of nuclear power equipment has strong significance, and can be further developed and applied in the diagnosis software package.

References

Nello, C., John, S.T.: An Introduction to Support Vector Machines and Other Kernel—Based Learning Methods. Cambridge University Press, Cambridge (2000)

Vojislav, K.: Learning and Soft Computing-Support Vector Machines, Neural Networks and Fuzzy Logic Models. The MIT Press, Cambridge (2001)

Han, T., Jiang, D., Zhao, Q., et al.: Comparison of random forest, artificial neural networks and support vector machine for intelligent diagnosis of rotatingmachiery. Trans. Inst. Meas. Contr. 40(8), 2681–2693 (2018)

Hu, Q., He, Z., Zhang, Z., Zi, Y.: Fault diagnosis of rotating machinery based on improved wavelet package transform and SVMs ensemble. Mech. Syst. Signal Process. 21(2), 688–705 (2007)

Zheng, J., Pan, H., Cheng, J.: Rolling bearing fault detection and diagnosis based on composite multistate fuzzy entropy and ensemble support vector machines. Mech. Syst. Signal Process. 85, 746–759 (2017)

Sun, H.C., Huang, Y.C.: Support vector machine for vibration fault classification of steam turbine-generator sets. Procedia Eng. 24, 38–42 (2011)

Li, Y., Xu, M., Wei, Y., Huang, W.: A new rolling bearing fault diagnosis method based on multiscale permutation entropy and improved support vector machine based binary tree. Measurement 77, 80–94 (2016)

Ahmed, H., Nandi, A.K.: Condition Monitoring with Vibration Signals, vol. 276, pp. 16–22. Brunel University London, UK (2020)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Gu, K., Lv, ZH., Xu, JQ., Zhang-yu, Peng, HQ. (2021). Application Research on Intelligent Fault-Diagnosis of Nuclear Power Plant Equipment Based on Support Vector Machine. In: Xu, Y., Sun, Y., Liu, Y., Gao, F., Gu, P., Liu, Z. (eds) Nuclear Power Plants: Innovative Technologies for Instrumentation and Control Systems. SICPNPP 2020. Lecture Notes in Electrical Engineering, vol 779. Springer, Singapore. https://doi.org/10.1007/978-981-16-3456-7_65

Download citation

DOI: https://doi.org/10.1007/978-981-16-3456-7_65

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-3455-0

Online ISBN: 978-981-16-3456-7

eBook Packages: EnergyEnergy (R0)