Abstract

In this paper, a sinusoidal diffraction grating is being used for designing a Surface Plasmon Resonance (SPR) structure. The operation of the structure has been examined by using the wavelength-interrogation technique. We have considered the reflected amplitude and absorption dip of the SPR response curve as design parameters for designing this structure. On the performance comparison of gold (Au)-based over silver (Ag)-based SPR structure, although the Ag-based SPR structure gives better results. Due to the poor chemical stability of silver, a thin film of gold is used over it which enhances the performance of the proposed bimetallic SPR structure. This can be used in bioscience for observing the variation of refractive index in an analyte.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Nowadays, SPR-based biosensor attracts more attention. In 1902, when a polarized light was illuminated by wood onto a diffraction grating, Surface Plasmon Waves (SPW) were observed for the first time [1]. A coupling method for Surface Plasmon excitation based on attenuated total reflection (ATR) was proposed [2]. Kretschmann [3] reported the well-known method named as Kretschmann configuration of ATR coupling for SPR sensors. Later on, the grating-based SPR sensors came into the picture due to their easy designing, miniaturization, and integration features. In 1983, the first application of SPR-based biosensor in gas sensing received more attention from researchers [4]. Sensing a small variation in the refractive index(RI) provides a better way to characterize gases, chemical molecules, and living cells, showing advantages of real-time and label-free detection [5,6,7,8]. Because the SPW vector is greater than the free space vector, so to fulfill the requirement of high index profile for excitation of SPR, we need the high index optical structure like a prism [9, 10], patterned nanostructures like diffraction grating [11, 12] or optical fibers [13,14,15,16,17,18]. In the past two decades, study interests in SPRs have been emerging very fastly, and a large number of practical applications particularly on biosensing are in progress to develop, for example, affinity, kinetics of bio-molecular interaction, specificity, concentration of an analyte, etc. [19] (Fig. 1).

Reproduced from [20]

Concept of SPR sensors.

The phenomenon of an SPR is caused when a p-polarized light vector is guided into a smooth, rough, or grating thin metal surface like silver, gold, and aluminum, etc. (Fig. 2).

Reproduced from [21]

a Condition for SPR occurrence, b TM electromagnetic wave guided between metal and dielectric interface. c Evanescent field and SPP distribution.

The free electrons near such surface collectively oscillate, and an SPW propagates at metal–dielectric interface. At the resonant condition, most of the part of light is coupled, and only small amounts of light loss is observed; a sharply reflected signal is being observed in intensity profile. The required e-field components corresponding to SPW should be p-polarized light because the metal layer and oscillations of e-field vector both are the same in-plane.

These resonance characteristics of SPR spectra (sensogram) provide information about surface (metal-dielectric) interactions in a real-time monitoring system [22]. The SPR sensors can be categorized based on wavelength-interrogation, angle-interrogation, intensity-interrogation, phase-interrogation, and polarization-interrogation techniques [23].

For the evaluation of SPR sensor performance, metal’s dielectric constant plays a vital role. Here, the performance of gold (Au) and silver (Ag)-based SPR structure was compared and found that silver-based SPR structure has better performance over the gold-based structure. In the end, to eliminate oxidation problem that arose in silver-based structure, a thin gold film is layered on its surface.

2 Mathematical Modeling

The condition of SPR condition occurs only at the boundary of two different mediums having opposite dielectric constants in nature [24]. A simple SPR contains a metal layer and has a permittivity of \(\epsilon_{{{\text{metal}}}} = \epsilon_{{{\text{metal}}}}^{\prime } + ~{\text{i}}\epsilon_{{{\text{metal}}}}^{\prime }\) and a dielectric layer with a permittivity \(\epsilon _{{{\text{diel}}}} = \epsilon _{{{\text{diel}}}}^{\prime } + {\text{~i}}\epsilon _{{{\text{diel}}}}^{\prime }\) [8]. SPW has a property of an evanescent wave containing maximum magnetic field intensity at the metal–dielectric interface and decaying into both the medium [6]. SPW is a transverse-magnetic (TM) wave in nature, guided between metal and dielectric interface [25]. The Surface Plasmon’s Wave vector \(\left( {K_{{{\text{Sp}}}} } \right)\) can be expressed for the metal–dielectric interface as

where dielectric constant for metal is \(\epsilon _{{{\text{metal}}}}\) and for the dielectric layer is given by \(\epsilon _{{{\text{diel}}}}\). The incident light vector is generally less than SPW vector, which is defined as \(~k_{\alpha } = ~\frac{{2\pi }}{\lambda }n_{x} \sin \theta _{{x~}}\)(Refractive Index of an analyte is \(n_{x}\) and the angle in the analyte is \(~\theta _{x}\)). In the coupling mechanism of grating, the diffracted light beam vector (\(k_{\beta }\)) is the sum of \(~k_{\alpha }\) and the grating wave vector [7, 26].

where diffraction order \(\gamma\) is an integer number and \(P\) is grating constant. So, now SPR excitation condition can be expressed as \(k_{\beta } = ~~k_{{{\text{sp}}}}\), which is written as

Here, \(\epsilon _{{{\text{diel}}}}\) is replaced by \(n_{x}^{2}\), the sign ‘ ± ’ shows the propagation of Surface Plasmon along the positive or negative direction.

Silver and gold are preferably used metals for the designing of SPR sensors since they exhibit a narrow resonance curve [27]. Based on these two metals, SPR structure’s performance is analyzed. Lorentz–Drude equation [28] is used to calculate the value of \(\epsilon _{{{\text{metal}}}}\).

where \(~\omega = ~\frac{{2\pi c}}{\lambda }\) and \(\varphi _{P} = ~\surd f_{0} \omega _{P}\) is the plasma frequency, \(f_{0}\) is the oscillator strength, and \(\Gamma _{0}\) is the damping constant. The values of \(f_{0} ,~\omega _{P} ,~\) and \({{\Gamma }}_{0}\) are calculated from [29, 30].

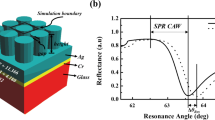

3 Designing and Simulation

A schematic for designing the proposed SPR structure using sinusoidal grating is shown in Fig. 3. Grating thickness (g), constant/period (p), and substrate thickness (t) are being considered as constructor parameters for designing the proposed SPR structure. The wavelength-interrogation-based performance of SPR sensor can be calculated by resonance wavelength shift and absorption dip of reflected signal in the SPR response spectra. The amplitude of reflected signal and resonance wavelength shifts and must be significantly large for observing a distinctive and high precision signal.

Figure 4a states the reflection curve of silver (Ag)-based SPR structure for grating constants p1 = 800 nm and p2 = 1000 nm. The other parametric values of the structure are grating thickness (g) = 50 nm, substrate thickness (t) = 40 nm. Here, the wavelength of 633 nm is being used as a guiding light signal. In Fig. 4a, we observed that the grating period/constant (p) increases from 800 to 1000 nm, and the resonance wavelength’s amplitude decreases. So, we selected the grating constant p = 800 nm as an optimal value. It was observed that as the grating constant was increased, the reflectance dips of the SPR response curve also rose. For better performance of SPR structure, we need a larger reflectance dip of the SPR response curve. Similarly, Fig. 4b displays the reflection curve of silver (Ag)-based SPR structure for grating thicknesses g1 = 50 nm and g2 = 100 nm. It is clear that at 50 nm grating thickness SPR, we got the smallest SPR dip along with the smallest reflected amplitude at g = 30 nm. But when g = 100 nm, the SPR dip observed was wider. Here, it is clear that for optimal performance, the value of grating thickness should lie between 30 and 100 nm. So, when the grating thickness (g) is 50 nm, the reflected amplitude is the highest, and the SPR dip is also very small

This is the condition, where the maximum light of incident wave is being coupled. Therefore, based on the above consideration, we selected the grating thickness (g) = 50 nm as optimal value.

Figure 5 illustrates the reflection curve of silver (Ag)-based SPR structure for grating substrate thickness t1 = 40 nm and t2 = 80 nm. The light is launched onto the grating surface vertically. By considering the substrate thickness (t) below 40 nm, the reflected amplitude observed was small as compared to the 40 nm thickness. Similarly, on increasing the substrate thickness beyond the 40 nm, there was no variation observed in reflected amplitudes of the SPR dips. Hence, the substrate thickness (t) = 40 nm provides better performance for proposed structure

Figure 6a states the reflection curve of gold (Au)-based SPR structure for grating constants p1 = 800 nm and p2 = 1000 nm. The parametric values of the structure are the same as a silver-based sensor, grating thickness (g) = 50 nm, and substrate thickness (t) = 40 nm. As the grating period/constant was increased from 800 to 1000 nm, the resonance wavelength decreased. It was observed that as the grating constant was increased, the reflectance dips of the SPR response curve also rose. Since we needed a larger reflectance amplitude, so we selected grating constant (p) = 800 nm as optimal value. Figure 6b displays the simulated reflection spectra of gold (Au)-based SPR structure for grating thicknesses g1 = 50 nm and g2 = 100 nm. It was observed that below 50 nm and on and beyond 100 nm grating thickness, the SPR response curve did not meet the requirement. At grating thickness (g) = 50 nm, the maximum incident light coupled with SPW

Figure 7 illustrates the reflection curve of gold (Au)-based SPR structure for grating substrate thickness t1 = 40 nm and t2 = 80 nm. The best performance of Au-based structure was observed at substrate thickness (t) = 40 nm. Here, we observed that the gold-based structure has a wider resonance dip than a silver-based structure

But we require a sharp resonance dip as per the requirement of a high-performance SPR sensor. So, we suggested a bimetallic gold (Au)–silver (Ag)-based structure and simulated under the same parametric values.

The wavelength SPR curves of the Ag-based sensor and Au-based sensor are illustrated corresponding in Fig. 8a, b. It clearly witnessed that as the RI of the analyte \(n_{a}\) increases, the reflectance dips move gradually to the leftward. It can be evidenced that the reflectance dip value of gold-based sensor analogous to the resonance wavelength is higher than that of silver-based sensor. Since at resonant wavelength, silver offers the lower reflectance dip compared with gold, so we consider that silver-based sensor exhibits superior resonance performance. We got the sensitivities of 890.26 nm/RIU for silver-based and 646.74 nm/RIU for gold-based sensor. It clearly states that the silver-based sensor has larger sensitivity than gold-based sensor. But, there is problem associate with silver metal, i.e., oxidation. This kind of problem decreases the durability and reliability of such SPR structure. That’s why, a bimetallic gold (Au)–silver (Ag)-based structure is suggested and simulated under the same parametric values. In designing perspective, a bimetallic structure is construct with an Ag-layer of thickness 47 nm and an Au- layer (as a protective layer) of thickness 3 nm over it, which practically enhances the durability of this SPR sensor.

The SPR curve for bimetallic-based sensor illustrates in Fig. 9. The bimetallic SPR curve is almost similar to the Ag-based SPR structure as depicted in Fig. 8a. The sensitivity of bimetallic SPR sensor is 842.28 nm/RIU. This value is small to some extent that of Ag-based sensor. Results show that there is no significant difference in the sensitivity of the silver-based SPR structure compared to the bimetal SPR structure. Both sensitivities values are quite similar.

Here the proposed bimetallic SPR structure is better in reliability point of view as compared to silver SPR structure. Here we observed minimum reflectivity of proposed SPR structure that indicates that maximum light is being coupled and also enhances the efficiency of SPR structure.

4 Conclusion

A practical simulation of a SPR-based sensor is done in this research work to witness the impact of silver and gold thin metal’s film on the performance parameters of the proposed structure. The investigation was performed using a reflectivity graph which provide the information about the shift in Plasmon dip of coupled optical signal at a particular angle of incidence. Subsequently, a numerical investigation was performed that reflected the influence of structural parameters on the performance analysis of proposed SPR biosensor. The effect of sinusoidal grating on the output of the proposed SPR was assessed by varying the grating thickness, grating constant, and thickness of the substrates. For optimized values of grating’s design parameters, the shift of the Plasmon wavelength was determined. The main feature of this SPR biosensor is the use of sinusoidal bimetallic (gold–silver) grating to improve the quality of the SPR signals. The RI dynamic range of this sensor ranges from 1.31 to 1.33 and has the highest sensitivity (842.28 nm/RIU). We have ensured minimum possible reflectivity with maximum sensitivity in this proposed biosensor.

References

Jamil NA, Menon PS, Said FA, Tarumaraja KA, Mei GS, Majlis BY (2017) Proc IEEE Reg Symp Micro Nanoelectron RSM 2017:112–115

Wood RW (1902) On a remarkable case of uneven distribution of light in a diffraction grating spectrum. Lond Edinb Dublin Philos Mag J Sci 4:396–402

Otto A (1968) Excitation of nonradiative surface plasma waves in silver by the method of frustrated total reflection. Zeitschrift für Physik A Hadrons and Nuclei 216:398–410

Kretschmann E (1996) Determination of optical constants of metals by excitation of surface plasmon sensing. Sens Actuators B Chem 35:212

Liedberg B, Nylander C, Lunström I (1983) Surface plasmon resonance for gas detection and biosensing. Sens Actuators 4:299–304

Homola J, Yee SS, Gauglitz G (1994) surface plasmon resonance sensors: review. Sens Actuators B 54:3–15

Wijaya E, Lenaerts C, Maricot S, Hastanin J, Habraken S, Vilcot JP, Boukherroub R, Szunerits S (2011) Surface plasmon resonance-based biosensors: from the development of different SPR structures to novel surface functionalization strategies. Curr Opin Solid State Mater Sci 15:208–224

Homola J (2008) Surface plasmon resonance sensors for detection of chemical and biological species. Chem Rev 108:462–493

Tong L, Wei H, Zhang S, Xu H (2014) Recent advances in plasmonic sensors. Sensors 14:7959–7973

Kretschmann E, Raether H (1968) Radiative decay of non-radiative surface plasmons excited by light. Z Naturforsch 23A:2135–2136

Otto A (1968) Excitation of nonradiative surface plasma waves in silver by the method of frustrated total reflection. Z Phys A Hadron Nuclei 216:398–410

Cullen DC, Brown RG, Lowe CR (1987) Detection of immuno-complex formation via surface plasmon resonance on gold-coated diffraction gratings. Biosensors 3:211–225

Jory MJ, Vukusic PS, Sambles JR Development of a prototype gas sensor using surface plasmon resonance on gratings. Sens. Actuators B Chem

Bhatia P, Gupta BD (2011) Surface-plasmon-resonance-based fiber-optic refractive index sensor: sensitivity enhancement. Appl Opt 50:2032–2036

Bhatia P, Gupta BD (2013) Surface plasmon resonance based fiber optic refractive index sensor utilizing silicon layer: effect of doping. Opt Commun 286:171–175

Singh S, Mishra SK, Gupta BD (2013) Sensitivity enhancement of a surface plasmon resonance-based fiber optic refractive index sensor utilizing an additional layer of oxides. Sens Actuators A Phys 193:136–140

Tabassum R, Gupta BD (2015) Performance analysis of bimetallic layer with zinc oxide for SPR-based fiber optic sensor. J Lightw Technol 33:4565–4571

Tabassum R, Gupta BD (2017) Influence of oxide overlayer on the performance of a fiber optic SPR sensor with Al/Cu layers. IEEE J Sel Top Quantum Electron 23:81–88

Usha SP, Gupta BD (2017) Performance analysis of zinc oxide-implemented lossy mode resonance-based optical fiber refractive index sensor utilizing thin-film/nanostructure. Appl Opt 56:5716–5725

Homola J, M Piliarik (2006) Surface plasmon resonance (SPR) sensors. Ser Chem Sens Biosens 4:45–67

Reports on progress in physics. IOPscience 75:036501 (2012)

Liedberg B, Lundstrom I, Stenberg E (1993) Principles of biosensing with an extended coupling matrix and surface plasmon resonance. Sens Actuators B Chem 11(1–3):63–72

Homola J (2003) Anal Bioanal Chem 377:528

Schasfoort RB (2017) Handbook of surface plasmon resonance. Royal Society of Chemistry, Cambridge, UK

Homola J, Koudela I et al (1999) Surface plasmon resonance sensors based on diffraction gratings and prism couplers: sensitivity comparison. Sens Actuators B 54:16–24

Homola J (1997) On the sensitivity of surface plasmon resonance sensors with spectral interrogation. Sens Actuators B Chem 41:207–211

Byun KM, Kim SJ et al (2007) Grating-coupled transmission-type surface plasmon resonance sensors based on dielectric and metallic gratings. Appl Opt 46:5703–5708

Ung B, Sheng Y (2007) Interference of surface waves in a metallic nanoslit. Opt Expr 15:1182–1190

Rakić AD, Djurišić AB, Elazar JM, Majewski ML (1998) Optical properties of metallic films for vertical-cavity optoelectronic devices. Appl Opt 37:5271–5283

Ung B, Sheng Y (2007) Interference of surface waves in a metallic nanoslit. Opt Express 15:1182–1190

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Jangid, M., Saharia, A., Nitesh Mudgal, Singh, S.V., Singh, G. (2022). Performance Enhancement of Surface Plasmon Resonance (SPR) Structure Using a Sinusoidal Diffraction Grating. In: Tiwari, M., Maddila, R.K., Garg, A.K., Kumar, A., Yupapin, P. (eds) Optical and Wireless Technologies. Lecture Notes in Electrical Engineering, vol 771. Springer, Singapore. https://doi.org/10.1007/978-981-16-2818-4_13

Download citation

DOI: https://doi.org/10.1007/978-981-16-2818-4_13

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-2817-7

Online ISBN: 978-981-16-2818-4

eBook Packages: EngineeringEngineering (R0)