Abstract

The electrocardiogram signals of humans heart are usually estimated using wet silver/silver chloride (Ag/AgCl) electrodes. These wet electrodes cannot be reused and require extra skin preparation (application of conductive gel) which may cause skin aggravation in long run, and also during measurement of the electrocardiogram signals, it enhances a common-mode noise due to loose contact with skin. Therefore, this paper proposes the design, fabrication and testing of dry electrodes for recording the ECG signals which overcomes the problems associated with wet Ag/AgCl electrodes. These electrodes are adaptable, biocompatible, reusable and conduction gel-free. Carbon paste was coated on a flexible circular polymer substrate of different diameters (E1-20 mm, E2-16 mm, E3-1 mm) to prepare dry Electrocardiogram electrodes. The conducting performance of E1, E2, E3 and Ag/AgCl electrodes was analysed by measuring the skin–electrode impedance and observed that the skin impedance is inversely proportion to the electrodes area. The skin–electrode impedance results concluded that the electrodes with the largest diameter exhibited better performance in terms of the conductivity for acquisition of quality electrocardiogram signals. The skin impedance of dry electrodes (E1, E2, E3) and Ag/AgCl electrodes was measured and compared at a common frequency of 10 Hz. The raw electrocardiogram signal detected should be pre-processed through various signal processing units to overcome the high level noise. The aim of this work is to design dry electrodes and also pre-process the signals recorded by the dry electrocardiogram electrodes which can be further used for portable applications. Also, this paper presents the working of dry electrodes and its comparison with wet Ag/AgCl electrodes for medical and research purposes.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The rapid growth of cardiovascular diseases (CVDs), including diabetes mellitus, hypertension, myocardial infarction, can lead to the death of human life. According to the WHO, CVDs are the number one cause of death globally and annually more people die from CVDs than any other disease. In 2016, around 17.9 million people died from CVDs which represent 31% of all global deaths. Out of these, heart attack is the major cause for the deaths. It is observed that these deaths take place mostly in developing and underdeveloping countries [1]. Thus, a consistent monitoring electrocardiography of patients is required. ECG is a device which measures the electrical activity of the human’s heart over a period of time. The originator of the electric signal in the human’s heart is the sinus node, and the signal generated by the sinus node is responsible for the contraction of cardiac muscles. These electrical pulses are detected by electrode either by an invasive manner or non-invasive manner, and the graph recorded in the ECG is represented as a series of electric waves, with specific structures and period that repeat in each cardiac cycle such as the P, T and the QRS complex wave as shown in Fig. 1. These waves represent to the various successions of cardiovascular muscle exercises, which make it conceivable to assess the cardiac state and can be utilized to measure the rate and rhythm of heartbeats, the size and position of the heart chambers, the presence of any damage to the heart's muscle cells, the effect of heart drugs and the capacity of artificial pacemakers [2].

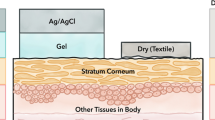

The conventional ECG sensor is classified into two types—implantable-type ECG sensor and patch-type ECG sensor. In the case of the implantable-type ECG sensor, medical procedure is required to place the electrode in the heart for ECG measurements. Consequently, it is pricey and intrusive while in patch-type ECG sensor at least three electrodes should be fixed to a human body to record the ECG signal. In this strategy, two electrodes are utilized for detecting the voltage difference on the body surface and the third electrode is utilized as a ground electrode [3–5]. Usually ECG signals are commonly obtained through wet Ag/AgCl electrodes, which are accessible at low cost and can give high-calibre and stable signals. The coupling with the skin is upheld by an ionic component for instance solid or fluid hydrogel in order to improve the quality of the contact, thereby diminishing the skin impedance. This sort of electrodes cannot be used for long-term monitoring as they can cause skin irritations and also spreading the conductive gel may provoke a short circuit when electrodes are put near to each other. Therefore, alternative dry flexible ECG electrodes are required for ECG recording [6, 7].

Dry electrodes are the option in contrast to the ordinary Ag/AgCl anode [8, 9]. Various types of dry electrodes are available, viz. capacitive electrodes, small spike electrodes, conductive polymer electrodes. The capacitive electrodes are susceptible to motion artefacts [10]. Furthermore, these kinds of electrodes are complex and its volume is bigger than that of other types of electrodes. The spike electrodes with spikes array could penetrate through the external skin layer. However, this type of electrodes may cause uneasiness and skin injury to users. While dry carbon electrodes are flexible and comfortable as well as harmless to the skin [11–16], this paper presents the novel carbon-based textile and dry flexible electrodes for measuring the ECG signal. The design and fabrication of dry electrodes are discussed in Section two followed by its characterization. The working principle and ECG signal processing are discussed in Sections four and five, respectively. The circuit simulation and circuit hardware are discussed in Sections six and seven, respectively. Similarly, the results and conclusion are discussed in consecutive sections.

2 Design and Fabrication

2.1 Design

This section describes methodology for the design of carbon-coated ECG electrodes. The material selection, design of ECG electrodes and also the steps for fabricating the electrodes are discussed.

2.1.1 Materials

Kapton is a polyimide film introduced by DuPont in the late 1960. It remains stable across a wide variety of temperature from -269 to + 400 °C. [17, 18]. Kapton tape of thickness 120 μm is used to prepare the mask file. Carbon is used as the conducting material and is coated on a cotton fabric. Although graphene acts as a good conducting material than carbon, in this work carbon is used as the sensing material as it is cheap, compatible and easily available. The cotton fabric has good adhesive properties than the Kapton substrate. It gives protection against short circuit caused from the body sweats and electrodes. Therefore, the cotton fabric has been chosen for carbon coating [19]. Figure 2 shows the coating of carbon material on both cotton and Kapton substrate.

2.1.2 AutoCAD-2D Design

The 2D structure for the mask file is designed using AutoCAD [20]. Mask files of various diameters (E1-20, E2-16, E3-12) mm are designed as shown in Fig. 3 [21].

2.2 Fabrication

2.2.1 Preparation of Mask File

The Kapton tape which is used as the mask file is cut into different sizes of diameters using a laser cutter [22]. After cutting a Kapton tape, the mask file is washed using an Isopropanol solution to remove the dust particles attached. The mask is kept in the oven for 1 h at a temperature of 150 °C. The final mask of different diameters is as shown in Fig. 4. The cotton fabric substrates are also cut in round shape with different diameters of (20, 16, 12) mm for coating carbon on it.

2.2.2 Coating of Conducting Materials

Various methodologies are available for the screen printing. Commercially ECG electrodes can be produced by injecting ink of carbon on a substrate using a screen printing machine but in this work for the prototype model, the carbon is coated manually on the substrate with the help of a mask file. The thickness of carbon ink coated on a substrate is 120 μm. This type of coating carbon layer on the substrate is adopted from a concept of pattern casting. In casting, a pattern is a replica of the object to be cast, which is utilised to set up the hole into which molten material will be poured during the casting process. Similarly, the mask here is similar to the pattern required and the thick paste of carbon is applied on a cavity created by the mask [23].

3 Characterization of Skin–Electrode Impedance

The characterization of the fabricated dry ECG electrodes and commercial wet Ag/AgCl electrodes was performed to compare their performance. The skin–electrode impedance should be as low as possible to minimize the common-mode rejection noise for the better quality of the ECG signal. The skin–electrode impedance can be modelled as a parallel combination of the RC circuit where R1 and C1 represent the impedance and the capacitance formed due to the skin and electrode coupling. R2 represents the resistance of the conducting gel. E represents the potential applied between the two electrodes [24]. The equivalent circuit diagram of the skin–electrode impedance for dry and wet electrodes is shown in Fig. 5.

The total skin impedance is given as

For dry ECG electrode,

For wet Ag/AgCl electrode,

where

From Eq. (1), the total impedance is the function of frequency. Thus, the measurement of impedance was performed in the frequency range from 1 to 700 Hz. An electrode is placed on a human’s wrist with the help of a rubber band at a nearby distance (<2 cm) from the other electrode as shown in Fig. 6. A potential of 4v was applied to the skin through two electrodes in the frequency range from 1 to 700 Hz. The skin impedance frequency response curves for the dry ECG electrodes (E1, E2, E3) and the Ag/AgCl electrodes are shown in Fig. 7.

From Fig. 7, it is seen that the skin–electrode impedance is dependent on the size of electrodes and it can be concluded that the skin–electrode impedance is inversely proportional to the diameter of the electrodes [20]. For instance, the skin impedance of dry electrodes having diameters of 12 mm, 16 mm, 20 mm is 585 kΩ, 571 kΩ and 565 kΩ, respectively, at a common frequency of 10 Hz. The results also concluded that skin impedance of carbon-coated dry electrodes (E1, E2, E3) were higher than that of wet Ag/AgCl electrodes at a frequency of 10 Hz. This is due to the fact that wet Ag/AgCl electrodes contain electrolyte gel. Though the fabricated dry electrodes have high skin impedance than wet electrodes, they are in well range of impedance value to measure ECG signal.

4 Working Principle

ECG electrodes record the electrical activity generated by the heart’s muscle contraction and relaxation which propagate in/as pulsating electrical waves through the skin. The contraction and relaxation of cardiac muscles are due to electrical signals received from the sinus node. Electrodes are suitably placed on a body, thereby the small electric signal which is generated by the polarization, and depolarization of the heart’s muscle can be detected. The voltage change is sensed by measuring the current change across two electrodes positive and negative [25]. A poor choice of electrode material and improper location of electrodes could lead to unnecessary polarization. The potential caused by the polarization could cause noise which weakens the signal.

The requirements for the experimental setup are as follows. It consists of a power supply, a digital oscilloscope(display screen), printed dry ECG electrodes, and an ECG data acquisition electronic circuit as shown in Fig. 8. The experiment set-up for estimations of ECG were led at room temperature. Three dry electrodes, with same radius, were placed on the body of a healthy volunteer at three different positions: left forearm, right forearm and right leg, without removing the hair and with no skin preparation as shown in Fig. 9 [26]. The experiment was carried out for different diameters of electrodes, and their performances were compared. The output from the ECG acquisition circuit was connected with an Arduino board for imaging and recording the ECG signal on the laptop screen.

5 ECG Signal Processing

The ECG signal detected by the electrodes was very weak electrical signals, and its amplitude was varying from 0.03 to 4 mv. These signals are usually affected by noise, such as low-frequency noise, muscle noise and electromagnetic noise. The signal sensed by the electrodes is within the range of 0.05 to 200 Hz signals [20, 27]. Due to the high impedance of the human body, the impedance of the ECG signal can reach several Ω to KΩ. So, the main challenge in signal processing of the ECG signal is to eliminate the noises and amplify the small magnitude ECG signal to properly stabilize ECG signals [25, 28]. The complete block diagram for the signal processing of the ECG signal is shown in Fig. 10.

For the acquisition of the ECG signal, the electrical signal obtained from the human body passes through various filtering and amplifying circuits. Proper care must be taken while designing the data acquisition circuit to suppress interference. The different circuits involved in the acquisition of ECG data and their design are shown below.

5.1 Design of Instrumentation Amplifier

The instrumentation amplifier is the main part of the ECG signal processing circuit. It has very high common-mode rejection ratios (CMRR) of the order of 100 dB and high input impedance which is required for the acquisition of electrical signals from the human body [29]. The AD620AN instrumentation amplifier which is used in this project is low price, low power consumption and easily available amplifier. While designing this amplifier, the gain can be adjusted by varying the external resistor. The gain of this amplifier is [30]

5.2 Design of High-Pass and Low-Pass filter

In order to eliminate the DC offset present in the output signal obtained from the instrumentation amplifier, the signal is passed through the high-pass filter. The operation amplifier LM324AN is used to design the second-order high-pass filter for this task which eliminates the low-frequency interference. It is designed with a cut-off frequency of 2 Hz. The second-order low-pass filter is also designed using LM324AN to filter high-frequency noise. In this project, the low-pass filter is designed to filter the frequency above 200 Hz. The cut-off frequency for second-order low-pass and high-pass filter is given as [31]:

if \(R_{1} = R_{2 } = R\,{\text{and}}\,C_{1} = C_{2} = C\), then

5.3 Design of Notch Filter

The interference caused by the supply frequency of 50 Hz in the ECG acquisition process is eliminated by a notch filter. This interference is mainly caused by the power supply in the form of a differential mode signal. The frequency designed for this filter is

7 Circuit Hardware

All the electronic components were assembled on a zero PCB board as per the circuit design. The ECG acquisition circuit assembly is shown in Fig. 12. All the filters and amplification circuits were assembled step by step, and testing of each stage was carried out by testing the output signal for each constructed stage. The input signal from the signal generator was fed to each stage, and their corresponding waveform is observed on an oscilloscope. The two 9 V batteries were used for the ±9 V dual supply for the operation while its common terminal provides the ground for the circuit [32].

8 Result and Discussion

Finally, the ECG signals were measured using both the commercial electrodes and proposed ECG electrodes. For the commercially available electrodes, the conducting gel was used to decrease the impedance between the skin and the electrodes. The ECG was measured for both conditions when the body was in motion and in rest. The ECG recording when the body was in motion is shown in Fig. 13. This ECG signal contains lots of interference due to the motion of arms and is difficult to identify the P, Q, R, S, T waves.

The working of wet electrodes and dry electrodes was compared since the ECG signal obtained from both types of electrodes contains visible P, Q, R, S, T waves. Therefore, they were easily compared and analysed by calculating their respective peak and amplitude with respect to time [33]. Figure 14a shows the ECG obtained from the wet Ag/AgCl electrode, and Fig. 14b shows ECG obtained from a carbon-coated dry electrode when the body is at rest.

MATLAB is useful and handy on ECG signal processing that everyone can easily monitor his/her heart condition. Normally, the ECG signal procurement equipment can eliminate the power line interference. However, the baseline wandering and other wideband noises cannot be easy to suppress by hardware, while on the other hand, the MATLAB software is more powerful for suppressing all type of band noises and feasible for offline ECG signal processing. After recording the ECG signals, the recorded signal was processed through MATLAB processing software. The raw ECG signal extracted from the human body is subjected to various filtering stages like baseline wander removal, wavelet decomposition, noise cancellation (filtering), bandpass filtering, removal of a linear trend to remove unwanted signals. The MATLAB signal processing is based on software coding rather than using the hardware components. All processing units are designed mathematically, and working of each stage was analysed. Figure 15 shows the entire signal processing stages for recording ECG signal of the patient in MATLAB.

9 Conclusion

In this work, a detailed process for developing carbon-based textile dry and flexible electrodes for recording ECG signals is presented in a simple way. The fabricated dry ECG electrodes are wearable, adaptable, biocompatible, reusable and gel-free. The proposed ECG measuring device is eco-friendly and easily handled by common consumers without any medical knowledge. The electrical characteristics of fabricated dry electrodes (E1, E2, E3) were compared with wet Ag/AgCl electrodes by measuring skin–electrode impedance and found that the skin impedance of dry electrodes having a diameter of 12 mm, 16 mm, 20 mm are 585 kΩ, 571 kΩ and 565 kΩ, respectively, at a common frequency of 10 Hz. This experiment strongly proves that the electrodes with the largest diameter exhibit better performance in terms of signal intensity. This can be attributed to the fact that the skin–electrode impedance is inversely proportional to the diameter of electrodes. Also from the results, it was observed that skin impedance measured by dry electrodes (E1, E2, E3) was higher than that of wet Ag/AgCl electrodes at a common frequency of 10 Hz. However, the measured values are still within the range of low impedance values to measure ECG signal. The reason for the low skin impedance of the Ag/AgCl electrodes than dry electrodes is due to the fact that the Ag/AgCl electrodes contain conducting gel. Experimentally, the ECG was recorded at two different conditions, motion and relaxed (rest), and found that the ECG recorded during motion displayed lot of disturbances than in a relaxed position. The recorded ECG graph also confirmed that the signals acquired from the dry electrodes have high quality in terms of peak intensity therefore easy to analyse than the signals acquired from conventional Ag/AgCl electrodes. Therefore, the proposed dry ECG electrodes are economic, convenient and have high potential to replace conventional wet electrodes.

References

S. Balambigai, P. Jeevitha, A survey on investigation of vital human parameters from photoplethsmography signal to predict the risk of cardiovascular diseases, in 2017 International Conference on Advanced Computing and Communication Systems (ICACCS), Coimbatore, (2017), pp. 1–4. https://doi.org/10.1109/ICACCS.2017.8014561

S. Mejhoudi, R. Latif, A. Toumanari, W. Jenkal, A. Elouardi, Implementation and evaluation of ECG signal processing algorithms on embedded architectures, in 2017 International Conference on Electrical and Information Technologies (ICEIT), Rabat, (2017), pp.1–6. https://doi.org/10.1109/EITech.2017.8255287

M.H. Chowdhury, Q.D. Hossain, P. Saha, M.M. Rahaman, Design, fabrication and performance evaluation of a three electrode ECG recorder, in 2016 International Conference on Innovations in Science, Engineering and Technology (ICISET), Dhaka, (2016), pp. 1–4. https://doi.org/10.1109/ICISET.2016.7856500

B.B. Winter, J.G. Webster, Driven-right-leg circuit design. IEEE Trans. Biomed. Eng. BME-30(1), 62–66 (1983)

E.M. Spinelli, N.H. Martinez, M.A. Mayosky, A transconductance driven-right-leg circuit. IEEE Trans. Biomed. Eng. 46(12), 1466–1469 (1999)

H. Kim, Y. Kim, Y. Kim, Miniature electrocardiography sensor using a flexible printed circuit and MEMS technology, in 2008 IEEE International Conference on Multisensor Fusion and Integration for Intelligent Systems, Seoul, (2008), pp. 545–550. https://doi.org/10.1109/MFI.2008.4648052.

A. Searle, L. Kirkup, A direct comparison of wet, dry and insulating bioelectric recording electrodes. Physiol. Meas. 21(2), 271 (2000)

A. Gruetzmann, S. Hansen, J. Müller, Novel dry electrodes for ECG monitoring. Physiol. Meas. 28(11), 1375 (2007)

Y. Zhou, X. Ding, J. Zhang, Y. Duan, J. Hu, X. Yang, Fabrication of conductive fabric as textile electrode for ECG monitoring. Fiber Polym. 15(11), 260–2264 (2014)

H. Jung, J. Moon, D. Baek, J. Lee, Y. Choi, J. Hong, S. Lee, CNT/PDMS composite flexible dry electrodes for long-term ECG monitoring. IEEE Trans. Biomed. Eng. 59(5), 1472–1479 (2012)

A. Karilainen, J. Hansen, S. Muller, Dry and capacitive electrodes for long-term ECG-monitoring, in Proceedings of the 8th Annual Workshop on Semiconductor Advances for Future Electronics, Veldhoven, (2005), pp. 155–161

P. Griss, H.K. Tolvanen-Laasko, P. Meriläinen, G. Stemme, Characterization of micromachined spiked biopotential electrodes. IEEE Trans. Biomed. Eng. 49(6), 597–604 (2002)

K.P. Hoffmann, R. Ruff, Flexible dry surface-electrodes for ECG long-term monitoring, in Engineering in Medicine and Biology Society, Proceedings of the 29th Annual International Conference of the IEEE, EMBS, Lyon, (2007), pp. 5739–5742

C. Fonseca, J.P. Silva Cunha, R.E. Martins, V.M. Ferreira, J.P. Marques de Sá, M.A. Barbosa, A. Martins da Silva, A novel dry active electrode for EEG recording. IEEE Trans. Biomed. Eng. 54(1), 162–165 (2007)

J.Y. Baek, J.H. An, J.M. Chio, K.S. Park, S.H. Lee, Flexible polymeric dry electrodes for the long-term monitoring of ECG. Sens. Actuators A 143, 423–429 (2008)

W.C. Ng, H.L. Seet, K.S. Lee, N. Ning, W.X. Tai, M. Sutedja, J.Y.H. Fuh, X.P. Li, Microspike EEG electrode and the vacuum-casting technology for mass production. J. Mater. Process. Technol. 209, 4434–4438 (2009)

M.Q. Lokman, F. Ahmad, H. Yahaya, O. Mikami, F.K.C. Harun, S. W. Harun, Printed silver nanoparticles on kapton tape as passive saturable absorber, in TENCON 2017—2017 IEEE Region 10 Conference, Penang, (2017), pp. 2383–2387. https://doi.org/10.1109/TENCON.2017.8228260

K. Yang et al., Comparison between KAPTON polyimide insulation layers and nylon plates in superconducting tapes winding, in 2015 IEEE International Conference on Applied Super conductivity and Electromagnetic DevicesASEMD), Shanghai, (2015), pp. 294–295. https://doi.org/10.1109/ASEMD.2015.7453580

C.L. Lam, N.N.Z.M. Rajdi, D.H.B. Wicaksono, MWCNT/cotton-based flexible electrode for electrocardiography, in Sensors, 2013 IEEE, Baltimore, MD, (2013), pp. 1–4. https://doi.org/10.1109/ICSENS.2013.6688179

J. Yoo, H.J. Yoo, Fabric circuit board-based dry electrode and its characteristics for long-term physiological signal recording. Ann. Int. Conf. Eng. Med. Bio. Soc. 2497–2500 (2011)

V. Perumal, Mask design and simulation: computer aided design for lab-on-chip application. Adv. Mater. Res. 832, 84 (2013). https://doi.org/10.4028/www.scientific.net/AMR.832.84

M.T. Shahid, M. Ammar Khan, M.Z. Khan, Design and development of a computer numeric controlled 3D Printer, laser cutter and 2D plotter all in one machine, in 2019 16th International Bhurban Conference on Applied Sciences and Technology (IBCAST), Islamabad, Pakistan, (2019), pp. 569575. https://doi.org/10.1109/IBCAST.2018667138

M. Abu-Saude, B.I. Morshed, Polypyrrole (PPy) conductive polymer coating of dry patterned vertical CNT (pvCNT) electrode to improve mechanical stability, in 2016 IEEE Topical Conference on Biomedical Wireless Technologies, Networks, and Sensing Systems (BioWireleSS), Austin, TX, (2016), pp. 84–87. https://doi.org/10.1109/BIOWIRELESS.2016.7445569

P. Das, Md.F. Hossain, J.-Y. Park, Chemically reduced graphene oxide-based dry electrodes as touch sensor for electrocardiograph measurement. Microelectron. Eng. 180 (2017). https://doi.org/10.1016/j.mee.2017.05.048

M. G. Srinivasa, P.S. Pandian, Dry electrodes for bio-potential measurement in wearable systems, in 2017 2nd IEEE International Conference on Recent Trends in Electronics, Information & Communication Technology (RTEICT), Bangalore, (2017), pp. 270–276. https://doi.org/10.1109/RTEICT.2017.8256600

O.J. Escalona et al., Wrist and arm body surface bipolar ECG leads signal and sensor study for long-term rhythm monitoring, in 2017 Computing in Cardiology (CinC), Rennes, (2017), pp. 1–4. https://doi.org/10.22489/CinC.2017.071-458

J. Datta, S. Saha, S. Chowdhury, A. Acharya, Development of an ECG signal acquisition module, in 2017 Devices for Integrated Circuit (DevIC), Kalyani, (2017), pp. 419-421. https://doi.org/10.1109/DEVIC.2017.8073983

W. Baochun, L. Min, Y. Yaning, Z. Weiwei, ECG acquisition circuit design based on C8051F330, in Proceedings of 2012 IEEE-EMBS International Conference on Biomedical and Health Informatics, Hong Kong, (2012), pp. 93–96. https://doi.org/10.1109/BHI.2012.6211515

E. Spinelli, R. Pallàs-Areny, M. Mayosky, AC-coupled front-end for biopotential measurements. IEEE Trans. Biomed. Eng. 50(3), 391–395 (2003). [FILTER] B. Winter, J. Webster, Driven-right-leg circuit design. IEEE Trans. Biomed. Eng. 30(1), 62–66 (1983)

W. Wang, Z. Wu, H. Huang, C. Luo, Low-Power Instrumental Amplifier for Portable ECG, in 2009 IEEE Circuits and Systems International Conference on Testing and Diagnosis, Chengdu, (2009), pp. 1–4. https://doi.org/10.1109/CAS-ICTD.2009.4960836

W.Y. Du, W. Jose, Design of an ECG sensor circuitry for cardiovascular disease diagnosis. Int. J. Biosen. Bioelectron. 2(4), 120–125 (2017). https://doi.org/10.15406/ijbsbe.2017.02.00032

M. Fernandes, K. Lee, R. Ram, J. Correia, P. Mendes, Flexible PDMS-based dry electrodes for electro-optic acquisition of ECG signals in wearable devices, in Proceedings of IEEE Engineering in Medicine and Biology Society (EMBC), (2010), pp. 3503–3506

A. Arcelus, M. Sardar, Mihailidis, Design of a capacitive ECG sensor for unobtrusive heart rate measurements, in IEEE International Instrumentation and Measurement Technology Conference (I2MTC), (2013), pp. 407–410

H. Jeong, J. Seo, Electrode design on plastic substrates using laser patterned double-sided tape and gold leaf, in 2019 41st Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Berlin, Germany, (2019), pp. 1286–1289. https://doi.org/10.1109/EMBC.2019.8857635

Acknowledgements

The authors gratefully acknowledge the facilities, support and guidance extended by the faculty and staff of Packaging Lab, CeNSE, IISc, Bangalore. Also, the authors would like to thank the Center for Nanomaterials and MEMS, NMIT, Bangalore, for extending the facilities to carry out this work and for the continuous support and encouragement.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Rai, N., Shaik, H., Veerapandi, N., Nagaraj, V.S., Veena, S. (2022). Carbon-Based Textile Dry and Flexible Electrodes for ECG Measurement. In: P., S., Prabhu, N., K., S. (eds) Advances in Renewable Energy and Electric Vehicles. Lecture Notes in Electrical Engineering, vol 767. Springer, Singapore. https://doi.org/10.1007/978-981-16-1642-6_4

Download citation

DOI: https://doi.org/10.1007/978-981-16-1642-6_4

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-1641-9

Online ISBN: 978-981-16-1642-6

eBook Packages: EnergyEnergy (R0)