Abstract

The internal combustion engines remain preferred prime movers for on-road and off-road applications over many decades. However, for reducing the usage of fossil fuels and the harmful pollutants emitted by the conventional engines, it has become imperative that the alternative strategies are developed. In this regard, alcohol fuels are established as one of the alternative energy resources for internal combustion engines. Alcohol fuels have many advantages such as presence of fuel-bound oxygen, higher octane number, higher volatility, etc., compared to those of gasoline. The alcohol fuels are considered as the second-generation biofuel, which is employed as alternative fuels for SI engines and the blending of alcohol fuels such as methanol, ethanol, and butanol with biodiesel, also assists in mitigating the biodiesel-NOx penalty in diesel engines. Moreover, the alcohol fuels are effective in advanced combustion strategy like low-temperature combustion (LTC). It is opined that the alcohol fuels make use the full merits of LTC which is attributed to the increased octane number, wider equivalence ratio, broad operational range with reduction in emission, higher auto-ignition resistance, and longer ignition delay. Hence, this chapter is aimed to present significant details on combustion and emission characteristics of alcohol-fuelled engines operated on advance combustions strategy of LTC.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

5.1 Introduction

Due to higher compression ratio, better thermal efficiency, and good torque characteristics of diesel engine compared to its counterpart spark ignition (SI) gasoline engines, the diesel engines have become indispensable to meet the power demands for on-road and off-road applications. However, the oxides of nitrogen (NOx) and smoke emission from the diesel engine are its major concerns. To surmount the depletion of fossil fuel resources and harmful emissions from these sources, the emission norms are tightened. Currently, the stringent emission norms keep the researchers in active mode to establish feasible solutions to mitigate the emissions from conventional fossil fuels. Several alternative strategies, namely alternate fuels, advanced combustion technology, and after treatment techniques, are practiced. In this regard, the alternate fuels from biomasses like alcohol and biodiesel are proved to be effective alternate fuels for internal combustion engines. Alcohol fuels have many advantages like renewable in nature, higher latent heat of evaporation (beneficial in NOx reduction), and fuel-bound hydroxyl (OH) group (reduces smoke emission). However, direct usage of alcohols in compression ignition (CI) engines needs ignition aids due to their lower cetane and viscosity characteristics. Therefore, the alcohol–diesel blends or dual-fuel mode is preferred in CI engines. Biodiesel fuel is an efficient alternative fuel for CI engines. The biodiesel fuels have several advantages like renewable in nature, the presence of fuel-bound oxygen, and high miscibility with diesel. However, many researchers have reported an increase in NOx emission from biodiesel compared to that of diesel fuel. Blending alcohol with biodiesel fuels decreases the NOx emission by reducing in-cylinder temperature. In diesel engines, the NOx and soot emissions’ formation is influenced by flame temperature and equivalence ratio, respectively. Hence, the simultaneous reduction of these emissions is possible by controlling the flame temperature and local equivalence ratio. This is achieved in an advanced low-temperature combustion (LTC) strategy. Numerous articles are available in the open literature on the effect of LTC on performance, combustion, and emission characteristics of CI engines (Amorim et al. 2017; Carlucci et al. 2014; Fang et al. 2013a). The LTC could be attained with the help of advanced combustion strategies like homogeneous charge compression ignition (HCCI), partially premixed combustion (PPC), premixed charge compression ignition (PCCI), and reactivity-controlled compression ignition (RCCI). In LTC mode, preparing homogeneous mixture is one of the primary tasks, which can be done effectively with alcohol fuels because of its higher volatility (Kumar and Rehman 2017). Alcohols are one of the favorable alternative fuels for LTC due to their higher octane number, wide equivalence ratio range, and widened operational range with emissions reduction capabilities (Pachiannan et al. 2019). Moreover, alcohol and biodiesel fuels are used in an internal combustion engine with minimal or without major modifications (Çelebi and Aydın 2019). Numerous articles on the use of alcohol fuels with diesel and biodiesel in both the SI and CI engines are accessible from the literature (Nour et al. 2019; Yusri et al. 2017; Shirazi et al. 2019). Hence, an effort is made to comprehend the outcome of alcohol fuels on combustion and emission characteristics of low-temperature combustion engines as shown in Fig. 5.1.

5.2 Overview of Alcohol Fuels

Methanol, ethanol, and butanol are the extensively utilized alcohols in both SI and CI engines. The chemical structure of alcohol is represented as CnH2n+1OH. The higher octane number of alcohol can reduce the knocking tendency in spark-ignition (SI) engines, whereas the presence of fuel oxygen content in alcohol diesel blends lowers the soot formation tendency in compression ignition engines. Concomitantly, blending alcohol results in lower emissions in both the version of internal combustion engines (Çelebi and Aydın 2019; Yusri et al. 2017).

5.2.1 Types of Alcohol Fuels

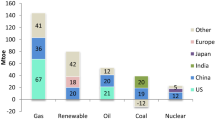

Among the oxygenated fuels, methanol came into the spotlight as a clean alternative fuel supplementing conventional fossil fuels and is produced from fossil or bioenergy resources. The merits of blending methanol with gasoline include high research octane number and hence higher engine efficiency, higher latent heat, and wider flammability limits than those of gasoline result in lower combustion temperature and thus lesser pollutant formation. Ethanol is a clear, colorless liquid and also known as grain alcohol. The USA and Brazil produce 85% of the world's ethanol as shown in Fig. 5.2. In USA, corn is used to produce the majority of ethanol, while in Brazil sugarcane is the preferred feedstock. n-propanol (1-propanol) and isopropanol (2-propanol) are the two isomers of propanol (C3H7OH). Though the energy density of propanol is higher than ethanol, they are not recommended in the automotive fuel segment due to their higher production cost. Hence, only very few studies are attempted in comparison to ethanol and butanol isomers (Shirazi et al. 2019). Among the different isomers of butanol (C4H9OH), n-butanol and isobutanol are the potential blends for spark-ignition engines.

Major ethanol-producing countries in the world (Annual Fuel Ethanol Production 2020)

The other isomers, viz. secondary butanol and tertiary butanol, are not recommended due to their extremely low motor octane rating (32) and higher melting point (about 25 °C), respectively. Though butanol can be obtained from both fossil and renewable resources, production through biological pathways is highly preferred to mitigate greenhouse gas emissions. Biobutanol is produced through fermentation of straw, sorghum, sugar beets, wheat, corn, sugar cane, and cassava (Shirazi et al. 2019). In comparison with propanol and butanol, methanol is toxic and less volatile (Yusri et al. 2017). Table 5.1 provides the property comparison of methanol, ethanol, propanol, and butanol fuels. In particular, the four alcohols have higher octane number, heat of evaporation, and auto-ignition temperature than those of fossil fuels, and also they contain fuel-bound oxygen.

Among the alcohol groups, butanol has higher boiling point, thus requires higher temperatures for the evaporation. Longer ignition delay periods could be observed in the case of methanol and ethanol due to their higher heat of vaporization. Due to their higher heating values, propanol and butanol lower the fuel consumption for the same power output. The higher flash point of propanol and butanol offers safer storage and fuel transportation.

5.2.2 Standard Requirements

Flexible-fuel vehicles (FFVs) are designed to operate on alcohol and gasoline in any combination from a single fuel tank. As shown in Table 5.2, ASTM Standards provide the specification for methanol fuel blends (M51–M85), ethanol fuel blends (E51–E83), butanol for use in automotive spark-ignition engines equipped with flexible-fuel and dedicated spark-ignition engines. For optimum vehicle operation, the alcohol content in the fuel blend is a vital parameter to ascertain the proper air–fuel ratio by the fuel metering system of the FFVs.

5.2.3 Economic Benefits of Alcohol Fuels

The pricing policy of biofuels is a crucial parameter to sustain their growth in comparison to conventional fossil fuels. European Union has set a goal to consume 10% of biofuels by 2020, and the USA is aiming for 36 billion gallons of biofuels by 2022 (Çelebi and Aydın 2019). Gallagher et al. (2005) emphasized the relation between capital costs and plant size for the economical production of biofuels. Typical biofuel productions in large scale were assumed to be 245 million L/year for ethanol and 110 million L/year for biodiesel (Pimentel and Patzek 2005). Lin et al. (2013) recommended utilizing waste feedstock (such as food waste or reused cooking oil) to lower the production cost of biofuels. Considering the Indian scenario, Thangaraja and Srinivasan (2019) found that the price of coconut biodiesel blend (B20) is slightly higher (0.017 $) in comparison to fossil diesel. Figure 5.3 summarizes the price variation between fossil and biofuel blends (E85 and B20) in major clean cities of the USA. It is interesting to observe that the price of biofuel blends is converging closer to fossil fuels in recent years.

Average retail fossil and biofuel blend prices in the USA (Clean Cities Alternative Fuel Price Reports 2020)

5.2.4 Implementation of Alcohol Fuels in Combustion Engines

The current stringent emission norms led the researchers to shift their focus toward establishing alternative fuels and to develop advanced combustion strategies for subsiding the fossil fuel dependency and mitigating the deleterious emission from the internal combustion engines. In this regard, one of the promising alternate fuels such as alcohol deemed to be a suitable source to overcome the adverse impact of emission caused by internal combustion engines. However, the concurrent decrease of NOx and soot emissions is one of the major inherent drawbacks of the diesel engine. LTC is one of the advanced combustion strategies which show the potential of reducing NOx and soot emissions. The LTC is accomplished with the help of altering the injection timing, a higher rate of exhaust gas recirculation (EGR), varying the fuel reactivity, etc. To abate the consequences of high rate of EGR and retarded injection timing, it is desirable to implement a fuel which has lower cetane number and higher volatility, like alcohol fuel (Zhang et al. 2012; Fang et al. 2013b). Moreover, alcoholic fuels are considered as suitable in LTC due to their desirable properties, namely high auto-ignition resistance and enhanced ignition delay, which helps in allowing adequate time for mixing the air and fuel and evaporating the fuel faster. Its hydroxyl group and higher latent heat of vaporization reduce the smoke emission especially at high loads (Lapuerta et al. 2010) and NOx emission significantly vis-à-vis diesel fuel (Doǧan 2011). Therefore, the next section describes the potential of alcohol fuels in achieving low combustion strategies and their effect on combustion and emission characteristics of internal combustion engines.

5.3 Usage of Alcohol Fuels in LTC Strategies

It is well known that the simultaneous reduction of NOx and PM emissions necessitates avoiding both the high-temperature stoichiometric regions and local fuel-rich regions which are inherent in diesel combustion. It is informed that the low-temperature combustion improves fuel atomization and mixing, lowers the local equivalence ratio and reduces combustion temperature (Leermakers and Musculus 2015; Yousefi et al. 2018) which can abate the NOx and particulate matter (PM) emissions simultaneously (El-Asrag and Ju 2014; Niemeyer et al. 2015). The alcohol fuels make use of the full merits of HCCI combustion due to their desirable properties such as higher octane number, wider range of equivalence ratios with a reduction in emissions (Maurya and Agarwal 2014). The alcohol fuel used in other mode of LTC such as RCCI engine increases the thermal efficiency along with decrease in harmful exhaust pollutants (Dou et al. 2017; Jamrozik 2017). As this chapter discusses the effect of alcohol fuels on LTC, for the sake of brevity the LTC concept is not explained in detail. Though several papers published on alcohol fuels, this work provides the effect of alcohol fuels which is characterized in terms of number of fuels used for blending. This section describes the suitability of alcohol fuel for LTC strategies and their effect on performance, combustion, and emission characteristics of engines under LTC mode.

5.3.1 Binary Blends

The binary blends consist of alcohol fuels blended with gasoline–diesel–biodiesel. This section describes the use of binary blends on LTC mode.

5.3.1.1 Diesel–Alcohol Blends

In the normal mode of combustion, it is reported that the alcohol fuels increase the intensity of premixed combustion phase due to increase in ignition delay period and heat release which in turn increases the combustion temperature (Ning et al. 2020). However, the high volatility and low reactivity of ethanol fuel suit LTC operation in diesel engines (Asad et al. 2015). Increasing the quantity of ethanol reduces the premixed phase of combustion and NOx and soot emissions but it increases HC emission. The reduction of NOx is attributed to the reduction in combustion temperature due to charge cooling. The higher premixed ratio (increase in ethanol fraction) increases the delay period and retards combustion due to higher resistance to auto-ignition of ethanol fuel and lower cetane number which in turn affects the auto-ignition process, respectively (Mancaruso and Vaglieco 2015). The binary blend diesel–ethanol (15% of ethanol) in a double-injection strategy reduced the NOx and smoke emissions by 85% and 33%, respectively (Srihari and Thirumalini 2017). The reduced heat release rate, and combustion temperature and the higher latent heat of evaporation of ethanol fuel caused the NOx reduction. The smoke reduction is attributed to the fuel-bound oxygen of ethanol fuel and improved fuel–air mixing. However, the HC and CO emissions are observed to increase at all the load conditions. It is suggested that increasing the inlet air temperature can decrease CO and HC emissions with a trade-off in NOx emission (Maurya and Agarwal 2011).

The use of diesel with higher alcohols like isobutanol and n-pentanol blends (Rajesh Kumar and Saravanan 2016) established an increase in ignition delay and rate of premixed combustion phase with retarded occurrences. Butanol blends increased the ignition delay, peak pressure, and combustion efficiency vis-à-vis pentanol blends which is attributed to low cetane number and higher oxygen content of butanol fuel compared to those of pentanol. The viscosity and density of isobutanol are lower compared to those of n-pentanol which enhance the spray behavior. While the butanol blends are noted to be comparable with the performance of diesel fuel, it is observed to be better than pentanol. In emission standpoint, butanol offered a huge reduction in NOx than pentanol blends due to longer delay period, reduction in combustion flame temperature, and lower oxygen content of butanol blend. However, the lower oxygen content of butanol increased the smoke emission.

The RCCI strategy is one of the LTC variants, which addresses the several problems associated with HCCI and PCCI mode such as extending LTC to higher load, combustion phasing for a wide range of engine load conditions and excessive pressure rise rates at higher loads. Since the homogeneity of the fuel plays a major role in LTC, the use of port injected low reactivity fuel (LRF) and earlier direct injection of high reactivity (HRF) fuel is suggested for RCCI engines. The proper fuel blending provides the required fuel reactivity which can be changed by varying the quantity of LRF and HRF. These varying reactivities between LRF and HRF help control the various parameters of LTC for extending the range of engine load and speed conditions (Splitter and Reitz 2014). It is proved that the spatial stratification of the fuel reactivity influences the duration of combustion. For obtaining the necessary fuel reactivities, alcohol fuels, namely methanol, ethanol, and butanol, qualify as LRFs in the RCCI combustion concept. Among the variety of alcohol fuels, butanol is one of the potential low-reactivity fuels for RCCI mode due to its higher heating value, more energy density, low hydrophilicity, and non-corrosiveness (No 2016; Pan et al. 2017). The use of alcohol fuels achieves stable and extends the operation of RCCI engine (Dempsey et al. 2013; DelVescovo et al. 2015) due to their low reactivity and higher latent heat of evaporation. A small fraction of ethanol (about 10–20%) reduces the NOx and smoke emissions in compliance with EURO VI emission norms with enhanced HC and CO emissions for a wide range of engine loads (Benajes et al. 2015). However, higher premixed ratios of ethanol are observed to increase CO and HC emission, while lowering NOx and soot emissions significantly due to enhanced cooling effect and reduction in in-cylinder temperature, respectively (Qian et al. 2015). It is stated that the increasing the ethanol premixed ratio delays the phasing of combustion and reduces NOx emission to an extremely low level, and hence the alcohol fuel becomes a good choice as LRF for RCCI engine (Zhu et al. 2015). The methanol–diesel combination in the RCCI engine emits low NOx emission vis-à-vis gasoline–diesel pair (Li et al. 2016) which is attributed to reduced local combustion peak temperature and equivalence ratio. However, in general, CO and HC emissions increase (Tutak 2014; Işık and Aydın 2016) with ethanol fuel. In RCCI mode, it is found that the isobutanol–diesel blend is capable of mitigating CO, HC, NOx, and particulate matter emissions vis-à-vis gasoline–diesel combination (Pan et al. 2020). The isobutanol–diesel retards the combustion phase with higher mean in-cylinder temperature along with the longer ignition delay and lower rate of pressure rise vis-à-vis gasoline–diesel. Recently, alcohol fuels are more focused as LRF for the RCCI engine because of their superior physical and chemical properties (Liu et al. 2018; Zheng et al. 2018).

5.3.1.2 Biodiesel–Alcohol Blends

Biodiesel and higher alcohols have gained popularity among the other alternative fuels for diesel engines due to their renewable characteristics. It is concluded that adding the higher alcohols to biodiesel fuel lowers the density and viscosity of biodiesel and hence enhances the atomization and auto-ignition characteristics. It also assists the combustion process to occur in semi-LTC with reduced NOx emissions (Atmanli and Yilmaz 2020). As shown in Fig. 5.4, the combination of higher alcohols has lowered the NOx emission significantly than that of diesel (D) and waste cooking biodiesel (WB).

NOx emission from the various fuels (Atmanli and Yilmaz 2020). Legend: D—Diesel, WB—waste cooking biodiesel, WBC3—biodiesel + propanol, WBC4—biodiesel + n-butanol and WBC5—biodiesel + n-butanol

It is showed that the particle number concentrations are significantly reduced when two fuel-bound oxygen fuels, namely biodiesel and ethanol are used (Su et al. 2013). This explains the benefit of the fuel oxygen content in decreasing the PM emission. n-butanol reduced the NOx and soot emissions by 75% and 98%, respectively, compared to those of diesel fuel in LTC mode due to low-combustion temperature and oxygen content. However, it is reported that an incomplete combustion during the premixed phase of combustion increased the CO and HC emissions (Soloiu et al. 2013). Use of n-butanol with high-pressure direct injection is suggested for LTC operation compared to diesel fuel (Han et al. 2013). The n-butanol decreases soot emission due to low boiling point, low viscosity, and higher latent heat of evaporation and significant improvement in the fuel–air mixing. As n-butanol easily blends with diesel (Rakopoulos et al. 2010; Merola et al. 2014) because of its less hydrophilicity and higher miscibility nature compared to ethanol, n-butanol has good potential for LTC engines. Usage of alcohol fuels like n-butanol reduces the particulate matter emission to nearly zero levels (Han et al. 2013) and also reduces PM emission significantly even at a higher rate of EGR rate (Huang et al. 2016).

5.3.1.3 Gasoline–Alcohol Blends

The most important drawback of the HCCI engine is the extension of its operating range over a wide range of engine loads. This can be surmounted by employing alcohol–gasoline fuel blends with the optimal start of injection and blend ratio (Turkcan et al. 2014). In this study, ~80% of the total fuel (of the ethanol–gasoline blend) is injected in suction stroke, and the balance fuel is injected towards the later stage of compression stroke to control the ignition timing. It is concluded that for the fixed start of injections, the blend ratio affected the control of HCCI combustion phases significantly. However, n-butanol–gasoline blend auto-ignites earlier vis-à-vis ethanol–gasoline blends and reduced the combustion duration (He et al. 2015). n-butanol–gasoline blends also decreased the indicated mean effective pressure (IMEP) and indicated thermal efficiency (ITE).

5.3.2 Ternary Blends

In order to avoid the separation of ethanol from diesel fuel, an emulsifier or a surfactant is essential for increasing the premixed ratio of ethanol (Satgé De Caro et al. 2001; Xing-Cai et al. 2004). Fortunately, biodiesel stabilizes the diesel and ethanol mixture and helps in achieving a homogeneous mixture of ethanol–diesel blends (Fernando and Hanna 2005; Kwanchareon et al. 2007). The increase in smoke emission at higher load during LTC operation can be mitigated with the help of oxygenated fuels like biodiesel, and hence, it extends the higher operational load limit of LTC engines (Ickes et al. 2009). It is proved that biodiesel and ethanol blends reduce the smoke emission vis-à-vis conventional diesel combustion (Xue et al. 2011; Zhu et al. 2011). In an investigation, with the blends of ethanol–diesel–biodiesel (waste cooking oil) and EGR (Fang et al. 2013b), among the various blends of biodiesel–ethanol–diesel, it is observed that the ethanol blends lower the NOx and smoke emissions about 8.55 and 31.79% (for BDE10—blend of 10% ethanol + 10% biodiesel + remaining diesel) and 23.08 and 73.44% (for BDE20—blend of 20% ethanol + 10% biodiesel + remaining diesel) due to lower energy release and higher latent heat of evaporation of alcohol fuel, respectively. Similar kinds of results, i.e., decrease in NOx and smoke emissions and increase in HC and CO emissions, are also reported with diesel–rape seed biodiesel–ethanol blends (Pidol et al. 2012).

In ethanol RCCI combustion mode, it is observed that the engine knock is completely eliminated with reduced heat losses (Işık and Aydın 2016). Increase in quantity of ethanol reduced NO emission for all the tested fuel blends. BSFC is found to increase in 30% ethanol RCCI operation for all fuels vis-à-vis 50% ethanol RCCI operation. In 50% ethanol RCCI operation, the BSFC is comparable to that of single fuel mode. This shows the effect of blending modes on the performance of the engines. It is shown that 5% rice wine alcohol with 75% diesel and 20% neem methyl ester increases the brake thermal efficiency by 8% and decreases the brake specific fuel consumption by 3.33% compared to those of diesel fuel. However, NOx emission increased because of the presence of oxygenated biodiesel. The NOx emission of 20, 5, and 10% biodiesel fuel (with 5% rice wine and remaining fraction is diesel) are noted to be 6.4%, 4.26, and 2.14% higher than vis-à-vis base line diesel fuel (Reang et al. 2020).

5.3.3 Quaternary Blends

The experimental investigation (Appavu et al. 2019) established that the use of higher alcohol like pentanol as a quaternary blend with diesel, biodiesel, and vegetable oil overcomes the demerits involved with neat biodiesel operation. It is noted that at full load condition, the quaternary blends reduced the NOx emission by 11.23%. This is ascribed to higher latent heat of vaporization of the blends which caused LTC, eventually decreasing the NOx emission. The NOx emission is found to be less for all the pentanol blends (from DBOP10 to DBOP40) compared to that of B100 (neat biodiesel—refer Fig. 5.5). However, increasing the pentanol concentration increased the NOx emission while it decreased hydrocarbon, carbon monoxide, and smoke emissions. In another experimental investigation (Yesilyurt et al. 2020), the various fuel blends such as binary (diesel and biodiesel), ternary (diesel, biodiesel and vegetable oil) and quaternary blends (diesel, biodiesel, vegetable oil and isopentanol/isopropanol/n-butanol) are considered for the study.

NOx emission variation for various tested fuels (Appavu et al. 2019)

The brake thermal efficiency of all quaternary blends is observed to be higher than B100, which increases with increasing the pentanol concentration. Increasing the concentration of pentanol in blend increased NOx emission and reduced CO, HC, and smoke emissions vis-à-vis diesel fuel. It is also observed that diesel–gasoline–n-butanol blends increased the brake-specific fuel consumption, CO and HC emissions and reduced NOx and soot emissions (Huang et al. 2016). In RCCI mode, diesel–biodiesel–ethanol–gasoline blends increased the peak pressure at higher loads, decreased both the NOx (below EURO VI) and smoke emissions and increased CO and HC emissions (Benajes et al. 2015). The effect of alcohol blends on LTC engines is summarized and shown in Table 5.3.

5.4 Summary

The detailed discussion on alcohol fuels reveals that the alcohol fuels are capable of achieving low-temperate combustion by utilizing the entire advantages of this combustion concept. The oxygen content of alcohol fuel helps solve one of the major drawbacks of LTC such as higher CO and HC emissions. The alcohol fuels are reported to widen the operating load range of LTC. Thus, the various alcohol fuels become more suitable for LTC, and the conclusion of the chapter is presented in the next section.

5.5 Conclusions

This chapter provided the essential details of the alcohol fuel as alternate fuels for internal combustion engines. Alcohol fuels are characterized by their renewability, closer to the properties of gasoline, better adaptability with diesel and advantages of emission reduction. This chapter explained the potential of various alcohol fuels in terms of emission reduction when it is adapted to low-temperature combustion techniques. The alcohol fuel is found to be suitable for any mode of LTC such as HCCI, PCCI, PPC, and RCCI. The fuels are used without major or no modification of the existing engines. Moreover, alcohol fuels are one of the appropriate alternate fuels for the HCCI engine which effectively utilizes the full merits of LTC. The higher octane number, oxygen content, and lower latent heat of evaporation of alcohol fuels suit the requirement of reactivity stratification in RCCI engines. Alcohol fuels are capable of overcoming the major drawback of extending the operational range of LTC engines. Therefore, it is concluded that the alcohol fuel has the potential as effective alternative fuels and for reducing the harmful emissions from internal combustion engines especially in the LTC mode.

- B20:

-

80% diesel and 20% biodiesel blend

- BSNO:

-

Brake-specific nitric oxide

- BTE:

-

Brake thermal efficiency

- CI:

-

Compression ignition

- CO:

-

Carbon monoxide

- CO2:

-

Carbon dioxide

- EGR:

-

Exhaust gas recirculation

- FFV:

-

Flexible fuelled vehicles

- HC:

-

Hydrocarbon

- HCCI:

-

Homogeneous charge compression ignition

- HRF:

-

High-reactivity fuel

- IMEP:

-

Indicated mean effective pressure

- ITE:

-

Indicated thermal efficiency

- LRF:

-

Low-reactivity fuel

- LTC:

-

Low-temperature combustion

- MTBE:

-

Methyl tertiary butyl ether

- PCCI:

-

Premixed charge compression ignition

- PPC:

-

Partially premixed combustion

- NOx:

-

Oxides of nitrogen

- RCCI:

-

Reactivity-controlled compression ignition

- SI:

-

Spark ignition

- WB:

-

Waste cooking biodiesel.

References

Amorim RJ, Novella R, Garcia A, Molina S (2017) Study on LTC for light duty engines—part 2—spray enhancements. Fuel 193:206–219. https://doi.org/10.1016/j.fuel.2016.12.050

Annual Fuel Ethanol Production (2020). https://ethanolrfa.org/statistics/annual-ethanol-production/, last accessed 2020/04/29

Appavu P, Ramanan MV, Venu H (2019) Quaternary blends of diesel/biodiesel/vegetable oil/pentanol as a potential alternative feedstock for existing unmodified diesel engine: performance, combustion and emission characteristics. Energy 186:115856. https://doi.org/10.1016/j.energy.2019.115856

Asad U, Kumar R, Zheng M, Tjong J (2015) Ethanol-fueled low temperature combustion: a pathway to clean and efficient diesel engine cycles. Appl Energy 157:838–850. https://doi.org/10.1016/j.apenergy.2015.01.057

ASTM Standard D5797-18 (2018) Standard specification for methanol fuel blends (M51–M85) for methanol-capable automotive spark-ignition engines. ASTM International, United States

ASTM Standard D7862-19 (2019) Standard specification for butanol for blending with gasoline for use as automotive spark-ignition engine fuel. ASTM International, United States

ASTM Standard D5798-20 (2020) Standard specification for ethanol fuel blends for flexible-fuel automotive spark-ignition engines. ASTM International, United States

Atmanli A, Yilmaz N (2020) An experimental assessment on semi-low temperature combustion using waste oil biodiesel/C3-C5 alcohol blends in a diesel engine. Fuel 116357. https://doi.org/10.1016/j.fuel.2019.116357

Benajes J, Molina S, García A, Monsalve-Serrano J (2015) Effects of direct injection timing and blending ratio on RCCI combustion with different low reactivity fuels. Energy Convers Manage 99:193–209. https://doi.org/10.1016/j.enconman.2015.04.046

Carlucci AP, Laforgia D, Motz S, Saracino R, Wenzel SP (2014) Advanced closed loop combustion control of a LTC diesel engine based on in-cylinder pressure signals. Energy Convers Manage 77:193–207. https://doi.org/10.1016/j.enconman.2013.08.054

Çelebi Y, Aydın H (2019) An overview on the light alcohol fuels in diesel engines. Fuel 890–911. https://doi.org/10.1016/j.fuel.2018.08.138

Clean Cities Alternative Fuel Price Reports (2020). https://afdc.energy.gov/fuels/prices.html, last accessed 2020/04/29

DelVescovo D, Wang H, Wissink M, Reitz RD (2015) Isobutanol as both low reactivity and high reactivity fuels with addition of di-tert butyl peroxide (DTBP) in RCCI combustion. SAE Int J Fuels Lubr 8(2):329–343. https://doi.org/10.4271/2015-01-0839

Dempsey AB, Walker NR, Reitz R (2013) Effect of cetane improvers on gasoline, ethanol, and methanol reactivity and the implications for RCCI combustion. SAE Int J Fuels Lubr 170–187. https://doi.org/10.4271/2013-01-1678

Doǧan O (2011) The influence of n-butanol/diesel fuel blends utilization on a small diesel engine performance and emissions. Fuel 2467–2472. https://doi.org/10.1016/j.fuel.2011.02.033

Dou Z, Yao C, Wei H, Wang B, Liu M, Chen C, Gao J, Shi J (2017) Experimental study of the effect of engine parameters on ultrafine particle in dieselmethanol dual fuel engine. Fuel 192:45–52. https://doi.org/10.1016/j.fuel.2016.12.006

El-Asrag HA, Ju Y (2014) Direct numerical simulations of NOx effect on multistage autoignition of DME/air mixture in the negative temperature coefficient regime for stratified HCCI engine conditions. Combust Flame 161(1):256–269. https://doi.org/10.1016/j.combustflame.2013.07.012

Fang C, Yang F, Ouyang M, Gao G, Chen L (2013a) Combustion mode switching control in a HCCI diesel engine. Appl Energy 110:190–200. https://doi.org/10.1016/j.apenergy.2013.04.060

Fang Q, Fang J, Zhuang J, Huang Z (2013b) Effects of ethanol-diesel-biodiesel blends on combustion and emissions in premixed low temperature combustion. Appl Therm Eng 54(2):541–548. https://doi.org/10.1016/j.applthermaleng.2013.01.042

Fernando S, Hanna M (2005) Phase behavior of the ethanol-biodiesel-diesel micro-emulsion system. Trans Am Soc Agric Eng 48(3):903–908. https://doi.org/10.13031/2013.18494

Gallagher PW, Brubaker H, Shapouri H (2005) Plant size: capital cost relationships in the dry mill ethanol industry. Biomass Bioenerg 28(6):565–571. https://doi.org/10.1016/j.biombioe.2005.01.001

Han X, Zheng M, Wang J (2013) Fuel suitability for low temperature combustion in compression ignition engines. Fuel 109:336–349. https://doi.org/10.1016/j.fuel.2013.01.049

He BQ, Liu MB, Zhao H (2015) Comparison of combustion characteristics of n-butanol/ethanol-gasoline blends in a HCCI engine. Energy Convers Manag 95:101–109. https://doi.org/10.1016/j.enconman.2015.02.019

Huang H, Zhou C, Liu Q, Wang Q, Wang X (2016) An experimental study on the combustion and emission characteristics of a diesel engine under low temperature combustion of diesel/gasoline/n-butanol blends. Appl Energy 170:219–231. https://doi.org/10.1016/j.apenergy.2016.02.126

Ickes AM, Assanis DN, Bohac SV (2009) Load limits with fuel effects of a premixed diesel combustion mode. SAE Technical Paper, 4970. https://doi.org/10.4271/2009-01-1972

Işık MZ, Aydın H (2016) Analysis of ethanol RCCI application with safflower biodiesel blends in a high load diesel power generator. Fuel 184:248–260. https://doi.org/10.1016/j.fuel.2016.07.017

Jamrozik A (2017) The effect of the alcohol content in the fuel mixture on the performance and emissions of a direct injection diesel engine fueled with diesel-methanol and diesel-ethanol blends. Energy Convers Manage 148:461–476. https://doi.org/10.1016/j.enconman.2017.06.030

Kumar P, Rehman A (2017) Homogeneous charge compression ignition (HCCI) engines: a review. IOSR J Mech Civ Eng 11(6):47–67

Kwanchareon P, Luengnaruemitchai A, Jai-In S (2007) Solubility of a diesel-biodiesel-ethanol blend, its fuel properties, and its emission characteristics from diesel engine. Fuel 86(7–8):1053–1061. https://doi.org/10.1016/j.fuel.2006.09.034

Lapuerta M, García-Contreras R, Campos-Fernández J, Dorado MP (2010) Stability, lubricity, viscosity, and cold-flow properties of alcohol-diesel blends. Energy Fuels 24(8):4497–4502. https://doi.org/10.1021/ef100498u

Leermakers CAJ, Musculus MPB (2015) In-cylinder soot precursor growth in a low-temperature combustion diesel engine: laser-induced fluorescence of polycyclic aromatic hydrocarbons. Proc Combust Inst 35(3):3079–3086. https://doi.org/10.1016/j.proci.2014.06.101

Li Y, Jia M, Chang Y, Xie M, Reitz RD (2016) Towards a comprehensive understanding of the influence of fuel properties on the combustion characteristics of a RCCI (reactivity controlled compression ignition) engine. Energy 99(x):69–82. https://doi.org/10.1016/j.energy.2016.01.056

Lin J, Gaustad G, Trabold TA (2013) Profit and policy implications of producing biodiesel-ethanol-diesel fuel blends to specification. Appl Energy 104:936–944. https://doi.org/10.1016/j.apenergy.2012.11.049

Liu H, Ma G, Hu B, Zheng Z, Yao M (2018) Effects of port injection of hydrous ethanol on combustion and emission characteristics in dual-fuel reactivity controlled compression ignition (RCCI) mode. Energy 145:592–602. https://doi.org/10.1016/j.energy.2017.12.089

Mancaruso E, Vaglieco BM (2015) Spectroscopic analysis of the phases of premixed combustion in a compression ignition engine fuelled with diesel and ethanol. Appl Energy 143:164–75. https://doi.org/10.1016/j.apenergy.2015.01.031

Maurya RK, Agarwal AK (2011) Experimental study of combustion and emission characteristics of ethanol fuelled port injected homogeneous charge compression ignition (HCCI) combustion engine. Appl Energy 88(4):1169–1180. https://doi.org/10.1016/j.apenergy.2010.09.015

Maurya RK, Agarwal AK (2014) Experimental investigations of performance, combustion and emission characteristics of ethanol and methanol fueled HCCI engine. Fuel Process Technol 126:30–48. https://doi.org/10.1016/j.fuproc.2014.03.031

Merola SS, Tornatore C, Iannuzzi SE, Marchitto L, Valentino G (2014) Combustion process investigation in a high speed diesel engine fuelled with n-butanol diesel blend by conventional methods and optical diagnostics. Renew Energy 64:225–237. https://doi.org/10.1016/j.renene.2013.11.017

Niemeyer KE, Daly SR, Cannella WJ, Hagen CL (2015) Investigation of the LTC fuel performance index for oxygenated reference fuel blends. Fuel 155(x):14–24. https://doi.org/10.1016/j.fuel.2015.04.010

Ning L, Duan Q, Chen Z, Kou H, Liu B, Yang B, Zeng K (2020) A comparative study on the combustion and emissions of a non-road common rail diesel engine fueled with primary alcohol fuels (methanol, ethanol, and n-butanol)/diesel dual fuel. Fuel 117034. https://doi.org/10.1016/j.fuel.2020.117034

No SY (2016) Application of biobutanol in advanced CI engines—a review. Fuel 183:641–658. https://doi.org/10.1016/j.fuel.2016.06.121

Nour M, Attia AMA, Nada SA (2019) Combustion, performance and emission analysis of diesel engine fuelled by higher alcohols (butanol, octanol and heptanol)/diesel blends. Energy Convers Manag 313–329. https://doi.org/10.1016/j.enconman.2019.01.105

Pachiannan T, Zhong W, Rajkumar S, He Z, Leng X, Wang Q (2019) A literature review of fuel effects on performance and emission characteristics of low-temperature combustion strategies. Appl Energy 251(301):113380. https://doi.org/10.1016/j.apenergy.2019.113380

Pan S, Li X, Han W, Huang Y (2017) An experimental investigation on multi-cylinder RCCI engine fueled with 2-butanol/diesel. Energy Convers Manag 92–101. https://doi.org/10.1016/j.enconman.2017.10.047

Pan S, Liu X, Cai K, Li X, Han W, Li B (2020) Experimental study on combustion and emission characteristics of iso-butanol/diesel and gasoline/diesel RCCI in a heavy-duty engine under low loads. Fuel 116434. https://doi.org/10.1016/j.fuel.2019.116434

Pedrozo VB, May I, Lanzanova TDM, Zhao H (2016) Potential of internal EGR and throttled operation for low load extension of ethanol-diesel dual-fuel reactivity controlled compression ignition combustion on a heavy-duty engine. Fuel. https://doi.org/10.1016/j.fuel.2016.03.090

Pidol L, Lecointe B, Starck L, Jeuland N (2012) Ethanol-biodiesel-diesel fuel blends: performances and emissions in conventional diesel and advanced low temperature combustions. Fuel 93(x):329–338. https://doi.org/10.1016/j.fuel.2011.09.008

Pimentel D, Patzek TW (2005) Ethanol production using corn, switchgrass, and wood; biodiesel production using soybean and sunflower. Nat Resour Res 14(1):65–76. https://doi.org/10.1007/s11053-005-4679-8

Qian Y, Ouyang L, Wang X, Zhu L, Lu X (2015) Experimental studies on combustion and emissions of RCCI fueled with n-heptane/alcohols fuels. Fuel. https://doi.org/10.1016/j.fuel.2015.09.022

Rajesh Kumar B, Saravanan S (2016) Effects of iso-butanol/diesel and n-pentanol/diesel blends on performance and emissions of a di diesel engine under premixed LTC (low temperature combustion) mode. Fuel 170:49–59. https://doi.org/10.1016/j.fuel.2015.12.029

Rakopoulos CD, Dimaratos AM, Giakoumis EG, Rakopoulos DC (2010) Investigating the emissions during acceleration of a turbocharged diesel engine operating with bio-diesel or n-butanol diesel fuel blends. Energy 35(12):5173–5184. https://doi.org/10.1016/j.energy.2010.07.049

Reang NM, Dey S, Debbarma B, Deb M, Debbarma J (2020) Experimental investigation on combustion, performance and emission analysis of 4-stroke single cylinder diesel engine fuelled with neem methyl ester-rice wine alcohol-diesel blend. Fuel 117602. https://doi.org/10.1016/j.fuel.2020.117602

Satgé De Caro P, Mouloungui Z, Vaitilingom G, Berge JC (2001) Interest of combining an additive with diesel-ethanol blends for use in diesel engines. Fuel 565–574. https://doi.org/10.1016/S0016-2361(00)00117-4

Shirazi SA, Abdollahipoor B, Windom B, Reardon KF, Foust TD (2019) Effects of blending C3-C4 alcohols on motor gasoline properties and performance of spark ignition engines: a review. Fuel Process Technol 106194. https://doi.org/10.1016/j.fuproc.2019.106194

Soloiu V, Duggan M, Harp S, Vlcek B, Williams D (2013) PFI (port fuel injection) of n-butanol and direct injection of biodiesel to attain LTC (low-temperature combustion) for low-emissions idling in a compression engine. Energy 52:143–154. https://doi.org/10.1016/j.energy.2013.01.023

Splitter DA, Reitz RD (2014) Fuel reactivity effects on the efficiency and operational window of dual-fuel compression ignition engines. Fuel 118:163–175. https://doi.org/10.1016/j.fuel.2013.10.045

Srihari S, Thirumalini S (2017) Investigation on reduction of emission in PCCI-DI engine with biofuel blends. Renew Energy 114:1232–1237. https://doi.org/10.1016/j.renene.2017.08.008

Su J, Zhu H, Bohac SV (2013) Particulate matter emission comparison from conventional and premixed low temperature combustion with diesel, biodiesel and biodiesel-ethanol fuels. Fuel 113:221–227. https://doi.org/10.1016/j.fuel.2013.05.068

Thangaraja J, Srinivasan V (2019) Techno-economic assessment of coconut biodiesel as a potential alternative fuel for compression ignition engines. Environ Sci Pollut Res 26(9):8650–8664. https://doi.org/10.1007/s11356-018-04096-9

Turkcan A, Ozsezen AN, Canakci M (2014) Experimental investigation of the effects of different injection parameters on a direct injection HCCI engine fueled with alcohol-gasoline fuel blends. Fuel Process Technol 126:487–496. https://doi.org/10.1016/j.fuproc.2014.05.023

Tutak W (2014) Bioethanol E85 as a fuel for dual fuel diesel engine. Energy Convers Manage 86:39–48. https://doi.org/10.1016/j.enconman.2014.05.016

Xing-Cai L, Jian-Guang Y, Wu-Gao Z, Zhen H (2004) Effect of cetane number improver on heat release rate and emissions of high speed diesel engine fueled with ethanol-diesel blend fuel. Fuel 83:14–15. https://doi.org/10.1016/j.fuel.2004.05.003

Xue J, Grift TE, Hansen AC (2011) Effect of biodiesel on engine performances and emissions. Renew Sustain Energy Rev 15(2):1098–1116. https://doi.org/10.1016/j.rser.2010.11.016

Yesilyurt MK, Aydin M, Yilbasi Z, Arslan M (2020) Investigation on the structural effects of the addition of alcohols having various chain lengths into the vegetable oil-biodiesel-diesel fuel blends: an attempt for improving the performance, combustion, and exhaust emission characteristics of a compression ignition engine. Fuel 117455. https://doi.org/10.1016/j.fuel.2020.117455

Yousefi A, Guo H, Birouk M (2018) An experimental and numerical study on diesel injection split of a natural gas/diesel dual-fuel engine at a low engine load. Fuel 332–346. https://doi.org/10.1016/j.fuel.2017.10.053

Yusri IM, Mamat R, Najafi G, Razman A, Awad OI, Azmi WH, Ishak WFW, Shaiful AIM (2017) Alcohol based automotive fuels from first four alcohol family in compression and spark ignition engine: a review on engine performance and exhaust emissions. Renew Sustain Energy Rev 169–181. https://doi.org/10.1016/j.rser.2017.03.080

Zhang Q, Yao M, Zheng Z, Liu H, Xu J (2012) Experimental study of n-butanol addition on performance and emissions with diesel low temperature combustion. Energy 47(1):515–521. https://doi.org/10.1016/j.energy.2012.09.020

Zheng Z, Xia M, Liu H, Shang R, Ma G, Yao M (2018) Experimental study on combustion and emissions of n-butanol/biodiesel under both blended fuel mode and dual fuel RCCI mode. Fuel 226:240–251. https://doi.org/10.1016/j.fuel.2018.03.151

Zhu L, Cheung CS, Zhang WG, Huang Z (2011) Combustion, performance and emission characteristics of a di diesel engine fueled with ethanol-biodiesel blends. Fuel 90(5):1743–1750. https://doi.org/10.1016/j.fuel.2011.01.024

Zhu L, Qian Y, Wang X, Lu X (2015) Effects of direct injection timing and premixed ratio on combustion and emissions characteristics of RCCI (reactivity controlled compression ignition) with N-heptane/gasoline-like fuels. Energy 93:383–392. https://doi.org/10.1016/j.energy.2015.09.069

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Rajkumar, S., Thangaraja, J. (2021). The Potential of Various Alcohol Fuels for Low-Temperature Combustion Engines. In: Shukla, P.C., Belgiorno, G., Di Blasio, G., Agarwal, A.K. (eds) Alcohol as an Alternative Fuel for Internal Combustion Engines . Energy, Environment, and Sustainability. Springer, Singapore. https://doi.org/10.1007/978-981-16-0931-2_6

Download citation

DOI: https://doi.org/10.1007/978-981-16-0931-2_6

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-0930-5

Online ISBN: 978-981-16-0931-2

eBook Packages: EnergyEnergy (R0)