Abstract

Stress sensitivity is common in tight sandstone gas reservoirs. For gas reservoirs developed with natural energy, We should fully consider the impact of stress sensitivity on production capacity. There are two defects in the stress sensitivity obtained by core testing First, the pore structure has changed greatly when the core is taken out of the reservoir, Second, due to the limitations of core size and testing methods, The stress sensitivity of core test can not truly reflect the stress sensitivity of reservoir. According to the relationship between binomial productivity equation coefficient and reservoir permeability, We can calculate the reservoir stress sensitivity by using the test data of field productivity, This calculation method is more in line with the actual production situation. According to the production test results of nearly one hundred gas wells in Sulige tight sandstone gas reservoir, Revealing the change of reservoir permeability with formation pressure. The results show that the Sulige tight sandstone gas reservoirs is moderately stress-sensitive.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The Sulige gas field is a typical representative of tight sandstone gas reservoirs. The permeability of the reservoir ranges from 0.01 − 0.1 × 10−3 μm2. Whether the reservoir has stress sensitivity during the development process has not been accurately determined.

At present, there are many researches on the stress sensitivity of the reservoir at home and abroad, but most of them are evaluated based on the core test data in the laboratory. This evaluation method has certain limitations. On the one hand, the core is taken from the reservoir to the surface. Due to changes in overburden pressure and pore pressure, the pore structure has changed greatly [1,2,3]; on the other hand, the test results accuracy is closely related to the quality of the coring and the test method, and for heterogeneous reservoirs, because the size of the core is usually small, the test results have certain limitations [4,5,6,7,8,9,10] and cannot meet the requirements of on-site production.

In this paper, the reservoir within the discharge range of the gas well is compared to a core, and the production process of the gas well is compared to an experiment. By establishing the relationship between the coefficient of the binomial productivity equation and the reservoir permeability, and using the test results of the productivity test at different production stages of the Sulige gas field, Revealing the change law of reservoir permeability with formation pressure, which effectively solved the disadvantages of core testing and evaluation of reservoir stress sensitivity, and quantitatively evaluates the stress sensitivity characteristics of the Sulige tight sandstone gas reservoirs.

2 Relationship Between Productivity Equation Coefficient and Reservoir Permeability

For gas wells that do not produce water, the binomial productivity equation under steady flow can usually be expressed as:

Formula: \( q_{sc} \)—daily gas production under standard conditions, m3/d; \( k \)—effective permeability of gas layer, 10−3 μm2; \( \mu_{g} \)—gas viscosity under average pressure \( (p_{e} + p_{wf} )/2 \), mPa • s; \( T \)—gas layer temperature, K; \( h \)—gas layer effective thickness, m; \( r_{w} \)—gas well radius, m; \( r_{e} \)—supply radius, m; \( \gamma_{g} \)—relative density of natural gas; \( p_{e} \)—formation pressure, MPa; \( p_{wf} \)—the bottom hole flowing pressure, MPa.

At the initial stage of gas well production, the original formation pressure is \( p_{0} \), and the binomial productivity equation can be expressed as:

During gas well production, the formation pressure drops to \( p_{1} \) and the binomial productivity equation can be expressed as:

If no transformation measures have been taken during the production of the gas well, the parameters of \( T,h,r_{e} ,r_{w} ,\gamma_{g} ,s \) in the equation coefficients can be considered to remain unchanged. We can get:

Using Eqs. 6 and 7, According to the productivity equation coefficients of gas wells in different periods, we can obtain the variation law of reservoir permeability under different formation pressures, but considering the physical significance of the productivity equation coefficients B, which is to evaluate the pressure change caused by the high-speed gas seepage near the gas well, so when evaluating reservoir stress sensitivity, we should be used A for analysis.

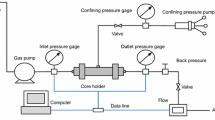

3 Calculation of Gas Well Productivity Equation

Well Su-A is a production well in the Sulige gas field, puting into production in January 2014. The Production horizon is the 8th Member of Permian Xiashihezi Formation, the thickness of the reservoir is 12.3 m. At the initial stage of gas well production, in order to obtain the gas well productivity equation, There carried out a modified isochronous well test work, The test data is shown in Table 1.

According to the test results, We plot the gas production q and the quasi-pressure difference Ψ (P0) − Ψ (Pwf)/q in a rectangular coordinate system (Fig. 1), and determine the gas well productivity equation (Eq. 8):

In March 2015, the cumulative gas production of the well reached 9.4 million cubic meters, and the formation pressure dropped to 18.1 MPa. In order to further evaluate the current gas production capacity of the gas well, there carried out the second revised isochronous well test. The test data is shown in Table 2.

According to the second test data, the gas well productivity equation is determined as (Fig. 2):

The evaluation results of the productivity equation show that both the coefficients A and B change. According to Eq. (6), when the formation pressure decreases from the original formation pressure to 20.3 MPa, the ratio between the reservoir permeability at this time and the permeability under original formation pressure is 0.74.

4 Evaluation of Reservoir Stress Sensitivity

According to the above productivity evaluation method, based on the productivity test results over the years, it is preferable to select 89 gas wells with similar physical properties and no water production, find the productivity equation, and We can calculate the ratio of reservoir permeability at a certain point in the production process to the permeability at the original formation pressure (Table 3).

According to the above productivity evaluation results of 89 wells, we can drawn the curve of permeability ratio and formation pressure. The results show that the permeability of tight sandstone reservoirs in Sulige gas field decreases as the formation pressure decreases, and in the early stage of formation pressure decrease, the decrease of permeability is larger, and in the later stage, the decrease of permeability is smaller. When the formation pressure decreases from the original formation pressure (28.5 MPa) to 25 MPa, the reservoir permeability decreases by 15% compared with the initial period. For every 1 MPa decrease in formation pressure, the reservoir permeability decreases by 4.3%; when the formation pressure decreases from 25 MPa to 10 MPa, The reservoir permeability is 22% lower than the initial value when the formation pressure is 25 MPa, and every time the formation pressure decreases by 1 MPa, the reservoir permeability decreases by 1.5%; mathematical fitting shows that there is a good cubic polynomial function relationship between the reservoir permeability ratio and formation pressure (Fig. 3).

The change in reservoir permeability is mainly due to the change in the effective stress of the rock caused by the drop in formation pressure, which ultimately leads to a change in the pore structure of the rock. By plotting the relationship between the permeability ratio and the effective stress of the rock, it is found that there is a good cubic polynomial function relationship between the reservoir permeability ratio and the formation pressure.

The stress sensitivity index of permeability is defined as the rate of permeability loss when the formation pressure drops by 10 MPa, i.e.

Formula: \( SI_{p} \)—stress sensitivity index, f; \( k_{0} \)—permeability under original formation pressure, 10−3 μm2; \( k_{1} \)—permeability when formation pressure drops by 10 MPa, 10−3 μm2.

The greater the stress sensitivity index, the stronger the rock’s stress sensitivity. The evaluation criteria of stress sensitivity are: when \( SI_{p} < 0.1 \), the stress sensitivity is weak; when \( SI_{p} > 0.3 \), the stress sensitivity is strong; when \( SI_{p} \) is 0.1–0.3, the stress sensitivity is medium [11].

From Fig. 4, we can see that when the formation pressure is lower than the original formation pressure by 10 MPa, the ratio of the reservoir permeability at this time to the reservoir permeability at the original formation pressure is 0.71, and the permeability loss rate is 0.29. It is moderately stress sensitive.

5 Conclusions

(1) The binomial productivity equation coefficients under different formation pressures of gas wells can be used to quantitatively evaluate the reservoir stress sensitivity. This method can effectively overcome the shortcomings of core testing.

(2) the permeability of tight sandstone reservoirs in Sulige gas field decreases as the formation pressure decreases, and in the early stage of formation pressure decrease, the decrease of permeability is larger, and in the later stage, the decrease of permeability is smaller.

(3) Taking the Sulige gas field as an example, it is confirmed that the tight sandstone gas reservoir has stress-sensitive characteristics. When the formation pressure is lower than the original formation pressure by 10 MPa, the reservoir permeability loss rate is 0.29, which is moderately stress sensitive, but very close to strong stress sensitivity.

References

He, Y., Yang, L.: Testing study on variational characteristics of rockmass permeability under loading-unloading of confining pressure. Chin. J. Rock Mech. Eng. 23(3), 415–419 (2004)

Xu, T., Huang, T., Xiu, D., et al.: A new method for stress sensitivity evaluation of low permeability reservoirs. Spec. Oil Gas Reserv. 21(06), 126–129+148 (2014)

Yao, S., Dou, H., Chen, J., et al.: Technology supervision in petroleum industry journal agency. Technol. Superv. Petrol. Ind. J. Agency 340(12), 26–29 (2017)

Li, C., Zhu, S.: Misunderstanding of measuring methods of stress sensibility. Lithol. Reserv. 27(06), 1–4+29 (2015)

Xiao, W., Li, M., Zhao, J., et al.: Laboratory study of stress sensitivity to permeability in tight sandstone. Rock Soil Mech. 31(03), 775–779+798 (2010)

Fatt, I., Davis, D.H.: Reduction in permeability with overburden pressure. J. Petrol. Technol. 4(12), 16 (1952)

Davies, J., Davies, D.: Stress-dependent permeability characterization and modeling. Soc. Petrol. Eng. J. 6(2), 224–235 (2001)

Lorenz, J.C.: Stress-sensitive reservoirs. J. Petrol. Technol. 51(1), 61–63 (1999)

Sun, J., Yang, Z., Liu, X., et al.: Study of permeability stress-sensitivity characteristics and its evaluation method of ultra-low permeability reservoir using different of fluid media. Chin. J. Rock Mech. Eng. 32(02), 324–332 (2013)

Gao, J., Lu, J., Wang, J.: Evaluation on stress sensibility of low permeability rock under reservoir condition. Chin. J. Rock Mech. Eng. 28(Supp.2), 3899–3902 (2009)

Li, C.: Fundamentals of Reservoir Engineering, 2nd edn., pp. 96–100. Petroleum Industry Press, Beijing (2011)

Acknowledgments

The project is supported by National Natural Science Foundation (Number 2016E-0509).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Liu, Pc., An, Hy., Zheng, Ln., Yue, J., Huo, Mh. (2021). A New Method for Stress Sensitivity Evaluation of Tight Sandstone Gas Reservoirs. In: Lin, J. (eds) Proceedings of the International Field Exploration and Development Conference 2020. IFEDC 2020. Springer Series in Geomechanics and Geoengineering. Springer, Singapore. https://doi.org/10.1007/978-981-16-0761-5_60

Download citation

DOI: https://doi.org/10.1007/978-981-16-0761-5_60

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-0762-2

Online ISBN: 978-981-16-0761-5

eBook Packages: EngineeringEngineering (R0)