Abstract

Multicomponent crystals, which include cocrystals and salts, have been of great interest to the pharmaceutical field owing to their ability to be used as an alternative solid form of drugs with better physicochemical properties compared to their corresponding parent drugs and as a potential source for patents and research opportunities. Although multicomponent crystal formation was originally seen to only improve the solubility and dissolution rate profiles of drug molecules, it has also shown potential applications in overcoming other problems, such as hygroscopicity, poor tabletability, instability, and bitter taste. This chapter highlights some multicomponent crystal applications that tackle common unfavorable physicochemical properties of drugs in the pharmaceutical field. The multicomponent crystal design has been covered with regard to the relation between the crystal structure and physicochemical properties. The study cases presented in this chapter emphasize the structural aspect of multicomponent crystals to provide a molecular-level understanding of the physicochemical property changes accompanying multicomponent crystal formation.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

1.1 Solid Active Pharmaceutical Ingredients (APIs)

Active pharmaceutical ingredients (APIs) are classified in numerous ways, based on the existing pharmaceutical disciplines. In general, APIs can be classified based on their chemical nature, source, target organ, therapeutic uses, physiological system, physical effect, phase, etc. [1]. In this chapter, we will focus on the classification that is based on the phase system. In the pharmaceutical field, APIs can be grouped into three phases: solid, liquid, and gas (i.e., nitrous oxide) [2, 3]. APIs are most commonly formulated in the solid-state, in which their physical and chemical stabilities are typically better. Moreover, solid-state preparation of APIs is more practical due to ease of handling, processing, and packaging during the various stages of drug development and preparation [4, 5].

The study of solid APIs involves many scientific disciplines because many phenomena influence the physicochemical properties of solid APIs: stability, hygroscopicity, dissolution rate, color, etc. [6,7,8,9,10]. Solid APIs can generally be classified as amorphous and crystalline solids. Crystalline solids include polymorphs, hydrates, solvates, cocrystals, and salts, as shown in Fig. 9.1 [11]. The classification of crystalline solid API evolves continuously, allowing each type of crystalline solid to merge with other types, resulting in new subsets of crystalline solids, i.e., polymorphs of hydrates, hydrate cocrystals, hydrate salts, etc. [12,13,14].

Amorphous solids are defined as solid materials that lack a long-range order in their internal structure [15]. The molecules within an amorphous material exhibit liquid state disorder but solid rheological properties. There are various techniques to produce an amorphous solid, such as spray drying, freeze-drying, grinding, melt extrusion, melt quenching, and co-precipitation [16]. A molecule in amorphous form is in a higher energy state compared to its crystalline counterpart [17]. This can be exploited in pharmaceutical applications to increase the solubility of problematic APIs. However, from a thermodynamic point of view, the amorphous state of a solid is unstable and has the tendency to convert to its low-energy and more stable crystalline form over time [18]. Therefore, the number of successful products available in this solid form in the market is still limited.

Most marketed APIs, therefore, consist of crystalline solids. In contrast with amorphous solids, crystalline materials consist of minimal building blocks called unit cells that contain all the structural features and symmetry elements of the crystal and are repeated regularly in three-dimensional space [19]. Furthermore, API crystalline molecules are typically amenable to form multiple crystal forms known as polymorphs [20]. Organic molecules, including APIs, generate polymorphic crystals through two mechanisms. The first mechanism leads to so-called packing polymorphs, in which molecules with relatively rigid conformations can be assembled into different three-dimensional structures. The second mechanism occurs when a flexible molecule bends into different conformations to subsequently be packed into alternative crystal structures [21]. Some polymorphic APIs have mixed mechanisms and exhibit different packing and conformational polymorphs [22].

API crystalline molecules can also exist as multicomponent crystals by incorporating other molecules into the crystal lattice. “Pseudopolymorph” is the widely accepted term for crystals with solvent molecules incorporated into their lattice [23,24,25]. Hydrates are crystalline solid adducts that contain water molecules and are known as the largest class of pseudopolymorps [4]. If a crystalline solid accommodates another solvent molecule than water, the solvate terminology is generally used [26]. If a multicomponent crystal contains two components, both of them solid in ambient conditions, the multicomponent crystal can further be classified as cocrystal and salt [27]. Cocrystals are generally defined as crystalline materials comprising two or more neutral molecules in the same crystal lattice [27]. Contrarily, a salt is formed if any part of an API gives or receives a proton to or from another molecule [28]. Polymorphic, pseudopolymorphic, cocrystal, and salt states have quickly evolved from being relative obscure to widely studied crystal forms in the context of pharmaceutical science and engineering [12, 13].

When APIs form multicomponent crystals, the driving force is typically a molecular synthon, such as a hydrogen bond, π-π interaction, or halogen bond, which involves supramolecular chemistry [28]. To put this in the pharmaceutical science context, the study of multicomponent crystal APIs, particularly their physicochemical properties relevant to clinical performance and long-term stability, represents an important aspect in drug discovery and development. In the past decade, pharmaceutical multicomponent crystals have emerged as promising tools for solid formulation testing during drug discovery and development, as their design can profoundly influence their physicochemical properties. Pharmaceutical multicomponent crystals offer massive opportunities for research topics and patent development, as well as for functional materials applications. The number of research projects and patent applications in the multicomponent crystal field should, therefore, be unsurprising.

1.2 Challenges of Solid APIs

In the pharmaceutical industry, one of the bottlenecks in the discovery and development of APIs is the optimization of drug product performance by pre-formulation research [29, 30]. The goal of pre-formulation research is to provide optimized APIs featuring suitable physiological profiles that can later be formulated into pharmaceutical dosage forms [31, 32]. As mentioned before, APIs are most commonly formulated in solid form, i.e., tablets, capsules, and granules, because the chemical stability is superior to that of a solution. Furthermore, solid-state dosage forms provide more practical processing, packaging, handling, and allow, for most patients, the preferred choice of drug intake, oral delivery.

Solid APIs are generally used for dosage forms intended for oral delivery. It should be noted that oral delivery typically requires the dissolution of active ingredients at the absorption site, while avoiding precipitation during gastrointestinal transit, until complete absorption [33]. Unfortunately, about 40% of marketed drugs and almost double the percentage of drug candidates are thought to have solubility issues in oral administration [34, 35]. Meanwhile, many solid APIs exhibit other unfavorable physicochemical properties, such as hygroscopicity, [36] brittleness, [37] and chemical instability, [38] which become a problem during manufacturing and storage. In general, low solubility and stability pose a serious threat for candidate APIs by preventing the drug from reaching minimum therapeutic concentrations in the biological system [39,40,41].

Moreover, some drugs exhibit more than one unfavorable physicochemical property, creating the need for an ultimate simultaneous solution. Hygroscopicity is considered an unfavorable physicochemical property, which leads to increased production costs. By far, the biggest challenge posed hygroscopicity is the extra effort required to dry the APIs during processing and then before packaging. The judicious use of production rooms with controlled humidity and sealed packaging systems is advisable in many cases [42]. Brittleness is another hostile physicochemical property that is mostly related to processing bulk APIs. Difficulties due to brittleness often arise during milling, filling, and compaction, due to the poor mechanical properties of bulk powders [43]. The physicochemical properties of insolubility and chemical instability are strongly negatively related to the safety, quality, and efficacy of APIs [44, 45].

Some approaches that tackle these unfavorable physicochemical properties can be divided into formulation, particle engineering, and crystal engineering (Fig. 9.2). In formulation, an API is combined with other substances or excipients to optimize the physicochemical properties, therapeutic potential, safety, and stability of the final dosage form. The formulation of the drug also covers the processing methods and devices, and the packaging [46]. Particle engineering involves the methodology used to obtain the optimal particle size, size distribution, morphology, and surface characteristics. Particle engineering can cover all aspects that modify the morphology and surface behavior of a drug, with or without the addition of excipients [47, 48].

The latter is crystal engineering which is a popular terminology for multicomponent crystal formations. Crystal engineering in the pharmaceutical field utilizes non-covalent interaction, such as hydrogen and halogen bonds, and π-π interactions, to create a new crystal structure containing APIs and coformer that can be a typical excipient or other generally recognized as safe (GRAS) compounds. Pharmaceutical scientists, crystallographers, and solid-state chemists have taken advantages of crystal engineering to remedy deficiencies of different nature of APIs. The next sub-chapter provides some interesting examples of design and formation of multicomponent crystal in the pharmaceutical field which overcome the unfavorable physicochemical properties of solid APIs.

2 Structural Design and Investigation of Physicochemical Alteration in Pharmaceutical Multicomponent Crystals

2.1 Solubility Improvement by Layered Structure Formation

Solubility improvement is arguably the most common topic in multicomponent crystal research, reflected not only by a large number of publications and patents but also by the fact that multicomponent crystals can alter the solubility of problematic APIs. In this review, we emphasize the benefits of solubility improvement by layered structure formation. Particularly, the structural origin of the improved solubility of the epalrestat cocrystal will be described briefly.

Epalrestat (EPR, Scheme 9.1 left) is an aldose reductase inhibitor used for the treatment of diabetic neuropathy [49]. Marketed EPR formulations are known to have low bioavailability. In addition, EPR, which is a class II molecule, according to the Biopharmaceutical Classification System (BCS), exhibits poor solubility and a slow dissolution rate [50]. Therefore, the solubility and dissolution rate reasonably constitutes the rate-limiting step of its bioavailability. The solid-state properties of EPR have been widely investigated; EPR exists in five known polymorphic forms and several crystalline solvates, and it is commercially available in the form I EPR 51,52,53,54,55,56,57].

EPR has a carboxylic acid moiety in its molecular structure, which can potentially be employed as a supramolecular synthon. From an analysis of the Cambridge Structural Database (CSD), caffeine (CAF, Scheme 9.1 right) might be particularly suited to act as a promising coformer in the formation of a neutral cocrystal. Moreover, CAF is widely used as the coformer, when trying to avoid proton transfer, since its ionization is only limited to strong acids. A search in the CSD also reveals promising neutral cocrystal structure reports, resulted from the interaction between compounds containing carboxylic acid moieties and CAF.

The preparation of the cocrystal involved several cocrystal screening methods such as liquid-assisted grinding, neat grinding, ball milling, and solvent evaporation. The above-mentioned single-phase cocrystal can be prepared by ethanol liquid-assisted grinding. However, to grow a single crystal, we used methanol as a solvent in the solvent evaporation technique. All cocrystals in this method were prepared by mixing EPR and CAF in a 1:1 molar ratio. The powder diffraction patterns from both the liquid-assisted grinding and solvent evaporation technique were the same as the simulated powder diffraction pattern, indicating that these methods led to a pure phase (Fig. 9.3).

Reproduced from Ref. [58] with permission from the Royal Society of Chemistry

The PXRD pattern of a EPR, b CAF, EPR–CAF from c the liquid-assisted grinding technique, d the solvent evaporation technique, and e simulation from single-crystal data.

The EPR–CAF cocrystal generated a triclinic crystal system with the space group P-1. An asymmetric unit contains a CAF molecule and an EPR molecule. The CAF molecule was refined to be disordered around a non-crystallographic two-fold axis through O4–C16–C20 with the occupancy of the major part determined at 0.518(5). The extensive hydrogen bonding between the EPR and CAF molecules created a layered structure. Further, only one conventional hydrogen bond, between the oxygen atom (O3) in EPR’s carboxylic acid and the oxygen atom (O4) in the CAF molecule was observed. The other two hydrogen bonds (C2–H⋯O and C5–H⋯O2) connected an EPR molecule with two adjacent EPR molecules and were considered unconventional weak hydrogen bonds. These interactions resulted in a layered structure, perpendicular to the c-axis, as illustrated in Fig. 9.4. In this architecture, the EPR layer was sandwiched between two CAF layers.

Reproduced from Ref. [58] with permission from the Royal Society of Chemistry

Layered structure, resulted from the interaction between EPR–CAF and EPR–EPR. The hydrogen atoms and minor component molecules are omitted for clarity.

The solubility change through cocrystallization is particularly important in this case, as EPR is classified as a class II drug, according to BCS. We predict that the poor aqueous solubility of EPR, in general, maybe due to its high molecular weight (319.04 g mol−1) and the lack of a functional group that can interact with a solvent molecule. Therefore, the equilibrium solubility and intrinsic dissolution rate of EPR and its cocrystal were evaluated.

The equilibrium solubility of EPR, CAF, and EPR–CAF were 2.956, 33.280, and 4.557 mg L−1, respectively. The equilibrium solubility of the cocrystal was almost twice as that of the pure drug. This result needed to be reinforced by the kinetic behavior of EPR, represented by the dissolution rate. Intrinsic dissolution tests were conducted for tablets of each material to avoid the influence of particle orientation, agglomeration during dissolution, and particle size variability. As shown in Fig. 9.5, the intrinsic dissolution rate of the cocrystal is almost four times that of raw EPR. Close PXRD pattern examinations of residues remaining after solubility and dissolution rate experiments indicate that no EPR–CAF to EPR phase dissociation occurred. Furthermore, no significant pH change was detected before and after the solubility and dissolution rate experiments.

Reproduced from Ref. [58] with permission from the Royal Society of Chemistry

Intrinsic dissolution rate curves of EPR (blue) and EPR–CAF (red).

The improvement in solubility and intrinsic dissolution rate can be explained by the molecular arrangement of the cocrystal. As previously mentioned, a layered structure is formed by alternate arrangements of EPR and CAF molecules, wherein a layer of EPR molecules resides in the channel formed between two layers of CAF molecules. This configuration, in contrast to an extended chain structure, only composed of EPR molecules in raw form with a strong hydrogen bond, predictably facilitates the improvement in solubility and dissolution by facilitating contact with the solvent. When the more soluble conformer is in contact with the solvent it dissolves and the only interaction between EPR–CAF is broken (Eint = −27.45 kJ mol−1); consequently, the chain consisting of EPR molecules is exposed to the solvent media. Since the EPR molecules within the chain have weak interactions (Eint of C2–H2⋯O2 = −2.30 kJ mol−1 and Eint of C5–H5⋯O2 = −2.61 kJ mol−1), the EPR will dissolve more easily, leading to increased solubility. The proposed mechanism suggests that the internal arrangement of molecules in a crystal lattice plays an important role in tuning the physicochemical properties of solid forms. It should also be noted that here, the EPR–CAF cocrystal, being more soluble and having a faster dissolution, enables possible EPR dose reductions in future applications. In addition, from a pharmacological point of view, the dose of CAF in this cocrystal will not exceed the maximum daily intake (200 mg per day) for a diabetic patient [58].

2.2 Simultaneous Modulation of Hygroscopicity and Solubility of APIs by Drug-Drug Multicomponent Crystal Formation

Hygroscopicity or the stability of solid APIs to water vapor is a major concern for the pharmaceutical industry. The conversion of an API into a wet powder could bring undesired physicochemical properties and difficulties for both drug storage and processing. The preparation of new multicomponent crystals, cocrystals, and salts alike has been widely reported to prevent API hydrate formation. The potential of multicomponent crystals containing drug combinations to offer physicochemical properties superior to the parent drugs has been investigated [59, 60]. This family of crystals, besides providing technological advantages, also offers improved pharmacological effects and patient compliance [61]. These are likely the most important advantages of drug-drug multicomponent crystals over single drug and nondrug multicomponent crystals.

A screening of marketed combination drug formulations yielded the combination of non-insulin-dependent diabetes mellitus (NIDDM) drugs metformin (MET, Scheme 9.2 right) and gliclazide (GLI, Scheme 9.2 left). MET is a blood glucose-normalizing derivative of guanidine, and GLI is a potent oral hypoglycaemic agent for the long-term treatment of diabetes mellitus. MET and GLI are effective in the treatment of NIDDM in both single and combined therapies. Recently, combination oral therapies have become widely used and clinically needed. Indeed, the combination of MET and GLI offers better control of blood glucose and lipid index, major concerns in the treatment of diabetes [62].

Unfortunately, both MET and GLI exhibit unfavorable physicochemical properties. The base form of MET is a hygroscopic powder. Attempts to overcome this hygroscopicity, through special treatment during the manufacturing process and the use of a closed packaging system, are expensive and may increase the cost of the drug [63]. Therefore, in order to avoid hygroscopicity, MET is found on the market as a hydrochloride salt [64]. In addition, GLI, a class II molecule, according to the Biopharmaceutical Classification System, exhibits low solubility [65].

The single-phase multicomponent crystal of MET and GLI could be obtained from liquid-assisted grinding and ball milling. However, the solvent evaporation technique was used to grow single crystals. Surprisingly, “halo” peaks were observed in the powder pattern of the GLI and MET mixture after the ball milling experiment. After milling for 24 h, the crystals were amorphized. These amorphized powders were stored for one month without any physical treatment. After 4 weeks, the amorphous powder transformed into a multicomponent crystal of GLI-MET, as shown in Fig. 9.6f and g. The amorphous phase, well known as energetically unstable has the ability to turn to the crystalline phase during storage. It is interesting that all three techniques successfully form the same multicomponent crystal instead of different crystal growth mechanisms (Fig. 9.6).

Reprinted (adapted or reprinted in part) with permission from [66]. Copyright 2011 American Chemical Society

PXRD patterns of a GLI, b MET, MET-GLI from c liquid-assisted grinding, d solvent evaporation, e ball milling, f 2 weeks after ball milling, and g 4 weeks after ball milling.

Single-crystal X-ray analysis reveals that the GLI-MET multicomponent crystal is a salt. A proton transfer was reasonable because ΔpKa was greater than 3. The intermolecular interactions in the MET-GLI crystal are shown in Fig. 9.7. The MET molecules formed a centrosymmetric dimer structure through two N8–H···N6 hydrogen bonds (Fig. 9.7, right). MET also interacted with three GLI molecules via relatively strong hydrogen bonds. The interaction between MET and the first GLI molecule was formed by the N5+–H···O(1) carbonyl hydrogen bond. Charge transfer-mediated hydrogen bonds in N5+–H···N3 − connected MET to the second GLI molecule. An additional hydrogen bond in the N7–H···O2 sulfonyl stabilized the interaction with the second GLI molecule. N7 formed bifurcated hydrogen bonds through N7–H···N1 and N7–H···O1 carbonyl with the third GLI molecule. The hydrogen bond in the N8–H···O1 carbonyl also contributed to the interaction with the third GLI molecule.

Reprinted (adapted or reprinted in part) with permission from [66]. Copyright 2011 American Chemical Society

Infinite one-dimensional (1D) hydrogen bond chain of the MET-GLI crystal along the a-axis (blue for MET and red for GLI). Insets show the detailed interaction between MET-MET (right) and MET-GLI (left) presented in default color according to the different elements. Blue-dashed lines indicate hydrogen bonds.

In the hydrogen-bonding analysis, all donor and acceptor moieties of the hydrogen bonds in MET actually formed hydrogen bonds with both MET and GLI molecules. Such characteristic hydrogen-bonding ability indicated that MET can act as a promising coformer during the formation of multicomponent crystals. Based on the intermolecular interactions described above, a continuous hydrogen bond chain could be observed along the a-axis, in which the MET molecules were sandwiched between GLI molecules.

The physicochemical evaluation started with dynamic vapor sorption (DVS) analysis of the multicomponent crystal and the individual intact materials (Fig. 9.8). During the tests, the relative humidity (RH) did not exceed 80% because the MET powder exhibited a considerable hygroscopicity. MET started to absorb atmospheric water from 60% RH and became deliquescent at higher values. However, the GLI powder crystals were stable at RH values up to 80% with no significant amount of water being absorbed. This result is in agreement with the low water solubility of GLI, aspect that is not soluble in water and hence not hygroscopic.

Reprinted (adapted or reprinted in part) with permission from [66]. Copyright 2011 American Chemical Society

DVS charts of a MET, b GLI, and c MET-GLI. The solid and open symbols represent absorption and desorption, respectively. d Dissolution rate of GLI (blue) and MET-GLI (red) in acidic medium (pH = 1.2).

Interestingly, multicomponent crystals of MET-GLI were present as a non-hygroscopic powder. The water uptake at an RH of 80% was only 3.3%, which corresponded to surface water. The reduced hygroscopicity of the multicomponent crystals as compared with MET alone could be explained by the crystal structure. As shown in Fig. 9.7, MET was located in the channel formed by GLI molecules; thus, the GLI molecules, which were less hydrophilic, protected MET and formed hydrogen bonds to close potential hydrogen-bonding sites. Thus, it is reasonable to conclude that the multicomponent crystals of MET-GLI showed lower hygroscopicity than MET.

As shown in Fig. 9.8d, the multicomponent crystals enabled a significantly higher dissolution rate than GLI alone and consistently higher released drug amounts at each dissolution time, reaching a maximum value of nearly 100%. Whereas MET-GLI dissolved rapidly, reaching equilibrium after 40 min, pure GLI maintained a slow rate from the beginning of the experiment, achieving equilibrium after 70 min.

Surprisingly, we observed desirable hygroscopicity and solubility changes at the same time, despite the general coincidence of these physicochemical properties, difficult to reconcile simultaneously because these factors are contradictory. In many cases, the hygroscopicity of a substance can be reduced by decreasing its solubility and vice versa. The above-mentioned work presents a remarkable exception where the hygroscopicity can be reduced but by channel formation, the solubility can be maintained.

The physicochemical property changes are strongly related to the superficial molecular configuration of materials. As shown in Fig. 9.9a, the dominant crystal face (001) was hydrophobic, with the exception of side faces (010) and (100), which provided access to the hydrophilic MET channel. The hydrophobic frame could reduce the probability of water vapor contact with the hydrophilic MET, thus eventually reducing the hygroscopicity of the multicomponent crystals.

Reprinted (adapted or reprinted in part) with permission from [66]. Copyright 2011 American Chemical Society

a Calculated crystal morphology and packing view of each face of MET-GLI. MET (hydrophilic compound) and GLI (hydrophobic compound) are drawn in blue and red, respectively. b Microscopic visualization of single crystals of MET-GLI from the (001) face direction during the solubility experiment.

The channel structures of the hydrophilic side faces could play an important role in solubility improvement, owing to the molecular characteristics of the surface. Furthermore, the direct observation of a single crystal’s shape variation during solubilization offered reasonable evidence for underlying structure–solubility relationships. As illustrated in Fig. 9.9b, the crystal shrunk along the direction of hydrophilic faces (010) and (100), indicating that the solvent gradually penetrated and extracted molecules from those surfaces. Moreover, a loss of face transparency suggested solubilization, as observed in the (010) and (100) faces. On the other hand, the dominant (001) face appeared transparent during this observation, suggesting that no significant solubilization occurred on this face [66].

2.3 Improving Mechanical Properties

The most convenient and arguably the most common pharmaceutical dosage form is the tablet. One of the most important aspects of tablet preparation is the evaluation of mechanical properties. This is particularly important for APIs that constitute a large portion of the tablet [67]. The mechanical properties of APIs can also affect the overall formulation design and manufacturing strategies [68].

In many cases, poor API mechanical properties can be overcome by the addition of excipients such as lactose or microcrystalline cellulose that improve tabletability. However, this strategy can be considered a curative remedy for tablet brittleness instead of an improvement to the mechanical properties of APIs themselves. The crystal engineering strategies are an alternative way of addressing poor compaction behavior that overcomes the root of poor mechanical properties itself, the arrangement of API molecules within the crystal structure [69].

This section presents the study case of desloratadine (DES, Scheme 9.3 left), a derivative of loratadine used to treat allergic rhinitis, urticaria, and inflammation. Pharmacologically, DES is a selective H1 histamine receptor inverse agonist [70]. DES exhibits poor mechanical characteristics, manifested by capping during tablet compression and results in drug processing difficulties [71].

DES has pyridine and piperidine rings that can enable many potential intermolecular interactions with mildly acidic carboxylic acids. Therefore, the screening targeted generally recognized as safe (GRAS) compounds containing carboxylic acid moieties. The attempts to prepare a multicomponent crystal of DES used highly efficient cocrystal generating methods, such as liquid-assisted grinding, slurry mixing, dry milling, and solvent evaporation techniques.

Surprisingly, in the PXRD analysis of potential single-phase crystals, only benzoic acid (BA, Scheme 9.3 right) generated a pattern change, which indicates that a new phase could have been obtained. The new, purely single-phase DES-BA multicomponent crystal was prepared using the solvent evaporation method, aided by a rotary evaporator; conversely, liquid-assisted grinding, slurry mixing, and dry milling were not successful. Notably, the utilization of a rotary evaporator was essential for avoiding the formation of a fat-based suspension. As illustrated in Fig. 9.10, no trace of DES or BA impurities is observable. Moreover, the experimental and calculated PXRD patterns are similar, indicating the absence of significant amounts of impurities. It should be noted here that the differences between the experimental and simulated powder patterns, in this case, might be caused by experimental factors such as differences in temperature and preferred orientation.

Reprinted from [72]. Copyright 2012, with permission from Elsevier

The PXRD patterns of a DES, b BA, and DES-BA from c experimental and d simulation data from a single crystal.

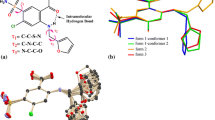

Single-crystal structure analysis revealed that the DES-BA multicomponent crystal is a salt. The crystal structure of DES-BA is constructed both by conventional N–H···O and unconventional C–H···O hydrogen bonds. The charge-assisted hydrogen bonds of N2–H···O1 and N2–H···O2 connect DES and BA along the c-axis. Therefore, each DES molecule is hydrogen-bonded to two neighboring BA molecules, and conversely, each BA molecule is hydrogen-bonded to two DES molecules. The outcome of these interactions is a layered structure formed by one-dimensional chain structures. The weak hydrogen bond of C17–H···N1 stabilizes this layered structure by connecting DES molecules within the chain (Fig. 9.11a). One layered structure is connected to two other adjacent layered structures through the C13–H···O1 and C18–H···O2 weak hydrogen bonds, as illustrated in Fig. 9.11b, c. These weak hydrogen bonds form slip planes, parallel to the dominant crystal face (001), and are considerably important for the tabletability of the DES-BA salt multicomponent crystal.

Reprinted from [72]. Copyright 2012, with permission from Elsevier

Molecular packing motifs in the crystal showing a a layered structure formed by a one-dimensional chain hydrogen bond between DES-BA along the c-axis, and b the interaction among layered structures. c The packing view along the c-axis shows the existence of slip planes parallel to (001). DES and BA are drawn in capped stick and space fill settings in (c), respectively. The conventional NH···O and unconventional CH···O hydrogen bonds are drawn as blue and orange dashed lines, respectively. Hydrogen atoms are omitted for clarity.

The tabletability profiles of DES and DES-BA as a function of compaction pressures between 25 and 350 MPa are shown in Fig. 9.12a. The tensile strength of the DES tablet was lower than that of the DES-BA tablet: it started at ~0.9 MPa at a 25 MPa compaction pressure, maintained ~1.6 MPa at a 250 MPa compaction pressure, and decreased at compaction pressures higher than 250 MPa. The tensile strength of DES tablets was poor (<1 MPa) at compaction pressures below 150 MPa. However, DES can form a relatively suitable tablet at compaction pressures between 150 and 250 MPa. Surprisingly, DES-BA generated better tabletability profiles than DES. DES-BA could be made into a suitable tablet until 350 MPa, which is the highest compaction pressure employed in this study. Furthermore, a tensile strength above 2 MPa could be attained at compaction pressures exceeding 200 MPa. It should be noted that a minimum tensile strength of 2 MPa has been proposed for ensuring the integrity of a pharmaceutical tablet. Therefore, a DES-BA formulation will probably have no substantial tabletability problems—even at high compaction pressures.

Reprinted from [72]. Copyright 2012, with permission from Elsevier

a Tabletability profiles and b elastic recovery as a function of compaction pressure of DES (red) and DES-BA (blue).

The elasticity-plasticity profiles of DES and DES-BA were investigated afterward. Plasticity and elasticity are defined by the elastic recovery in this case. The profiles of elastic recovery under different compression pressures are presented in Fig. 9.12b. The elastic recovery of DES gradually increased up to a compaction pressure of 150 MPa and decreased at higher compaction pressures. Therefore, an elastic recovery depletion tendency was observed in DES with increasing compaction pressures. We predicted that corrugated or interlocked hydrogen-bonded structures in the DES parent drug were responsible for the depletion of elastic recovery. By comparing the elastic recoveries of DES and DES-BA, the novel multicomponent crystal reported in this study is considerably more plastic than the parent drug; this may suggest that a DES-BA tablet has lower porosity and is stronger than a DES tablet for the same compaction pressures.

A tendency for capping was observed in the DES tablet if the compaction pressure was increased above 250 MPa (Fig. 9.13a). Such profiles are called ‘over-compaction’ profiles due to the elastic deformation of DES. However, neither capping nor lamination tendency was observed in the DES-BA multicomponent crystal, as illustrated in Fig. 9.13b.

Reprinted from [72]. Copyright 2012, with permission from Elsevier

Tablet overview of a DES and b DES-BA after applying a compaction pressure of 350 MPa.

The fact that DES-BA exhibited better tabletability profiles than DES can be understood from a structural point of view. Therefore, it is very useful to compare the crystal structures of DES and DES-BA. As illustrated in Fig. 9.14, the crystal structure of DES shows a corrugated, hydrogen-bonded chain structure containing only one weak CH···N hydrogen bond. Due to its rigidity, this structure possibly responds less to plastic deformation stress. In contrast with DES, the existence of a layered structure and of a slip plane parallel to (001) possibly provides an enhanced ability to form a tablet. As previously demonstrated, layered structures enable substantial tabletability improvements in many pharmaceutical multicomponent crystals. In addition, the existence of a slip plane, which is only composed of weak CH···O hydrogen bonds, might also facilitate shearing and possibly allows the layered structure to easily slide. These features can eventually lead to improved durability during the compaction-induced plastic deformation [72].

Reprinted from [72]. Copyright 2012, with permission from Elsevier

Corrugated, hydrogen-bonded chain structure in DES parent drugs. The hydrogen atoms are omitted for clarity. The crystal structure was obtained from Cambridge Structural Database (REFCODE: GEHXEX).

2.4 Improving Photostability by Preventing Tautomerization

Although many drugs successfully surmount the long development process, many of them still have chemical stability problems. It is suggested that these drugs are still present in the market due to their pharmacological importance. Drugs that pose stability problems usually require a strict control strategy in their design and development stages. Chemical instability is considered an ominous feature, which not only leads to drug ineffectiveness but also endangers the patient through potentially toxic decomposition products [73]. Therefore, chemical instability is a subject of increased concern for the pharmaceutical industry.

Numerous studies described the benefits of cocrystals in overcoming the stability problems of APIs. A common strategy for producing pharmaceutical cocrystals utilizes the so-called pKa rule, [74] which states that a neutral cocrystal is generated instead of an ionic salt when the difference between the pKa of a base and that of its conjugate is negative or at least as low as possible. However, the proton transfer is sometimes unavoidable, even in systems with a low ΔpKa (<1) [45, 75]. An alternative approach features the use of a zwitterionic coformer to avoid the proton transfer between drug molecules. Since the proton donor and acceptor sites of zwitterionic molecules are already deprotonated and protonated, respectively, such coformers cannot participate in the proton transfer between drug molecules. They consequently enable the formation of zwitterionic cocrystals, a less explored type of cocrystals compared to molecular or ionic types [76]. In this context, we were particularly interested in betaine (BET, Scheme 9.4 right), a naturally occurring zwitterionic compound. This compound is widely distributed in nature as a metabolite of choline and is found in sugar beet and marine animals such as crabs and shrimp, thereby being an acceptable coformer candidate for the formation of API-containing cocrystals [77].

Herein, epalrestat (EPR, Scheme 9.4 left), an aldose reductase inhibitor used in diabetic neuropathy, was used as a model drug due to its photoinstability [53]. The photosensitivity of EPR manifests through E,Z to Z,Z isomerization upon exposure to light easily occurring even in ambient light irradiation (Fig. 9.15). Although an earlier study attempted to tackle EPR’s photosensitivity problem by cocrystallization and salt formation, it ended unsuccessfully [78].

Reprinted (adapted or reprinted in part) with permission from [79]. Copyright 2011 American Chemical Society

Photoisomerization of EPR accounting for its photoinstability.

The preparation of equimolar zwitterionic cocrystals involved methods such as liquid-assisted grinding, slurry mixing, dry milling, and solvent evaporation. However, PXRD pattern changes were only observed in the liquid-assisted grinding and solvent evaporation techniques, with peaks of BET remaining present in both cases. Therefore, further attempts to obtain pure cocrystals were only conducted using the above two techniques and a 2:1 EPR/BET molar ratio. As illustrated in Fig. 9.16, no raw material peaks were observed under these conditions, indicating the formation of a new phase. In addition, the new PXRD patterns matched well with the simulated ones, suggesting high sample purity. The minor differences between the experimental and simulated PXRD patterns were ascribed to the preferred orientation effect. As expected, the utilization of a zwitterionic coformer preserved the neutrality of EPR molecules.

Reprinted (adapted or reprinted in part) with permission from [79]. Copyright 2011 American Chemical Society

PXRD patterns of a EPR, b BET, and EPR–BET obtained by c liquid-assisted grinding and d solvent evaporation. e Simulated single-crystal pattern of EPR–BET.

The EPR–BET cocrystal structure was supported by complicated intermolecular interactions (Fig. 9.17a). From all the hydrogen bonds, two strong, charge-assisted bonds connected the carboxylate group of a BET molecule with the moieties of two EPR molecules (EPR I and II) via the O3–H···O8(−) and O6–H···O7(−) interactions (the blue, dashed lines in Fig. 9.17a). Notably, the O3···O8 and O6···O7 distances equaled 2.550(2) and 2.573(2) Å, respectively, being shorter than the O···O distances in common hydrogen bonds (∼2.74 Å). Abundant weak hydrogen bonds (the orange, dashed lines in Fig. 9.3a) further connected EPR I and BET molecules (C6–H···O8 and C34–H···O1) and EPR II and BET molecules (C16–H···O8 and C32–H···O5). The BET molecules were interconnected by weak C35–H···O8 hydrogen bonds in the (001) plane. The EPR I molecules were also joined by weak C2–H···O2 and C5–H···O2 hydrogen bonds. Finally, C1–H···O5 hydrogen bonds connected the EPR I and EPR II molecules via x + 1, y, z symmetry operations. The above hydrogen bonds resulted in a layered structure (Fig. 9.17b) with alternately arranged EPR I, BET, and EPR II molecules, stacked along the a-axis.

Reprinted (adapted or reprinted in part) with permission from [79]. Copyright 2011 American Chemical Society

Hydrogen bond architecture a and molecule packing b, viewed along the b-axis of a zwitterionic EPR–BET cocrystal, with blue and orange lines representing conventional and unconventional hydrogen bonds, respectively. In the packing view, the BET molecules are rendered in a space-filling view, with hydrogen atoms omitted for clarity.

Photoinstability is one of the greatest, not yet successfully tackled challenges of the pharmaceutical field. Solid-state EPR is stable in the dark, but undergoing E,Z to Z,Z isomerization even when exposed to ambient light. From a crystal engineering viewpoint, zwitterionic cocrystals should provide a good opportunity to overcome this problem, since the zwitterionic coformer is expected to form strong, charge-assisted hydrogen bonds with the EPR molecules, stabilizing their conformation, a phenomenon, however not yet observed in other EPR cocrystals and salts. Therefore, BET was selected as a coformer due to its inherent ability to form charge-assisted hydrogen bonds.

The photostability of zwitterionic EPR cocrystals was qualitatively examined by 1H NMR measurements aimed at detecting the E,Z to Z,Z photoisomerization. In addition, to reduce experimental conditions interference, the samples were prepared less than 5 min before the NMR spectra acquisition. As illustrated in Fig. 9.18, solid-state EPR underwent E,Z to Z,Z isomerization after a 24 h irradiation at 6000 lx, indicated by the appearance of new peaks in the 1H NMR spectra (see the small black dots corresponding to the Z,Z isomer). This isomerization induced a color change from orange to pale yellow (Fig. 9.19a), as previously reported. [79] Under the same conditions, the EPR–BET cocrystal exhibited no isomerization, also indicated by the absence of the above-mentioned color change (Fig. 9.19b).

Reprinted (adapted or reprinted in part) with permission from [79]. Copyright 2011 American Chemical Society

1H NMR spectra of EPR and EPR–BET before and after irradiation, with black dots indicating peaks of the Z,Z EPR isomer.

Reprinted (adapted or reprinted in part) with permission from [79]. Copyright 2011 American Chemical Society

Visual appearance of a EPR and b EPR–BET, before and after irradiation.

The observed photosensitivity was attributed to intermolecular interaction changes dependent on the reaction cavity size. It is generally known that (depending on their number and strength) intermolecular interactions constrain the EPR molecules in the lattice and prevent their E,Z to Z,Z isomerization. As described above, the EPR and BET molecules in the cocrystal were connected by numerous hydrogen bonds, including two strong O···O hydrogen bonds (DO···O = 2.550(2) and 2.573(2) Å) and many other weak bonds (EPR–EPR and EPR–BET). These bonds were expected to restrain the EPR molecules and therefore prevent their isomerization.

The photostability improvement can also be deducted from the “reaction cavity” concept: the space around a reactive group in a crystal structure [80] influences the probability of a solid-state reaction. Herein, the reaction cavity was characterized for both the whole EPR molecule and its olefin part, reflecting molecular mobility.

It should be noted that the intact form I EPR crystal contained two different EPR molecules, EPR A and EPR B. The calculated reaction cavity volumes of EPR A, EPR B, (from the intact-crystal EPR form I) EPR I, and EPR II (from the EPR–BET cocrystals) were 103.4, 108.6, 84.1, and 85.5 Å3, respectively (Fig. 9.20). Unsurprisingly, the reaction cavities of the cocrystal EPR were considerably smaller (by ∼30 Å3) than those of the intact-crystal EPR. In addition, the olefin reaction cavity volumes of the EPR A, EPR B, EPR I, and EPR II equaled 26.6, 18.0, 15.0, and 17.3 Å3, respectively, with cocrystal values also being smaller than those of EPR form I crystals. The above-mentioned reaction cavity decrease correlated with the limitation of E,Z to Z,Z isomerization; smaller reaction cavities limited the molecular motion and therefore hindered isomerization [79].

Reprinted (adapted or reprinted in part) with permission from [79]. Copyright 2011 American Chemical Society

Whole a–d and partial e–h reaction cavities (drawn as blue translucent spaces) of EPR molecules. EPR form I comprised EPR A (a and e) and EPR B (b and f) molecules and EPR–BET cocrystals contained EPR I (c and g) and EPR II (d and f) molecules.

2.5 Taste Masking of Bitter Drugs by Utilizing Artificial Sweeteners as Coformers

In the early days, it was believed that bitter-tasting drugs were more curable. However, bitter drugs are inconvenient nowadays, especially for pediatric and geriatric patients [81]. Several proposed solutions for the bitter taste of APIs involved cyclodextrin derivates, [82] or polymer encapsulation methods [83]. Crystal engineering also offers an answer to the bitter taste problem, by cocrystallization or salt formation, with sweeteners acting as coformers [84].

Benexate (BEX, Scheme 9.5 left), a defensive type anti-ulcer agent, was used as a model compound in the following study case. BEX’s defensive effects on the gastric mucosa have been demonstrated by the promotion of prostaglandin synthesis, protein secretion, and blood flow stimulation in the gastrointestinal tract [85]. This drug is marketed as a hydrochloride salt (BEX–HCl) and is part of an inclusion complex with β-cyclodextrin. The hydrochloride salt was originally meant to improve the low solubility of BEX, but that proved to be insufficient due to the high molecular weight of BEX–HCl (molecular weight = 445.93 g mol−1). Later, BEX–HCl was complexed with β-cyclodextrin, aiming to improve its solubility and to reduce the bitter taste [86, 87].

From the crystal engineering perspective, BEX is both an interesting and challenging compound because it has two major problems: bitter taste and low solubility. To date, no new reported salt structure could tackle these unfavorable characteristics of BEX. Therefore, we explored artificial sweeteners that can be used as salt coformers for naturally overcoming the native unpleasant taste of BEX. Artificial sweeteners have been reported to improve the solubility and dissolution rate of several drugs, including quinine, haloperidol, mirtazapine, pseudoephedrine, lamivudine, risperidone, sertraline, venlafaxine, zolpidem, amlodipine, and piroxicam [88]. This implies that artificial sweeteners are also potentially applicable to BEX’s low solubility issue.

The preparation of novel salts involved an anion exchange reaction between the chloride anion and the saccharinate (SAC, Scheme 9.5 middle) or cyclamate (CYM, Scheme 9.5 right) anion; therefore, the sodium salts of those sweeteners were chosen. Notably, other coformers used in either salt or acidic form failed to form new solid products. As illustrated in Fig. 9.21, no raw material trace was observed through this method, indicating the formation of new phases. Benexate-saccharinate (BEX–SAC,) and benexate-cyclamate (BEX–CYM,) were produced alongside a sodium chloride byproduct from the anion exchange reaction. However, BEX–SAC, and BEX–CYM could easily be separated from sodium chloride by filtration since these salts precipitated before sodium chloride, which was retained in solution. This method effectively produced pure BEX–SAC and BEX–CYM with high yields (>95%). The purities of the BEX–SAC and BEX–CYM salts were confirmed by the considerable agreement between experimental and simulated PXRD patterns and by the absence of raw material peaks. The difference between the experimental and simulated PXRD patterns was acceptable and attributed to the preferred orientation effect. Other attempts employing high salt formation methods and the same conformer and solvent system, such as slurry mixing, co-grinding, and dry milling failed, resulting in sticky, amorphous solids.

Reprinted from [89] by the author(s) licensed under CC BY 4.0

PXRD patterns of benexate hydrochloride (BEX–HCl) (blue), sodium saccharinate (red), benexate-saccharinate (BEX–SAC) (purple), sodium cyclamate (yellow), and benexate-cyclamate (BEX–CYM) (green). The solid and dashed lines represent the experimental and simulated PXRD patterns, respectively.

After the anion exchange reaction that yielded BEX–SAC and BEX–CYM, we were able to isolate single crystals from the reaction flask and perform single-crystal X-ray structure. The single-crystal structure analysis revealed an asymmetric BEX–SAC unit that contained one cationic benexate, one anionic saccharinate, and one water molecule. Similarly, an asymmetric BEX–CYM unit contained one cationic benexate and one anionic cyclamate molecule. Therefore, BEX–SAC and BEX–CYM existed as monohydrate and ansolvate/anhydrous crystals, respectively.

The crystal structure of BEX–SAC contained complicated hydrogen bonds, as illustrated in Fig. 9.22. One set of cationic benexate and anionic saccharinate were bound by a charge-assisted hydrogen bond, N2+–H···N4 − and a conventional hydrogen bond, N1–H···O5, which enclosed a \({R}_{2}^{2}\) (8) hydrogen bond loop. An additional weak hydrogen bond, C20–H···O5 stabilized this interaction. Two symmetrical N2–H···O6 hydrogen bonds connected two sets of one cationic benexate and one anionic saccharinate. These hydrogen bonds constructed an \({R}_{4}^{4}\) (20) loop around the center of symmetry, as shown in Fig. 9.22a. Figure 9.22b illustrates the one-dimensional (1D) chain structure built by connecting each pair of cationic benexate and anionic saccharinate sets along the (110) plane, with intercalated water molecules. The N3–H···O8 hydrogen bonds with two different symmetric operations (x + 1, y, z + 1 and –x + 2, − y, − z + 1) played important roles in building this 1D chain structure. 1D chains were connected to each other via O8–H···O4 and O8–H···O5 hydrogen bonds, leading to a two-dimensional (2D) sheet structure, as illustrated in Fig. 9.22c.

Reprinted from [89] by the author(s) licensed under CC BY 4.0

The hydrogen bond architecture of the BEX–SAC crystal. a The interaction involving two sets of cationic benexate and anionic saccharinate molecules and water constructs. b 1D chain structure parallel to the (110) plane. c 2D sheet structure composed of 1D chains (represented by different colors) that interact with each other to form (c) a 2D sheet structure. Conventional and non-conventional hydrogen bonds are drawn by dashed blue and orange lines, respectively. Hydrogen atoms have been omitted for clarity. The oxygen atoms from water molecules are drawn in ball-setting.

The crystal structure of BEX–CYM also contained intricate hydrogen-bond networks. Conventional (N–H···N and N–H···O) and unconventional (C–H···O and C–H···N) hydrogen bonds were observed in the crystal. The N3 atom of the guanidine radical in the benexate molecule formed three hydrogen bonds: N3–H3A···N4, N3–H3A···O6, and N3–H3B···O7, including bifurcated hydrogen bonds. The other N atoms of the guanidine moiety in the benexate molecule also interacted with O6 from the cyclamate anion to form N1–H···O6 and N2–H···O6 hydrogen bonds. These hydrogen bonds formed a 1D chain structure along the b-axis (Fig. 9.23a). The hydrogen bonds N2–H···O5 and N4–H···O7 along with the weak hydrogen bonds C29–H···N3 and C21–H···O5 connected two adjacent 1D chains. This is hereafter defined as the 2D sheet structure of BEX-CYM (Fig. 9.23b). These 2D sheet structures were stacked through C5–H···O2 and C7–H···O2 hydrogen bonds along the a-axis, as illustrated in Fig. 9.23c.

Reprinted from [89] by the author(s) licensed under CC BY 4.0

a 1D chain and b 2D sheet structures of the BEX–CYM crystal. c The 2D sheet structure is stacked along the a-axis through C5–H···O2 and C7–H···O2 hydrogen bonds. Conventional and non-conventional hydrogen bonds are drawn by dashed blue and orange lines, respectively. Hydrogen atoms have been omitted for clarity.

Despite the hydrogen bond network differences between BEX–SAC and BEX–CYM, these crystals shared something in common. As shown in Fig. 9.24, the packing motifs of BEX–SAC and BEX–CYM showed local layered-like structures composed of alternate arrangements between cationic benexate molecules and coformer molecules. Water molecules were also involved in the formation of a local layered-like structure in BEX–SAC.

Reprinted from [89] by the author(s) licensed under CC BY 4.0

Packing view of a BEX–SAC and b BEX–CYM. All molecules are rendered in a space-filling setting. Cationic benexate, anionic salt coformer, and water molecules are colored in dark blue, light green, and red, respectively.

In these two cases, it is expected that the BEX–SAC, and BEX–CYM formulations provide a sweeter taste than BEX–HCl due to the inherent sweetness of the anion molecules in these crystals. Notably, the sweetness level of cyclamate and saccharine is approximately 30–50 and 300 times higher than that of sucrose, respectively [90].

The solubility of BEX–HCL reached 104.42 ± 27.60 µg/mL. All the new solid forms presented in this study displayed improved solubility. The solubility of BEX–SAC and BEX–CYM was 512.16 ± 22.06 and 160.53 ± 14.52 µg/mL, respectively (Fig. 9.25a). This means a solubility increase of 5 and 1.5 times, respectively, relative to the marketed form of BEX. In agreement with the solubility results, the intrinsic dissolution rate showed a similar trend with BEX–SAC and BEX–CYM exhibiting improved dissolution rates of around 5 and 2 times higher than that of BEX–HCL, respectively (Fig. 9.25b). All solid forms maintained their molecular structures at the end of the solubility and dissolution rate experiments, as confirmed by PXRD measurements.

Reprinted from [89] by the author(s) licensed under CC BY 4.0

a The solubility and b intrinsic dissolution rate of BEX–HCl (blue), BEX–SAC (purple), and BEX–CYM (green). Solubility and dissolution rate experiments were conducted in triplicate.

We related the solubility and dissolution rate improvement to the molecular arrangement in the crystal structure. As mentioned above, the overall packing features of BEX–SAC, and BEX–CYM displayed local layered-like structures composed of an alternate arrangement between cationic benexate and coformer molecules. This local layered-like structure facilitated a structural collapse during dissolution by propagating a breach in the interaction between the drug and the salt coformer. This mechanism has been proposed in studies aimed at improving the solubility of insoluble drugs. Given the improved solubility and dissolution rate profiles observed in these novel BEX salts, a likely bioavailability improvement of BEX could also be observed if these solid forms are chosen for further development [89].

3 Conclusion

The use of multicomponent crystals is a new trend in pharmaceutical crystal engineering. They not only provide solutions to unfavorable physicochemical properties but also for the research and patent opportunities offered by new pharmaceutical solids. Multicomponent crystals have gained increasing interest and scientific value due to the possibility to deduct the physicochemical property changes from the multicomponent crystal structure. In this chapter, some examples that showcase the potential applications of multicomponent crystals in combatting common physicochemical difficulties faced in the pharmaceutical field are presented. Solution to unfavorable physicochemical properties, such as insolubility, hygroscopicity, tabletability, drug instability, and bitter taste, indicates the potential benefits of multicomponent crystals in pharmaceutical drug development.

References

Goodman, L.S., Gilman, A., Hardman, J.G., Gilman, A.G., Limbird, L.E.: Goodman and Gilmans’s the Pharmacological Basis of Therapeutics. McGraw-Hill, New York (1996)

Brittain, H.G.: Polymorphism in Pharmaceutical Solids. Informa, New York (2009)

Lynn, E.J., Walter, R.G., Harris, L.A., Dendy, R., James, M.J.: Nitrous oxide: it’s a gas. Psychedelic Drugs 5, 1–7 (1972)

Vippagunta, S.R., Brittain, H.G., Grant, D.J.W.: Crystalline solids. Adv. Drug. Deliv. Rev. 48, 3–26 (2001)

Shan, N., Zawarotko, M.J.: The role of cocrystals in pharmaceutical science. Drug Discov. Today 13, 440–446 (2008)

Byrn, S.R., Pfeiffer, R.R., Stephenson, G., Grant, D.J.W., Gleason, W.B.: Solid-state pharmaceutical chemistry. Chem. Mater. 6, 1148–1158 (1994)

Cheney, M.L., Weyna, D.R., Shan, N., Hanna, M., Wojtas, L., Zawarotko, M.J.: Supramolecular architectures of meloxicam carboxylic acid cocrystals, a crystal engineering case study. Cryst. Growth Des. 10, 4401–4413 (2010)

Sun, C.C., Hou, H.: improving mechanical properties of caffeine and methyl gallate crystals by cocrystallization. Cryst. Growth Des. 8, 1575–1579 (2008)

Chen, S., Guzei, I.A., Yu, L.: New polymorphs of ROY and new record for coexisting polymorphs of solved structures. J. Am. Chem. Soc. 127(27), 9881–9885 (2005)

Yu, L.: Polymorphism in molecular solids: an extraordinary system of red, orange, and yellow crystals. Acc. Chem. Res. 43, 1257–1266 (2010)

Bryn, S., Pfeiffer, R., Ganey, M., Hoiberg, C., Poochikian, G.: Pharmaceutical solids: a strategic approach to regulatory considerations. Pharm. Res. 12, 945–954 (1995)

Aitipamula, S., Banerjee, R., Bansal, A.K., Biradha, K., Cheney, M.L., Choudhury, A.R., Desiraju, G.R., et al.: Polymorphs, salts, and cocrystals: what’s in a name? Cryst. Growth Des. 12, 2147–2152 (2012)

Grothe, E., Meekes, H., Vlieg, E., ter Horst, J.H., de Gelder, R.: Solvates, salts, and cocrystals: a proposal for a feasible classification system. Cryst. Growth Des. 16, 3237–3243 (2016)

Kavanagh, O.N., Croker, D.M., Walker, G.M., Zaworotko, M.J.: Pharmaceutical cocrystals: from serendipity to design to application. Drug Discov. Today 24, 796–804 (2019)

Hancock, B.C., Zografi, B.: Characteristics and significance of the amorphous state in pharmaceutical systems. J. Pharm. Sci. 86, 1–12 (1997)

Hancock, B.C., Parks, M.: What is the true solubility advantage for amorphous pharmaceuticals? Pharm. Res. 17, 397–404 (2000)

Grohganz, H., Lobman, K., Priemel, P., Jensen, K.T., Graeser, K., Rades, T.: Amorphous drugs and dosage forms. J. Drug. Del. Sci. Tech. 23, 403–408 (2013)

Sibik, J., Lobmann, K., Zeitler, T., Rades, J.A.: Predicting crystallization of amorphous drugs with terahertz spectroscopy. Mol. Pharm. 12, 3062–3068 (2015)

Datta, S., Grant, D.J.W.: Crystal structures of drugs: advances in determination, prediction and engineering. Nat. Rev. Drug Discov. 3, 42–57 (2004)

Bernstein, J.: Polymorphism in Molecular Crystals. Clarendon, Oxford (2002)

Morissette, S.L., Almarsson, O., Peterson, M.L., Remenar, J.F., Read, M.J., Lemmo, A.V., Ellis, S., Cima, M.J., Gardner, C.R.: High-throughput crystallization: polymorphs, salts, co-crystals and solvates of pharmaceutical solids. Adv. Drug. Deliv. Rev. 56, 275–300 (2004)

Hilfiker, R.: Polymorphism in the Pharmaceutical Industry. Wiley, Weinheim (2006)

Seddon, K.R.: Pseudopolymorph: a polemic. Cryst. Growth Des. 4, 1087–1087 (2004)

Bernstein, J.: …And another comment on pseudopolymorphism. Cryst. Growth Des. 5, 1661–1662 (2005)

Putra, O.D., Pettersen, A., Lill, S.O.N., Umeda, D., Yonemochi, E., Nugraha, Y.P., Uekusa, H.: Capturing a new hydrate polymorph of amodiaquine dihydrochloride dihydrate via heterogeneous crystallization. Cryst. Eng. Commun. 2019(21), 2053–2057 (2019)

Healy, A.M., Worku, Z.A., Kumar, D., Madi, A.M.: Pharmaceutical solvates, hydrates and amorphous forms: a special emphasis on cocrystals. Adv. Drug Deliv. Rev. 117, 25–46 (2017)

Vioglio, P.C., Chierotti, M.R., Gobetto, R.: Pharmaceutical aspects of salt and cocrystal forms of APIs and characterization challenges. Adv. Drug Deliv. Rev. 117, 86–110 (2017)

Desiraju, G.R., Vittal, J.J., Ramanan, A.: Crystal Engineering: A Textbook. World Scientific, Singapore (2011)

Baghel, S., Cathcart, H., O’Reilly, N.J.: Polymeric amorphous solid dispersions: a review of amorphization, crystallization, stabilization, solid-state characterization, and aqueous solubilization of biopharmaceutical classification system class II drugs. J. Pharm. Sci. 105, 2527–2544 (2016)

Almarsson, O., Vadas, E.B.: Molecules, materials, medicines (M3): linking molecules to medicines through pharmaceutical material science. Cryst. Growth. Des. 15, 5645–5647 (2015)

Daousani, C., Macheras, P.: Biopharmaceutic classification of drugs revisited. Eur. J. Pharm. Sci. 82–87, 82–87 (2016)

Butler, J.M., Dressman, J.B.: The developability classification system: application of biopharmaceutics concepts to formulation development. J. Pharm. Sci. 99, 4940–4954 (2010)

Khadka, P., Ro, J., Kim, H., Kim, I., Kim, J.T., Kim, H., Cho, J.M., Lee, J.: Pharmaceutical particle technologies: an approach to improve drug solubility, dissolution and bioavailability. Asian J. Pharm. Sci. 9, 304–316 (2014)

Kawabata, Y., Wada, K., Nakatani, M., Yamada, S., Onoue, S.: Formulation design for poorly water-soluble drugs based on biopharmaceutics classification system: basic approaches and practical applications. Int. J. Pharm. 420, 1–10 (2011)

Onoue, S., Yamada, S., Chan, H.K.: Nanodrugs: pharmacokinetics and safety. Int. J. Nanomed. 9, 1025–1037 (2014)

Newman, A.W., Reutzel-Edens, S.M., Zografi, G.: Characterization of the “hygroscopic” properties of active pharmaceutical ingredients. J. Pharm. Sci. 97, 1047–1059 (2008)

Sun, C.C., Grant, D.J.W.: Improved tableting properties of p-hydroxybenzoic acid by aater of crystallization: a molecular insight. Pharm. Res. 21, 382–386 (2004)

Zu, B., Wang, J., Zhang, Q., Zu, B., Wang, J., Zhang, Q., Mei, X.: Improving dissolution and photostability of vitamin K3 via cocrystallization with naphthoic acids and sulfamerazine. Cryst. Growth Des. 16, 483–492 (2016)

Song, J.X., Yan, Y., Yao, J., Chen, J.M., Lu, T.B.: Improving the solubility of lenalidomide via cocrystals. Cryst. Growth Des. 14, 3069–3077 (2014)

Geng, N., Chen, J.M., Li, Z.J., Jiang, L., Lu, T.B.: Approach of cocrystallization to improve the solubility and photostability of tranilast. Cryst. Growth Des. 13, 3546–3553 (2013)

Good, D.J., Rodríguez-Hornedo, N.: Solubility advantage of pharmaceutical cocrystals. Cryst. Growth Des. 9, 2252–2264 (2009)

Visalakshi, N.A., Mariappan, T.T., Bhutani, H., Singh, S.: Behavior of moisture gain and equilibrium moisture contents (EMC) of various drug substances and correlation with compendial information on hygroscopicity and loss on drying. Pharm. Dev. Tech. 10, 489–497s (2005)

Sun, C.C., Grant, D.J.W.: Influence of crystal structure on the tableting properties of sulfamerazine polymorphs. Pharm. Res. 18, 274–280 (2001)

Gupta, D., Bhatia, D., Dave, B., Sutariya, V., Gupta, S.V.: Salts of therapeutic agents: chemical, physicochemical, and biological considerations. Molecules 23, 1719 (2018)

Putra, O.D., Yoshida, T., Umeda, D., Gunji, M., Uekusa, H., Yonemochi, E.: Crystallographic analysis of phase dissociation related to anomalous solubility of irsogladine maleate. Cryst. Growth Des. 16, 6714–6718 (2016)

Tovey, G.D.: Pharmaceutical Formulation: The Science and Technology of Dosage Forms. The Royal Society of Chemistry, Croydon (2018)

Iacocca, R.G., Burcham, C.L., Hilden, L.R.: Particle engineering: a strategy for establishing drug substance physical property specifications during small molecule development. J. Pharm. Sci. 99, 51–75 (2010)

Chattoraj, S., Sun, C.C.: Crystal and particle engineering strategies for improving powder compression and flow properties to enable continuous tablet manufacturing by direct compression. J. Pharm. Sci. 107, 968–974 (2018)

Ramirez, M.A., Borja, N.L.: Epalrestat: an aldose reductase inhibitor for the treatment of diabetic neuropathy. Pharmacotherapy 28, 646–655 (2008)

Steel, J.W., Faulds, D., Goa, K.L.: Epalrestat. a review of its pharmacology, and therapeutic potential in late-onset complications of diabetes mellitus. Drugs Aging 3, 532–555 (1993)

Swapna, B., Suresh, K., Nangia, A.: Color polymorphs of aldose reductase inhibitor epalrestat: configurational, conformational and synthon differences. Chem. Commun. 52, 4037–4040 (2016)

Igarashi, R., Nagase, H., Furuishi, T., Endo, T., Tomono, K., Ueda, H.: Crystal structure of epalrestat non-solvate. X-Ray Struct. Anal. Online 29, 23–24 (2013)

Ishida, T., In, Y., Inoue, M., Ueno, Y., Tanaka, C., Hamanaka, N.: Structural elucidation of epalrestat (ONO-2235), a potent aldose reductase inhibitor, and isomerization of its double bonds. Tetrahedron Lett. 30, 959–962 (1989)

Nagase, H., Kobayashi, M., Ueda, H., Furuishi, T., Gunji, M., Endo, T., Yonemochi, E.: Crystal structure of an epalrestat dimethanol solvate. X-Ray Struct. Anal. Online 32, 7–9 (2016)

Ishida, T., In, Y, Inoue, M., Tanaka, C., Hamanaka, N.: Conformation of (Z)-3-carboxymethyl-[(2E)-2-methyl-3-phenylpropenylidene]rhodanine (epalrestat), a potent aldose reductase inhibitor: X-ray crystallographic, energy calculational, and nuclear magnetic resonance Studies. J. Chem. Soc. Perkin Trans. 2(2), 1085–1091 (1990)

Umeda, D., Putra, O.D., Gunji, M., Fukuzawa, K., Yonemochi, E.: Epalrestat tetrahydrofuran monosolvate: crystal structure and phase transition. Acta Crystallogr. E Cryst. Commun. 73, 941–944 (2017)

Putra, O.D., Umeda, D., Fukuzawa, K., Gunji, M., Yonemochi, E.: A New solvate of epalerstat, a drug for diabetic neuropathy. Acta Crystallogr. E Cryst. Commun. 73, 1264–1267 (2017)

Putra, O.D., Umeda, D., Nugraha, Y.P., Furuishi, T., Nagase, H., Fukuzawa, K., Uekusa, H., Yonemochi, E.: Solubility improvement of epalrestat by layered structure formation via cocrystallization. Cryst. Eng. Commun. 19, 2614–2622 (2017)

Umeda, Y., Fukami, T., Furuishi, T., Suzuki, T., Makimura, M., Tomono, K.: Molecular complex consisting of two typical external medicines: intermolecular interaction between indomethacin and lidocaine. Chem. Pharm. Bull. 55, 832–836 (2007)

Wang, J., Yu, Q., Dai, W., Mei, X.: Drug-drug co-crystallization presents a new opportunity for the development of stable vitamins. Chem. Commun. 52, 3572–3575 (2016)

Bangalore, S., Kamalakkannan, G., Parkar, S., Messerli, F.H.: Fixed-dose combinations improve medication compliance: a meta-analysis. Am. J. Med. 120, 713–719 (2007)

Vilar, L., Canadas, V., Arruda, M.J., Arahata, C., Agra, R., Pontes, L., Montenegro, L., Vilar, C.F., Silva, L.M., Albuquerque, J.L., Gusmão, A.: Comparison of metformin, gliclazide MR and rosiglitazone in monotherapy and in combination for type 2 diabetes. Arq. Bras. Endocrinol. Metabol. 54, 311–318 (2010)

Jakobsen, D.F., Frokjaer, S., Larsen, C., Niemann, H., Buur, A.: Application of isothermal microcalorimetry in preformulation. I. hygroscopicity of drug substances. Int. J. Pharm. 156, 67–77 (1997)

Childs, S.L., Chyall, L.J., Dunlap, J.T., Coates, D.A., Stahly, B.C., Stahly, G.P.: A metastable polymorph of metformin hydrochloride: isolation and characterization using capillary crystallization and thermal microscopy techniques. Cryst. Growth Des. 4, 441–449 (2004)

Putra, O.D., Yonemochi, E., Uekusa, H.: Isostructural multicomponent gliclazide crystals with improved solubility. Cryst. Growth Des. 16, 6568–6573 (2016)

Putra, O.D., Furuishi, T., Yonemochi, E., Terada, K., Uekusa, H.: Drug-drug multicomponent crystals as an effective technique to overcome weaknesses in parent drugs. Cryst. Growth Des. 16, 3577–3581 (2016)

Tye, C.K., Sun, C.C., Amidon, G.E.: Evaluation of the effects of tableting speed on the relationships between compaction pressure, tablet tensile strength, and tablet solid fraction. J. Pharm. Sci. 94, 465–472 (2005)

Patel, S., Kaushal, A.M., Bansal, A.K.: Compression physics in the formulation development of tablets. Crit. Rev. Ther. Drug Carrier Syst. 23, 1–65 (2006)

Bag, P.P., Chen, M., Sun, C.C., Reddy, C.M.: Direct correlation among crystal structure, mechanical behaviour and tabletability in a trimorphic molecular compound. CrystEngComm 14, 3865–3867 (2012)

Canonica, G.W., Blaiss, M.: Antihistaminic, anti-inflammatory, and antiallergic properties of the nonsedating second-generation antihistamine desloratadine: a review of the evidence. World Allergy Organ. J. 4, 47–53 (2011)

Kumar, B.V.S., Kale, S.A., Choudhari, R.B., Pradhan, N.S.C.: Novel crystalline forms of desloratadine and processes for their preparation. Patent US2007/0135472A1 (2006)

Ainurofiq, A., Mauludin, R., Mudhakir, D., Umeda, D., Soewandhi, S.N., Putra, O.D., Yonemochi, E.: Improving mechanical properties of desloratadine via multicomponent crystal formation. Eur. J. Pharm. Sci. 111, 65–72 (2018)

Tao, W., Chen, J., Lu, T., Ma, L.: Phenazopyridine cocrystal and salts that exhibit enhanced solubility and stability. Cryst. Growth Des. 12, 3144–3152 (2012)

Stanton, M.K., Bak, A.: Physicochemical properties of pharmaceutical co-crystals: a case study of ten AMG 517 co-crystals. Cryst. Growth Des. 8, 3856–3862 (2008)

Putra, O.D., Yoshida, T., Umeda, D., Higashi, K., Uekusa, H., Yonemochi, E.: Crystal structure determination of dimenhydrinate after more than 60 years: solving salt-cocrystal ambiguity via solid-state characterizations and solubility study. Cryst. Growth Des. 16, 5223–5229 (2016)

He, H., Huang, Y., Zhang, Q., Wang, J., Mei, X.: Zwitterionic cocrystals of flavonoids and proline: solid-state characterization, pharmaceutical properties, and pharmacokinetic performance. Cryst. Growth Des. 16, 2348–2356 (2016)

Maeno, Y., Fukami, T., Kawahata, M., Yamaguchi, K., Tagami, T., Ozeki, T., Suzuki, T., Tomono, K.: Novel pharmaceutical cocrystal consisting of paracetamol and trimethylglycine, a new promising cocrystal former. Int. J. Pharm. 473, 179–186 (2014)

Swapna, B., Nangia, A.: Epalrestat-cytosine cocrystal and salt structures: attempt to control E,Z→Z,Z isomerization. Cryst. Growth Des. 17, 3350–3360 (2017)

Putra, O.D., Umeda, D., Nugraha, Y.P., Nango, K., Yonemochi, E., Uekusa, H.: Simultaneous improvement of epalrestat photostability and solubility via cocrystallization: a case study. Cryst. Growth Des. 18, 373–379 (2018)

Ohashi, Y., Tomotake, Y., Uchida, A., Sasada, Y.: Crystalline-state reaction of cobaloxime complexes by X-ray exposure. 13. A stepwise structure analysis of the concerted process of racemization. J. Am. Chem. Soc. 108, 1196–1202 (1986)

Couplands, J.N., Hayes, J.E.: Physical approaches to masking bitter taste: lessons from food and pharmaceuticals. Pharm. Res. 31, 2921–2939 (2014)

Del Valle, E.M.M.: Cyclodextrins and their uses: a review. Process Biochem. 38, 1033–1046 (2004)

Thakral, S., Thakral, N.K., Majumdar, D.K.: Eudragit: a technology evaluation. Expert Opin. Drug Deliv. 10, 131–149 (2013)

Wang, C., Hu, S., Sun, C.C.: Expedited development of a high dose orally disintegrating metformin tablet enabled by sweet salt formation with acesulfame. Int. J. Pharm. 532, 435–443 (2017)

Iwasaki, T., Matsunaga, K.: Nitric oxide-associated vasorelaxing effect of an anti-ulcer agent, benexate hydrochloride betadex. Drug. Dev. Res. 36, 13–19 (1995)

Hori, Y., Odaguchi, K., Jyoyama, H., Yasui, K., Mizui, T.: Differential effect of benexate hydrochloride betadex on prostaglandin levels in stomach and inflammatory sites in rats. Jpn. J. Pharmacol. 72, 183–190 (1996)

Muranushi, N., Yoshida, M., Kinoshita, H., Hirose, F., Fukuda, T., Doteuchi, M., Yamada, H.: Studies of benexate CD: effect of inclusion compound formation on the antiulcer activity of benexate, the effective ingredient of benexate CD. Folia Pharmacol. Jpn. 91, 377–383 (1988)

Banarjee, R., Bhatt, P.M., Ravindra, N.V., Desiraju, G.R.: Saccharin Salts of Active Pharmaceutical Ingredients, Their Crystal Structure, and Increased Water Solubilities. Cryst. Growth Des. 5, 2299–2309 (2005)

Putra, O.D., Umeda, D., Fujita, E., Haraguchi, T., Uchida, T., Yonemochi, E., Uekusa, H.: Solubility improvement of benexate through salt formation using artificial sweetener. Pharmaceutics 10(64) (2018)

Cattopadhyay, S., Raychaudhuri, U., Chakraborty, R.: Artificial sweeteners—a review. J. Food Sci. Technol. 51, 611–621 (2014)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Putra, O.D., Uekusa, H. (2020). Pharmaceutical Multicomponent Crystals: Structure, Design, and Properties. In: Sakamoto, M., Uekusa, H. (eds) Advances in Organic Crystal Chemistry. Springer, Singapore. https://doi.org/10.1007/978-981-15-5085-0_9

Download citation

DOI: https://doi.org/10.1007/978-981-15-5085-0_9

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-5084-3

Online ISBN: 978-981-15-5085-0

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)