Abstract

In this paper, three different materials, such as copper, MWCNT, and MWCNT composite PU/MWCNT (polyurethane C27H36N2O10), are used as conducting structures for the design of a rectangular patch antenna, which resonate in X-Band (8–12 GHz). These antenna structures are implemented using FR-4 substrate, having a dielectric constant of 4.4 and with a loss tangent of 0.02. This work concentrates on the comparison of these three antennas in terms of their performance metrics like return loss, VSWR, impedance bandwidth, gain, and radiation efficiency. Initially, these antennas are simulated using HFSS and fabricated. Their performance is tested using ROHDE&SCHWARZ ZVB 20 vector network analyzer. From the results, it is clear that among the three antennas, MWCNT-based antenna design provides wider impedance bandwidth when compared to composite MWCNT and copper-based structures, whereas PU/MWCNT exhibits similar bandwidth as of MWCNT, but it offers more mechanical strength, electrical conductivity, and thermal conductivity. Thus, both MWCNT and composite MWCNT are equally applicable in the X-band range. Both simulated and fabricated results are presented in this paper.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Each nanotube present on the surface of CNT material to resonate electromagnetic waves individually influences the impedance bandwidth [1]. Nanomaterials exhibit excellent electrical conductivity, and its conductive properties can be enhanced with the addition of composite material like PANI, PU, CFC, and epoxy are used to overcome the drawbacks of metals such as weight, fabrication procedure, and corrosion resistance [2,3,4]. Carbon nanotube (CNT) and CNT with conducting polymers are used to replace the copper patch antennas [5, 6]. An antenna designed using CNT composite material is a lossy antenna in nature as ohmic loss of the composite material is greater than that of conventional metal, i.e., copper. Hence, the composite antenna bandwidth is wider than that of the standard copper antenna operating in the X-band frequency range. As the ohmic loss increases, the bandwidth increases, and the Q-factor decreases, which is the actual behavior of the CNT composite antenna [7].

The current study deals with the design and fabrication of Cu, MWCNT, and polymer-based MWCNT composite patch antenna. These antennas are fabricated with thin film technology by depositing a thin layer of MWCNT, PU/MWCNT materials using spin coating and drop casting techniques are used to fabricate the MWCNT antennas on the FR-4 substrate [8,9,10].

The rest of the paper is organized as follows: Sect. 2 material used for experimentation, Sect. 3 discussed antenna design considerations. In Sect. 4, results and discussions of above antennas are discussed, and finally, conclusions are made in Sect. 5.

2 Experimentation

2.1 Material Used for Experimentation for MWCNT Antenna

MWCNTs, sodium dodecyl sulfate (SDS) (NaC12H25SO4), and ethanol (C2H5OH) were supplied by Sigma-Aldrich, which are used to fabricate the MWCNT antenna.

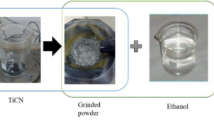

2.2 Material Preparation for MWCNT Antenna

The pure MWCNTs (98%) are dispersed in ethanol in the ratio of 1:1 by weight to acquire a stable and homogenous solution. The SDS surfactant is known to have the ability to disperse MWCNTs in aqueous media by establishing an excellent interface between the surface of MWCNT and ethanol. The weight concentration of MWCNT in ethanol was maintained at 0.1 mg ml−1. A stable solution with a required viscosity is attained by sonicating the dispersion for 8 h, at room temperature of 25 °C, employing bath sonicators. After the sonication process, the centrifugation technique is applied to separate large MWCNT aggregates from small MWCNT aggregates.

2.3 Material Used for Experimentation for Composite MWCNT Antenna

MWCNTs, polyurethane (PU) C27H36N2O10, dimethylformamide (DMF) C3H7NO, were supplied by Sigma-Aldrich; materials are used to fabricate the MWCNT composite antenna.

2.4 Material Preparation for Composite MWCNT Antenna

For the preparation of composite material, initially Polyurethane (PU) C27H36N2O10 granules are dissolved in dimethylformamide (DMF) which is an organic compound in nature with the formula C3H7NO. The composition is stirred using magnetic stirring for approximately 6 h. Now, MWCNTs were dispersed in an alternative beaker in DMF for 6 h, using ultra-sonication. The dispersed MWCNTs and dissolved polyurethane in DMF were mixed thoroughly using magnetic stirring for another 6 h. The mixed solution is now poured into a petri dish and placed in a vacuum oven for 12 h at 80 °C temperature for the solvent to evaporate. The final product is PU/MWCNT composite material. Here, 97% of polyurethane (PU), 3% weight MWCNT, and 50 ml DMF are used.

4 Results and Discussion

In this section, simulated and fabricated results of MWCNT, polymer-based MWCNT composite rectangular patch antennas are presented for X-band (8–12 GHz) applications, and these antennas are compared with the standard copper patch antenna. Figure 1 depicts the proposed simulated and fabricated antenna models. Fig. 2 shows test setup using vector network analyzer to measure the return loss, VSWR, impedance of the feed line. Figure 3 illustrates return loss and VSWR comparison between simulated and fabricated antennas. The measured impedance bandwidth of the fabricated MWCNT antenna is 19% which exhibits 2% greater than MWCNT composite antenna and 4% wider than the copper patch antenna. Figure 4 shows the simulated and fabricated smith charts, it shows impedance of the feed line, and antenna impedance matching with microstrip feed line is done by tuning the width of the feed line. Among these antennas, copper antenna has better impedance matching than other two antennas, the simulated antennas impedance values are 49.02 Ω for copper, 43.4 Ω for MWCNT composite, and 47.4 Ω for MWCNT, and fabricated antennas impedance values are 47 Ω, 33 Ω, and 35 Ω, respectively.

The simulated gain and radiation efficiency versus frequency plots are shown in Fig. 5. It is observed that all the designed antennas give almost equal amount of gain and efficiency values in the operating band, and copper patch antenna provides better gain and efficiency values when compared to other antennas (6.24 dB and 83%). Table 1 shows the material properties, and Table 2 depicts the dimensions of the three antennas. Overall simulated and fabricated results are listed in Table 3.

5 Conclusion

In this paper, the performance of MWCNT and PU/MWCNT composite rectangular patch antennas in X-band (8–12 GHz) is simulated and fabricated. The performance of these antennas is compared with basic copper antenna. Various antenna parameters such as return loss, VSWR, and impedance of the feed line are compared. Among these antennas, MWCNT antenna provides wider impedance bandwidth. Improvement in the impedance bandwidth is due to resonant behavior of each nanotube present on the surface. From simulated and measured results, the MWCNT antenna shows wider impedance bandwidth of 19% in the range of 11.2–9.3 GHz. It can be suitable for synthetic aperture radar (SAR) applications. Material properties can be modified by controlling the material concentration in CNT materials, and this is not possible with the standard copper material.

References

Suryanarayana V, Aanuradha MS, Paul Douglas S, Uzwala N (2018) Performance analysis of multi-walled carbon nanotube based rectangular patch antenna for X-band applications. JARDCS 2147–2155

Nikitin PV, Lam S, Rao KVS (2005) Low cost silver ink RFID tag antennas. In: Proceedings of IEEE antennas propagation society international symposium, pp 353–356

Ludmerer S (2007) Conductive inks for RFID antenna: the low cost high speed route to RFID labels. Parelec, Inc., Rocky Hill

Anguera J, Daniel J-P, Borja C, Mumbru J, Puente C, Leduc T, Laeveren N, Roy PV (2006) Metallized foams for fractal-shaped microstrip antennas. IEEE Antennas Propag Mag 50(6):20–38

Holloway CL, Sarto MS, Johansson M (2005) Analyzing carbon fiber composite materials with equivalent-layer models. IEEE Trans Electromagn Compat 47(4):833–844

De Rosa IM, Sarasini F, Sarto MS, Tamburrano A (2008) EMC impact of advanced carbon fiber/carbon nanotube reinforced composites for next-generation aerospace applications. IEEE Trans Electromagnet Compat 50(3):556–5632(5):99–110

Mehdipour A, Sebak AR, Rosca l, Hoa SV (2014) Carbon nanotube composites for wide band millimeter-wave antenna applications. Research gate

Iijima S (1991) Helical microtubules of graphitic carbon. Nature 354:56–58

Shokry ASA, El Morsi AK, Sabaa MS, Mohamed RR, El Sorogy HE (2014) Synthesis and characterization of polyurethane based on hydroxyl terminated poly butadiene and rein forced by carbon nanotubes. Egypt J Pet

Li H, Xu C, Banerjee K (2010) Carbon nanomaterials: the ideal interconnect technology for next-generation ICs. IEEE. Des Test Comput 27(4):20–31

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Suryanarayana, V., Satya Anuradha, M., Paul Douglas, S. (2021). Performance Analysis of Multiwalled Carbon Nanotube, Composite Multiwalled Carbon Nanotube, and Copper-Based Antenna in X-Band Applications. In: Chowdary, P., Chakravarthy, V., Anguera, J., Satapathy, S., Bhateja, V. (eds) Microelectronics, Electromagnetics and Telecommunications. Lecture Notes in Electrical Engineering, vol 655. Springer, Singapore. https://doi.org/10.1007/978-981-15-3828-5_46

Download citation

DOI: https://doi.org/10.1007/978-981-15-3828-5_46

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-3827-8

Online ISBN: 978-981-15-3828-5

eBook Packages: EngineeringEngineering (R0)