Abstract

Experimental augmentation of a concentric-tube heat exchanger with a heat pipe has been investigated. Methanol and acetone are used as working fluids to analyse the performance. Water is used as a heat-carrying fluid. In which, the investigation is carried out with the gravity-assisted angles of 0°, 45° and 90°. In this work, various parameters are such as temperatures of hot fluid range from 50 to 70 °C with an increment of 10 °C and cold fluid temperature is observed as 30.5 °C throughout the investigation. Mass flow rates of hot fluids are as 40–120 LPH with an increment of 20 LPH, cold fluid as 20–60 LPH with an increment of 10 LPH. The result suggests that an increase in effectiveness is occurred at acetone for 60 °C, 100 LPH and the influence of inclination angle at 0° reveals that 72% of an increase in effectiveness is achieved than methanol for optimum revealed conditions.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Heat pipe

- Concentric-tube heat exchanger

- Gravity-assisted angles

- Working fluids

- Mass flow rate

- Effectiveness

1 Introduction

The heat pipe shows the enrichment of heat transfer with a minimum gradient of temperature. This technique has been widely followed in various processing plants and industries. The influence of gravitational effect is analysed with segments in the section of heat pipe which was investigated in [1, 2]. The investigated heat pipe for various applications and analyses is carried out with numerical and experimental which were stated in [3, 4]. Esarte and Domiguez [5] experimentally investigated for various prototypes of flat heat pipes working against gravity assistance. In which, thermal resistance was minimum and coefficient of performance has twice the value than theoretical prediction. Fonseca et al.’s [6] investigation results with changing the working fluid with several fill ratios within 20–90%, and the optimal thermal performance at a fluid ratio was 69.68%.

Shabgard et al. [7] implemented a thermal network model to characterize the thermal behaviour in a high-temperature latent heat thermal energy storage system. Hossain et al. [8] observed result shows that performance depends upon various angles of inclination and different heat input and does not depend on coolant flow rate. The study shows that for the same heat input and inclination angle with acetone as working fluid, micro-heat pipe shows better performance.

Influence of nanofluids as working fluids for heat pipe is studied with several tests which were stated in [9, 10]. The heat pipe with different materials and tilt angles are analysed with the wick of the heat pipe which were reported [11, 12]. Heat pipe with different working fluids and fill ratios are investigated for various applications which are stated in [13, 14]. Işık et al. [15] fabricated a heat pipe using ammonia. The investigation was made on space applications and burst test in the heat pipe.

In the analysis of vast investigators, their research was carried out with minimum geometrical constraints on heat pipe heat exchanger. The constraints include geometrical parameters, working fluids, fill ratios and heat-carrying fluids in heat pipe. To rectify the above-stated constraints in this investigation, the heat pipe is designed with gravitational effect and analysed with a concentric-tube shell assisted heat exchanger. Further analysis is made with different tilt angles and working fluids. The inlet parameters of the heat-carrying fluids are measured with various mass flow rates and temperature inputs.

2 Fabrication and Working Process

2.1 Fabrication of Set-up

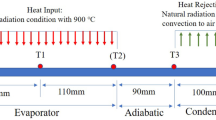

To investigate the heat transfer characteristics of a GICTSAHPHE, a set-up is designed and given in Fig. 1. In this research, GICTSAHPHE is designed with copper as a heat pipe and galvanized iron as shell material for heat exchanger with a diameter of 50 mm and length of 700 mm at evaporator zone. Heat pipe inner and outer diameter are as 19 and 17 mm and total length as 1000 mm. Condenser diameter is as 35 mm and length as 300 mm.

The two fluid tanks, for hot and cold fluids, are with a capacity of five litres, which contains one coiled immersion electric heater with two Kilowatts and a temperature controller to regulate the temperatures of hot fluid. The rotameters with a range of three litres per minute are used to regulate the flow rates of both hot and cold fluids. Two thermocouples observe the external surface temperature of the evaporator and condenser regions to measure the temperature interface with the environment.

2.2 Working Process

At the primary test, the heat pipe is filled with methanol and the secondary test is made with acetone as working fluids. Methanol and acetone are charged with fill ratios of one hundred per cent, and the thermo-physical properties of working fluids are given in Table 1. The heat-carrying fluid is chosen as water for the investigation.

At the primary stage, GICTSAHPHE is kept at a 0° tilt angle (horizontal axis) and the WF as methanol and water as HCF. The hot fluid mass flow rate and inlet temperature are fixed as 40 LPH and 50 °C. The cold fluid mass flow rate and inlet temperature are as 20 LPH and 30.5 °C as the ambient temperature condition for the investigation. At the evaporator zone of a concentric-tube heat exchanger, hot fluid transfers the heat to the methanol in the heat pipe. Thus, WF absorbs the heat and latent heat of phase change has occurred. The investigation is further carried out with other tilt angles of 45° and 90°. The hot and cold zones’ mass flow rates as Litre Per Hour (LPH) 60, 80, 100, 120 LPH and 30, 40, 50, 60 LPH. Temperatures at an inlet of hot and cold zones are 60, 70 and 30.5 °C. The above conditions are repeated for acetone as WF, and investigation is carried out for similar conditions.

3 Results and Discussion

To analyse the designed GICTSAHPHE, the investigation is done by the above-stated parameters, and Fig. 2 depicts the mass flow rate of hot fluid on effectiveness. This graph predicts that by using water as HCF and methanol as WF for the first test. The temperature of hot fluid at inlet (Thi) as 60 °C and for varying mass flow rate of hot fluid at inlet (mhi) from 40 to 120 LPH and inclination angle (ψ) as 0°, 45° and 90°. The maximum effectiveness observed is 32.2% at 100 LPH and ψ as 0° than other tilt angles and mass flow rates of hot fluids. When the mass flow rate increases by 120 LPH, the achieved effectiveness is 29.5% for 0°. In the second test, WF is chosen as acetone and HCF as water. The above-stated conditions are fixed, and at 100 LPH the observed effectiveness is 55.25% for 0°. At 120 LPH, the achieved effectiveness is 45.76% for 0°. In this analysis also, similar trends of graphs are predicted for 100 and 120 LPH. While comparing the tilt angles also, 0° and 90° show similar ranges of effectiveness than 45°. In both working fluids, the 45° shows inferior values than other tilt angles, this is due to the effect of gravitational, there is a formation of a liquid film at vapour core region, which reduces the phase transformation of working fluids at evaporator region inside the heat pipe and this reduces the heat absorption capacity. Similarly, while increasing the mhi from 100 to 120 LPH the same decrement in effectiveness is achieved for both working fluids. This decrement in effectiveness is due to the minimum heat absorption and release capability of the hot and cold fluid at both zones of the heat pipe. This graph clearly reveals that acetone has maximum effectiveness than methanol at a tilt angle of 0°, Thi as 60 °C and mhi as 100 LPH. Therefore, the effectiveness is calculated by Eq. (1)

Figure 3 predicts the inclination angle on effectiveness with respect to the temperature of the hot fluid inlet with water as HCF and methanol as WF, the observed maximum hot fluid mass flow rate is 100 LPH for various inclination angles (ψ) as 0°, 45° and 90°. The observation stated that the increment of effectiveness is attained from 27.69 to 32.2% for ψ as 0° for Thi of 50 to 60 °C. Similarly, for Thi as 60–70 °C the effectiveness starts reducing from 32.2 to 21.2% for ψ as 0°. In the above observation, it reveals that at 100 LPH at a tilt angle of 0° maximum effectiveness has been achieved while comparing with other tilt angles. While comparing the temperatures of hot fluid mass flow rate at 60 °C shows an increment in effectiveness than 50 and 70 °C. Similarly for acetone also, same trends of graphs are observed at ψ as 0° for Thi as 60 °C and the observed effectiveness is 55.25%. At inclination angle of 45° and 90° for temperature increment, there is increasing in effectiveness is observed but while comparing with 0° effectiveness of the system gets reduced. This graph also clearly reveals that at 0°, 60 °C and 100 LPH, the acetone shows superior results than methanol.

Figure 4 shows the mass flow rate of hot fluid on heat transfer rate. The conditions for the observation are Thi as 60 °C, and mhi ranges from 40 to 120 LPH and varying inclination angles from 0°, 45° and 90°. In the first test, methanol is used as WF. The heat transfer rate (Q) shows increment for 40–100 LPH at the range of 186.04–606.97 W for ψ as 0°. Similarly, for 120 LPH, the Q value is 552.31 W for ψ as 0°. This plot reveals that 100 LPH shows highest heat transfer rate in the system; in the second test with acetone as WF. The similar type of trends is achieved. The heat transfer rate (Q) shows increment for 40 to 100 LPH at the range of 337.20–947.66 W for ψ as 0°. Similarly, for 120 LPH, the Q value is 941.85 W for ψ as 0°. This observation also reveals that the same results at 100 LPH maximum (Q) values are achieved than 120 LPH. Both the investigations at 100 LPH and ψ as 0° have the highest results, but by comparing both the working fluids, acetone shows superior heat transfer rate than methanol. This increase in heat transfer rate is achieved by the maximum absorption of heat energy by the cold fluid at the condenser zone. When the inlet temperature of the hot fluid is at 60 °C, there is maximum heat transfer which occurs between HCF and working fluids at the evaporator zone. This decrease in trends shows lack of heat transfer at the 45° with a minimum release of sensible heat and effect of friction occurs due to gravitational effect at condenser region of the heat pipe. Hence, the heat transfer rate is calculated using below formulas (2) and (3)

Figure 5 inferred that mass flow rate of hot fluid on heat transfer coefficient with water as HCF. The conditions for observation are Thi as 60 °C, mhi from 40 to 120 LPH and varying inclination angle from 0°, 45° and 90°. The observed heat transfer coefficient (h) at 40–100 LPH for ψ as 0° is 238.30–797.98 W/m2 °C. At 120 LPH, ψ as 0° the observed value is 746.08 W/m2 °C. In acetone as WF, the similar value of trends is observed. At 40–100 LPH, the observed (h) value ranges as 546.46–1664.36 W/m2 °C for ψ as 0°. Similarly for 120 LPH, the observed (h) ranges as 1498.34 W/m2 °C for ψ as 0°. Both working fluids show similar trends in the investigation at 100 LPH highest value of (h) which is achieved than 120 LPH. While considering the tilt angles, the horizontal axis ψ as 0° possesses maximum heat transfer coefficient than ψ as 45° and 90°. Using the below equation, the convective heat transfer coefficient of cold fluid on GICTSAHPHE can be calculated by Eq. (4)

In comparing the 0° and 90°, the similar range of values is achieved than at 45°. This predicts the higher heat transfer coefficient at hot fluid for 100 LPH and 60 °C with the 0° inclination angle for acetone as WF. This is due to the higher release of sensible heat to the cold fluid, by the working fluids which lead to maximum heat transfer along with the system.

4 Conclusion

-

It is inferred that optimum conditions observed from the investigation are hot fluid mass flow rates (mhi) as 100 LPH and cold fluid (mci) as 50 LPH, temperature of hot fluid at an inlet (Thi) as 60 °C and the inclination angle (ψ) as 0º (horizontal axis).

-

While comparing both working fluids for above-revealed conditions, acetone shows maximum results when comparing with methanol. There is an increment in results of 72% for effectiveness, 56.13% for heat transfer rate, 108.57% for heat transfer coefficient which are achieved.

-

This investigation reveals that the heat pipe induced in concentric-tube heat exchanger with acetone shows superior in results, while comparing with methanol in all the observed conditions of the investigation.

Abbreviations

- A :

-

Area of heat transfer (m2)

- C :

-

Heat capacity rate (kW/K)

- C p :

-

Specific heat of the fluid (kJ/kg K)

- D :

-

Diameter (m)

- h :

-

Heat transfer coefficient (W/m2 °C)

- L :

-

Length (mm)

- m :

-

Mass flow rate of fluid (LPH)

- Q :

-

Heat transfer rate (W)

- GICTSAHPHE:

-

Gravity induced concentric-tube shell assisted heat pipe heat exchanger

- HCF:

-

Heat-carrying fluid

- LPM:

-

Litre per minute

- WF:

-

Working fluid

References

Khalid Joudi A, Witwit AM (2000) Improvements of gravity assisted wickless heat pipes. Energy Convers Manag 41:2041–2061

Alicetin G, Cannistrano C (1991) The inclination effect on the performance of water-filled heat pipes. Renew Energy 1:667–674

Lydia Wermer R, Martin Ward J, Justin Simpson D, Robert Zimmerman A, James Stewart A (2018) A high capacity self priming counter gravity heat pipe. Int J Heat Mass Transf 125:1369–1378

Zhang D, Li G, Liu Y, Tian X (2018) Simulation and experimental studies of R134a flow condensation in a pump assisted separate heat pipe. Int J Heat Mass Transf 126:1020–1030

Esarte J, Domiguez M (2003) Experimental analysis of a flat heat-pipe working against gravity. Appl Therm Eng 23:1619–1627

Fonseca LD, Pfotenhauer J, Miller F (2018) Result of a three evaporator in cryogenic helium heat pipe. Int J Heat Mass Transf. 120:1275–1286

Shabgard H, Bergman TL, Shariti N, Faghri A (2010) High temperature latent heat thermal energy storage using heat pipes. Int J Heat Mass Transf 53:2979–2988

Hossain RA, Chowdhuri MAK, Feroz CM (2010) Design fabrication and experimental study of heat transfer characteristics of a micro heat pipe. Jordan J Mech Ind Eng. 4:531–542

Shafai M, Blanoco V, Vafai K, Manco O (2010) An investigation of the thermal performance of cylindrical heat pipes using nanofluid. Int J Heat Mass Transf 53:376–383

Kempers R, Ewing D, Ching CY (2006) Effect of number of mesh layers and fluid loading on the performance of screen mesh wicked heat pipes. Appl Therm Eng 26:89–595

Pis mennyi EN, Khayrnasov SM, Rassamakin BM (2018) Heat transfer in evaporation zone of aluminium grooved heat pipes. Int J Heat Mass Transf. 127:80–88

Said Salem A, Bilal Akash A (1999) Experimental performance of a heat pipe. International Communication of Heat and Mass Transfer. 26(5):679–684

Bastakoti D, Zhang H, Cai W, Li F (2018) An experimental investigation of thermal performance of pulsating heat pipe with alcohols and surfactant solutions. Int J Heat Mass Transf 117:1032–1040

Vivek Patel K (2018) An efficient optimization and comparative analysis of ammonia and methanol heat pipe for satellite application. Energy Convers Manag 165:382–395

Işık HG, Ömür C, Uygur AB, Horuz I (2018) A novel burst test approach for the qualification of heat pipes developed for space applications. Int J Press Vessels Pip 165:241–248

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Ramkumar, P., Sivasubramanian, M., RajeshKanna, P., Raveendiran, P. (2020). An Experimental Augmentation of Gravity-Assisted Concentric-Tube Heat Pipe Induced Heat Exchanger Under the Influence of Methanol and Acetone Working Fluids. In: Yang, LJ., Haq, A., Nagarajan, L. (eds) Proceedings of ICDMC 2019. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-15-3631-1_55

Download citation

DOI: https://doi.org/10.1007/978-981-15-3631-1_55

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-3630-4

Online ISBN: 978-981-15-3631-1

eBook Packages: EngineeringEngineering (R0)