Abstract

3D printing, as a symbol for the 4th of industrial revolution, is now changing many aspects of our life, ranging from rapid manufacturing, mass customization to health care devices. There is no 3D printer that can produce a 3D object without a digital 3D model. Thus, the construction of the 3D model to achieve mass customization inevitably involves service matching and task scheduling in Cloud manufacturing (CMfg) platform. However, such a complex and dynamic CMfg environment poses a challenge to traditional service matching and selection. In this research, a non-cooperative dynamic game model based selection is presented. To obtain Nash equilibrium point, an evolution solving algorithm is designed to find an optimal solution. Experimental results indicate that the proposed method is practical and valid.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

With the gradual enhancement of computer functions and the further development of computing technology, more and more applications are changing the objective world and the interaction between human and the objective world by information technology. 3D printing, as a symbol for the third wave of industrial revolution, is one such technology that will undoubtedly have a profound impact on our lives. There is no 3D printer that can produce a 3D object without a digital 3D model. Thus, Mai et al. [6] indicate the construction of the 3D model in a cloud platform to achieve mass customization. Li et al. [4] think that cloud manufacturing (CMfg) is emerging as a new service-oriented manufacturing paradigm built on dynamic, flexible and on-demand resource allocation and sharing, supporting and driving revolutionizing manufacturing, reflected the philosophy of “Design Anywhere, Manufacture Anywhere (DAMA)”. Xu [9] consider it provides a mode that large-scale, heterogeneous and distributed physical manufacturing resources (hardware and software) and capabilities are effectively organised and encapsulated into different types of on-demand, configurable and self-contained cloud services available to different consumers through virtualisation and servitisation technologies and managed in an integration way. Given the dynamic nature of 3D printing services in CMfg, ever-changing progress in the execution procedure pose a challenge to traditional method of matching and selection. As a consequence, there is an urgent need to look for a new method aiming to solve this problem. With the economic development and the in-depth understanding of the objective world, game theory has gradually entered into people’s horizons. Myerson et al. [7] state that game theory is the study of competition and cooperation among rational decision-makers. Since Von et al. [8] introduced game theory into the economic research field, it provides a vital decision-making analysis tool to solve various problems. This paper presents the method of matching and selection based on non-cooperative game to obtain optimal result. An improved genetic algorithm (IGA) as a solution procedure is designed in search of Nash equilibrium (NE) point.

The remainder of this paper is structured as follows. The next section reviews the works related to service scheduling in CMfg. Section 3 describes the proposed non-cooperative game model. Section 4 presents the proposed scheduling method of 3D printing service. Section 5 gives a case study to illustrate the feasibility of this method. Section 6 presents concludes and future works.

2 Related Works

Since cloud computing as a today’s IT paradigm has widely applied to provide a driving force for manufacturing industry how to provision manufacturing resources and capabilities with complexity and variety, another new manufacturing paradigm is generated. With the introduction of the term ‘Cloud Manufacturing’ coined in 2010, Li et al. [4] are often credited with introducing the first conceptual description of the relationship between manufacturing resource service and customer demand task. Since that time, many scholars have begun to concern with service matching and task scheduling within CMfg. 3D printing is one of the most successful application demonstrations in the area of CMfg. Besides its unique feature, 3D printing is inevitably characterized by a very strong colour of task scheduling, which is a typical NP-hard problem. By far the usual practice to seek the solution to the practical problem is to formulate mathematical modelling. Therefore such a problem can be transformed as the multi-objective optimization problem. Then an improved algorithm is proposed to find an optimal solution to the problem. The typical method based on heuristic algorithm makes remarkable progress in multi-objective optimization problem of task scheduling in CMfg. Laili et al. [3] introduced a new comprehensive model to solve the optimal allocation of computing resources in consideration of main computation, communication, and reliability constraints. Cao et al. [2] presented a service selection and scheduling model for a single task in consideration of criteria TQCS and then proposed an improved ant colony optimization algorithm (IACO) to search overall optimal solution. In particular, the weight coefficient was calculated according to the analytic hierarchical process (AHP) in order to combine linearly into a single objective optimization. Mai et al. [6] developed a specific cloud platform to address how to intelligently and effectively manage and schedule distributed 3D printing services in CMfg. Zhou et al. [10] presented a service transaction model of distributed 3D printing services in CMfg and then designed an improve GA (IGA) to solve the multi-task scheduling problem. In this model, service attributes, task attributes and logistics were considered. Game theory is born for dealing with how to choose competition and cooperation among rational decision-makers. Game theory has been cut a striking figure as one of the most competitive strategy selection methods for task scheduling problem in the manufacturing industry. Liu et al. [5] investigated an underlying mechanism that can promote the development and implementation of CMfg. The evolutionary game theory was introduced to set up the model of CMfg system as a scale-free network, where nodes represent enterprises while links stand for a certain kind of relationship between two enterprises, and to analyze the saturation degree of manufacturing task which affects on CMfg platform. Bai et al. [1] analyzed the task scheduling problem and introduced a Public Goods Game (PGG) model realized in the BA scale-free network of to CMfg system. In this model, each manufacturing basic attribute was mapped to three elements of the game.

3 Problem and Model

3.1 3D Printing Service Matching in CMfg

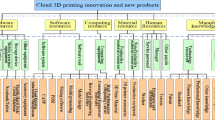

Based on the 3D printing service matching process shown in Fig. 1, the critical attributes of the 3D printing service is as follow:

-

(1)

Dimension

The dimension of 3D printing service can be described from length, width and height:

$$\begin{aligned}&min(l_{i,j},w_{i,j},h_{i,j})<=min(L_{k},W_{k},H_{k}) \end{aligned}$$(1)$$\begin{aligned}&max(l_{i,j},w_{i,j},h_{i,j})<=max(L_{k},W_{k},H_{k}) \end{aligned}$$(2)Equations (1) and (2) define allowable variation range of the dimension of 3D printing service.

-

(2)

Materials

The materials of 3D printing service can be expressed:

$$\begin{aligned} m_{i,j}=M_{k} \end{aligned}$$(3)Equation (3) ensures the same types of materials of 3D printing service.

-

(3)

Precision

The precision of 3D printing service can be expressed:

$$\begin{aligned} p_{i,j}=>P_{k} \end{aligned}$$(4)Equation (4) enforces that the preciseness of 3D printing service is not low than that of 3D printing task.

3.2 3D Printing Task Scheduling Model in CMfg

To simplify the 3D printing task scheduling model, the makespan of all tasks is considered.

3.3 Non-cooperative Game Model

A n-person non-cooperative game model can be composed as a tuple:

Where \(P=\{p_1,p_2,\cdots ,p_n\}\) is the set of n players. \(S=S_{1} \times S_{2} \cdots S_{n}\) represents the strategy profile space. \(s=(s_1,s_2,\cdots ,s_n) \in S\) is the strategy vector. \(u_i(s): S\rightarrow R\) represents the utility function of player i.

A Nash equilibrium (NE) is an ordered set of strategy choices, one for each player who can not reduce other payoff by unilaterally changing his strategy. So the strategy profile of NE \((s^*_i,s^*_{-i}) \in S\) can be denoted:

Where \(s^*_{-i}=(s^*_{1},\cdots ,s^*_{i-1},s^*_{i+1},\cdots ,s^*_{n})\) is the strategy profile except strategy of player \(i(i=1,2,\cdots ,n)\).

The non-cooperative game in this study can be described:

-

Players \(\{p_1,p_2,p_3\}\): the CMfg service provider

-

Strategies S: the set of available tasks and services from the CMfg service provider

-

Utility functions \(\{u_1(s),u_2(s),u_3(s)\}\): the makespan.

4 3D Printing Service Scheduling

4.1 Scheduling Method

The n-person non-cooperative dynamic game based matching selection of 3D printing service is described as follows.

-

(Step 1) Service allocation. Available services of 3D printing are allocated to three objectives sequentially until completed.

-

(Step 2) Objective mapping. Each objective corresponds to each player who can make decisions, independent of another player.

-

(Step 3) Strategy formation. The unallocated subtasks of each task are put into cloud service pool in which available services can match the corresponding subtasks according to the allocated rules.

-

(Step 4) Utility calculation. The three players from each feasible strategy profile are calculated their utility functions \(u_1(s)\), \(u_2(s)\) and \(u_3(s)\).

-

(Step 5) NE solving. The NE of the non-cooperative dynamic game is solved by IGA.

Figure 2 shows the non-cooperative dynamic game structure of 3D printing task scheduling in CMfg.

4.2 Solving Method of NE

Nash equilibrium is the most essential and the most core concept of game theory, which no player has any propensity to unilaterally deviate from the equilibrium. As mentioned above, how to search the NE of the non-cooperative dynamic game is urgent. Therefore, in this paper, we apply an improved genetic algorithm (IGA) to do this. The flowchart of the proposed method is illustrated in Fig. 3.

5 Case Study

5.1 Experimental Setting

We view the problem of 50 tasks \(\times \) 100 services in the CMfg environment. The parameters of the experiment are given in Table 1.

5.2 Results and Analyses

Compared with non-cooperative games based scheduling method (NDG), 3DPSS method [10] is selected as the reference. The convergence curves of the service selection solution is shown in Fig. 4.

For both 3DPSS and NDG, two methods shown in Fig. 4 can converge to the optimal solution. But the difference is that NDG can achieve smaller fitness value than 3DPSS with the increase of generation. Because 3D printing among services compete for tasks. However, game theory is the study of competition and cooperation among rational decision-makers, which gives 3D printing services to tend to choose cooperation for maximizing their own benefit. This indicates that the NDG has more efficiency and better probability to obtain the best results.

6 Conclusion

Service matching and task scheduling are one of the research hotspots of 3D printing services. However, existing scheduling methods have difficulty in adjusting given decision-making for ever-changing progress in the dynamic CMfg environment. In this research, we proposed a non-cooperative dynamic game-theory-based scheduling method for distributed 3D printing services in CMfg to generate optimal task solutions. Experimental results of this case study demonstrate the validity and practicality of the proposed method as well as illustrate why they are efficient. This contribution provides managers with new insight into blurring the lines between manufacturing and services.

In addition to the insights mentioned above, research directions for future work include: (1) investigating a comprehensive service matching and task scheduling policy for 3D printing including capacities of logistics services and multiple subtask sequences; (2) study uncertain events that affect the 3D printing service scheduling.

References

Bai, T., Liu, S., Zhang, L.: A manufacturing task scheduling method based on public goods game on cloud manufacturing model, pp. 1–6 (2018)

Cao, Y., Wang, S., Kang, L., Gao, Y.: A TQCS-based service selection and scheduling strategy in cloud manufacturing. Int. J. Adv. Manuf. Technol. 82(1–4), 235–251 (2016)

Laili, Y., Tao, F., Zhang, L., Sarker, B.R.: A study of optimal allocation of computing resources in cloud manufacturing systems. Int. J. Adv. Manuf. Technol. 63(5–8), 671–690 (2012)

Li, B.H., et al.: Cloud manufacturing: a new service-oriented networked manufacturing model. Comput. Integr. Manuf. Syst. 16(1), 1–7 (2010)

Liu, Y., Zhang, L., Tao, F., Wang, L.: Development and implementation of cloud manufacturing: an evolutionary perspective. In: ASME 2013 International Manufacturing Science and Engineering Conference collocated with the 41st North American Manufacturing Research Conference, pp. V002T02A007–V002T02A007. American Society of Mechanical Engineers (2013)

Mai, J., Zhang, L., Tao, F., Ren, L.: Customized production based on distributed 3d printing services in cloud manufacturing. Int. J. Adv. Manuf. Technol. 84(1–4), 71–83 (2016)

Myerson, R.B.: Game Theory. Harvard University Press, Cambridge (2013)

Von Neumann, J., Morgenstern, O.: Theory of Games and Economic Behavior (Commemorative edition). Princeton University Press, Princeton (2007)

Xu, X.: From cloud computing to cloud manufacturing. Robot. Comput. Integr. Manuf. 28(1), 75–86 (2012)

Zhou, L., Zhang, L., Laili, Y., Zhao, C., Xiao, Y.: Multi-task scheduling of distributed 3d printing services in cloud manufacturing. Int. J. Adv. Manuf. Technol. 96(9–12), 3003–3017 (2018)

Acknowledgement

This work is supported by the National Natural Science Foundation of China under Grant No. 61873014.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Liu, S., Liu, Y., Zhang, L. (2019). Distributed 3D Printing Services in Cloud Manufacturing: A Non-cooperative Game-Theory-Based Selection Method. In: Tan, G., Lehmann, A., Teo, Y., Cai, W. (eds) Methods and Applications for Modeling and Simulation of Complex Systems. AsiaSim 2019. Communications in Computer and Information Science, vol 1094. Springer, Singapore. https://doi.org/10.1007/978-981-15-1078-6_12

Download citation

DOI: https://doi.org/10.1007/978-981-15-1078-6_12

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-1077-9

Online ISBN: 978-981-15-1078-6

eBook Packages: Computer ScienceComputer Science (R0)