Abstract

The broad utilization of energy has prompted petroleum consumption and thus resulting in ascent in pollution. Sustainable power sources hold the key solution to this real time problem. This review aims to provide a brief overview of the performance characteristics as well as emission characteristics of variable compression ratio (VCR) engine, when biofuels produced from different sources like plastic, jatropha, annona methyl ester, muhua, pyrolysis oil of waste tyres, palm oil methyl ester, waste fried oil, biogas, etc. are used at different compression ratio (CR). It has been observed that for alteration of CR; brake specific fuel consumption (BSFC),brake thermal efficiency(BTE) and exhaust gas temperature(EGT) improved by maximum 45.9, 41.7 and 24.4%, respectively for different source of fuels. Hydrocarbon (HC) emissions and Carbon monoxide (CO) emissions also significantly came down up to 52 and 55%, respectively due to variation of CR.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The current world is in the era of evolution of competition in automotive industry and it is the main driving force for all the car manufacturing companies to improve their current existing model to the next level in terms of performance as well as emission characteristics. While serving the society with science and technology which are associated with automotive industry; one must not forget his or her responsibility towards the environment. Achieving more power and comfort along with polluting the environment more, must not be substitutional choice and it is not ethical for any individual in this world. Moreover the use of non-sustainable power sources like crude oil or natural gas is increasing day by day due to increasing demand which is again supported by population growth in this world. So for understanding and implementing sustainable growth, focused research on different source of biofuel for IC engine along with enhancing the performance of the engine is very much important. Thus this paper is a small contribution towards that sustainable growth as it deals with different sources of biofuels, blending of those with existing conventional oil which leads to lower consumption of conventional nonrenewable energy sources if it was used alone, along with considering the emission characteristics also. Changing the CR, is an enormous influencing factor for the characteristics of the engine [1,2,3,4] irrespective of types of fuel. The reported literature indicates that lot of efforts have been put towards the improvement of the performance and emission characteristics using different types of sources of fuels and variable compression engine (VCR) [5] adds more to that improvement and till now limited literature work has been reported regarding that. Thus this paper deals with characteristics of performance and emission of VCR engine when different sources of fuels are used and information obtained are compared and summarized at the end.

2 Engine Performance

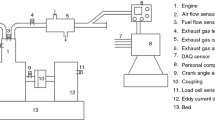

Many researchers had carried out experiments in IC engines with different biofuels at different CRs to investigate the performance characteristics mainly of BTE, BSFC and EGT. The performance characteristics of the engine using different biofuels were analyzed by different specialists and some of them are included underneath.

Rao et al. [2] carried out experiments on VCR engine at 1500 rpm and four different blends of plastic oil, diesel and ethanol were used, which are P100, P90D10, P90D5E5 and P80D10E10 (P-plastic oil, D-diesel, E-ethanol, the number following the alphabet indicates percentage of that respective fuel). The experiment was performed at two different CRs 17 and 18. It was found that BTE increases with CR for all the blends and for P90D5E5 it has been found that BTE increased by 15% when CR is changed from 17 to 18. It has been also noticed that when CR is increased BSFC had a reverse trend. Venkateswara Rao P. [3] conducted experiment on VCR diesel engine (stroke-4, single cylinder) with methyl ester of jatropha- JOME. Experiment was conducted for B20D80 (jatropha 20%, diesel 80%) at four different CRs 14,16,18,20 and for pure diesel at two different CRs 14 and 20. It has been accounted that with the increment of CR value, BTE showed an increasing nature irrespective of type of blend at any amount of load and maximum BTE was 24.5% for blend fuel at CR20. BSFC and volumetric efficiency decreased by 18.23% and 3.1%, respectively for variation of CR. Ajay et al. [4] have done an experimental investigation using Karanj (Pongamia), different blends were made using PME (pongomia methyl ester) and diesel. Experimental work was being conducted on a VCR (stroke-4, single-cylinder) engine at 1500 rpm. At CR 18.5, maximum BTE of 30.08% for PME20 (pongamia 20%, diesel 80%) was noticed which is higher than diesel by 5–10%. BSFC was found to be slightly increasing with an increase in CR from 17.5 to 18.5. For PME20 EGT decreased from 390 to 320 °C when compared with diesel at CR 18.5. Experiments were conducted by Jagannath et al. [6] with blend of diesel and methyl ester of waste fried oil on a diesel injection, single-cylinder engine of 4 kW rating, varying the CR from 16 to 19. BTE increased by maximum of 3.78% when CR is increased from 16 to 18. Similarly BSFC decreased by 3.7% when CR is changed from 17 to 18 but further increase in CR affected BSFC of 0.68%. Silambarasan et al. [7] had gone through experimental investigation with AME (Annona Methyl ester)- diesel blends (20, 40, 60, 80% of AME and rest is diesel) on single-cylinder VCR at different CRs (16.5, 18.5, 19.5). BTE gradually increased with increase in CR and it was maximum at 19.5 for A20 (AME 20% diesel 80%) which is almost equal to diesel. BSFC gradually decreased with increment of CR, for A20 3% reduction in BSFC was noticed. Bora et al. [8] had done experimental evaluation on 3.5 rated, water cooled, naturally aspirated, direct injection VCR engine (stroke-4, single-cylinder) which is again modified to dual fuel mode to run on biogas. Experiments were conducted at various CRs. BTEs were found increasing with increase in CR but at any specific CR BTEs of diesel were found better. The increase in CR resulted in low EGT and in dual fuel mode at CR 18 EGT reduced by 16.9% but EGT is higher at any CR when compared with diesel mode. For dual fuel mode BSEC also decreased by 19.38% when CR varied from 16 to 18. Dubey et al. [9] investigated influence of CR (15.5, 17, 18.5, 20) using biofuel (Turpentine and Jatropha) on a VCR engine (stroke-4, single cylinder). BTE was lower at low CR at 15.5 and 17, it increased with CR at 18.5 and 20, and it was found that BTE increased by 2.17% for JBT50 (Jatropha 50% and Turapentine 50%) in CR 20 when compared with pure diesel. Mohammed and Medhat [10] had performed experiments on a VCR (stroke-4, single-cylinder, speed 1000–2000 rpm) engine, with blends of biodiesel (from waste fuel)-diesel. Mean increase of BTE was 18.5% when CR was altered from 14 to 18 for B30. BSFC showed a reducing nature for an increase in CR and for B30 it has been seen that BSFC decreased by 17.3% when CR is changed from 16 to 18. Rehman and Ghadge [11] have conducted experiments on Ricardo E6 engine using blends of muhua biodiesel (B100) and HSD (high-speed diesel) at varying CR (ranging from 18 to 20. It was found that for B100 there was a reduction of BSFC by 45.9% with the change of CR. B100 was having the highest increase of 41.7% when CR is changed from 18 to 20 keeping other parameters constant. EGT showed a reducing nature for similar change in CR and 24.4% was reported the highest reduction for B100. Sharma and Murugan [12] have done experiments using oil produced from waste tyres by pyrolysis process. 20% of that and 80% biodiesel was taken to make the blend. The experiment was done on a diesel engine which is rated with 4.4 kW at 1500 rpm with provision of direct injection and it was naturally aspirated. CR was varied from 16.5 to 18.5. When CR is altered from 17.5 to 18.5, there was an increase of 8% BTE for the blend w.r.t diesel. Yadav et al. [13] used blends of diesel and hybrid reactor produced kaner biodiesel (KOME). Significant improvement was noticed for BTE when compared with neat diesel, for the blends as CR is increased and similar nature was observed for BSFC. Basavaraju and Jamunarani [14] had gone through experiments with methyl esters of mustard biodiesel blends M10 (diesel 90%, mustard oil 10%), M20 (diesel 80%, mustard oil 20%) at different CR (14, 16 and 18) on VCR engine (stroke-4, single cylinder). BTE was found increasing with CR, for M20, at full load maximum BTE was noticed 32.63% and it is 7–8% more than diesel. BSFC of M20 was lowest but EGT was found increasing compared with neat diesel for similar change in CR. Debnath et al. [15] executed experiments in VCR diesel engine using 100% methyl ester of palm oil (POME).The normal ascent of BTE of 7%, 5% and 3%, respectively were noticed, through CR alteration (16–18) and there was a drop in BSFC of average 11%, 12% and 1% for similar change in. EGT also reduced by 2%, 3% and 4% for similar change in CR. Anand et al. [16] performed experiments with COME (cotton oil methyl ester)-diesel blends on VCR engine (stroke-4, single-cylinder) for three different CRs (15, 17 and 19). At 1500 rpm the rated power was 3.7 kW. BTE had shown an increasing trend with CR and highest BTE of 29.28% was found for B20 at CR 19 which is very higher w.r.t diesel (27.92%). Jindal et al. [17] have done experimental investigation using JME (jatropha methyl ester B100), varying the CR (16, 17 and 18) and compared with the outcomes to that of diesel at CR 17.5. At 250 bar, BSFC showed a reverse trend with the change of CR and CR 18 provided an improvement of 10% BSFC. At CR 18 BTE improved by 8.9% to that of diesel. EGT was also reported to be decreased by 10%. Muralidharan and Vasudevan [18] conducted experiment in VCR (stroke-4, single-cylinder) engine with waste cooking oil methyl ester along with its blends of 80%, 60%, 40% and 20% with diesel. The experiment was done at 1500 rpm, the load was 50% and CR was taken 18,19, 20, 21 and 22. It has been reported that BTE of the blend B40 is 31.48% at CR 21 and for diesel it is 26.08%. SFC decreased with an increase in CR, the SFC of B40 at CR 21 was 0.259 kg/kWh compared to 0.314 kg/kWh of diesel. BP shown reducing trend with an increase in CR, the highest BP was obtained for B40 at CR 21 is 2.07 kW w.r.t 2.12 kW for diesel. EGT reduced with the increase in CR, the highest EGT was 233.48 °C for standard diesel but for B40 it was only 200.61 °C at CR 21. Nagaraja et al. [19] investigated the performance characteristics and emission characteristics of VCR (stroke-4, single-cylinder) engine at constant speed 1500 rpm, full load with preheated (at 90 °C) palm oil and its blends with diesel, varying the CR (16, 17, 18, 19 and 20). The blend O20 provided 14.6% higher mechanical efficiency and 6% higher BP at higher CR when compared with diesel. IMEP decreased at higher CR 20 and for blend O20 it was 6.22 bar to that of 6.87 bar for diesel. EGT decreased by 110 °C for O10 blend at CR 20 when compared with diesel. Hasan and Safak [20] performed experiments taking false flax biodiesel (100% FFME) [20]1, diesel-methanol (95% diesel, 5% methanol) [20]2, diesel-ethanol (95% diesel, 5% ethanol) [20]3, diesel-butanol (95% diesel, 5% butanol) [20]4, biodiesel-methanol (95% FFME, 5% methanol) [20]5, biodiesel-ethanol (95% FFME, 5% ethanol) [20]6, biodiesel-butanol (95% FFME, 5% butanol) [20]7, and from the reported graphs the performance and emission characteristics are compared (approximately) at different CR ratio

The comparison of variation of BTE, BSFC and EGT from different cited literatures, are shown in Figs. 1, 2 and 3, respectively.

3 Engine Emission

Though the use of different source of biofuels may improve few performance characteristics there will be always some sorts of emissions which are mainly CO (carbon monoxide), CO2 (carbon dioxide), NOX (oxides of nitrogen), HC (hydrocarbon) and smoke. Emission characteristics using different biofuels were inspected by different specialists and some of them are included underneath.

B Govinda Rao et al. [2] found that P80D10E10 was the best as it reduced HC emission by 66% when compared with diesel. CO emission also had shown similar nature with an increase in CR. It has been discovered that for P90D5E5, NOX outflow expanded by 13.6% at CR 18 when compared with diesel. The smoke emission was found deceasing with the expansion in CR for every blend at same other operating conditions. Venkateswara Rao P. [3] observed that at CR 20 the CO2 emission was 3.2% higher for blend fuel w.r.t diesel whereas 32.6% lower CO emission has been observed. For blend fuel HC emission was 26.7% less compared to diesel at most extreme load for CR 20 and moreover at maximum load HC emission decreased by 54.3% with the an increase in CR. NOX emission was 9.8% less compared to diesel at most extreme load for 20. Ajay et al. [4] noticed that for almost all the blends CO emission has been decreased except PME20, with the increase of CR from 17.5 to 18.5. At higher CR HC emissions of all blends were found higher. NOX emission slightly increased for similar change. Jagannath et al. [6] noticed that keeping other operating parameters constant, alternating CR (16 to 18) reduced smoke emission by 6.55%. Silambarasan et al. [7] found that HC emission reduced by 22.23% when compared to pure diesel. CO emission also had an inversely proportional nature with CR and for A20 at CR 19.5 is reduced by 40% w.r.t pure diesel. But it has been observed at 19.5 CR the blend A20 has 0.8% more NOX emission w.r.t pure diesel. Smoke emission also decreased with the increase of CR and the blend A20 shown 21.4% reduction in that at CR 19.5 when compared with pure diesel. Bora et al. [8] reported that there are low emissions for HC and CO by 41.97% and 26.22%, respectively when CR increased from 16 to 18 in dual fuel mode. But an increase of CO2 and NOX outflow by 27.18% and 66.65%, respectively was noticed for the same CR variation. Dubey et al. [9] reported that for dual mode at CR 20 CO, HC, NOX emission and smoke opacity was reduced by 13.04%, 17.5%, 4.21% and 30.8%, respectively but CO2 emission was increased by 11.04% when compared with diesel mode. Mohammed and Medhat [10] found that on an average NOX and CO2 emission were more by 36.84% and 14.28%, respectively when CR is changed from 14 to 18. But for the same change of CR, HC emission reduced by 52% and CO emission reduced by 37.5%. Sharma and Murugan [12] noticed that for the blend at high CR of 18.5 brake specific carbon monoxide (BSCO), brake specific hydrocarbon emission (BSHC) and smoke opacity were reduced by about 10.5%, 32%, 17.4%, respectively, than those of the original CR at full load. Yadav et al. [13] observed that at higher CR 18, the smoke opacity of diesel is more than biodiesel blends but at lower CR the trend is reversed. Basavaraju and Jamunarani [14] reported that CO and NOX emission were showing reducing nature but HC emission showed reverse nature, with an increase in CR. Debnath et al. [15] came to a conclusion that increase in CR from 16 to 18 reduces CO, NOX and HC emission by 40%, 46% and 40%, respectively however, there was an increment in CO2 outflow by 19% for the similar change. Anandet al. [16] reported that NOX discharge for all blends was little lower (for B10-75 ppm and for pure diesel- 146 ppm), at highest CR 19, CO emissions were also found reducing, for B10 it was lowest of 0.13% but for diesel it was 0.69%. HC emission was also noticed to show a bit lower values than diesel. Jindal et al. [17] found that HC emission and NOX emission was as low as 50% and 25%, respectively. However, CO and CO2 emissions were found higher as much as 38% and 2%, respectively. However, smoke opacity showed a decreasing trend when compared to diesel. Muralidharan and Vasudevan [18] came to the conclusion that HC and NOX discharge were higher for B40 w.r.t standard diesel. Nagaraja et al. [19] reported that O20 blend had lower CO and HC emissions to that of diesel by 45.45% and 24.24%, respectively at higher CR; however, CO2 emissions were found to be increasing. Hasan and Safak [20] also reported about variation in emission characteristics through graphical representation. The approximate comparison of the variation is taken into consideration in this paper.

The comparison of variation of CO, CO2, HC and NOX emissions from different cited literature, are shown below in Figs. 4, 5, 6 and 7, respectively.

4 Conclusions

Above mentioned reported literature work demonstrates that variation of CR is an enormous influencing factor to enhance the performance characteristics and emission characteristics of the engine. It has been perceived that variation of CR can result in maximum improvement of BTE, BSFC and EGT by 41.7%, 45.9% and 24.4%, respectively. CO and HC emission reduced for all source of fuels and maximum reduction of 55% and 52% were noticed, respectively. It has been seen that CO2 emission increased by maximum 55% (sign of complete combustion), for almost all the fuels NOx emission shows increasing trend with increasing CR which is an issue to be dealt with serious concern. In order to achieve overall optimum performance and emission characteristics, parametric optimization of injection pressure, injection timing, blend ratio should be done along with CR. In addition to that, the combined effect of parametric optimization, emulsification of fuel and use of additives should be investigated. By and large, it has been seen that CR is a critical parameter to explore the performance characteristics (BTE, BSFC, EGT) and emission reduction (CO, HC) of VCR engine.

References

Holweg, M.: The evolution of competition in the automotive industry. In: Parry G., Graves A (eds) Build To Order: the Road to the 5-Day Car, Glenn Parry, pp. 13–34. Springer Science & Business Media, UK (2008)

Govinda Rao B., Datta Bharadwaz Y., Virajitha C., Dharma Rao V.: Effect of injection parameters on the performance and emission characteristics of a variable compression ratio diesel engine with plastic oil blends—an experimental study. SAGE 0(0) 1–19 (2018). https://doi.org/10.1177/0958305x17753208

Venkateswara Rao, P.: Compression ratio effect on diesel engine working with biodiesel (JOME)—diesel blend as fuel. Res. J. Chem. Sci. 5(7), 48–51 (2015)

Kolhe, A.V., Shelke, R.E., Khandare, S.S.: Performance, emission and combustion characteristics of a variable compression ratio diesel engine fueled with Karanj biodiesel and its blends. World Acad. Sci. Eng. Technol. Int. J. Mech. Mech. Eng 8(4) (2014). https://doi.org/10.5281/zenodo.1094201

Shaik, A., Moorthi N.S.V., Rudramoorthy, R.: Variable compression ratio engine: a future power plant for automobiles—an overview. Proc. Institution Mech. Eng. Part D J. Autom. Eng. 221, 1159–1168 (2007). https://doi.org/10.1243/09544070jauto573

Jagannath, H., Vivek, B., Jisa, R.: Effect of compression ratio, injection pressure and injection timing on performance and smoke emissions of CI engine fuelled with waste fried oil methyl esters—diesel blend. Mater. Today Proc. 5(1), P1563–P1570 (2018). https://doi.org/10.1016/j.matpr.2017.11.247

Silambarasan, R., Senthil, R., Pranesh, G., Mebin, Samuel P., Manimaran, M.: Effect of compression ratio on performance and emission characteristics of biodiesel blend operated with VCR engine. National conference on recent trends and developments in sustainable green technologies. JCHPS Special Issue 5, 23–25 (2015)

Bora Bhaskor, J., Saha, U.K., Chatterjee, S., Veer, V.: Effect of compression ratio on performance, combustion and emission characteristics of a dual fuel diesel engine run on raw biogas. Energy Convers. Manag. 87, 1000–1009 (2014). https://doi.org/10.1016/j.enconman.2014.07.080

Pankaj, Dubey, Rajesh, Gupta: Influences of dual bio-fuel (Jatropha biodiesel and turpentine oil) on single cylinder variable compression ratio diesel engine. Renew Energy 115, 1294–1302 (2017). https://doi.org/10.1016/j.enconman.2014.07.080

El-Kassaby, M., Nemit-Allah, M.A.: Studying the effect of compression ratio on an engine fueled with waste oil produced biodiesel/diesel fuel. Alexandria Eng. J. 52, 1–11 (2013). http://dx.doi.org/10.1016/j.aej.2012.11.007

Raheman, H., Ghadge, S.V.: Performance of diesel engine with biodiesel at varying compression ratio and ignition timing. Fuel 87(12), 2659–2666 (2008). https://doi.org/10.1016/j.fuel.2008.03.006

Sharma, A., Murugan, S.: Potential for using a tyre pyrolysis oil-biodiesel blend in a diesel engine at different compression ratios. Energy Convers. Manag. 93, 289–297 (2015). http://dx.doi.org/10.1016/j.enconman.2015.01.023

Yadav, A.K., Khan M.E., Pal, A.: Kaner biodiesel production through hybrid reactor and its performance testing on a CI engine at different compression ratios. Egyptian J. Petroleum 26(2), 525–532 (2016). http://dx.doi.org/10.1016/j.ejpe.2016.07.006

Basavaraju, K., Jamunarani, G.: Performance and emission characteristics of a variable compression ratio diesel engine using methyl esters of mustard biodiesel blends. J. Eng. Res. Appl. 4(11), 20–28 (2014)

Debnath, B., Saha, U.K., Sahoo, N.: Effect of compression ratio and injection timing on the performance characteristics of a diesel engine running on palm oil methyl ester. Proc. Inst. Mech. Eng. Part A J. Power Energy, 227(3), 368–382 (2013). https://doi.org/10.1177/0957650912470907

Anand, R., Kannan, G.R., Reddy, Rajasekhar K., Velmathi, S.: Performance and emissions of a variable compression ratio diesel engine fuelled with bio-diesel from cotton seed oil. ARPN J. Eng. Appl. Sci. 4(9), 72–87 (2009)

Jindal, S., Nandwana, B.P., Rathore, N.S., Vashistha, V.: Experimental investigation of the effect of compression ratio and injection pressure in a direct injection diesel engine running on Jatropha methyl ester. Appl. Therm. Eng. 30(5), 442–448 (2010). https://doi.org/10.1016/j.applthermaleng.2009.10.004

Muralidharan, K., Vasudevan, D.: Performance, emission and combustion characteristics of a variable compression ratio engine using methyl esters of waste cooking oil and diesel blends. Appl. Energy 88(11), 3959–3968 (2011). https://doi.org/10.1016/j.apenergy.2011.04.014

Nagaraja, S., Sooryaprakash, K., Sudhakaran, R.: Investigate the effect of compression ratio over the performance and emission characteristics of variable compression ratio engine fueled with preheated palm oil—diesel blends. Procedia Earth Planetary Sci. 11, 393–401 (2015). https://doi.org/10.1016/j.proeps.2015.06.038

Hasan, Serin, Şafak, Yıldızhan: Influence of the compression ratio on the performance and emission characteristics of a VCR diesel engine fuelled with alcohol blended fuels. European Mech. Sci. 1(2), 39–46 (2017). https://doi.org/10.26701/ems.320255

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Saha, D., Sinha, A. (2020). Performance and Emission Characteristics of Variable Compression Ratio (VCR) Engine Using Different Biofuels—A Review. In: Biswal, B., Sarkar, B., Mahanta, P. (eds) Advances in Mechanical Engineering. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-15-0124-1_67

Download citation

DOI: https://doi.org/10.1007/978-981-15-0124-1_67

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-0123-4

Online ISBN: 978-981-15-0124-1

eBook Packages: EngineeringEngineering (R0)