Abstract

The novel metamaterial-based radiative cooling film has recently been developed and reported a 110 W/m2 cooling power on a daily average. The most convenient application of this metamaterial-based radiative cooling film is to integrate with building as the cool roof. However, the cool roof has always only benefit to the top floor of the building. Since the prefabricated building, commonly lower than two-floor, has relatively higher roof area to floor area ratio, the metamaterial-based cool roof is perfectly applicable to them as renewable energy-based new cooling mechanism. In this study, the prefabricated building is modelled with EnergyPlus, and then the detailed simulation analysis has been conducted for five locations in China, including Harbin, Beijing, Kunming, Nanjing, and Guangzhou. The results show that the adoption of metamaterial-based cool roof to low-rise prefabricated building will save cooling electricity consumption by 18.7–34.8% annually.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The energy consumption of buildings has been increased to 40% of total energy consumption, in which the building sector accounts for 37% in China [1]. The power consumption of air-conditioning accounts for a large proportion of total building energy usage and more than 50% of total building energy was consumed by air-conditioning systems to satisfy the increasing demand of thermal comfort and indoor air quality [2]. The temperature of outer space is close to zero, which can be considered as a giant cold source [3]. And the atmosphere is almost transparent in the 8–13 μm inferred band (i.e. atmosphere windows), which is consistent with the peak of the thermal radiation for the object at ambient temperature [4]. Thus, the radiative cooling can be achieved by radiating the heat from the device/surface on earth to the outer space through the atmosphere windows [5].

As a passive cooling technology, radiative cooling has received much attention as it generates “free” cooling to buildings [6,7,8,9]. However, most current radiative cooling materials either work for nocturnal cooling only or have high-cost issues [10]. With the development of micro/nanomaterials, daytime radiative cooling has become possible, especially for a recently proposed novel metamaterial-based radiative cooling film has been reported a 110 W/m2 cooling power on a daily average. This metamaterial potentially works for both nocturnal and diurnal cooling. As a typical application of radiative cooling, the cool roof has been proposed for many years [11]. Akbari et al. employed the cool roof on six commercial buildings in California [12]. Their study showed that the daily cooling energy consumption was reduced by 4% in a cold storage facility, 18% in a school building, and 52% in a retail store building. Romeo et al. found that the peak surface temperature of the roof could be lowered by 20 °C at maximum and the operating temperature in the room also could be dropped significantly while the cool roof with a solar reflectance of 0.86 was applied in the building of Trapani [13]. A simulation study for the laboratory building with cool roof in Heraklion (i.e. Mediterranean region) indicated that the cooling demand could be reduced by 25%, and the total energy demand per year could be reduced by about 20% [14]. Although the most convenient application of this metamaterial-based radiative cooling film is to integrate with building as the cool roof, the cool roof has always only benefit to the top floor of the building. Since the prefabricated building, commonly lower than two-floor, has relatively higher roof area to floor area ratio, the metamaterial-based cool roof is perfectly applicable to them as renewable energy-based new cooling mechanism.

In this study, the prefabricated building with the novel metamaterial-based cool roof was modelled with EnergyPlus, and then the detailed simulation analysis was conducted for five locations in China, including Harbin, Beijing, Kunming, Nanjing, and Guangzhou.

2 Methods

2.1 Modelling of Prefabricated Building

As shown in Fig. 1, a typical two-floor prefabricated building was modelled using EnergyPlus in this study. The roof surface area of this model was approximately 118 m2, and the floor area was about 204 m2. The model mainly consisted of two zones, including living zone and attic zone. The living zone had two floors and equipped with a traditional air conditioner. The first floor of living zone was placed on the ground, in which eight windows were located on each wall as well as two doors were installed on both south- and north-facing wall. The incline original roof (i.e. thermal insulation) was installed on the unconditioned attic zone with an angle of 45°. The metamaterial film (i.e. cool roof) was placed on the top of the original roof (i.e. metamaterial-based cool roof), in which the emissivity and solar absorption were 0.93 and 0.04, respectively. Other details of the model were given in Table 1.

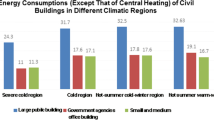

To indicate the energy-saving potential of metamaterial-based cool roof for prefabricated building in China, five locations in different climate zone were selected, including Harbin (i.e. severe cold zone), Beijing (i.e. cold zone), Kunming (i.e. moderate zone), Nanjing (i.e. hot-summer and cold-winter zone), and Guangzhou (i.e. hot-summer and warm-winter zone). And, the weather data originated from the US Department of Energy (DOE) were also used in this study.

2.2 Heat Transfer from Cool Roofs

The heat transfer of cool roof was relatively complex, which was shown in Fig. 2. The heat balance of the metamaterial-based cool roof could be expressed as,

where qRS is the net radiative cooling power of the metamaterial-based cool roof; qconv is the convective heat transfer between of the metamaterial-based cool roof and ambient air; qrad is the heat transfer between the metamaterial-based cool roof and outer space; qsol is the solar absorption by the metamaterial-based cool roof; and qcond is the conductive heat transfer from the metamaterial-based cool roof to the room.

In Eq. (1), the qconv could be calculated by [11],

where hRS is the convective heat transfer coefficient of the metamaterial-based cool roof; Troof is the metamaterial-based cool roof temperature; Tamb is the ambient air temperature; hn is the natural convection coefficient; hf is the forced convection heat transfer coefficient;

According to Stefan-Boltzmann’s theorem, qrad could be calculated by [15, 16],

where σ is the Stefan-Boltzmann constant, 5.67 × 10−8 W/m2 K4; εroof is the emittance of the metamaterial-based cool roof; Tsky is the effective sky temperature; and Td is the ambient dewpoint temperature.

Finally, qsol and qcond could be calculated by [17],

where λ is absorption coefficient, Isol is the incident solar radiation; ΔT is the temperature difference between metamaterial-based cool roof and attic; λroof is the thermal conductivity of the whole roof; and δ is thickness of whole roof.

3 Results and Discussion

3.1 Analysis of Cooling Benefit for Metamaterial-Based Cool Roof

The cold energy from the metamaterial-based cool roof was produced by the radiative cooling, which could be considered as a kind of “free” cooling energy. And, the monthly percentage of cooling load covered by cool roof was shown in Fig. 3. As shown in Fig. 3, the percentage of free cooling energy addressed by metamaterial-based cool roof was lower in cooling season (i.e. June–September). It was because the cooling load in cooling season was higher, but the radiative cooling energy was relatively lower. In the cooling season, the free cooling energy addressed by metamaterial-based cool roof was about 23.2–26.3% of the cooling load in Beijing, 18.2–27.2% of the cooling load in Harbin, 35.5–41.1% of the cooling load in Kunming, 26.7–28.9% of the cooling load in Nanjing, and 27.0–29.2% of the cooling load in Guangzhou. Furthermore, the percentage of annual cooling load by cool roof was 24.9% in Beijing, 20.7% in Harbin, 40.3% in Kunming, 27.2% in Nanjing, and 28.6% in Guangzhou for five locations in China, respectively. From Fig. 3, the percentage of cooling load provided by cool roof for several months (e.g. Beijing in January and Nanjing in February) was 100%. It was because there was no cooling demand in these months (i.e. heating season) which was not considered in this study.

3.2 Annual Cooling Electricity Saving Potential

The benefit of the building with metamaterial-based cool roof could be indicated by the cooling electricity consumption directly. As shown in Fig. 4, the comparison of the annual cooling electricity consumption for both of the building with metamaterial-based cool roof and original roof was calculated with EnergyPlus. And, the annual cooling electricity consumed by the buildings with metamaterial-based cool roof was lower than that with original roof for all five locations. Compared with the building with original roof, the cooling electricity of the building with metamaterial-based cool roof was approximately reduced by 392 kWh in Beijing, 197 kWh in Harbin, 159 kWh in Kunming, 354 kWh in Nanjing, and 589 kWh in Guangzhou. And, the cooling electricity consumptions were decreased by 26.8% in Beijing, 34.8% in Harbin, 31.4% in Kunming, 18.7% in Nanjing, and 18.9% in Guangzhou, respectively. Thus, the cool roof was perfect for the application of prefabricated building in China, especially for the buildings located in a severe cold zone, cold zone, and moderate zone.

3.3 Monthly Cooling Electricity Consumption

Most of the cooling electricity was consumed in the cooling season (i.e. June–September). To clearly indicate the cooling benefit of metamaterial-based cool roof, the monthly cooling electricity consumptions were also introduced in Fig. 5 for all five locations. As shown in Fig. 5, the average monthly cooling electricity consumptions of the building with metamaterial-based cool roof in cooling season were about 87.7 kWh in Beijing, 46.8 kWh in Harbin, 24.6 kWh in Kunming, 77.6 kWh in Nanjing, and 95.8 kWh in Guangzhou, resulting a reduction of 26.4%, 35.9%, 29.5%, 18.3%, and 17.6%, respectively, by comparing with the cooling electricity consumption of the building with original roof in these five locations. Thus, more benefit could be achieved from the cooling demand of building of these months.

4 Conclusions

In this study, the recently proposed metamaterial-based radiative cooling film was applied as the cool roof of prefabricated building. To reveal the cooling potential of metamaterial-based cool roof, a typical two-floor prefabricated building was simulated in EnergyPlus for five cities (i.e. Harbin, Beijing, Kunming, Nanjing, and Guangzhou) located in different climate zones of China. The cooling load addressed by metamaterial cool roof was analysed, and the energy consumption of the prefabricated building for both metamaterial-based cool roof and original roof was also discussed in detail. The main conclusions were as the followings:

-

The percentage of cooling load provided by the metamaterial-based cool roof for prefabricated building was 24.9% in Beijing (i.e. cold zone), 20.7% in Harbin (i.e. severe cold zone), 40.3% in Kunming (i.e. moderate zone), 27.2% in Nanjing (i.e. hot-summer and cold-winter zone), and 28.6% in Guangzhou (i.e. hot-summer and warm-winter zone).

-

Compared to the building with original roof, the building with metamaterial-based cool roof could save the annual electricity consumption by 26.8% in Beijing (i.e. cold zone), 34.8% in Harbin (i.e. severe cold zone), 31.4% in Kunming (i.e. moderate zone), 18.7% in Nanjing (i.e. hot-summer and cold-winter zone), and 18.9% in Guangzhou (i.e. hot-summer and warm-winter zone).

References

Delzendeh, E., Wu, S., Lee, A., Zhou, Y.: The impact of occupantsy behaviours on building energy analysis: a research review. Renew. Sustain. Energy Rev. 80, 1061–1071 (2017)

Chen, Z., Zhu, J., Bai, H.: Performance assessment of a membrane liquid desiccant dehumidification cooling system based on experimental investigations. Energy Build. 139, 665–679 (2017)

Zhu, L., Raman, A.P., Fan, S.: Radiative cooling of solar absorbers using a visibly transparent photonic crystal thermal blackbody. Proc. Natl. Acad. Sci. U.S.A. 112, 12282–12287 (2015)

Zhao, B., Hu, M., Ao, X., Pei, G.: Performance analysis of enhance radiative cooling of solar cells based on a commercial silicon photovoltaic module. Sol. Energy 176, 248–255 (2015)

Raman, A.P., Anoma, M.A., Zhu, L., Rephaeli, E., Fan, S.: Passive radiative cooling below ambient air temperature under direct sunlight. Nature 515, 540–544 (2014)

Cui, Y., Wang, Y., Huang, Q., Wei, S.: Effect of radiation and convection heat transfer on cooling performance of radiative panel. Renew. Sustain. Energy Rev. 99, 10–17 (2016)

Dyreson, A., Miller, F.: Night sky cooling for concentrating solar power plants. Appl. Energy 180, 276–286 (2016)

Hu, M., Pei, G., Wang, Q., Li, J., Wang, Y., Ji, J.: Field test and preliminary analysis of a combined diurnal solar heating and nocturnal radiative cooling system. Appl. Energy 179, 899–908 (2016)

Zhai, Y., Ma, Y., Zhao, D., Yang, R., Yin, X., David, S.N., Lou, R., Tan, G.: Scalable-manufactured randomized glass-polymer hybrid metamaterial for daytime radiative cooling. Science 355, 1062–1066 (2017)

Gentle, A.R., Smith, G.B.: A subambient open roof surface under the mid-summer sun. Adv. Sci. 2(9), 1–4 (2015)

Zhang, K., Zhao, D., Yin, X., Yang, R., Tan, G.: Energy saving and economic analysis of a new hybrid radiative cooling system for single-family houses in USA. Appl. Energy 224, 371–381 (2018)

Akbari, H., Levinson, R., Rainer, L.: Monitoring the energy-use effects of cool roofs on California commercial buildings. Energy Build. 37, 1007–1016 (2005)

Romeo, C., Zinzi, M.: Impact of the cool roof application on the energy and comfort performance in an existing non-residential building. Energy Build. 67, 647–657 (2013)

Kolokotsa, D., Diakaki, C., Papantoniou, S., Vlissidis, A.: Numerical and experimental analysis of cool roofs application on a laboratory building in Iraklion. Crete, Greece, Energy Build. 55, 85–93 (2012)

Eicker, U., Dalibard, A.: Photovoltaic-thermal collectors for night radiative cooling of buildings. Sol. Energy 85, 1322–1335 (2011)

Berdahl, P., Martin, M.: Emissivity of clear skies. Sol. Energy 32, 663–664 (1984)

McQuiston, F.C., Parker, J.D.: Heating, Ventilation, and Air Conditioning Analysis and Design, 6th edn. Wiley, Germany (2004)

Acknowledgements

This work is supported by grants from the National Natural Science Foundation of China (No. 51878342) and Jiangsu Provincial Department of Housing and Urban–Rural Construction (No. 2018ZD067).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Ma, M., Zhang, K., Tang, S., Chen, L., Niu, X., Li, F. (2020). Energy-Saving Analysis of Low-Rise Prefabricated Building Integrating with Metamaterial-Based Cool Roof in China. In: Wang, Z., Zhu, Y., Wang, F., Wang, P., Shen, C., Liu, J. (eds) Proceedings of the 11th International Symposium on Heating, Ventilation and Air Conditioning (ISHVAC 2019). ISHVAC 2019. Environmental Science and Engineering(). Springer, Singapore. https://doi.org/10.1007/978-981-13-9528-4_7

Download citation

DOI: https://doi.org/10.1007/978-981-13-9528-4_7

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-9527-7

Online ISBN: 978-981-13-9528-4

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)