Abstract

Injection of high-temperature steam is an effective and environment-friendly method for in situ upgrading of oil shale. In order to determine the variation rules of porosity and permeability of oil shale during the in situ upgrading process via steam injection, a numerical simulation model was established considering the deformed medium theory. This paper analyzed the influence of steam injection rate on medium deformation and oil production from several aspects, including the temperature distribution and kerogen decomposition. The results show that, under the action of kerogen decomposition and its products, the porosity and permeability of matrix increase gradually with the temperature. There is a rapid increase stage of cumulative oil production corresponding to the changes in average porosity and permeability of reservoir. The average porosity and permeability of reservoir increase faster with the steam injection rate; moreover, the rate of oil production is accelerated and the period of it becomes shorter. The research provides theoretical basis for the application and promotion of in situ upgrading of oil shale via steam injection.

Copyright 2018, Shaanxi Petroleum Society.

This paper was prepared for presentation at the 2018 International Field Exploration and Development Conference in Xi’an, China, 18–20 September, 2018.

This paper was selected for presentation by the IFEDC Committee following review of information contained in an abstract submitted by the author(s). Contents of the paper, as presented, have not been reviewed by the IFEDC Committee and are subject to correction by the author(s). The material does not necessarily reflect any position of the IFEDC Committee, its members. Papers presented at the Conference are subject to publication review by Professional Committee of Petroleum Engineering of Shaanxi Petroleum Society. Electronic reproduction, distribution, or storage of any part of this paper for commercial purposes without the written consent of Shaanxi Petroleum Society is prohibited. Permission to reproduce in print is restricted to an abstract of not more than 300 words; illustrations may not be copied. The abstract must contain conspicuous acknowledgment of IFEDC. Contact email: paper@ifedc.org.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Oil shale is a solid sedimentary rock that contains significant amounts of kerogen, and the kerogen can decompose through a series of chemical reactions into recoverable hydrocarbon products when it is heated to 300–600 ℃ [1]. As a kind of unconventional oil resources, a conservative estimate suggests that the total worldwide oil shale resources are approximately equivalent to 3 × 1012 bbl of oil [2], and China has abundant oil shale resources that are equivalent to about 3.5 × 1011 bbl of oil [3].

In order to avoid high pollution and low efficiency problems in the process of ground retorting [4], many researchers have began to investigate the in situ upgrading technologies of oil shale from the 1980s [5], including the overheat steam injection technology [6]. The way it works is injecting overheat steam through injection wells with the method of huff-puff or steam driving to heat oil shale reservoirs; then, the liquid and gas products during kerogen pyrolysis are produced by production wells [7]. Compared with the ground retorting technology, the overheat steam injection technology is environment-friendly and cost-effective [8]. Numerical simulation is an important research method for oil and gas field development, and some problems about in situ upgrading of oil shale have been solved by this way [9]. Due to the pyrolysis of kerogen, both porosity and permeability of oil shale increase gradually [10]. But the important characteristics are not considered in most numerical simulation studies, and they always be replaced by the average values’ definition of porosity and permeability in these models [11]. CMG is an effective reservoir simulator, and the results conducted by it can closely simulate the process of in situ upgrading of oil shale [12,13,14,15].

Therefore, in this paper, CMG was employed to establish a numerical simulation model considering the deformed medium theory. Then, the characteristics of medium deformation were revealed in the process of in situ upgrading of oil shale via steam injection, through analyzing the temperature distribution and kerogen decomposition comprehensively.

2 Reservoir Simulation

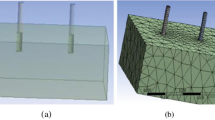

Shell has actively implemented a pilot project named in situ conversion process (ICP). The current version of the Shell ICP consists of a hexagonal pattern of six electric heaters surrounding one production well, but only a part of the well group with confined boundary was simulated due to the symmetry, as shown in Fig. 1. In this simulation, the electric heaters were changed into the steam injection wells, which were spaced 7 m apart, and the thickness of the simulated reservoir was 30 m.

Kerogen is a complex material, and the resulting pyrolysis products are also quite complex. Various conversion mechanisms of oil shale conversion to products have been proposed by previous researchers. Shell conducted experiments with samples obtained from the Green River Formation in the USA, and showed that kerogen pyrolysis of in situ upgrading can be simplified into several kinetic reactions. The kinetic reactions of kerogen pyrolysis including the main components are listed in Table 1. Kerogen pyrolysis was simulated using properties of lumped representative components. Thus, the pseudo-species IC37, IC13, and IC2 were used to represent the heavy oil, light oil, and hydrocarbon gas.

According to the characteristics of in situ upgrading of oil shale via steam injection, double-porosity model was used in this simulation. Matrix system represented the inorganic mineral skeleton where kerogen existed. Kerogen pyrolysis led to a large number of pores in matrix and further affected the matrix porosity and permeability. The relationship between porosity and permeability of matrix was described using deformed medium theory in the following equation. Kerogen pyrolysis also resulted in the cracks, which were represented by fracture system. And other main parameters of the reservoir simulation are listed in Table 2.

where \( \phi \) and \( \phi_{\text{o}} \) are the matrix effective porosity and the original porosity, respectively, fraction; \( k \) and \( k_{\text{o}} \) are the matrix effective permeability and the original permeability, respectively, 10−3 μm2.

3 Results and Discussion

Figure 2a shows the temperature distribution in formation when steam is injected for 2 years at 600 ℃. In this time, most of the formations attain the pyrolysis window where kerogen decomposition takes place. Figure 2b shows the distribution of kerogen concentration in heated interval over the duration of 2 years. Figure 2c shows that the matrix effective porosity increases near the steam injection wells, and the area expands to the production well gradually due to kerogen decomposition in the heating process. The distribution of matrix effective permeability corresponds to the matrix effective porosity as expected in Fig. 2d; it tends to increase with the matrix effective porosity.

In addition, various simulations were performed to assess the influence of steam injection rate on in situ upgrading of oil shale via steam injection, and three levels of it were 20, 30, and 40 t/d. Affected by the theory of double-porosity media, the results for changes in average porosity and permeability of reservoir are shown in Figs. 3 and 4. Both the curves of average porosity and permeability increase with the heating time, and there is a rapid increase stage in curves before reaching the maximum values. With the increase in steam injection rate, the faster average porosity and permeability of reservoir increase.

The results for cumulative oil production are shown in Fig. 5. Based on the analysis of Figs. 3 and 4, it can be seen that due to the large-scale improvement of physical properties of the reservoir, there is a rapid increase stage of cumulative oil production corresponding to the changes in average porosity and permeability of reservoir. When the average porosity and permeability are close to the maximum values, the oil production rate becomes slower caused by the decrease of the remaining oil. With the increase in steam injection rate, the faster cumulative oil production increases.

4 Conclusions

-

1.

A numerical simulation model of in situ upgrading of oil shale via steam injection is established considering the deformed medium theory.

-

2.

The results show that, under the action of kerogen decomposition and its products, the porosity and permeability of oil shale increase gradually with the temperature.

-

3.

Due to the large-scale improvement of physical properties of the reservoir, there is a rapid increase stage of cumulative oil production corresponding to the changes in average porosity and permeability of reservoir.

-

4.

The average porosity and permeability of reservoir increase faster with the steam injection rate; moreover, the rate of oil production is accelerated and the period of it becomes shorter.

References

Qian J. Oil shale:supplementary energy of Oil. China Petrochemical Press; 2011.

Dyni JR. Geology and resources of some world oil-shale deposits. US Geological Survey: US Department of the Interior; 2006.

Liu Zhaojun, Dong Qingshui, Ye Qingsong. Current situation of oil shale resources in China. J Jilin University (Edition of Natural Science). 2006;36(6):869–76.

Li J, Tang D, Xun H. Preliminary exploration on the feasibility of in situ exploitation of oil shale in China. J University of Southwest Petroleum (Edition of Natural Science). 2014; 36(1):58–64.

Brandt AR. Converting oil shale to liquid fuels: energy inputs and greenhouse gas emissions of the shell in-situ conversion process. Environ Sci Technol. 2008;42(19):7489–95.

Dexun L, Hongyan W, Dewen Z et al. Progress of in-situ exploitation of oil shale in the world. Nat G Ind. 2009;5:128–132.

Li S, Geng C, Qian J. Global oil shale exploration, development and utilization—two oil shale symposiums held in 2013. Sino-Glob Energy. 2014; 19(1):25–33.

Niu Jihui, Chen Dianyi. Foreign oil shale in-situ upgrading method. J Jilin University (Earth Sciences Edition). 2006;36(6):1029–30.

Wang H. Oil shale resources and development technology. China Petroleum Industry Press; 2010.

Kang Z. Pyrolysis characteristics of oil shale and simulation study of in-situ injection thermal recovery of oil and gas. Taiyuan University of Technology; 2008.

Fan Y, Durlofsky LJ, Tchelepi HA. Numerical simulation of the in-situ upgrading of oil shale. SPE J. 2010;15(2):368–81.

Shen C. Reservoir simulation study of an in-situ conversion pilot of Green-River oil shale. SPE 123142; 2009.

Bauman JH, Deo MD. Parameter space reduction and sensitivity analysis in complex thermal subsurface production processes. Energy Fuels. 2011;25(1):251–9.

Bauman JH. Significant parameter identification and characterization of complex in situ reservoir simulations. University of Utah; 2012.

Guanglun L, Zi L, Chuanjin Y et al. Numerical simulation on in-situ upgrading of oil shale via steam injection. J China University of Petroleum (Edition of Natural Science) 2017; 41(2):100–107.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Zheng, Y., Lei, G., Yao, C., Pei, S., Wang, L., Zhang, X. (2020). Numerical Simulation of Deformed Medium on In Situ Upgrading of Oil Shale via Steam Injection. In: Lin, J. (eds) Proceedings of the International Field Exploration and Development Conference 2018. IFEDC 2018. Springer Series in Geomechanics and Geoengineering. Springer, Singapore. https://doi.org/10.1007/978-981-13-7127-1_57

Download citation

DOI: https://doi.org/10.1007/978-981-13-7127-1_57

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-7126-4

Online ISBN: 978-981-13-7127-1

eBook Packages: EngineeringEngineering (R0)