Abstract

Roller cone bit is one of the main rock-breaking tools in oil and gas well engineering, and its performance could directly affect well drilling speed and cost. The particular structure of roller cone bit and the random breakage in heterogeneity rock make it difficult to study the problem of rock-breaking mechanism of roller cone bit under bottom-hole condition. Although, research on this topic has been carried out and drilling speed models under down hole conditions have been proposed. The research was based on rock intrusion theory and included the condition of bottom-hole pressure. Theoretical analysis shows that during the transient process of strata changing from soft form and medium-hard form to hard form, the drilling rate model is able to explain the influence of various ways of rock breakage on the drilling rate or the rate of penetration (ROP) of roller cone bit. The test results also show that the invasion depth of conical insert and chisel teeth both decreases exponentially with the increase in bit angle and fluid column pressure, where conical insert has greater decreasing rate than chisel teeth. In addition, the present study demonstrates that the intrusive coefficient is essential to quantify the intrusive-resistance capacity of bottom-hole rock.

Copyright 2018, Shaanxi Petroleum Society.

This paper was prepared for presentation at the 2018 International Field Exploration and Development Conference in Xi’an, China, September 18–20, 2018.

This paper was selected for presentation by the IFEDC Committee following review of information contained in an abstract submitted by the author(s). Contents of the paper, as presented, have not been reviewed by the IFEDC Committee and are subject to correction by the author(s). The material does not necessarily reflect any position of the IFEDC Committee, its members. Papers presented at the Conference are subject to publication review by Professional Committee of Petroleum Engineering of Shaanxi Petroleum Society. Electronic reproduction, distribution, or storage of any part of this paper for commercial purposes without the written consent of Shaanxi Petroleum Society are prohibited. Permission to reproduce in print is restricted to an abstract of not more than 300 words; illustrations may not be copied. The abstract must contain conspicuous acknowledgment of IFEDC. Contact email: paper@ifedc.org.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Oil and gas well engineering

- Drilling rate model

- Roller cone bit

- Rock-breaking mechanism

- Formation pressure

1 Introduction

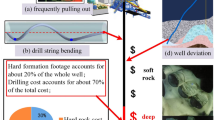

Roller cone bit, drag bit, and diamond bit constitute three common categories of bits extensively applied in oil and gas well engineering. Of these three categories, the number of roller cone bit takes up to 80–90% of the total bits being used in China. The drilling speed and cost are directly related to the performance of roller cone bit [1]. The drilling rate or the rate of penetration (ROP) of roller cone bit is influenced by several factors, such as multiple pressure (including overlying formation pressure, horizontal stress, pore pressure, and fluid column pressure), bit structure, and various ways of rock breaking [2,3,4,5]. Currently, the common ROP models applied to well drilling include Bingham drilling rate equation, Yangge drilling rate equation, and Armco equation. These drilling rate equations are proposed by analyzing the mechanical and hydraulic parameters. In these equations, the formation drillability coefficient has been included, but the characteristics of rock-breaking mechanism of roller cone bit are not considered [6,7,8,9,10]. This makes the equations unable to analyze effectively the distinction of ROP between different types of insert and between different conditions of formation. In view of the problem mentioned above, a new ROP model of roller cone bit is proposed by considering the pressure environment in the deep strata and rock-breaking characteristics of the teeth on roller cone bit. The new ROP model is based on single-tooth intrusion theory, and it lays foundation for real-time analysis of ROP of roller cone bit.

2 Bottom-Hole Force Analysis of Teeth on Roller Cone Bit

When roller cone bit crushes rock information and forms borehole, the crustal stress at wall and bottom changes accordingly. Besides the effects of crustal stress and pore pressure \(P_{P}\), the bottom-hole rock is exposed to the fluid pressure \(P_{m}\) in borehole and additional pressure \(\Delta P_{w}\) generated by drilling fluid circulation. Assuming equal horizontal stresses in two directions, the effective normal principal stress \(\sigma_{n}^{e}\) and effective horizontal stress \(\sigma_{Hh}^{e}\), which act at certain point on the bottom face, can be expressed as:

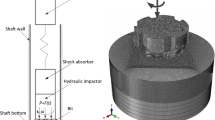

The process of teeth invading rock on the bottom face with \(2\theta\) angle under the action of axial load P can be simplified in Fig. 1.

By considering the bottom-hole pressure environment with rock shear breakage, the normal stress \(\sigma\) and shear stress \(\tau\) generated by axial load P are related through:

3 The Intrusive Coefficient of Teeth

According to Mohr-Coulomb criteria, when the bottom-hole rock has shear failure, the condition of rock breakage on blade side satisfies the following equation:

From Eqs. (2a), (2b), and (3), it is possible to obtain

\(\tau - \mu \sigma\) is a function of \(\varphi\). \(\tau - \mu \sigma\) reaches its maximum value when the derivation of Eq. (4) is equal to zero. Now we can get

It is shown that if the horizontal crustal stress, the pore pressure and the fluid column pressure remain unchanged, the ratio of load and invasion depth of teeth in every forward movement is a constant K, namely the intrusive coefficient of teeth under bottom-hole condition. Equation (5) is the intrusive equation at the under-balanced bottom. In addition, if the condition of the environmental effect of under-balanced bottom-hole pressure is removed, then the intrusive equation is under the atmospheric condition. In the case of no axial load, invasion depth, or bit angle, the intrusive coefficient becomes essential to describe the intrusive-resistance capacity of bottom-hole rock.

4 The ROP Model of Roller Cone Bit

The shapes of teeth on roller bit are mainly conical. To improve its rock-breaking efficiency, several designs including overhanging, axis-shifting, and complex cones have been adopted to enable the teeth to cut into and crush rocks by rotation and shear.

The shape of teeth on indoor microcone bit is chiseled, so the formed craters can be described by triangular prism. According to the triangle relation, the volume of crater next to a single tooth is:

Considering the uneven working face at the bottom during the crushing process and the effect of adjacent teeth, a factor C is introduced to better describe the process. Then, the ROP of microcone bit in unit time is expressed as:

With the form of pure rolling motion, the shape of crater is conical. The volume of bottom-hole rock crushed by single insert is:

Considering the hydraulic purification coefficient \(C_{\text{H}}\) and differential pressure influence coefficient \(C_{\text{P}}\), the ROP equation for roller cone bit with conical insert is expressed as:

Similarly, the ROP equation of roller cone bit with chisel teeth in pure rolling motion is:

If the rock breakage is under the joint action of rolling invasion and sliding shear, then the crater by conical insert invading rocks can be described by triangular prism. The ROP equation is:

From the above mentioned, the ROP equations are given by Eqs. (10), (11), and (12) for different motion patterns and different shapes of teeth. The equations take into account the effects of bottom-hole pressure and the teeth structure on ROP.

5 The Model for Indoor Experiments and Result Analysis

Xushen Oil Field is a typically deep and hard-drilling block across Daqing Oil Field. Its hard formation and high value of formation drillability significantly reduce the ROP of the whole block. Research has been carried out to analyze the invasion depth and intrusive coefficient of teeth and ROP. The tests include the intrusion generated by microroller cone bit and confining pressure.

5.1 Test by Using Microroller Cone Bit

The experimental device is a rock drillability tester. The microroller cone bit, with a diameter of 31.75 mm, is composed of eight tips of hard alloy with a thickness of 2.5 mm. Sandstone is selected as the sample. The physical and mechanical parameters are as follows: volume density = 2.31 g/cm3, elastic modulus = 1.32 × 104 MPa, cohesive force = 8.6 MPa, and angle of internal friction = 25°.

The size of the sample is determined by specific experimental requirements.

Test results are shown in Figs. 2 and 3. The result indicates that the ROP of microroller cone bit represents a linear increase with the increase in rotation speed and shows exponential increase with the increase in axial load.

5.2 Test in Balanced Pressure

The condition of bottom-hole is represented by \(\sigma_{\text{Hh}} = 42\,{\text{MPa}}\), \(P_{\text{m}} = 20\,{\text{MPa}}\) The test results of single-tooth intrusion are shown in Figs. 4 and 5. The results show that the invasion depth of both conical insert and chisel teeth experiences exponential decreases with the increase in bit angle, the bluntness of teeth, and the decrease in invasion depth. This is consistent with the known rules. The invasion depth also represents exponential decrease with the increase in fluid column pressure in borehole, the increase in rock compaction effect in working face, and the increase in rock hardness. The decreasing rate of conical insert is greater than that of chisel teeth. The invasion of conical insert is deeper than chisel teeth under the same level of fluid column pressure.

5.3 Test in Under-Balanced Pressure

The physical and mechanical parameters of the rock core sample are as follows: volume density = 2.63 g/cm3, elastic modulus = 1.32 × 104 MPa, compressing strength = 75.39 MPa, cohesive force = 30.06 MPa, angle of internal friction = 31.7°, and three values of bit angle: 10°, 15°, and 20°.

With the bit angle equal to 10°, the horizontal stress equal to 25.4 MPa, the fluid column pressure equal to 11.5 Mpa, and the pore pressure equal to 10 MPa, the theoretical curve between the intrusive coefficient and the angle of internal friction can be drawn according to Eqs. (5) and (7). As shown in Fig. 6, the intrusive coefficient decreases exponentially with the increase in angle of internal friction over different values of effective normal stress. The values of intrusive coefficient also change by choosing different values of effective normal stress, and a larger value of effective normal stress corresponds to a larger value of intrusive coefficient. Due to the fact that intrusive coefficient in under-balanced pressure is obviously smaller than that in over-balanced pressure, it is thus easier for teeth to invade and crush bottom-hole rock with the same mechanical parameters.

Figure 7 shows the effect of angle of internal friction on ROP. It can be noted that the ROP increases and reaches a maximum value at the angle of approximately 25° and then it decreases. The ROP in under-balanced pressure is obviously greater than that in over-balanced pressure.

In order to analyze the effect of sharpness degree of teeth on intrusive coefficient and ROP, single-tooth intrusion experiment is carried out under the condition of both bottom-hole and NPT, as shown in Figs. 8 and 9, respectively.

From the figures, it is evident that the capacity of invading rock becomes weaker and the intrusive coefficient becomes greater with bigger bit angle and blunter teeth. The theoretical and experimental values in Figs. 8 and 9 show that the intrusive coefficient increases exponentially while ROP represents decreases exponentially with the increase in bit angle. The effective normal stress has a significant impact on the intrusive coefficient and ROP.

6 Conclusions

The ROP equation is proposed by different types of teeth on roller cone bit under the bottom-hole condition. Theoretical analysis shows that during the transient process of strata changing from the soft, medium-hard to hard form, the ROP model can explain the ROP of roller cone bit in different ways of rock breakage and under bottom-hole condition.

The test result shows that the invasion depth of both conical insert and chisel teeth exhibits exponential decrease with the increase in bit angle. The invasion depth decreases exponentially with the increase in fluid column pressure in borehole. The invasion of conical insert is deeper than that of chisel teeth under the same level of fluid column pressure.

The intrusive coefficient, as a significant parameter of the intrusive equation, is essential to describe the intrusive-resistance capacity of bottom-hole rock.

The research has been done to analyze the effects of the angle of internal friction and bit angle on the intrusive coefficient and ROP. The result verifies that the main reason for the improvement in ROP by the under-balanced well drilling lies in the reduction in the intrusive coefficient of bottom-hole rock.

Abbreviations

- \(P_{P}\) :

-

Pore pressure

- \(P_{m}\) :

-

Fluid pressure

- \(\Delta P_{w}\) :

-

Additional pressure generated by drilling fluid circulation

- \(\sigma_{n}^{e}\) :

-

Effective normal principal stress

- \(\sigma_{Hh}^{e}\) :

-

Effective horizontal stress

- \(\sigma\) :

-

Normal stress

- \(\tau\) :

-

Shear stress generated by axial load

- P :

-

Axial load

- \(\theta\) :

-

Bit angle

- \(\varphi\) :

-

Angle between sheer failure surface and the horizontal bottom

- C :

-

Cohesive force

- \(\phi\) :

-

Angle of internal friction

- K :

-

Intrusive coefficient of bottom-hole rock

- x :

-

Half length of crater, \(x = h\,\tan \varphi\)

- \(L_{\text{h}}\) :

-

Width of chisel teeth

- m:

-

Number of teeth on each cone in contact with rock in bottom at some point

- \(d_{\text{b}}\) :

-

Diameter of bit

- \(n_{\text{b}}\) :

-

Rotation speed of bit

- \(C_{\text{H}}\) :

-

Hydraulic purification coefficient

- \(C_{\text{P}}\) :

-

Differential pressure influence coefficient

- \(d_{\text{c}}\) :

-

Diameter of cone

- \(n_{\text{c}}\) :

-

Rotation speed of cone around the cone axis

- Z:

-

Number of teeth in outward ring on cone, similarly

References

Chen TP, Hu JB. Petroleum Engineering. Beijing: Petroleum Industry Press; 2000.

Li SB, Dou TW, Dong DR, et al. Stress state of bottom-hole rocks in underbalanced drilling. Acta Petrolel Sin. 2011;32(2):329–35.

Yan T, Li W, Bi XL, et al. A new evaluation method of rock crushing efficiency base on the crushing work ratio. Fractal representation of rock drillability. Acta Petrol Sin. 2009; 30(2): 291–293.

Jin Yang. Correlation model of rock strength and formation pore pressure and application of the modle. J Univ Pet Ed Nat Sci. 2001;25(2):1–5.

Zheng DS, Feng JP. Mechanism of effect of down hole pressures on rock failure and its applications. Rock Soil Mech. 2011;32(1):205–8.

Liu YG, Wang HY. Initial research on rock-breaking mechanism for gas drilling in Xushen Gas Field. Acta Petrolei Sin. 2008;29(5):773–6.

Yan T, Li SB. Deep wellbore rock mechanics theory and practice. Petroleum Industry Press, Beijing; 2002.

Yan T, Li W, Bi XL, et al. Fractal analysis of energy consumption of rock fragmentation in rotary drilling. Chin J Rock Mechan Eng. 2008;27(2):3649–54.

Young FS. Computerized drilling control. JPT. 1969; 483–496.

Zhang H, Gao DL. A new method for predicting drillability of un-drilled formation. Acta Petrolel Sin. 2006;27(1):97–100.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Wei, L., Bing, L., Wenfeng, S., Siqi, L., Huan, Z. (2020). A Drilling Rate Model for Roller Cone Bit with Experimental Verification. In: Lin, J. (eds) Proceedings of the International Field Exploration and Development Conference 2018. IFEDC 2018. Springer Series in Geomechanics and Geoengineering. Springer, Singapore. https://doi.org/10.1007/978-981-13-7127-1_17

Download citation

DOI: https://doi.org/10.1007/978-981-13-7127-1_17

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-7126-4

Online ISBN: 978-981-13-7127-1

eBook Packages: EngineeringEngineering (R0)