Abstract

Enzymatic methods for the polymerisation of vinyl monomers are presented and critically discussed. Vinyl monomers can be polymerised initiated by enzyme-catalysed radical formation. The most widely used initiators for this purpose are β-diketo compounds, which can be transformed into the corresponding radicals via peroxidase- or laccase-catalysed oxidation. For this, peroxidases use hydrogen peroxide as oxidant, while laccases rely on molecular oxygen. Both enzyme classes comprise specific advantages and disadvantages that are discussed in this chapter. Also, parameters to control the polymer properties are introduced and discussed.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

11.1 Introduction

Polymers obtained from vinyl monomers represent an important class of plastics with widespread applications. The most predominant mechanism for their synthesis relies on radical initiation followed by radical chain propagation and termination yielding the final product.

Next to the classical radical chain initiators, enzymatic radical initiation has received growing interest (mostly from the academic world) as possibly milder and more benign alternative.

In this chapter we will outline the current mechanistic understanding of the most important enzyme-initiated vinyl polymerisation reactions, present some recent application examples and discuss the advantages and drawbacks of these methods compared to the current chemical state of the art.

11.2 General Topics

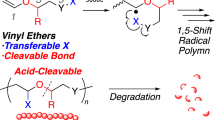

The term ‘enzymatic polymerisation of vinyl monomers’, which is frequently found in the literature, is somewhat misleading as it suggests the biocatalyst being involved in the actual polymerisation reaction. In fact, the biocatalysts discussed in this chapter exclusively catalyse the first step of the polymerisation reaction (i.e. the initiation reaction), while the polymer formation occurs spontaneously. Hence, classical benefits of biocatalysis such as stereoselectivity [1] cannot be expected from this sort of polymerisation reactions. In essence, the course of an enzyme initiated polymerisation differs from a ‘classical’ chemical polymerisation reaction only in the initiation reaction (Scheme 11.1).

11.2.1 Mechanism of Enzyme-Initiated Polymerisations

Laccases and peroxidases are the enzymes most widely used for the enzyme-initiated polymerisation of vinyl monomers [2,3,4]. Their ‘natural’ substrates are phenolic (and related) compounds, and the enzymes catalyse a H-atom abstraction yielding reactive radical compounds. Therefore, laccases and peroxidases are also widespread used in the polymerisation of phenolics (Chaps. 9 and 10).

Next to phenols, laccases and peroxidases also mediate H-atom abstraction reactions from other activated starting materials, especially from β-diketo compounds (Scheme 11.2). The resulting radicals function as radical initiators (In•) for the polymerisation of vinyl monomers as discussed throughout this chapter.

The catalytic mechanisms of peroxidases and laccases differ considerably. Peroxidases are generally heme-dependent enzymes, which in the presence of hydrogen peroxide (or other organic peroxides) form a highly oxidised (formal) FeV-oxo-species (compound I). Compound I is best described as oxyferryl (FeIV) embedded in a porphyrin radical cation [5]. Compound I performs two successive H-atom abstraction reactions from activated substrates (phenols or β-diketones) forming two radical initiators (Scheme 11.3).

Laccases also catalyse H-atom abstraction reactions from substrates very similar to those of the aforementioned peroxidases. In contrast, however, laccases utilise molecular oxygen instead of hydrogen peroxide as oxidant for this reaction. Laccases contain four copper ions (which is why they are also called blue-copper oxidases) classified as T1, T2 and T3 [6, 7]. Generally speaking, the T1 Cu ion performs four successive single-electron oxidation steps on the starting material transferring the reducing equivalents to the T2/T3-Cu ions. O2 reduction occurs in the T2/T3 cluster (which also very tightly binds the intermediate, partially reduced oxygen species, Scheme 11.4).

Next to the predominant peroxidases and laccases, also a few other enzymatic systems to generate polymerisation initiators are worth mentioning here. Alcohol oxidases catalyse the aerobic oxidation of alcohols to the corresponding carbonyl groups yielding hydrogen peroxide as by-product. In the presence of FeII ions, the latter can initiate Fenton-like reactions with reactive oxygen species (ROS) as initiators (Scheme 11.5) [8]. Similarly, xanthine oxidase can be used for the generation of ROS; in contrast to alcohol oxidases, this enzyme generates superoxide directly (Scheme 11.5) [8].

11.2.2 Factors Influencing the Outcome of Enzyme-Initiated Polymerisation of Vinyl Monomers

As for every radical polymerisation reaction, the yield and properties of the final product largely depend on the ratio of radical initiator to the monomer and the presence of possible chain growth inhibitors.

The in situ concentration of the active initiator radical can be influenced by parameters such as the enzyme concentration (its activity, respectively). Lalot and coworkers have investigated the effect of enzyme and initiator concentration on the polymer size of the HRP-initiated polymerisation of acrylamide (AAm, Scheme 11.7) [9]. These authors confirmed that a lower in situ concentration of the active initiator molecule (Acac radical) favours high molecular weights. This concentration directly correlates (increases) with the concentration of Acac and HRP. Qualitatively, the same trend was also found for the laccase-initiated polymerisation [10]. Overall, controlling the in situ concentration of the initiator radical via overall initiator concentration and/or enzyme concentration is a very good handle to control the polymer weight of the final product.

Also the oxidant concentration can play an important role in the polymerisation reaction but needs careful adjustment. In the case of peroxidases, H2O2 should not be applied in too high concentrations as H2O2 also is an efficient inactivator of the heme-enzymes [11]. The exact mechanism is not defined yet, and probably different inactivation pathways exist (Scheme 11.6), but it is clear that high in situ concentrations of H2O2 should be avoided.

Therefore, H2O2 often is added several times in small portions to minimise H2O2-caused inactivation. More elegantly, some in situ H2O2 generation systems have been developed in the past years, which may be applicable to use peroxidases more efficiently in polymerisation processes [12,13,14,15,16,17,18,19,20].

For laccases, O2 serves as oxidant to initiate the polymerisation reaction. The issue with O2 is that it also is an efficient radical scavenger inhibiting the polymerisation reaction. Therefore, also in the case of laccases (though not for enzyme stability reasons), the oxidant concentration needs to be carefully controlled [10]. This is also true for peroxidase reactions as also here trace O2 amounts can significantly impair the polymerisation reaction. Very recently an efficient measure to reduce the O2 content simply by adding glucose/glucose-oxidase to the reaction mixture was proposed by Stevens and coworkers [21, 22] (Scheme 11.7).

It is generally assumed that the enol form of the β-diketo compound (more phenol-like) represents the actual substrate for the laccase- or peroxidase-catalysed H-atom abstraction [23]. Hence, factors influencing the keto-enol equilibrium will influence the in situ concentration of the actual enol substrate. Using more alkaline pH values is a double-edged measure; on the one hand, higher pH values favour higher enol concentrations, while on the other hand, the pH optima of laccases and peroxidases are more in the slightly acidic range [24]. Another possibility is to engineer the β-diketo compound itself and favour the enol content through steric and/or electronic variations. It should, however, be kept in mind that both factors may interfere with the acceptance of the β-diketo compound by the enzyme (especially in case of sterically demanding starting materials) or with the polymer-initiation activity of the resulting radical (particularly in case of using electronegative substituents to increase the enol content). Kaplan and coworkers systematically investigated the influence of the initiator molecule on the polymer properties for the horseradish peroxidase (HRP)-catalysed polymerisation of styrene [25] and acrylamide [26] (Table 11.1) impressively demonstrating the influence the initiator can have on the conversion as well as on polymer properties such as molecular weight (MW) and polydispersity (PD).

Ideally, the initiator molecule would be circumvented at all. This would not only eliminate its cost contribution but would also be favourable from an enzyme activity point of view (many initiators exhibit solvent-like properties and can – in too high concentrations – inactivate the biocatalyst). Early reports claiming initiator-free enzyme-initiated polymerisation [27, 28] could not be reproduced by others [10, 26, 29].

Finally, also the solvent can have a significant influence on the polymerisation reaction. Especially if hydrophobic monomers are used, their solubility in the mostly aqueous reaction mixtures can be an issue. Polar organic solvents can be used to increase the monomer solubility [25, 30]. But frequently the presence of water-mixable cosolvents impairs the stability of the biocatalyst used. An alternative to increasing the water solubility of the monomers is to use a biphasic reaction mixture containing an aqueous reaction mixture with the biocatalyst and a hydrophobic organic phase composed of the monomer in high concentrations (ideally neat). Such emulsion polymerisations have been investigated especially for styrenes [29, 31, 32]. Even better than a biphasic system would be to use neat reaction conditions without any cosolvent whatsoever. For this, immobilised preparations of the biocatalyst are required [33,34,35,36,37,38,39,40,41]. Another interesting approach is to solubilise the hydrophilic enzymes in organic media by coating them with surfactants [42].

11.3 Selected Examples

In recent years the number of reported examples for enzyme-initiated vinyl polymerisations has been growing steadily. Scheme 11.8 gives a representative overview over some of the literature examples.

Graft polymerisation is receiving increasing attention especially using HRP as catalyst. For example modifying starch with (poly)acrylamide [55], (poly) methyl acrylate [56] or (poly)butyl acrylate [57] has been reported (Scheme 11.9) [58]. As grafting mechanism, H-atom abstraction from a starch-OH-group by HRP-generated Acac has been proposed.

Another interesting grafting approach has been reported with silica surfaces using laccases [59] or HRP [60]. In the latter case, for example, SiO2 particles were first covered with the initiator (Acac) followed by HRP-initiated grafting of acrylamide onto the SiO2 particle (Scheme 11.10).

Also lignin represents an attractive target to graft polymers onto. Interestingly, this appears to be a laccase domain [61,62,63,64,65,66,67].

Cross-linking of chitosan using laccases was used to self-immobilise the enzyme [68].

In polymer chemistry, the so-called reversible deactivation radical polymerisation (RDRP) is very much in focus now due to its power to control the molecular weight and the polydispersity of the polymer products. Also in enzyme-initiated polymerisations, RDRP is being used more frequently [54, 69, 70].

11.4 Conclusions

The use of enzymes to initiate radical polymerisation reactions is enjoying steadily growing interest. Partially, this may be due to the fact that enzymatic reactions are generally perceived to be more environmentally benign than ‘chemical’ reactions. A quantitative study comparing the environmental impact of both, however, is lacking so far. It should be kept in mind that not only the actual reaction (conditions) determines the environmental impact but also factors such as catalyst’s preparation and downstream processing to obtain the desired product. Hence, perceived advantages such as mild reaction conditions or the use of water as solvent may well turn out to be less important than thought or maybe even counterproductive.

Nevertheless, enzyme-initiated polymerisation remains an active and dynamic field of research, and some exciting new developments may be expected in the future.

Today, the peroxidase from horseradish is by far the most popular biocatalyst in use, which is somewhat astonishing considering that the number of available peroxidases/peroxygenases and laccases is steadily increasing [71]. Though it is not expected that new enzymes will have a significant impact on the polymer structure, it may well be that increased activity and/or stability may contribute to the economic feasibility of these processes.

References

Torrelo G, Hanefeld U, Hollmann F (2015) Biocatalysis. Catal Lett 145(1):309–345

Shoda S, Uyama H, Kadokawa J et al (2016) Enzymes as green catalysts for precision macromolecular synthesis. Chem Rev 116(4):2307–2413

Kobayashi S, Makino A (2009) Enzymatic polymer synthesis: an opportunity for green polymer chemistry. Chem Rev 109(11):5288–5353

Hollmann F, Arends IWCE (2012) Enzyme initiated radical polymerizations. Polymers 4(1):759–793

Hofrichter M, Ullrich R (2014) Oxidations catalyzed by fungal peroxygenases. Curr Opin Chem Biol 19(0):116–125

Riva S (2006) Laccases: blue enzymes for green chemistry. Trends Biotechnol 24(5):219–226

Rodríguez-Delgado MM, Alemán-Nava GS, Rodríguez-Delgado JM et al (2015) Laccase-based biosensors for detection of phenolic compounds. Trends Anal Chem 74:21–45

Gross RA, Kumar A, Kalra B (2001) Polymer synthesis by in vitro enzyme catalysis. Chem Rev 101(7):2097–2124

Durand A, Lalot T, Brigodiot M et al (2001) Enzyme-mediated radical initiation of acrylamide polymerization: main characteristics of molecular weight control. Polymer 42(13):5515–5521

Hollmann F, Gumulya Y, Toelle C et al (2008) Evaluation of the laccase from Myceliophthora thermophila as industrial biocatalyst for polymerization reactions. Macromolecules 41(22):8520–8524

Valderrama B, Ayala M, Vazquez-Duhalt R (2002) Suicide inactivation of peroxidases and the challenge of engineering more robust enzymes. Chem Biol 9(5):555–565

Zhang W, Fernández-Fueyo E, Ni Y et al (2018) Selective aerobic oxidation reactions using a combination of photocatalytic water oxidation and enzymatic oxyfunctionalizations. Nat Catal 1:55–62

Gomez de Santos P, Canellas M, Tieves F et al (2018) Selective synthesis of the human drug metabolite 5′-hydroxypropranolol by an evolved self-sufficient peroxygenase. ACS Catal 8(6):4789–4799

Zhang W, Burek BO, Fernández-Fueyo E et al (2017) Selective activation of C-H bonds by cascading photochemistry with biocatalysis. Angew Chem Int Ed 56(48):15451–15455

Ni Y, Fernández-Fueyo E, Baraibar AG et al (2016) Peroxygenase-catalyzed oxyfunctionalization reactions promoted by the complete oxidation of methanol. Angew Chem Int Ed 55:798–801

Paul CE, Churakova E, Maurits E et al (2014) In situ formation of H2O2 for P450 peroxygenases. Bioorg Med Chem 22(20):5692–5696

Churakova E, Kluge M, Ullrich R et al (2011) Specific photobiocatalytic oxyfunctionalization reactions. Angew Chem Int Ed 50(45):10716–10719

Perez DI, Mifsud Grau M, Arends IWCE et al (2009) Visible light-driven and chloroperoxidase-catalyzed oxygenation reactions. Chem Commun 44:6848–6850

Zavada S, Battsengel T, Scott T (2016) Radical-mediated enzymatic polymerizations. Int J Mol Sci 17(2):195

Zavada SR, McHardy NR, Scott TF (2014) Oxygen-mediated enzymatic polymerization of thiol-ene hydrogels. J Mater Chem B 2(17):2598–2605

Chapman R, Gormley Adam J, Stenzel Martina H et al (2016) Combinatorial low-volume synthesis of well-defined polymers by enzyme degassing. Angew Chem Int Ed 55(14):4500–4503

Chapman R, Gormley AJ, Herpoldt K-L et al (2014) Highly controlled open vessel RAFT polymerizations by enzyme degassing. Macromolecules 47(24):8541–8547

Baader WJ, Bohne C, Cilento G et al (1985) Peroxidase-catalyzed formation of triplet acetone and chemiluminescence from isobutyraldehyde and molecular oxygen. J Biol Chem 260(18):10217–10225

Chang A, Scheer M, Grote A et al (2009) BRENDA, AMENDA and FRENDA the enzyme information system: new content and tools in 2009. Nucleic Acids Res 37:D588–D592

Singh A, Ma D, Kaplan DL (2000) Enzyme-mediated free radical polymerization of styrene. Biomacromolecules 1(4):592–596

Teixeira D, Lalot T, Brigodiot M et al (1999) ß-Diketones as key compounds in free-radical polymerization by enzyme-mediated initiation. Macromolecules 32(1):70–72

Parravano G (1951) Chain reactions induced by Enzymic systems. J Am Chem Soc 73(1):183–184

Derango R, Chiang L-C, Dowbenko R et al (1992) Enzyme-mediated polymerization of acrylic monomers. Biotechnol Tech 6(6):523–526

Emery O, Lalot T, Brigodiot M et al (1997) Free-radical polymerization of acrylamide by horseradish peroxidase-mediated initiation. J Polymer Sci A: Polymer Chem 35(15):3331–3333

Kalra B, Gross RA (2000) Horseradish peroxidase mediated free radical polymerization of methyl methacrylate. Biomacromolecules 1(3):501–505

Qi GG, Jones CW, Schork FJ (2006) Enzyme-initiated miniemulsion polymerization. Biomacromolecules 7(11):2927–2930

Shan J, Kitamura Y, Yoshizawa H (2005) Emulsion polymerization of styrene by horseradish peroxidase-mediated initiation. Coll Polym Sci 284(1):108–111

Hanefeld U, Gardossi L, Magner E (2009) Understanding enzyme immobilisation. Chem Soc Rev 38(2):453–468

Iyer PV, Ananthanarayan L (2008) Enzyme stability and stabilization–Aqueous and non-aqueous environment. Process Biochem 43(10):1019–1032

Zhao Q, Sun JZ, Ren H et al (2008) Horseradish peroxidase immobilized in macroporous hydrogel for acrylamide polymerization. J Polym Sci Pol Chem 46(6):2222–2232

Fernández-Fueyo E, Ni Y, Gomez Baraibar A et al (2016) Towards preparative peroxygenase-catalyzed oxyfunctionalization reactions in organic media. J Mol Catal B Enzym 134:347–352

Dordick JS, Marletta MA, Klibanov AM (1987) Polymerization of phenols catalyzed by peroxidase in nonaqueous media. Biotechnol Bioeng 30(1):31–36

Zaks A, Klibanov AM (1985) Enzyme-catalyzed processes in organic solvents. Proc Natl Acad Sci U S A 82(10):3192–3196

Zaks A, Klibanov AM (1984) Enzymatic catalysis in organic media at 100°C. Science 224(4654):1249–1251

Klibanov AM, Berman Z, Alberti BN (1981) Preparative hydroxylation of aromatic compounds catalyzed by peroxidase. J Am Chem Soc 103(20):6263–6264

Kreuzer LP, Männel MJ, Schubert J et al (2017) Enzymatic catalysis at nanoscale: enzyme-coated nanoparticles as colloidal biocatalysts for polymerization reactions. ACS Omega 2(10):7305–7312

Angerer PS, Studer A, Witholt B et al (2005) Oxidative polymerization of a substituted phenol with ion-paired horseradish peroxidase in an organic solvent. Macromolecules 38(15):6248–6250

Kohri M, Uzawa S, Kobayashi A et al (2013) Enzymatic emulsifier-free emulsion polymerization to prepare polystyrene particles using horseradish peroxidase as a catalyst. Polymer J 45(3):354–358

Kohri M (2014) Development of HRP-mediated enzymatic polymerization under heterogeneous conditions for the preparation of functional particles. Polymer J 46(7):373–380

Singh A, Roy S, Samuelson L et al (2001) Peroxidase, hematin, and Pegylated-Hematin catalyzed vinyl polymerizations in water. J Macromol Sci A 38(12):1219–1230

Sanchez-Leija RJ, Torres-Lubian JR, Resendiz-Rubio A et al (2016) Enzyme-mediated free radical polymerization of acrylamide in deep eutectic solvents. RSC Adv 6(16):13072–13079

Villarroya S, Thurecht KJ, Howdle SM (2008) HRP-mediated inverse emulsion polymerisation of acrylamide in supercritical carbon dioxide. Green Chem 10(8):863–867

Durand A, Lalot T, Brigodiot M et al (2000) Enzyme-mediated initiation of acrylamide polymerization: reaction mechanism. Polymer 41(23):8183–8192

Lalot T, Brigodiot M, Maréchal E (1999) A kinetic approach to acrylamide radical polymerization by horse radish peroxidase-mediated initiation. Polymer Int 48(4):288–292

Kalra B, Gross RA (2002) HRP-mediated polymerizations of acrylamide and sodium acrylate. Green Chem 4:174–178

Bao S, Wu D, Su T et al (2015) Microgels formed by enzyme-mediated polymerization in reverse micelles with tunable activity and high stability. RSC Adv 5(55):44342–44345

Singh A, Kaplan DL (2004) Vitamin C functionalized poly(methyl methacrylate) for free radical scavenging. J Macromol Sci A 41(12):1377–1386

Ikeda R, Tanaka H, Uyama H et al (1998) Laccase-catalyzed polymerization of acrylamide. Macromol Rapid Commun 19(8):423–425

Fodor C, Gajewska B, Rifaie-Graham O et al (2016) Laccase-catalyzed controlled radical polymerization of N-vinylimidazole. Polym Chem 7(43):6617–6625

Shogren RL, Willett JL, Biswas A (2009) HRP-mediated synthesis of starch-polyacrylamide graft copolymers. Carbohyd Polym 75(1):189–191

Wang S, Wang Q, Fan X et al (2016) Synthesis and characterization of starch-poly(methyl acrylate) graft copolymers using horseradish peroxidase. Carbohydr Polym 136:1010–1016

Wang S, Xu J, Wang Q et al (2017) Preparation and rheological properties of starch-g-poly(butyl acrylate) catalyzed by horseradish peroxidase. Process Biochem 59:104–110

Karaki N, Aljawish A, Humeau C et al (2016) Enzymatic modification of polysaccharides: Mechanisins, properties, and potential applications: a review. Enz Microb Technol 90:1–18

Qiao L, Wang X, Gao Y et al (2016) Laccase-mediated formation of mesoporous silica nanoparticle based redox stimuli-responsive hybrid nanogels as a multifunctional nanotheranostic agent. Nanoscale 8(39):17241–17249

Fukushima H, Kohri M, Kojima T et al (2012) Surface-initiated enzymatic vinyl polymerization: synthesis of polymer-grafted silica particles using horseradish peroxidase as catalyst. Polym Chem 3(5):1123–1125

Munk L, Punt AM, Kabel MA et al (2017) Laccase catalyzed grafting of -N-OH type mediators to lignin via radical-radical coupling. RSC Adv 7(6):3358–3368

Mai C, Milstein O, Hüttermann A (2000) Chemoenzymatical grafting of acrylamide onto lignin. J Biotechnol 79(2):173–183

Mai C, Milstein O, Hüttermann A (1999) Fungal laccase grafts acrylamide onto lignin in presence of peroxides. Appl Microbiol Biotechnol 51(4):527–531

Witayakran S, Ragauskas AJ (2009) Modification of high-lignin softwood kraft pulp with laccase and amino acids. Enz Microb Technol 44(3):176–181

Gillgren T, Hedenström M, Jönsson LJ (2017) Comparison of laccase-catalyzed cross-linking of organosolv lignin and lignosulfonates. Int J Biol Macromol 105:438–446

Yu C, Wang F, Fu S et al (2017) Laccase-assisted grafting of acrylic acid onto lignin for its recovery from wastewater. J Polymers Environ 25(4):1072–1079

Dong A, Yuan J, Wang Q et al (2014) Modification of jute fabric via laccase/t-BHP-mediated graft polymerization with acrylamide. J Appl Poly Sci 131(12)

Sun H, Huang W, Yang H et al (2016) Co-immobilization of laccase and mediator through a self-initiated one-pot process for enhanced conversion of malachite green. J Colloid Interface Sci 471:20–28

Renggli K, Sauter N, Rother M et al (2017) Biocatalytic atom transfer radical polymerization in a protein cage nanoreactor. Polym Chem 8(14):2133–2136

Zhang B, Wang X, Zhu A et al (2015) Enzyme-initiated reversible addition–fragmentation chain transfer polymerization. Macromolecules 48(21):7792–7802

Martínez AT, Ruiz-Dueñas FJ, Camarero S et al (2017) Oxidoreductases on their way to industrial biotransformations. Biotechnol Adv 35:815–831

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Zhang, W., Hollmann, F. (2019). Synthesis of Vinyl Polymers via Enzymatic Oxidative Polymerisation. In: Kobayashi, S., Uyama, H., Kadokawa, Ji. (eds) Enzymatic Polymerization towards Green Polymer Chemistry. Green Chemistry and Sustainable Technology. Springer, Singapore. https://doi.org/10.1007/978-981-13-3813-7_11

Download citation

DOI: https://doi.org/10.1007/978-981-13-3813-7_11

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-3812-0

Online ISBN: 978-981-13-3813-7

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)