Abstract

Polyhydroxyalkanoates (PHAs) are the biodegradable polyesters synthesized from the bacterial origin with high therapeutic importance due to their major biopolymer properties like biodegradability, biocompatibility, non-toxicity and thermo-plasticity. These hypotheses make the PHAs as one of the drug carrier or nanovehicles for therapeutic drug delivery. Drug delivery is one of the emerging fields in biological science, which gives application of delivering the promising drug molecules in the desired drug target, with increasing dissolution rate and bioavailability. Understanding the drug-polymer interactions and controlled release makes the combo of the perfect drug molecule and the biopolymer, and in this, the PHA is reported to be a better natural origin drug carrier. Several reports suggest that, chemical entities of PHA show enhanced activity and used as one of the promising nanocarrier. Experimental test by several assays shows PHA’s as one of the compatible biopolymers in tissues. This chapter comes up with various applications related to PHAs like medical implants, adhesion barriers, drug carriers, tissue engineering, Nano based targeted delivery. Overall, this chapter will provide a perfect base for studies on PHA related to drug carrier studies.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Biopolymer

- Polyhydroxyalkanotes

- Carriers

- Nanovehicles

- Implants

- Scaffolds

- Suture

- Cancer

- Wound healing

- Bioplastics

- Drug delivery

6.1 Introduction

As far with trending biological science, the Bioplastics are playing the core importance in multiple applications, holds the specialty of the pollution free product and environment friendly materials. In this, one of the notable bioplastic called “Polyhydroxyalkanoates”(PHAs) has introduced a several applications which replace the conventional plastics with various physical attributes. Polymers are the renewable resources among which the PHA is a biodegradable polymer accumulated as storage materials in the cytoplasm of the bacterial cells (Troschl et al. 2017). PHA is produced in the lack of nutrients, namely nitrogen and phosphorous, with carbon source found plethora. The first discovery of Polyhydroxybutyrate (PHB), which is a member of PHA family by Lemoine in 1927. PHA is very easily produced by the microorganisms in nature which shows its biodegradability (Kourmentza et al. 2017). It acts as an alternative for the traditional polymers where PHA exhibits mechanical and thermal properties similar to the plastics. The side chain length plays a vital role in maintaining these properties which give them stability. There are more than 150 different types of hydroxy alkanoic acids known for the bacterial storage polyesters. Ecological niches namely the marine habitats, estuaries, rhizosphere, microbial mats and marine sediments are the most convenient places for the microbes to perform its role and interact with all other microorganisms to constitute the ecosystem. The PHA accumulation will be occurred by microorganisms, with the higher stress lever in the environmental factors and considering this factor, the researchers have focused the industrial waste and effluents from textile industry, distilleries, dairy farms, oil mills, paper industry, animal residues, agricultural wastes and biodiesel waste products for PHA production. Since PHAs are produced under scarcity of nutrients, but with excess carbon, they are stored as inclusion bodies in polymerized form. The PHA has been previously produced from the sludge by aerobic dynamic feeding and anaerobic system in fermented effluents and sequencing batch reactors. The production of PHA from mixed cultures enriched the glycogen accumulating organisms, phosphate accumulating organisms and Archae.

PHA as a stored energy source makes the bacterium Bacillus megaterium in water a biocontrol agent (Defoirdt et al. 2009). The product which contains PHA breaks down completely into carbon dioxide and water, which are the major significant molecules for the photosynthesis. This could be a reason; PHA fits into the carbon cycle similar to petroleum-based plastics. The nanoparticles have a wide range of applications in various fields, as for the medical fields is concerned, they are used as the covering material for the drugs, which can be peculiarly designed and altered with respect to the target sites without altering the durability of the living cells. The PHA overcomes the commercial bioplastics like poly lactic acid (PLA), s-poly-glycolic acid (PGA) and poly (dl-lactide-co-glycolide) (PLGA), since the monomers of 3-hydroxybutyric acid and 4-hydroxybutyric acid are removed from the body in less than an hour since they are less acidic when compared to other bioplastics. The elimination or the eradication of PHA depends on the dispensation methods like nanofibers, films, scaffolds and also varies from one tissue to the other. The PHA degradation products like 3HB (3-hydroxy butyrate) and 3 HV (3-hydroxy valerate) are less acidic with pKa values of 4.7 than the glycolic and lactic acid with 4.72 (Fig. 6.1).

The drug deliveries are highly significant tools for the delivery of pharmacological compounds to the tissues, organs and cells. They are done by the polymers which make the drugs reach the target site safer with reduced side effects. One of the traditionally used polymers is the silicone which has been uncertain to cause cancers. To overcome these drawbacks, there is a growing need to find nontoxic, biocompatible and biodegradable polymers (Michalak et al. 2016). The poly(3-hydroxybutyrate) and the poly(3-hydroxybutyrate-co-3-hydroxyvalerate (PHBV) are the commonly used drug carriers and has more merits than the other polymers in tissue engineering. The polylactate, polyglycolate and poly(lactide-co-glycolide) are the chemically synthesized polymers which are biodegradable and biocompatible. The merit of PHA over other polymers is that they are impregnated into the human body and need not be removed, which are degraded by the system without any adverse effects. Hence it is aid to be a better bet against synthesized polymers (Errico et al. 2009). On hydrolytic degradation PHB produces 3 hydroxy butyrate, a metabolite in the human blood, were 3HB itself contains pharmaceutical properties. In order to improve the efficacy, the copolymers are blended with hexanoate, 1,4-butanediol, propionate and valerate. Poly(3-hyroxybutyrate-co-3-hydroxyhexanoate) belonging to the PHA family is physically blended with PHB (Misra et al. 2010). The glycosaminoglycans are used along with PHAs to improve the mechanical strength and biological properties of PHA biopolymer. There are certain inorganic compounds like bioactive glass, nano-HA (hydroxyapatite), calcium silicate and zinconium oxides added to PHB and PHBV for enhancing the cell interactions in tissue engineering and bone implants (Pascu et al. 2013). For example, calcium silicate enhances the bone bioactivity; cell adhesion of the composite, the bioglass grades 45S5 (45 wt% SiO2, 24.5 wt% Na2O, 24.5 wt% CaO, and 6.0 wt% P2O5) interconnects PHB with the formation of hydroxyalkanote within a short period, making it an excellent material for bone regeneration. The PHB is soluble in few solvents like dimethyl formamide, dichloromethane and chloroform and hence mixing of polymers with PHB is a challenging task. More care is taken during thermal molding, which makes the polymers break (Vroman and Tighzert 2009; Manavitehrani et al. 2016).

6.2 Structure of PHA

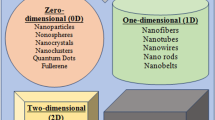

PHA’s are crystalline in nature, hydrophobic with chirally pure configuration monomers. The PHAs inside the bacterial cells as refractile bodies and as environmental friendly degradable plastics was initially found in early 1988 (Shrivastav et al. 2013). The PHA composition has been established by Griebel in 1968, in bacterium Bacillus megaterium. These have a huge array of applications in the fields of marine, medical and agriculture industry. The PHAs are stored as granules in the bacterial cells (Shively 2011). These granules contain proteins (1.87%), lipids (0.46%) and polyesters (97.7%). The region depicted in brackets is one monomer and R is the residual group, which varies based on the length of the carbon chains (Fig. 6.2). There are different types of PHA, which are differentiated based on the length of the side chain and the main chains. The types are based on the number of the carbon atoms in the monomeric units, as the short chain length PHA’s (scl-PHAs) with three to five carbons and medium chain length PHA’s (mcl-PHAs) with six to fourteen carbon atoms (Aslan et al. 2016). The enzyme involved in PHA biosynthesis is the PHA synthase, which polymerizes the monomeric hydroxyalkanote substrates.

There are around 14 pathways involved in the PHA biosynthesis and are classified based on the primary sequences.

-

Class I: One type- PhaC which forms homodimer, Scl monomer C3-C5 carbon chain lengths.

-

Class II: Two types- PhaC1 and PhaC2, Mcl monomer C6-C14 carbon chain lengths.

-

Class III: PhaC-PhaE, PhaC and PhaR, and forms heterodimer, Scl monomer C3-C5 carbon chain lengths

-

Class IV: Similar to class III, Scl monomer C3-C5 carbon chain lengths

In spite of the discovery three decades ago, there is no structural information of PHB synthase, the first structure of the catalytic domain of a PHB synthase is the PhaC from C. necator with PDB ID: 5T6O (Structure of the catalytic domain of the class I polyhydroxybutyrate synthase from Cupriavidus necator) (Fig. 6.3) (Chek et al. 2017). The scl-PHAs are used for the production of packing materials and disposable items, whereas the mcl-PHAs are of highly important applications like medicinal implants, matrix for drug delivery, surgical sutures etc., (Chen 2009a, b). Due to the diverse properties and different strategies used in the production of PHA, the functional group modifications like –COOH, OH, halogens and epoxy may enhance the thermal and mechanical properties. As the Scl and Mcl possess different monomeric units, their mixture possesses greater physical and thermal properties which are through the enzyme engineering (Sharma et al. 2017).

6.3 Bacterial PHA

PH3B, a homopolymer of 3-hydroxybutyrate is the most widely used member of PHA. The molecular weight of PHA depends upon the organism’s growth conditions and the extraction methods. The organisms Bacillus megaterium, Ralstonia eutrophus is said to produce PHB due to the physiological stress in a mixed or pure culture. The microbial synthesis of PHB involves condensation of two molecules of acetyl CoA to produce acetoacetyl CoA which is reduced to hydroxybutyryl CoA which is the monomer to polymerize PHB (Laycock et al. 2013).

6.4 PHA Production

The commercial production of PHA is by the fermentation of microorganisms namely Ralstonia eutropha, Pseudomonas putida, Escherichia coli, Aeromonas caviae, Azotobacter sp, Bacillus sp, and Methylobacterium sp. Though various microorganisms produce PHA, only a few are selected for the commercial production. Those organisms which have the metabolic activity of synthesizing PHA molecules are specifically selected. They play a vital role in the ion channel complexes, where degradation of PHB polymer yields 3-hydroxybutyrate which is a natural metabolite responsible for the formation of ketone bodies in animals. The ketone body is biosynthesized in the mitochondria of liver and used by brain (Roy 2015). One of the commonly used strains is Cupriavidus necator for the industrial production of PHB, P3HB4HB and PHBV. The recombinant Escherichia coli are used in the production of PHA, PHV and PHBV were PHAs are also produced in plants (Fig. 6.4).

6.5 Biosynthetic Pathways of PHA

The composition of the monomer is based on the used carbon source; there are three major pathways of PHA. Pathway 1 is two acetyl CoA from the TCA cycle are condensed to form aceto-acetyl CoA with the generation of 3HB monomers in the presence of enzyme β-keto-thiolase. The acetyl CoA reductase and acetyl CoA form the 3-hydroxybutyryl-CoA, finally yielding poly (3-hydroxybutyrate) P(3HB). Pathway 2 is the fatty acid metabolism which generates different hydroxyalkanote monomers, where the trans-2-enoyl-CoA is converted to (R)-hydroxyacyl-CoA by a (R)-specific enoyl-CoA hydratase. Pathway generates monomers form carbon sources like sucrose, glucose and fructose, which involves the conversion of acyl carrier protein (ACP) form to the CoA form by the enzyme acyl-ACP-CoA trans-acylase (Fig. 6.5).

6.6 Sources and Microorganisms Used for PHB Production

6.6.1 Eubacteria

In the year 1925, PHB accumulation was reported in Bacillus megaterium in the form of cytoplasmic inclusions, the PHA synthesizing bacteria are most commonly seen in nitrogen fixing organisms. They are classified into two groups based on the culture conditions, with the first group containing bacteria which requires excess carbon and limited nitrogen and oxygen, and the second group does not require limited nutrients. For the large-scale production, the culture conditions are the most important factor to be taken on account. The recombinant E. coli was shown to have high PHA accumulation due to the presence of PHA biosynthesis genes (Attia et al. 2010; Shukla 2017).

6.6.2 Archaea

Haloarchaea are the class of Euryarchaeota, which requires high salt concentrations to grow, and they are saturated with salt in order to maintain the cell wall stability, in the absence of the salt the cell wall breaks (Fig. 6.6).

6.6.3 Cyanobacteria

Cyanobacteria accumulated PHA by making use of the energy sources like CO2 and sunlight. These bacteria naturally possess PHA synthase enzyme. Synechocystis sp. PCC6803, spirulinaplatensis UMACC 161, accumulates 10% PHB as of the cell dry weight. Some of the cyanobacteria require phosphate limited conditions for the accumulation of PHB (Sudhesh et al. 2006).

6.6.4 Agro-industrial Residue

To reduce the production costs of the bioplastics the industrial and agricultural wastes as nitrogen and carbon sources are utilized for the biosynthesis of degradable bioplastics.

6.6.5 Molasses

The by-product obtained during the refining process of grapes, sugar beet and sugarcane. The accumulation of PHB was reported in the year 1992, in Azobactervinelandii UWD species. PHA production involves a three-step process, with step I, the fermentation of molasses into organic acids, followed by the Step II with the accumulation of PHA, and the step III, with the production of PHA in batches. On the refinement of the sugar beet, sugarcane and soy molasses PHA accumulation was observed in certain organisms (Fig. 6.7).

6.6.6 Whey Hydrolysates

Whey is the by-product of cheese and dairy industry obtained from the separation of casein from whole milk. The cheese whey equals the amount of milk used during processing, and the disposal of these waste causes pollution to the environment. PHA production has been reported in the cheese whey, in Paracoccusdenitrificans DSM 413 (Pantazaki et al. 2009; Koller et al. 2011) (Fig. 6.8).

6.6.7 Lignocellulose Material

Lignocelluloses consist of 30–50% cellulose, 15–35% lignin, and 20–50% hemicelluloses. The wheat straw is an agricultural residue, a most abundant cheap carbon source in bioplastics production. The Halomonasboliviensis from the wheat bran was reported for the production of PHB, were the wheat bran hydrolyzed by the enzyme to provide mixture of sugars. Similarly, the wheat straw, rice bran and extruded rice bran are the sources, for the organisms in the production of PHB (Fig. 6.9).

6.6.8 Vegetable Oils and Fats

The triacylglycerols (TAG) are an important feedstock for the production of PHA, the Aeromonascaviae biosynthesize PHA from the triacylglycerol. The type of the substrate and the monomer type have a relationship, were the high saturated fats produce high saturated PHA monomers and the high unsaturated fats produce unsaturated monomers. Olive oil, palm oil and other animal fats are responsible for the production of medium chain length PHAs (Fig. 6.10).

6.7 Microbial Biodegradation

Due to the presence of xenobiotic compounds the microorganisms face the environmental stress which in turn makes the chances to produce more PHA. The amount of carbon is found to be seen in higher amount at the oil contaminated sites with lesser nitrogen, which makes a prerequisite for the microbes Pseudomonas, Acinetobacter, brochothrix, Ralstonia, andYokenella to produce PHA. It has been reported that the organism Ralstoniaeutropha produces PHB nearly up to 50% of cell dry weight due to the presence of sodium benzoate and phenol as carbon sources but limiting nutrients. The waste products comprising toluene as constituent enables various microbes like Rhodococcusaetherivorans to produce copolymer P(3HB-co-HV) as it makes more carbon source with limiting nutrients. Hence these wastes can be made as useful valuable products like PHA (Hori et al. 2009) (Fig. 6.11).

6.7.1 Extremophile Organisms

Halophiles are organisms which live in high salt concentrations, also known as salt loving organisms. They are classified under Archae, still there are some bacterial halophiles and eukaryota. They live in salt concentrations nearly five times higher than the salt concentrations in oceans, islands and salt lakes. For the first time the Halobacterium marismortui was found to have PHB accumulation identified using the freeze fracture technique (Robenek and Severs 2008). The bacterium Haloferaxmediterranei is said to produce around 65% of PHA of cells dry weight, in case were the glucose and sucrose acts as the carbon source, limitation of the oxygen enhances the PHA production. H.boliviensis, are said to produce higher amount of PHB nearly up to 88% of cell dry weight with sodium acetate and butyric acid as carbon sources (Kourmentza et al. 2017).

6.7.2 Phosynthetic Bacteria

Cyanobacteria are reported to produce PHA by oxygenic photosynthesis, as they can produce PHA naturally and have the tendency to store PHA. The PHA producing organisms are found to be species specific, and mostly produce PHB.

6.7.3 Rhizospheres

The rhizospheres are the place for the microbes to harbor which enhances the growth of roots in plants, and it’s the place of exchange of nutrients for interaction of microbes hence the rhizospheres are the reservoirs of PHA. Pseudomonas extremaustralis, Pseudomonas orientalis, Pseudomonas brassicacearum, Burkholderiaterricola and Lysobactergummosusare reported to be the PHA producers. The microbe Azospirrillumbrasilenseis a growth promoting rhizobacterium in plants (Muller-Santos et al. 2015). The need for the utilization and storage of poly-𝛽-hydroxyalkanoate is for the maintenance of shelf-life of bacteria. There are various merits in the production of PHA like growth promotion in plants, cell multiplication, motility and colonization. Hence the oilseed rape, sugar beet and wheat rhizospheres have more PHA production, which means those plants which are rich in oily and carbohydrates products are said to produce more PHA.

6.7.4 Antibiotic Producers

Streptomyces, gram positive, aerobic bacteria are said to produce PHA as intracellular granules with rich carbon source for the antibiotics synthesis. Various other strains of Streptomyces produce PHB and play’s an important role in antibiotic production.

6.8 Different Types of PHAs

Based on the number of carbons, the types of PHAs are classified. Among various types PHB and PHBV are the extensively used commercial polymeric biomaterials. The molecular weight and the structure are manipulated by changing the growth conditions.

6.8.1 PHB

The Poly-β-hydroxybutyrate (PHB) is a homopolymer of (R) – β-hydroxybutyric acid, a head to tail homopolymer, naturally found in bacteria (Chen and Wu 2005; Philip et al. 2007). It’s the biodegradable and biocompatible polymer when used as implants gets degraded gradually by the temperature and produces non-toxic metabolites which are excreted through urine. Polyhydroxy butyrate and polyvinyl alcohol are used as scaffolds, prepared by the electro spinning in the field of tissue engineering. The collagen coated Nano fibrous PHBV loaded with somatic stem cells showed better healing property in rat models (Asran et al. 2010).

6.8.2 PHV, PHHx, PHHp, PHO

The polyhydroxyvalerate obtained from the P.oleovorans, in the activated sludge, few other monomers like 3HV, 3- hydroxyheptanoate (3HHp), and 3-hydroxyhexanoate (3HHx) existed as major components (Chen et al. 2013) (Fig. 6.12). The Poly (hydroxyhexanoate) (PHHx) from P. putida KTHH03, polyhydroxyheptanoate (PHHp) from P. putida KTHH03, PHO Poly(hydroxyoctanoate) from Streptmoyceslividansand PHN from Alcaligenessp. The therapeutic applications are mentioned in the Table 6.1 and medical applications are mentioned in the Fig. 6.13.

6.9 Biodegradability of PHA

An important role which makes the PHAs compatible is its biocompatibility. Since the PHAs are of the biological origin they are catabolized into water and carbon dioxide by microbes found in water, soil and sewage (Jaglan et al. 2017). These microbes excrete extracellular enzymes to hydrolyze solid PHA into water soluble monomers and oligomers, and use the end products as nutrients. The detriment of PHB seems to be faster in vivo than the in vitro because of the enzymes which catalyze the degradation at body temperature. The PHA polymers are degraded at the site of implantation by natural nonspecific esterase and lipases (Shrivastav et al. 2013). Lobler reported that there could be some impact of lipases on the PHA implants which has been shown by the lipase activities observed near the PHA implants in rat gastrointestinein vivo. For the use in medical applications PHA must be very specific and biocompatible, which should not cause any serious reactions as it must be introduced into the host organisms. The PHA must not evoke any immune response, when impregnated with the drug as the carrier vehicle. Over a period the PHA releases the drug which acts as the dosing agent. The dosage of the compounds can be altered by changing the properties of the biopolymer, like different side chains for PHA. As the PHA are biocompatible and does not elicit any immune response they can be used in the implants and sutures.

6.10 Biocompatibility of PHA

The implant material though being biodegradable should also be biocompatible with the host organisms. The polymers should not produce any toxic responses in the body, its supports the cell adhesion and growth which are the key factors for the commercialization.

6.10.1 In Vitro Cell and Tissue Compatibility

Basically, the monomers as they are not harmful for the tissues and cells, the biodegradable products are preferred for the medicinal applications. The PHB polymer when used as a pericardial patch in sheep, did not elicit any adverse effects. The PLAs are used as the standard polymer approved by FDA for implantation, the PHBHHx elicited a mild tissue response and found superior than PLA, as they exhibit thermo and mechanical properties. The PHBVHHx studied using human bone marrow mesenchymal cells showed better adhesion property than the PLA film and also enhanced osteogenic differentiation. Similarly, they showed better adhesion and proliferation of the Wharton’s jelly derived mesenchymal stem cells. On comparison with other PHA materials, P3HB4HBHHx and PHBVHHx exhibited better adhesion and cellular proliferation than tricalcium phosphate.

6.10.2 In Vivo Medical Implants

The PHAs are used as drug delivery matrices for encapsulating the hydrophobic drugs in the form of nanoparticles. The PHA nanoparticles, proteins or polypeptides fused with PhaP are developed, were PhaP fused with ligands and the overexpression of the genes of E.Coli attaches to the hydrophobic particle. These ligands pull the PhaP and PHA particles to the targets; this ligand-PhaP-PHA complex has been proved for specific drug delivery in both in vivo and in vitro. The insulin phospholipid complex (INS-PLC) loaded with PHBHHx was tested with the rats and found that the 20% of insulin released in the first 8 h within 31 days. The hypoglycemic effect sustained for more than 3 days and the subcutaneous injection of INS-PLC-NPs prolonged the therapeutic effect than administering with insulin solution indicating the challenging role of INS-PLC-NPs complex, with long term insulin release formulation. For targeting the microcapillary endothelial cells in the pancreas, the PHBHHx microspheres were prepared. Adenoviruses carrying a green fluorescence protein gene complexed with PHBHHx microspheres and injected in the pancreas of mice. About 40% of the cells were labeled after 5 days from surgery and the islet cells labeled occasionally. The insulin entrapment in PHBHHx nanoparticles, enhanced the efficiency of insulin in INS-PLC-NPs system. These paved the way for targeting capillary related disorders using PHBHHx microsphere-adenoviral complex (Zhang et al. 2012).

6.11 Biomedical Implants

The PHAs like PHO, PHB, PHBHHx, PHBV, and P4HB are used in biomedical applications since they are in sufficient quantities. For past 20 years PHA and composites have been used for many biomedical applications like sutures, staples, screws, plates(bone), slings, patches, adhesion barriers, nerve guides, filling agents, scaffolds, dressings, substitutes for skin injury, ligaments, cell implants, hemostats, orthopedic pins, tissue regeneration, meniscus regeneration, done dowels and spinal fusion cages (Chen et al. 2001; Chen and Wu 2005; Wang et al. 2008; Bian et al. 2009). The composition of PHA is altered to enhance the biocompatibility, degradation time under physiological conditions. 3-hydroxybutyrate promoted cell proliferation in highly dense cultures which prevented the cell death making the biopolymer PHBHHx a good candidate for tissue engineering, which may regenerate large number of cells. PHBHHx microparticles also promote the L929cell proliferations with increase in the intracellular calcium concentration. The P4HB is the successfully used implant material approved by FDA (Cheng et al. 2006). For the disease osteomyelitis, the poly(3HB-co-3 HV) rods with the sulperazone antibiotic were used. The rods loaded with 50% of the drug in the form of granules to the poly(3HB-co-3HV) solvent solution and the resulting paste was molded as rods. The animal studies were performed using staphylococcus aureus infected implants in rabbit tibias and replaced with the biopolymeric rods. The infection was found to be totally eradicated in 15 days. Similarly using poly(3HB-co-3HV) rods with the drug sulbactam-cefoper for the treatment of osteomyelitis has been reported (Gursel et al. 2002). (Korkusuz et al. 2001) used the poly(3HB-co-3HV) and poly(3HB-co-4HB) as antibiotic carriers for the osteomyelitis, the poly(3HB-co-4HB) was less rigid and easier to handle.

6.12 Subcutaneous Implants

The lipophilic drugs when administered orally are normally destroyed by the liver, so the transdermal delivery makes an option of delivering lipophilic drugs. The skin is one of the toughest paths for the diffusion of the drugs, which consist of a lipid bilayer; hence more focus is towards the transdermal delivery (Metcalfe and Ferguson 2006). The gonadotropin releasing hormone is entrapped with the P(3HB) and placed in sheep subcutaneously. The hormone induces ovulation and promotes the pre-ovulatory follicular growth. The release of the hormone was observed for about 2–4 h, and the incidence of ovulation was observed.

6.13 Ceramic Scaffolds

The ceramic scaffolds and biodegradable polymers are the drug delivery vehicles, and certain synthetic polymers could not be used for drug delivery as it produces adverse responses due to acidic degradation product. Therefore, the biocompatible polymer like PHAs supports cellular growth. The PHAs when in combinations with the bioactive ceramics improves the mechanical properties of the scaffolds.

6.14 Urology

The poly(3HB) and poly(3HB-co-3HV) material used in the repair and reconstruction of ureter. The interlaced tubes were coated with poly(3HB-co-3HV) and implanted in dogs for urethra replacement. The urethra tissue has been reconstructed in all tested animals after a period of 6–9 months, showing the efficiency of the poly(3HB) in reconstruction without any adverse effects (Jiménez and Kenny 2014).

6.15 Blood Vessels and Heart Valve

Due to the flexible property of PHAs they are used for the biomedical applications in making artificial blood vessels and heart valves. The P3HB4HB containing 4 hydroxy butyrate showed the formation of the elastin and its strength, which has the ability to induce formation of elastins and hence P3HB4HB polymers are used for making the artificial blood vessels (Cheng et al. 2008). As P3HB4HB is more fragile and less strong, copolymers with strong structures using poly (propylene glycol)- poly(ethylene glycol)-poly(propylene glycol) (PPG-PEG-PPG), were synthesized using 1,6-hexamethylene di-isocyanate (HDI).The stronger blood vessel materials are made using the materials like PHBHV and cellulose. The blending was made by the solvent casting method into films with varying ratios based on the blood vessels, when blended with other materials makes the PHBHHx a more suitable for engineering blood vessels. Blending of PHBHHx with poly propylene carbonate (PPC) increases the mechanical properties of the biopolymer making an ideal model. The porcine aortic valves decellularized and coated with the PHBHHx and implanted in the sheep without cardiopulmonary bypass. Then explanted valve is studied after 16 weeks for its histological and biochemical examination. It was observed that the valves maintained the original shape with less calcification than the control. The in vitro assay revealed the PHBHHx increases the tensile strength and enhanced repopulation of the cells making it similar to the native for valve replacement. The P4HB is absorbable and more flexible and found to be superior to the traditional polymeric materials. It finds use in wound healing, drug delivery and orthopedic surgeries (Wu et al. 2007a, b). The vascular cells from the ovine carotid arteries were harvested in vitro and seeded on the P4HB valve scaffold by cardiopulmonary bypass. The native valves were cut out and replaced using the 2 cm segments of pulmonary artery by cell seeded construct. After the observations all the animals survived with no thrombus formation. Such scaffold using P4HB can be used as tissue engineered heart valves and functions for a period of 120 days (Sodian et al. 2000a, b).

6.16 Hard and Soft Tissue Engineering

As the PHAs are biocompatible and long term degradability make it favorable biopolymer for the tissue engineering. The commonly used polymers in hard tissue engineering are the poly lactide-co-glycolide and polyethylene glycol. The P(3HB) strengthens the natural bone and induces osteogenesis and healing (Yang 2001). The P(3HB) are used in recovering the damaged gastrointestinal tract, pericardial patches, repair of peripheral nerves (Novikov et al. 2002). The medium chain length biopolymers are favorable for the soft tissue engineering due to their elastomeric and soft properties. The P(3HO-co-3HHx) is used to replace soft tissues like blood vessels and valves and also in hard tissue engineering like bones (Sodian et al. 2000a, b; Stock et al. 2000).

6.17 Hydrogels

The hydrophilic polymers with large water content are the hydrogels, which forms three-dimensional macro molecular networks. It is advantageous in tissue engineering as because of its permeability to nutrients. The 3D printing, molding and micro patterning has the impact on the hydrogels. There are natural and synthetic hydrogels based on the polymeric material as its components. The natural hydrogel forming polymers are agarose, chitosan, alginate and dextran and the synthetic hydrogel forming polymers are the polyethylene oxide, polyacrylic acid and polyvinyl alcohol. The hybrid hydrogels consist the peptide and the synthetic domains. The macromolecular polymers made of cross linked chains are used in the drug development and in various biomedical applications. The most favorable property for the hydrogels is its porous morphology which allows easier diffusion of drugs and nutrients within and outside the matrix. Hence these hydrogels are widely used as the drug carrier vehicle. The drug release rate can be altered or modified based on the mesh size of the network which enhances diffusion mediated release. The drugs impregnated hydrogels are used to induce therapeutic applications and the controlled release of the small molecule drugs, proteins or peptides. These gels are grafted onto biomaterials by polymerization, entrapment and graft coupling. Hydrogels are used as cardiovascular implants, urinary tracts, dressing of wounds and as controlled drug release devices. The coating with the help of hydrogels makes the biomaterials more compatible. The role of hydrogels in antibacterial activity using curcumin loaded nanoparticles into hydrogel was studied by (Vimala et al. 2014). The thin films were fabricated by the adsorption of dextran sulphate (DS) and poly (allylamine hydrochloride) (PAH) to drug delivery. The leaf extracts of Hybanthus enneasermus were used for the silver nanoparticles production and prepared as thin films and these silver nanoparticles along with the films showed the release of the drug more efficiently. The drug release of the silver nanoparticles coated polyelectrolyte thin films showed high release of moxifloxacin hydrochloride than the silver nanoparticles alone (Fig. 6.14).

6.18 Wound Healing

The largest organ in the human body is the skin and those damages caused might be due to the injury, burn or diseases. Skin act as a barrier in the human body which protects from the environment, skin substitutes are done mainly for the purpose as the grafts for healing wounds and for in vitro assay for skin testing of products. The skin replacements are through tissue engineered substitutes, like biomaterials and these biomaterials are designed for the skin wounds, and must enhance the growth of skin cells like fibroblast, keratinocytes and melanocytes. The biomaterials act as an artificial extracellular matrix for the attachment of the cells. Both the natural and synthetic polymers like glycosaminoglycans, polypeptides, hyaluronan and polylactide are used as substitutes were there are few demerits for the materials. The main demerit includes the inability of molecular signaling making it a tough task during surgery. Hence to overcome these issues PHAs are used for tissue regeneration. The seeding of melanocytes on the polymer scaffolds and in glands namely sebaceous gland and sweat glands. The drawback of the synthetic materials is lack of cell recognition as the heparin binding domains present on the binding sites of many proteins. The P(3HO) films supports cell differentiation and maturation of the HaCaT cell line. The PHA material terpolyster P(3HB-co-3 HV-co-HHx), used as a scaffold material in skin substitutes. This complex as it contains the 3HB, 3 HV, 3HHx polymers they have high mechanical and thermal properties.

6.19 Nerve Conduits

The PHB is brittle and the high elastic properties make it an ideal material as elastic conduit with tube structures. The PHB scaffold enhances proliferation and attachment of Schwann cells and its regeneration. The PHB conduits were tested for nerve injury, the peripheral nerve regeneration was studied using rabbits and showed these PHBs would be suitable for long term nerve injuries. The PHBHHx promotes central nervous system growth and differentiation on 2D and 3D matrices beneficial for the CNS repair. On comparison with 2D, the 3D nanofibers were more suitable for the central nervous system attachment, synaptogenesis and synaptic outgrowth. The PHA with varying ratios of PHB was found to be rough which makes the stiffness in the polymer when PHB is increased. Though they are blended with many ratios, the one with 25:75makes it significant for the neuronal cells in growth and differentiation. The PHAs would serve as the base for the manufacture of nerve conduits (Lizarraga-Valderrama et al. 2015).

6.20 Biomedical 3D Printing

The 3D porous cubes were made based on the laser sintering technology and the cubes are altered as per the virtual model. On comparison of the clinically used PLA, PGA and PLGA, PHB implants showed unaltered pH which makes them tolerated by cells. The PHB are used as coating materials for the dissolving implants (Meischel et al. 2016).

6.21 Biomedical Lithography

The two lithographic methods micro molding and hot embossing are used for PHBHHx arrays of microstructures in culturing cells in local environment in desired shapes, with different configurations like octagons, rectangles and squares. The microstructures of PHBHHx are used to impersonate cellular microenvironment for cell culture (Zhou et al. 2012; Li et al. 2014).

6.22 Injections

The PHBHHx dissolved in nontoxic solvents like dimethylacetamide, N-methylpyrrolidone, 1,4-dioxane, dimethyl sulphoxide, and 1,4-butanolide, which is the injectable implant method and forms a film around the site of injection in animals. The films were formed due to the interaction between the body fluids and the PHBHHx solvents. Such implant system was used for the tissue adhesion preventing film formation in surgeries (Dai et al. 2009).

6.23 Eyelid Reconstruction

The eyelid reconstruction involves the tarsal repair, were the traditional methods did not show satisfactory effects. The PHBHHx material is used as the tarsal substitute tested on the Sprague Dawley rats. Both the commercial scaffolds and the PHBHHx showed better effects though it showed inflammation for 2 weeks but still better than the blank. Since it’s a strong material with high elastic proprieties and biodegradability it’s proved that PHBHHx would be a good candidate for tarsal repair (Zhou et al. 2010). The transplantation of Islets is the alternative for the treatment of diabetes. The spherical islet like structures were observed on the PHBHHx films on cultivation, and cells when assayed by MTT showed high metabolic activity. After a growth on the PHBHHx films the extracellular secretion and the insulin gene expression were upregulated making it ideal for islet transplantation (Yang et al. 2009).

6.24 Osteogenic and Chondrogenic Effects

The biomaterial initiates the changes on the cell behavior which has specific surface features. The planar and grooved films exhibit osteogenic and chondrogenic effects on mesenchymal stem cells (Li et al. 2014). The presence of the biomaterials impacts the increase and decrease of specific genes for the variation in cellular response, which shows that the surface modifications are the major factor for the cellular response. The cells sense the material through adhesion formation or the integrin clusters. The strategy behind the proliferation of the cell lines are through the enhanced combination of a PHA binding protein with a mcl-PHA (Geiger et al. 2009).

6.25 Tissue Engineered Heart Valve

Sodian and his team made an attempt in tissue engineering using the flexible properties of the PHA, in implanting a trileaflet tissue engineered heart valve in a lamb with P(3HHx-co-3HO) polymer. It was found to work very efficiently for more than 3 months without any clots but had slight contraction (Sodian et al. 2000a, b; Levine et al. 2015). The poly glycolic acid when used as a blend with Poly (3hydroxyhexanoate-co-3hydroxyoctanoate), the heart valve regurgitation was seen after implantation in 6 months. The surface modification has a high impact when designing the PHA biopolymer (Qu et al. 2006).

6.26 Medical Scaffolding Material

In the medical terms the scaffolding is made of polymer fibers used for bone and tissue regrowth in various organs. The scaffolds are inserted into the host for the repair of the damaged tissue, once the tissue grows the scaffolds, are absorbed in the body and completely disappears.

Few studies report the hydroxyapatite as scaffolds used in the treatment of bone disorders. The PHB and polyglycolic acid were used as scaffolds for the pulmonary arteries in the sheep, where the PHA based scaffold are inserted surgically into the host. Also, the PHB were used in the rats with the spinal cord injury by neuronal generation (Novikov et al. 2002).

6.27 Surgical Material (Sutures)

The sterile fibers may be absorbable or non-absorbable used in the medical applications for tissue fixation, ligation and wound healing. During the implantation, absorbable sutures are made which loses their tensile strength and gets degraded as nontoxic products (Chen et al. 2014). The polymeric materials are more specific for making sutures, were the material must exhibit high tensile strength for the effectiveness of the sutures made for closure of wounds. The sutures must exhibit high tensile strength, flexibility, resistance to bacterial growth, easily to tie, grip, good absorbance and eventually disappearing property. The polymers Poly(3hydroxybutyrate-co-3hydroxyhexanoate) and PLA exhibited such properties and have been used as biomedical application. The TephaFLEX suture is the most well-known first approved suture by US FDA, which are more familiar due to its mechanical properties.

6.28 Drug Release

PHA are used as devices in drug delivery, an in vitro assay using P(HB-co-HV) polymer, impregnated with drug gentamicin showed a slow release of the drug into the aqueous solution for 2 weeks. The release of the drug can be altered using the amount of drug loaded. The sustained release using biopolymers makes the drugs reach the target site at a given concentrations (Gursel et al. 2002).

6.29 Drug Carriers

As PHAs are hydrophobic and biocompatible they are turned into porous matrices, microspheres, nanoparticles, films and micro capsules. So, the drugs like antibiotics, anticancer, anesthetic agents, anti-inflammatory agents, vaccines and steroids can be trapped in the polymer and delivered to the host organisms. The PHA microspheres are used as carriers of steroids, were PHB is used in the preparation of microspheres containing the progesterone as drug. PHB microspheres showed the higher rate of release of the drug when compared with other polymers. The anticancer drug lomustine incorporated in PHB and PLA microspheres as drug carriers and found the release of drug faster from the PHB microspheres than PLA. The increased rate of drug release was observed with the incorporation of butyl esters in PHB microspheres (Chen et al. 2009a, b; Shrivastav et al. 2013). The PHBV polymers incorporated with tetracycline acts as the carriers for the periodontal diseases and were found to be effective for the controlled release of the drug. The tetracycline are loaded in PHBV microspheres and in micro capsules in both the acidic and neutral forms, showed the complete release of the drug before degradation (Chang and Sultana 2017). The PHB microspheres were incorporated with rubomycin an antitumor drug, in mice for its proliferative activity in Ehrlich’s carcinoma. (Lu et al. 2011) reported PHA nanoparticles as drug carriers for ant cancerous studies. The sustained release of the PI3K(TGX221) for blocking the proliferation of cancer cell lines. The TGX221 slowly released from the PHA based nanoparticles, gradually inhibited the growth of cancerous cells. The chemotherapeutic drugs which are highly toxic and poorly water soluble are encapsulated with PHA nanoparticles. The chemotherapeutic molecule Docetaxel (DTXL) used in treatment of tumor types. DTXL formulated with PHB nanoparticles increased the therapeutic index and blood longevity. The PLGA is the traditionally used nanoparticles for DTXL whereas the product of PHB is the nontoxic compound, 3-hydroxybutyric acid. In terms of loading, release and cytotoxicity the PHB polymers exhibited high loading capacity.

Cisplatin, a familiar chemotherapeutic agent used against different tumors, loaded in self assembled copolymer nanoparticles, showed the sustained the release of the cisplatin from the hydrophobic domain enhancing the apoptosis of the tumor cells (Shah et al. 2012). The PHA polymers releases 3HB monomers, which increases the calcium level in the cells inturn protecting the mitochondria, hence suggesting these biopolymers as a drug for nervous and bone disorders. For obtaining a purified R10 monomer the medium chain length PHA (R10) was depolymerized and conjugated with a D-peptide (DP18) and derivatives, which enhanced the anticancer activities. The anticancer activity was more superior with the R10-DP18 than the peptides combined with decanoic acid (O’Connor et al. 2013).The PHA nano particles can be used for targeted drug delivery (Shrivastav et al. 2013). The carcinogenicity of PHAs were analyzed using deoxyribonucleic acid (DNA) aneuploid and telomerase activity, which showed that the PHAs supports cell growth and hence not susceptible to tumor induction, which implies PHAs as safe biopolymers (Peng et al. 2012). The PhaP called as Phasins, the PHA binding protein is seen immobilized on the surface of the nanoparticles through hydrophobic interactions between PHA and PhaP. The overexpression of the recombinant genes in microbes produces PhaP fused ligands. The ligand-PhaP-PHA nano based drug delivery has been proved in vitro and in vivo (Yao et al. 2008). The costimulation of T-cells by B7(costimulatory molecules), showed hetrologous expression of the B7-2 molecule and construction of an immobilized molecule using PHA nano particles as immune activation agent. The B7-2 molecule fused at the N terminal with PhaP and expressed in E.coli strain DE3. The purified B7-2-PhaP was immobilized on the surface of nanoparticle. The immobilized particle provide the signals to induce activation of T-cell and in vitro proliferation (Li et al. 2012).

6.30 Microparticulate Carriers

The drug delivery methods with controlled and sustained release of the drugs with maximum activity and minimized side effects are the microparticulate drug delivery. The drugs in the form of solids or liquids covered by the polymers of different thickness depending upon the permeability of the cell membrane. The poly 3HB and poly (3HB-co-3HV) are the examples of microparticulate carriers produced by solvent evaporation method, which varies by the composition of polymers, particle size, crystallization rate and molecular weight. The valerate content usually slows down the drug release rate due to less crystalline and hence valerate incorporated with poly 3HB tends to decrease the physical damage. Before the degradation of the polymers the drugs are completely released, which is diffusion based.

6.31 Tablets

The tablets were prepared using poly(3HB) containing diltiazem, the vasodilator and tested in vitro. The complete release of the drug was seen when drug loaded with the higher concentration of biopolymer and the release rate was slower with lower concentrations (Korkusuz et al. 2001). The contraceptive pills are the commonly used steroids; estrogens are readily absorbed through mucous membranes, gastrointestinal tract and through skin. There are certain adverse effects on steroids, but still due to the missing steroid synthesis, they are taken endogenously. Estrogens are used for the treatment of ovarian development failure, prevention of heart attacks and osteoporosis. The steroids encapsulated with biopolymer PHA are used to minimize the side effects. The PHB and P(3HB-3HV) are used to prepare microspheres containing the progesterone. The surface of the microspheres is based on the composition and temperature, when there is a change in the solvents the microspheres becomes smoother. The in vitro release was seen slowest with the other polymers were as found to be efficient with PHB (Chen and Davis 2002).

6.32 Drugs

The derivatives of 3HB are the ketone body produced in animals and also human, which is the degradation product of PHA. The derivatives of 3HB plays a role in the cell apoptosis and the in the cytosolic Ca2+concentration in the mouse glial cells, in the presence of 3HB the apoptosis decreased significantly (Xiao et al. 2007). The in vitro assay showed that elevation of cytosolic Ca2+ concentration is because of the 3HB derivatives. The intracellular and the extracellular calcium contributed for the increase in calcium level mediating the signaling of cellular pathways. The 3HBME which is also one of the derivative of 3HB shown to be efficient in cellular permeation than the other derivatives D-3HB and DL-3HB. The brain which is the most sensitive organ requires more energy for the activity, which is supplemented with metabolic substrates. The metabolic activity of the neuroglial cells was seen elevated in the presence of the PHB derivatives. An increase in the ERK2and connexin 36 protein in brain tissues was observed with the treatment using 3HBME. Through the signaling pathways 3HB enhances the memory and the learning skills (Zou et al. 2009).

6.33 Prodrug

Prodrugs are those inactive compounds metabolized inside the human system as drugs with the action of enzymes. The poly(4HB) is the prodrug of 4-hydroxybutyrate, which were tested using the rats given with low molecular weight polymer poly(4HB). The serum concentration was elevated within a short period of time. The prolonged release of monomers had an importance for the narcolepsy (Sudesh et al. 2000). The properties of the prodrug depends on the susceptibility, physiochemical properties and the enzymatic regeneration were as the chemical modifications alone does not enhance the activity of prodrug, in turn the combinations with the polymeric conjugates (Williams and Martin 2005). The controlled release of 5-fluoro-2′-deoxyuridine (FUdR) ester prodrugs as microspheres using PHB were investigated. The PHB-450 microspheres containing the drug showed rapid complete release containing FUdR within 24 h. The release profiles were observed with the poly lactic acid and the FUdR prodrug and the lower content spheres showed significant faster release. To identify the drug release rate for anti-tumor activity an in vivo assay using P388 mouse leukemia cells through intraperitoneal injections and the single administration containing FUdR was effective with the use of high molecular weight PHB. The combinations of the prodrug and the biopolymer PHB showed a controlled and sustained release with increased therapeutic applications as the anti-tumor agent FUdR. The molecular weight along with the physio chemical properties of PHB microspheres was biocompatible and with low toxicity.

6.34 Drug Delivery of PHAs

Drug delivery is the reach of the therapeutic drug at the given concentration to the target, which triggers the pharmacological response. The dosage of the drugs and its frequency has to be increased to overcome the side effects of the drugs. The biopolymers designed, and its composition is based on the target place of the drug release. An in vitro and in vivo assay of the drug 7- hydroxyetheophylline in P(3HB) tablets, implanted on the neck fold subcutaneously showed a high drug release rate for 80% drug loading, and the complete release was observed within 24 h (Brigham and Sinskey 2012; Ali and Jamil 2016; Ferre-Guell and Winterburn 2018). On comparison with the P(3HB) and PHV polymers the release rate was slower with the P(3HB-co-3 HV) compressed biopolymers. The main difference between the drug releases was the structure, composition and porosity.

6.35 Mechanism of Controlled Release

6.35.1 Diffusion Release Mechanism

-

Monolithic device

-

Reservoir device

The active pharmaceutical ingredient is added to the polymeric solution or dispersed within the polymer. The drug is slowly released into the physiological fluid by dissolution, followed by diffusion. Though the drug release may not be 100% but it’s the simplest method of drug delivery, is the monolithic device.

In reservoir device, active pharmaceutical ingredient is placed on the film, based on the porosity and the thickness the drug released. The drug with low solubility makes a possibility to stop the process, and those with high solubility makes the drug burst increasing the concentration of the drug to the surrounding parts (Vasant and John 2011).

6.36 Osmotic Release

The drug delivery which employs the osmotic pressure for delivering the active pharmaceutical ingredient, were the drug is coated with the semi permeable material. The orally administered drug involves this type of release. The permeability is based on the degree of acetylation, were the permeability increases with increase in acetyl content. When the drug immersed in the aqueous medium, due to the hydrostatic pressure within the drug, it diffuses through the membrane. The thickness ranges from 200 to 300 μm. Around 80% of the drugs are expelled completely beyond which the residual release rate is slower (Kwon and Furgeson 2007).

6.37 Polymer Erosion

The importance of the polymer is highly noted only by the biodegradability. The drug releases through three different mechanisms.

-

The drug is attached with the polymer backbone by covalent linkage, and the drug release is observed when the backbone is hydrolytically cleaved.

-

The drug is encapsulated with the biopolymer and released when the polymer undergoes degradation. The drug release rate is proportional to the polymer degradation rate.

-

This mechanism involves the diffusion and erosion of the polymer.

The small chain length PHA is ideal for drug delivery than medium chain length as they are degraded by surface erosion. The rate of drug release is based on the crystallinity of the polymer. On the other hand, medium chain length polymer provides controlled drug release because of their low melting point. The drawback of Mcl PHAs is the inability of production in large quantity.

6.38 Oral Drug Delivery

The larger molecules like proteins and peptide are challenging task in reaching the targets when taken orally (Yang 2001). The orally taken drugs must maintain its stability and structure until reaching the site of action. The hindrances are due to the enzymes in the stomach which prevents the drugs bioactivity and the pharmacokinetics. The mucosal lining prevents the penetration of the drugs to the site of action (Shishatskaya et al. 2011). Hence P (3HB) is used for the sustained release of the drug to be delivered, which is based on the molecular weight of the polymer. For example when the molecular weight increased from 3000 to 6000 kDa, the release rate also increases. The P(3HB) were used as compressed compact discs for the treatment of periodontal diseases for the delivery of tetracycline and the reduction of the gingival infections has been observed over a period of 10 days (Volova 2004). Similarly P(3HB) microspheres encapsulation sulphamethizole was taken orally in greyhound dogs. The absorption rate was good in both the in vivo and in vitro profiles (Koller 2018). The vasodilator, Diltrazem compressed with the P(3HB) tablets was used in studying the drug release rate in vitro. When there is 45% drug loading complete release of the drug has been observed.

6.40 Nanoparticles-Based Targeted Drug Delivery

The drug when reaches the target becomes an efficient molecule against the disease, were there are no side effects when the drug reaches the target. Cancer is one of the dreadful diseases and focus towards the targeted drug delivery is based on the delivery particles its accumulation within the target. The new approach to target the cancer cells for drug delivery and imaging based on the oil-water emulsion method, using the PHA synthase as catalyst. The coupling of hydrophobic surface of PHB nanoparticle and the PHB chain, in the presence of the synthase linked with a ligand, organizes the nanoparticle in the aqueous environment. RGD4C fused with PHA synthase and the tumor specific ligand, organizes the surface of the nanoparticle, which showed affinity towards the MDA-MB-231 breast cancer cells. Hence showing the capability of the drug carrier molecule especially bound towards the PHB nanoparticle (Lee et al. 2011). The development in the field of nanotechnology has been a promising aspect in the drug delivery. The delivery of drugs to various parts of the body, to the targets and the sustained release of the drug. Based on the target the surface of the nanoparticles can be modified. The hydrophobic and hydrophilic drugs, vaccines, proteins, macromolecules and vaccines are delivered using the nano particles. Based on the target of the drugs, targeted based drug delivery system plays a vital role in delivering the exact dosage of drugs for the specified time without any adverse effects on other parts. More focus towards the chemotherapeutic drugs and proteins and peptides which are delicate (Yamamoto et al. 2005). The modification in the nanoparticles with the ligand enhances the efficacy and the cellular uptake of nanoparticles through cell mediated endocytosis, an increase in the intracellular concentration of the drug increases the therapeutic activity. The PHB microspheres used for the delivery of formalinized vaccine of Staphylococcal Enterotoxin B for the lymphoid tissue (Fig. 6.15) In Payer’s patches the microspheres exhibited good absorption (Shi et al. 2010).

6.41 Folate Mediated Targeting

Folate is important in the biosynthesis of bases for DNA synthesis and hence required in large amounts. Since because of its role in DNA synthesis, the folate receptor is regulated in various cancer types. There are various reports which shows the over expression of folate receptors in ovarian carcinomas. The density of the folate receptor gradually increases with the progression of the disease, and hence focusing folate in targeted drug delivery for cancers.

Zhang et al. proposed targeting a drug delivery system using [P(3HB-co-3HO)] as carrier, folic acid as ligand and doxorubicin as anticancer drug. The folate conjugated particles were endocytosed by HeLa cells than the non-folate conjugate. The cytotoxicity was high, and the in vitro assay has shown the intracellular uptake of the nano particles were efficient with the HeLa cells. The in vivo studies on mice having the HeLa tumors xenograft exhibited similar activity with minimal side effects (Zhang et al. 2010). In a study, the chemotherapeutic drug etoposide (ETO) was delivered with the P(3HB-co-3HHx) conjugated with the folate(FA). From the treatment it was observed that the complex ETO/FA- P(3HB-co-3HHx) showed higher cytotoxicity than the non-conjugated particles. The L929 cells, which have low folate receptor expression, and this may be the reason behind the reduced effect. On comparison DOX/FA-P(3HB-co-3HHx) was more cytotoxic than complex with etoposide which may be due to the difference in the drugs. Though both the drugs are topoisomerase II inhibitors, doxorubicin generated reactive oxygen species (ROS), due to which they exhibit more cytotoxicity. So, targeting folate receptor with the folate conjugated PHA increases the selectivity and cytotoxicity for the cancer therapeutics (Andronescu and Grumezescu 2017).

6.42 Targeting Ligands by PHA Binding Proteins

The targeting method based on the ligand conjugates using PhaP and PhaC, were PhaP is the amphiphilic protein with low molecular weight produced during the PHA biosynthesis, and these forms a layer on the granules and stabilizes the intracellular environment in the bacteria. And PhaC is covalently linked to the granules by the cysteine residues, and these PhaC and PhaP genes produces fusion proteins. As PhaP has higher affinity towards PHAs, they are linked to the PHA particles, and the fusion proteins seem to maintain the enzyme activity (Chen 2009a, b). Based on the ligand targeting, the PhaP fused with the human epidermal growth factor (rhEGF), the upregulation of the EGF is an important consideration in cancer types mainly hepatocellular carcinoma. The rhEGF-PhaP fusion proteins were linked with the drug loaded nanoparticles, the P(3HB-co-3HHx) (Fig. 6.16). The drug loaded is the rhodamine B isothiocynate (RBITC) used for analysis of tissue deposition. The murine hepatoma22 (H22) model cells were implanted in mice and then treated with the drug RBITC. The fluorescence assay showed the accumulation of RBITC loaded rhEGF-PhaP-PHBHHX nanoparticles within tumors (York et al. 2002; Potter 2005; Yao et al. 2008; Kwon et al. 2014).

6.43 Targeting Using Superparamagnetic Iron Oxide Nanoparticles

The superparamagnetic iron oxide nanoparticles encapsulated with P(3HB-co-3 HV) forms a theragnostic particles, which means the combination of therapeutic and diagnostic properties in a single agent (Jain et al. 2008; Vilos et al. 2013). The SPION-P(3HB-co-3HV) are biocompatible and inhibits the generation of ROS. This superparamagnetic property facilitates the accumulation of the drug in the targeted site. The in vivo assay, with the administration of the drug Alexa-Fluor encapsulated with SPION-P(3HB-co-3 HV) to the rats in the presence or absence of magnetic field. The accumulation of the nanoparticles measured through fluorescence showed for the accumulation of SPION-P(3HB-co-3 HV nanoparticles in the target was higher with those particles exposed to magnetism. Hence these PHA biomaterials are compatible with the controlled drug release and the nanoparticles can be altered based targeting ligands in order to have increased effects within the tissues. If the drugs of higher doses are administered, drug localization plays a vital role to reduce the risk of side effects (Allen 2004). An example of such therapies is the cancer therapeutics as small molecule kinase inhibitors and monoclonal antibodies (Grillo-Lopez et al. 2000). Based on the target antigen and the agents, PHAs act as a better nano carrier for targeted drug delivery.

6.44 Polyhydroxyalkanoate Microsphere-Based Protein Encapsulation

Proteins are used as vaccines, enzymes, growth factors and hormones for biomedical applications. The major disadvantage of proteins is the short half lives in vivo. Due to the high molecular weight of proteins, they are not completely absorbed by the system. The protein stability is maintained by the microencapsulated capsules. Biopolymer microspheres provide an opportunity in decreasing the recurrent injections, which is based on the size of the microspheres (Yang 2001).

6.45 Chemical Modification of PHA

The PHA contains the methyl, bromine, hydroxyl and nitrophenyl derivatives produced from the microorganisms. These functional groups are said to enhance the activity and the biomedical applications of the PHAs. Such modifications are still under progress and challenging to modulate the structure of the polyesters by making alterations in the functionality and the molecular weight. Introducing functional groups to the PHA by chemical reactions makes a possibility to widely use the PHA as biocompatible and biodegradable component in the application of medicinal therapeutics. There are various chemical modifications like the hydroxylation, carboxylation, epoxidation and the chlorination.

6.46 Modification Using Hydroxyl Group

6.46.1 Monohydroxylated Macromonomer

The acid or base catalyzed reactions with para-toluene sulfonic acid monohydrate (APTS) and methanolysis produced oligomers with terminal hydroxyl group. The ester bonds of PHO are stable at pH 12 and after hydrolysis the pH was 14 with the formation of hydroxyl group at one end of the chain. The decrease in the molar mass is based on the nature of the solvent; the chain cleavage occurred more rapid in toluene than dichloroethane. From the spectral analysis the acid catalyzed condition using APTS ended in the formation of hydroxyl group in one end and the carboxylic group on the other. The cyclic structures have been observed and the high molecular weight polyhydroxyalkanotes are exposed to methanolysis in the presence of a catalyst sulphuric acid resulted in the formation of monohydroxylated macromonomers with carboxylic acid were formed. Thus, many such monohydroxylated PHAs can be formed (Nguyen et al. 2002; Sun et al. 2007; Timbart et al. 2007; Xiao et al. 2007; Wu et al. 2008; Zhou et al. 2012).

6.46.2 Dihydroxylated Macromonomer

The transesterification with 1,4-butanediol in the presence of catalyst p-toluenesulfonicacid. The hydroxyl group in the molecule cleaves the ester bond forming a telechelic polymer, which is a prepolymer and enters into various reactions with the end groups, as the cleavage is an important mechanism the molecular weight decreases gradually. By the combinations of PHAs with different side chain length the P3 poly(esterurethane)s, 4HB poly(esterurethane)s and PHBHHx poly(esterurethane)s are obtained. These possess more cell compatibility than the pure forms, and hence used as biomaterials for would healing. During synthesis the PHBHHx replaced by PHHxHO, the polymer obtained becomes more hydrophobic, hence modifying the physical properties enhances the biomedical applications of the polymers (Saad et al. 2001a, b; Chen et al. 2009a, b).

6.46.3 Modification Using the Carboxylic Group

The functional groups with carboxylic acids play an important role for the binding of targeting enzymes, bioactive compounds and the hydrophilic components. These carboxylic groups when incorporated in the polymers enhance the hydrophilicity (Renard et al. 2007). The PHAs with the unsaturated groups can be converted to carboxyl groups by oxidation process, theses polymers are used as graft copolymers preparation. In another approach the PHA oligomers terminated with carboxyl group forms methacrylic PHAs (Lee and Park 2000; Kurth et al. 2002).

6.46.4 Modifications Using Epoxy Group

The reaction by which alkenes is converted to epoxide; the epoxidation involves the chemical modifications to enhance the physical property like the elasticity of the compounds. The conditions like cross-linking and attachment of ionizable groups plays a role in the epoxidation process. In the acidic conditions there is no much change in the chains of poly(3-hydroxyoctanoate-co-3-hydroxyundec-10-enoate) whereas cross linked PHOUS are formed from the epoxidation reactions in the presence of succinic anhydride, and these cross linking enhances the elasticity of the polymers without disturbing the biodegradability (Hazer 2010; Kai and Loh 2013; Li et al. 2016).

6.46.5 Modification Using Chlorination

The process of passing of chlorine gas through the unsaturated PHAs gives the PHA-Cl complex with the chlorine content of about 5–40%. And these thermal properties of the PHA-Cl complex were changed in terms of the transition temperature. Due to the chlorination the temperature increased, and the mobility of the molecules were dependent on the chlorine content. From the PHA chlorinated derivatives the quaternary ammonium salts, and phenyl derivatives were obtained, the benzene and the PHA-Cl complex forms the cross linked polymers (Arkin and Hazer 2002).

6.47 Conclusion

Biopolymers like polyhydroxyalkanoates are produced as energy- and carbon-storage materials by many bacteria. The PHAs produced from the bacteria are with varying monomer based on the substrates, due to the physical properties from flexible to brittle and elastic makes better replacements for the petroleum based plastics. The PHA production from various sources like industrial waste, molasses, cheese and whey products, lignocellulosic materials, oils from cooking wastes which are the cheapest sources for the PHA production. As they are more peculiar due to the biocompatibility, biodegradability, non-toxicity, and chemical diversity they are with various biomedical applications like sutures, surgical implants, and as drug carriers which has increased the interest in the use of PHAs. The tissue engineering is one of the research areas growing exponentially and the scaffold materials play a vital role. PHA based targeted drug delivery in cancer therapy, and in the delivery of biological molecules, vaccines and steroids. The unmodified PHAs are highly hydrophobic and crystalline, due to poor compatibility between polymers, and the different chemical modifications may come up with novel class of biopolymers as water soluble PHAs. They are considered favorable as they are reproducible and are synthesized from natural renewable resources. The applications of PHAs make the replacement with the commercial plastics as better improvements and as environmental friendly materials in the formulating into useful biomedical products.

6.48 Prospects and Challenges

Despite various advantages of PHA, all PHAs produced to date are mainly from the bacterial origin, which is a very costly process, and this is a main reason for the exploitation of PHA from research. The harmful effects of the plastics from petroleum-based materials and the hike in petroleum prices will create a big challenge for the production of bioplastics. The PHAs have a wide application as drug carrier for cancer therapy and tumor treatment, with the formulation as micro capsules, microspheres and Nano particles, corresponds to the speedy release and to reach the target. PHAs without any modifications chemically leads to high crystallinity, and porous formation on the cell surface which leads to uncontrolled release of the drugs. The development of PHAs with respect to related molecular weight, its physico-chemical and surface properties are main considerations for the distribution of the drug.

Few PHA types have shown to exhibit antimicrobial properties, which reduce the amount of drug used for the treatment and free from side effects.

-

Through the metabolic engineering methods PHAs with unique monomers can be obtained.

-

Novel bacterial strains of bacteria which can produce unique monomers with enhanced properties.

-

Advancements can be made in the production of bioplastics with peculiar properties like nontoxic and biocompatibility to prevent from immune response.

-

Production of PHA using low cost substrates, to improve the economy.

-

Genetic modifications of bacteria to improve the yield of PHA.

-

So far, no studies have been proved for the carcinogenesis implanting PHA in vivo, though PHA promotes cell proliferation.

-

Blending of smaller and larger PHA helps maintaining the stability and increases biodegradation. Blending PHA with PLGA increases the rate of degradation.

-

The poly-4-hydroxybutyrate is the only approved material for the sutures by FDA which took more than a decade for approval.

-

The PHAs are more focused towards the packaging industries, which has to be directed towards the biomedical applications.

-

The purification of the PHAs for the complete removal of lipopolysaccharides, bacterial impurities and residual proteins to make it suitable for the biomedical implants.

-

A great demand in the field of plastic surgery, the 3D printing material plays a vital role.

-

Treatment and diagnosis using single particle administration, production of multifunctional theragnostics particles.

-

Targeting using superparamagnetic approach for specificity and localization of the cells within tissues.

Abbreviations

- APTS:

-

para-toluene sulfonic acid monohydrate

- DTXL:

-

Docetaxel

- HA:

-

hydroxyapatite

- HDI:

-

1,6-hexamethylene di-isocyanate

- P3:

-

poly(esterurethane)s

- P3HB4HB:

-

poly(R-3-hydroxybutyrate-co-4-hydroxybutyrate)

- P4HB:

-

poly-4-hydroxybutyrate;

- PHA(s):

-

Polyhydroxyalkanoate(s)

- PhaP:

-

amphiphilic PHA granule binding protein

- PhaR:

-

PHA synthesis repressor protein

- PHB:

-

poly-(R)-3-hydroxybutyrate;

- PHB:

-

Polyhydroxybutyrate

- PHBHHx:

-

poly(R-3-hydroxybutyrate-co-R-3-hydroxyhexanoate)

- PHBHx:

-

Poly(hydroxybutyrate-co-hydroxyhexanoate)

- PHBO:

-

Poly(hydroxybutyrate-co-hydroxyoctanoate)

- PHBV:

-

Poly(hydroxybutyrate-co-hydroxyvalerate)

- PHBV:

-

poly(R-3-hydroxybutyrate-co-R-3-hydroxyvalerate)

- PHBVHHx:

-

poly(R-3-hydroxy-butyrate-co-R-3-hydroxyvalerate-co-R-3-hydroxyhexanoate)

- PHHx:

-

Poly(hydroxyhexanoate)

- PHHx:

-

Poly(hydroxyhexanoate)

- PHO:

-

Poly(hydroxyoctanoate)

- PHO:

-

poly-(R)-3-hydroxyoctanoate;

- PPC:

-

Poly propylene carbonate

References

Ali I, Jamil N (2016) Polyhydroxyalkanoates: current applications in the medical field. Front Biol 11:19–27. https://doi.org/10.1007/s11515-016-1389-z

Allen TM (2004) Drug delivery systems: entering the mainstream. Science 303:1818–1822. https://doi.org/10.1126/science.1095833

Andronescu E, Grumezescu AM (2017) Nanostructures for oral medicine, 1st edn. Elsevier, Amsterdam. ISBN: 9780323461498

Arkin AH, Hazer B (2002) Chemical modification of chlorinated microbial polyesters. Biomacromolecules 3:1327–1335. https://doi.org/10.1021/bm020079v

Aslan AK, Ali MD, Morad NA, Tamunaidu P (2016) Polyhydroxyalkanoates production from waste biomass. IOP Conf Ser: Earth Environ Sci 36:012040. https://doi.org/10.1088/1755-1315/36/1/012040

Asran AS, Razghandi K, Aggarwal N, Michler GH, Groth T (2010) Nanofibers from blends of polyvinyl alcohol and polyhydroxy butyrate as potential scaffold material for tissue engineering of skin. Biomacromolecules 11:3413–3421. https://doi.org/10.1021/bm100912v

Attia R, Nazia J, Nighat N, Shahida H (2010) Bacteria from contaminated urban and hilly areas as a source of polyhydroxyalkanoates production. Afr J Biotechnol 9:1919–1925. https://doi.org/10.5897/ajb09.1003

Bian Y, Wang Y, Aibaidoula G, Chen G, Wu Q (2009) Evaluation of poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) conduits for peripheral nerve regeneration. Biomaterials 30:217–225. https://doi.org/10.1016/j.biomaterials.2008.09.036

Bonartsev AP, Zharkova II, Yakovlev SG, Myshkina VL, Makhina TK, Zernov AL, Kirpichnikov MP (2016) 3D-Scaffolds from Poly(3-hydroxybutyrate) Poly(ethylene glycol) Copolymer for Tissue Engineering. J Biomater Tissue Eng 6:42–52. https://doi.org/10.1166/jbt.2016.1414

Brigham CJ, Sinskey AJ (2012) Applications of polyhydroxyalkanoates in the medical industry. Int J Biotech Well Ind 1:53–60. https://doi.org/10.6000/1927-3037.2012.01.01.03

Chang HC, Sultana N (2017) PLA/PHBV electrospun membrane: fabrication, coating with conductive PEDOT:PSS and antibacterial activity of drug loaded membrane. Cogent Eng, 4. https://doi.org/10.1080/23311916.2017.1322479

Chek MF, Kim S, Mori T, Arsad H, Samian MR, Sudesh K, Hakoshima T (2017) Structure of polyhydroxyalkanoate (PHA) synthase PhaC from Chromobacterium sp. USM2, producing biodegradable plastics. Sci Rep 7. https://doi.org/10.1038/s41598-017-05509-4

Chen G (2009a) ChemInform abstract: a mcrobial polyhydroxyalkanoates (PHA) based bio- and materials industry. ChemInform, 40. https://doi.org/10.1002/chin.200948268

Chen G (2009b) A microbial polyhydroxyalkanoates (PHA) based bio- and materials industry. Chem Soc Rev 38:2434. https://doi.org/10.1039/b812677c

Chen J, Davis SS (2002) The release of diazepam from poly(hydroxybutyrate- hydroxyvalerate) microspheres. J Microencapsul 19:191–201. https://doi.org/10.1080/02652040110065431

Chen G, Wu Q (2005) The application of polyhydroxyalkanoates as tissue engineering materials. Biomaterials 26:6565–6578. https://doi.org/10.1016/j.biomaterials.2005.04.036

Chen G, Zhang J (2017) Microbial polyhydroxyalkanoates as medical implant biomaterials. Artif Cells Nanomed Biotechnol 46:1–18. https://doi.org/10.1080/21691401.2017.1371185

Chen GQ, Zhang G, Park SJ, Lee SJ (2001) Industrial scale production of poly(3-hydroxybutyrate-co-3-hydroxyhexanoate). Appl Microbiol Biotechnol 57:50–55. https://doi.org/10.1007/s002530100755

Chen Z, Cheng S, Xu K (2009a) Block poly(ester-urethane)s based on poly(3-hydroxybutyrate-co-4-hydroxybutyrate) and poly(3-hydroxyhexanoate-co-3-hydroxyoctanoate). Biomaterials 30:2219–2230. https://doi.org/10.1016/j.biomaterials.2008.12.078

Chen Z, Cheng S, Li Z, Xu K, Chen G (2009b) Synthesis, characterization and cell compatibility of novel poly(ester urethane)s based on poly(3-hydroxybutyrate-co-4-hydroxybutyrate) and poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) prepared by melting polymerization. J Biomater Sci Polym Ed 20:1451–1471. https://doi.org/10.1163/092050609x12457419007621

Chen D, Fang J, Shao Q, Ye J, Ouyang D, Chen J (2013) Biodegradation of tetrahydrofuran by Pseudomonas oleovorans DT4 immobilized in calcium alginate beads impregnated with activated carbon fiber: mass transfer effect and continuous treatment. Bioresour Technol 139:87–93. https://doi.org/10.1016/j.biortech.2013.04.037

Chen Y, Tsai Y, Chou I, Tseng S, Wu H (2014) Application of biodegradable polyhydroxyalkanoates as surgical films for ventral hernia repair in mice. Int J Polym Sci 1–11. https://doi.org/10.1155/2014/789681

Cheng S, Wu Q, Zhao Y, Zou B, Chen G (2006) Effect of poly(hydroxybutyrate-co-hydroxyhexanoate) microparticles on growth of murine fibroblast L929 cells. Polym Degrad Stab 91:3191–3196. https://doi.org/10.1016/j.polymdegradstab.2006.07.010

Cheng S, Chen Z, Chen G (2008) The expression of cross-linked elastin by rabbit blood vessel smooth muscle cells cultured in polyhydroxyalkanoate scaffolds. Biomaterials 29:4187–4194. https://doi.org/10.1016/j.biomaterials.2008.07.022

Dai Z, Zou X, Chen G (2009) Poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) as an injectable implant system for prevention of post-surgical tissue adhesion. Biomaterials 30:3075–3083. https://doi.org/10.1016/j.biomaterials.2009.02.015

Defoirdt T, Boon N, Sorgeloos P, Verstraete W, Bossier P (2009) Short-chain fatty acids and poly-β-hydroxyalkanoates: (New) Biocontrol agents for a sustainable animal production. Biotechnol Adv 27:680–685. https://doi.org/10.1016/j.biotechadv.2009.04.026

Ding Y, Li W, Muller T, Schubert DW, Boccaccini AR, Yao Q, Roether JA (2016) Electrospun polyhydroxybutyrate/Poly(ε-caprolactone)/58S sol–gel bioactive glass hybrid scaffolds with highly improved osteogenic potential for bone tissue engineering. ACS Appl Mater Interfaces 8:17098–17108. https://doi.org/10.1021/acsami.6b03997