Abstract

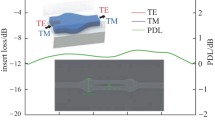

SiN-based mode-size converter with high coupling efficiency and low polarization loss has been designed, in which length is 98.7 μm. The simulated coupling efficiency for TE mode is 87%, and the simulated coupling efficiency for TM mode is 81%. It is polarization-insensitive when the converter coupled with single-mode fiber at the wavelength of 800 nm. For both TE and TM mode, the 1-dB bandwidths are 34 nm and 32 nm, respectively, and the alignment tolerance for 1-dB excess loss is ±0.8 μm in the horizontal and vertical directions. The core part of converter is supported with SiO2 beams to prevent light leaking from the substrate, and this converter can compress spot and couple it into the SiN waveguide effectively and smoothly.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Quantum communication is one of the most popular research areas in the world, and single-photon detectors are the core components for implementing quantum teleportation systems which are based on single-photon transmission. Si is a good choice for the preparation of detectors, but the absorption coefficient of Si is higher at the wavelength of 800 nm, which is not conducive to the transmission of signals, but the transmission loss of silicon nitride at this wavelength is low [1], so SiN is selected as an optical transmission medium for the on-chip optical path of the quantum optical communication. When the wavelength is 800 nm, the mode field diameter of the silicon nitride linear waveguide is very small, and when it is directly coupled with the single-mode fiber, a large extra loss may occur due to the mismatch of mode field diameters. In order to solve the huge coupling loss in direct coupling, scientists have proposed and produced high-performance converters with high coupling efficiency and low polarization loss. There are surface coupling based on grating couple and edge coupling based on inverse taper. In 2011, Fang [2] produced a Si waveguide-based converter with 1-dB bandwidth of TE and TM modes are more than 120 nm. Jia [3] uses silicon nitride with refractive index is 1.5 as an intermediate material and is combined with reverse tapered and cantilever structures to reduce mismatch losses when coupled with single-mode fiber. In 2015, the IBM [4] made O-band metamaterial coupler and transmission loss achieved −1.3 dB between standard single-mode fiber and silicon nano-waveguide; however, this cantilever-type converter length is about 875 μm, which is quite long for silicon photonic devices. In 2016, our group [5] produced cantilever-type converter with good performance such as low coupling loss, uncorrelated wavelength, and wide bandwidth.

2 Converter Design

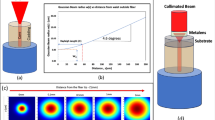

As shown in Fig. 1, we have designed a mode-size converter that is tapered in the horizontal direction. The key structure of the entire converter is supported by SiO2 beams, and this suspended design prevents light signal leaking from the substrate which reduces coupling loss. Etching only in the horizontal direction makes the manufacturing steps and processes simpler.

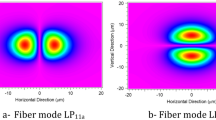

The mode-size converter can be divided into three parts along the propagation direction. The first part is a SiO2 rectangular waveguide that connects with the single-mode fiber, the second part is a taper that tapered in the horizontal direction, and the third part is composed of SiN reverse taper that embedded in the middle of SiO2 waveguide. The compressed spot is further pressed into the SiN waveguide when optical signal propagates to the third part. We set the thickness of the buried oxide layer as 2 μm, since the diameter of the single-mode fiber is between 4 and 6 μm at 800 nm, and we choose the size of SiO2 waveguide that connected to the single-mode fiber to be 5 μm × 5 μm. We use a Gaussian light with wavelength of 800 nm as the launching field to launch into single-mode fiber and calculate fundamental mode, and the obtained fundamental mode is used to couple with SiO2 rectangular waveguide of the converter.

In the third part, since the refractive index of silicon nitride is larger than the refractive index of silicon dioxide, the light energy is gradually pressed into the silicon nitride waveguide. The optical path of light propagating is simulated by Rsoft software in the mode-size converter, as shown in Fig. 2. When the light travels in the Z-axis direction, the spot is significantly smaller and its size is compressed horizontally into the SiN waveguide. For both TE and TM mode, coupling efficiency are 86 and 81%.

In order to obtain the optimal size of converter more accurately, we placed two monitors to monitor the optical field energy in SiO2 and silicon nitride waveguide, respectively. We have obtained the coupling efficiency by changing the height, width, and length of the silicon nitride tapered waveguide as shown in Fig. 3. Figure 3a, b shows the coupling efficiency as the change of height and width of the SiN waveguide, and Figure 3c shows the variation of the coupling efficiency with the width of the SiN waveguide. From these figures, we can see that the coupling efficiency reaches the highest when the height, length, and width of the SiN waveguide taper are 0.2 μm × 48 μm × 0.15 μm. Calculate some parameters by simulation, second cladding SiO2 taper length is 29.5 μm, second width of the end of cladding SiO2 taper is 2.28 μm, third pitch of SiN waveguide tip and end of second is 6.2 μm, and the highest coupling efficiency can be achieved.

In order to obtain performance parameters of the converter, we simulated and calculated the device's alignment tolerance and the coupling efficiency that varies with wavelength. Figure 4 shows the coupling efficiency with the variation of offset, and the alignment tolerance that produces 1-dB extra loss in the horizontal and vertical directions are ±0.8 μm. Figure 5 shows the change of coupling efficiency as a function of wavelength, Fig. 5 shows the coupling efficiency with the change of wavelength, for both TE and TM mode, the 1 dB bandwidths are 34 and 32 nm.

Finally, we designed a cantilever-type mode-size converter which operates at 800 nm with high coupling efficiency and low polarization loss. The heart of the converter is supported by SiO2 beams, and it has neither vertical taper nor vertical etching.

References

Ting HU, Dong B, Luo X, Liow TY, Song J, Lee C, Guo-Qiang LO (2017) Silicon photonic platforms for mid-infrared applications [invited]. Photon Res 5(5):417

Fang Q, Song J, Luo X, Yu M, Lo G, Liu Y (2011) Mode-size converter with high coupling efficiency and broad bandwidth. Opt Express 19(22):21588–21594

Jia L, Song J, Liow TY, Luo X, Tu X, Fang Q, Koh SC, Yu M, Lo G (2014) Mode size converter between high-index-contrast waveguide and cleaved single mode fiber using SiON as intermediate material. Opt Express 22(19):23652

Barwicz T, Jantapolczynski A, Khater M, Yan T, Leidy R, Maling J, Martel S, Engelmann S, Orcutt JS, Fortier P (2015) An O-band metamaterial converter interfacing standard optical fibers to silicon nanophotonic waveguides. In: Optical fiber communications conference and exhibition, pp 1–3

Fang Q, Song J, Luo X, Tu X, Jia L, Yu M, Lo G (2016) Low loss fiber-to-waveguide converter with a 3-D functional taper for silicon photonics. IEEE Photon Technol Lett 28(22):2533–2536

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 61764008 and No. 61674072) and by the Opened Fund of the State Key Laboratory of Integrated Optoelectronics No. IOSKL2017KF11, Natural Science Foundation of Shanxi Province of China (Grant Nos. 2017JM6075), Foundation of Shaanxi Provincial Education Department (Grant Nos. 17JK0335), and Foundation of State Key Laboratory of Functional Materials for Informatics (Grant Nos. SKL201804).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Hu, J., Chen, X.l., Fang, Q., Song, F. (2021). Design of SiN-Based Mode-Size Converter for Single-Photon Communication. In: Xu, L., Zhou, L. (eds) Proceedings of the 8th International Multidisciplinary Conference on Optofluidics (IMCO 2018). IMCO 2018. Lecture Notes in Electrical Engineering, vol 531. Springer, Singapore. https://doi.org/10.1007/978-981-13-3381-1_4

Download citation

DOI: https://doi.org/10.1007/978-981-13-3381-1_4

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-3380-4

Online ISBN: 978-981-13-3381-1

eBook Packages: EngineeringEngineering (R0)