Abstract

A novel microwave resonator loaded with an active amplifying circuit is present, which consists of a corrugated ring structures and two coupled microstrip. Compared with passive structure, the introduction of active amplifying can compensate for the metal loss of passive structure at resonant frequency and increase quality factor significantly. The Q value of the passive structure is around 50, while the Q value of another structure is 500 times more than before, up to 25,000. Subsequently, we proposed an active liquid microwave sensor combined the proposed active resonator and microfluidic channel. Although fluid injection may lead to greater loss, active amplifying circuit can make up for these losses. The simulated results have verified its high resolution with different concentration of glucose solution. It is easy to sight the frequency offset even though the change of the concentration is only 0.2 mmol/L. These results demonstrate the proposed sensor has advantages of low costs, compactness, and high resolution for liquid detection.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Surface plasmons (SPs) could be either propagating (surface plasmon polaritons, SPPs) in extended interfaces or localized (localized surface plasmons, LSPs) in finite metal particles [1]. Although SPs can realize many novel applications due to their novel properties of deep subwavelength confinement and field enhancement, metals behave similarly to perfect electric conductors (PEC) which does not support the SPs at lower frequencies, like microwave frequency [2]. In order to achieve the SPs at lower frequencies, the concept of spoof SPPs based on the structured metal surfaces has been proposed [3]. Spoof LSPs have been proposed and experimentally verified at microwave frequencies [4, 5]. Subsequently, various devices based on spoof LSPs have been designed, such as metallic spiral structure [6], closed subwavelength high contrast gratings [7], and closed corrugated ring [8]. However, quality factors (Q value) of the resonance peaks are still hard to get a significant boost due to their inherent loss.

In this paper, we proposed an active liquid microwave sensor combined the active microwave resonator and microfluidic channel. Compared with passive sensor, the introduction of active amplifying can compensate for the loss of passive structure at resonant frequency and increase quality factor significantly. The simulated results have verified its high resolution with different concentration of glucose solution. It is easy to sight the frequency offset even though the change of the concentration is only 0.2 mmol/L. These results demonstrate the proposed sensor has advantages of low costs, compactness, and high resolution for liquid detection.

2 Active Microwave Sensor Based on Spoof LSPs

2.1 Microwave Active Planar Resonator Based on Spoof LSPs

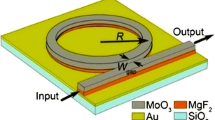

Figure 1a, b shows the proposed ultra-thin corrugated ring based on spoof LSPs with and without the active amplifying circuit. The corrugated ring is similar to Ref. [8], and the difference is metal of outer ring is removed to miniaturize the size and loading coupling branches. The S-parameters are calculated by simulated software HFSS (the negative resistance is used to replace the active amplifying circuit), and the results are displayed in Fig. 1d. The introduction of active amplifying can compensate for the metal loss of passive structure at resonant frequency and increase quality factor significantly. We can see that the curve S11 becomes more sharp with the introduction of active circuits. Meanwhile, the quality factor of two cases has been calculated by the method of group delay. The Q value of the passive structure is around 50, while the Q value of another structure is 500 times more than before, up to 25,000, consistent with expectations.

2.2 Active Planar Microwave Sensor for Glucose Solution

Reference [8] has verified that the closed corrugated ring has high sensitivity with changes in dielectric constant of the surrounding environment and the active circuit improved Q value so as to higher resolution. Based on these, we proposed an active liquid microwave sensor consists of proposed corrugated ring loading microfluidic channel as shown in Fig. 2a. Although fluid injection may lead to greater loss, active amplifying circuit can make up for these losses to obtain very high resolution. The simulated S11 of proposed sensor with different concentration of glucose solution is shown in Fig. 2b. It is observed that the proposed sensor has very high Q value even if different concentration of glucose solution is injected, and it is easy to sight the frequency offset even though the change of the concentration is only 0.2 mmol/L. These results demonstrate that the proposed sensor has advantages of low costs, compactness, and high resolution for liquid detection.

3 Conclusions

In this paper, we proposed an active liquid microwave sensor combined the active microwave resonator and microfluidic channel. Compared with passive sensor, the introduction of active amplifying can compensate for the loss of passive structure at resonant frequency and increase quality factor significantly. The simulated results have verified its high resolution with different concentration of glucose solution. It is easy to sight the frequency offset even though the change of the concentration is only 0.2 mmol/L. These results demonstrate that the proposed sensor has advantages of low costs, compactness, and high resolution for liquid detection.

References

Barnes WL, Dereux A, Ebbesen TW (2010) Surface plasmon subwavelength optics. Nature 424(6950):824–830

Garciavidal FJ, Martínmoreno L, Pendry JB (2005) Surfaces with holes in them: new plasmonic metamaterials. J Opt A Pure Appl Opt 7(2):S97

Pors A, Moreno E, Martinmoreno L et al (2012) Localized spoof plasmons arise while texturing closed surfaces. Phys Rev Lett 108(22):223905

Shen XP, Cui TJ (2014) Ultrathin plasmonic metamaterial for spoof localized surface plasmons. Laser Photonics Rev 8(1):137–145

Gao Z, Gao F, Xu H et al (2016) Localized spoof surface plasmons in textured open metal surfaces. Opt Lett 41(10):2181

Huidobro PA, Moreno E, Martin-Moreno L et al (2014) Magnetic localized surface plasmons. Phys Rev X 4(2):340–342

Li Z, Xu B, Liu L et al (2016) Localized spoof surface plasmons based on closed subwave-length high contrast gratings: concept and microwave-regime realizations. Sci Rep 6:27158

Yang BJ, Zhou YJ, Xiao QX (2015) Spoof localized surface plasmons in corrugated ring structures excited by microstrip line. Opt Express 23(16):21434–21442

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Cai, J., Zhou, Y.J. (2021). Active Planar Plasmonic Sensor for Measuring Glucose Concentration. In: Xu, L., Zhou, L. (eds) Proceedings of the 8th International Multidisciplinary Conference on Optofluidics (IMCO 2018). IMCO 2018. Lecture Notes in Electrical Engineering, vol 531. Springer, Singapore. https://doi.org/10.1007/978-981-13-3381-1_2

Download citation

DOI: https://doi.org/10.1007/978-981-13-3381-1_2

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-3380-4

Online ISBN: 978-981-13-3381-1

eBook Packages: EngineeringEngineering (R0)