Abstract

This work presents the study of numerical modelling of the fluid flow and circular cylinder interaction to investigate the cross-flow induced vibrations in the rod bundle. It is assumed that failure due to flow-induced vibrations of the rod can be described by the reduction of the rod mass, the rod support stiffness or damping coefficient. The metamodel-based approach is applied to investigate the main trends of the system’s characteristic behaviour related to the variations of the chosen parameters. The two-dimensional Finite Volume models have been developed using open-source software to get a mapping of input and output variables for the metamodel. The impact of assumed failure parameters (the mass, the stiffness and the damping) on the vibration amplitude and frequency of the oscillating rod is analysed.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The flow around tubes and rods has been extensively investigated because of its wide applications in engineering fields. The high-velocity fluid flow interaction with structural elements can induce vibrations of these components. To safely operate engineering plants, it is necessary to continuously monitor if the system does not exceed its operational limits because of some failures. Due to the complexity of the most of systems, there is useful to utilise low-dimensional representations of the system to realise monitoring process.

The present paper constitutes the starting point for the development of a fast simulation tool useful for monitoring. There is chose three design variable which could describe the failure of the rod: the mass of the rod, the rod support stiffness and damping. The analysis is applied to determine which factor has the most significant influence on the model outputs (detected vibration amplitudes and frequencies of the flexibly-mounted cylinder). The metamodelling approach is applied to capture the input-output relationship. In this paper, a metamodel is defined as a mathematical approximation of the computer simulation or analysis [1].

The system response on input parameters is calculated using Computational Fluid Dynamics (CFD) open source tool OpenFOAM (OF). Due to high fluid velocity through the tube bundle, the turbulence phenomenon is observed, and it increases the complexity of the analysed problem. A response surface approximation is used to keep a number of CFD simulations to the minimum. The response surface approximation can be effective in smoothing out the undesirable fluctuations which could come from the complexity of the numerical modelling (turbulence models, discretisation etc.) [2, 3].

The sample points where CFD simulations are done is find using the space-filling approach: Latin hypercube sampling. Latin hypercube design is chosen as analysis strategy due to its frequent use as design type of computer experiments [4]. The second-order polynomial is used as the response surface, which runs fitting by coefficients of quadratic polynomial model weighted by the coefficient w: \(m = [ (n + 1)(n + 2) ] / 2 \cdot w\), where n is the number of design variables. In this study, the coefficient w is dependent on numbers of factors, 1.6 for a three-factors case and 2.667 for a two-factors case.

The estimation of the error of a given metamodel is done with cross-validation method [5]. Meckesheimer et al. [1] are studied a leave-k-out cross-validation error measure to provide an assessment of the fidelity of a metamodel. The experimental research shows that for low-order polynomial metamodels leave-one-out cross-validation strategy is effective and recommended for providing a prediction error.

2 CFD Simulations

The impact of the flexibly-mounted rod mass, support stiffness and damping coefficient on the rod oscillation amplitude and frequency at sample points has been predicted by numerical simulations of incompressible, unsteady, turbulent water cross-flow through a rod bundle in a triangular arrangement.

2.1 Implementation

Fluid Dynamics. The incompressible water flow field is described by Reynolds-Averaged Navier-Stokes (RANS) for steady-state cases and Unsteady RANS equations for time-dependent cases. The gap Reynolds number is approximately \(8 \cdot 10^4\); therefore turbulence should be taken into account. Three two-equation turbulence models were selected for checking: standard k-epsilon, RNG k-epsilon and k-omega SST.

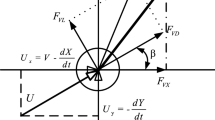

Structural Dynamics. The motion of the cylinder is modelled as a mass-damper-spring system (1), see Fig. 1.

where dot denotes the time derivative of coordinate x, m is oscillating mass, c is a damping coefficient, k is a stiffness coefficient, and F(t) is an external force, including flow-induced force.

The built-in OF six degree-of-freedom rigid body motion solver was used to describe a flexibly-mounted cylinder motion in time in an otherwise rigid cylinder array. In simulated cases, the oscillating cylinder has two degree-of-freedom, i.e. it can move in the x-y plane without rotation.

Mesh Dynamics. Mesh modifications are performed after each time step. Laplace’s equation for the motion displacement (2) has been solved to calculate the updated position of mesh points.

where \(\gamma \) is the diffusion coefficient. Diffusivity model of the inverse distance has been applied for a determination of points movement.

A ring-shaped area around oscillating cylinder where mesh cells cannot be shrunk or expanded due to the cylinder motion is defined. It ensures that boundary layer cells are unchanged and a non-dimensional distance \(y^+\) are not dependent on an instantaneous position of the vibrating cylinder.

2.2 Computational Domain

Due to the complexity of the problem, the two-dimensional cases are simulated. The rod bundle has closely-packed configuration with pitch-to-diameter ratio of \(P/d=1.1\). In the model, rods are described as 2D cylinders. Experimental results of Weaver and El-Kashlan [6] show that for studying flow-induced vibrations in the tube bundle, it is recommended six tube rows in the array. In the present study, the cylinder array consists of 8 rows with five whole cylinders or four whole and two half-cylinders in each one (see Fig. 1). Flexibly-mounted cylinder TC with diameter, d is located in the middle of the fourth row.

The computational domain is discretised by \(~1.48 \cdot 10^6\) quadrilateral cells. Maximum dimensionless parameter \(y^+\) from the wall to the first mesh node is from 12.5 till 41.5.

Boundary Conditions. At the inlet is defined constant uniform velocity, \(U_\infty \), which corresponds to 1.418 m/s. Turbulence intensity level of \(5~\%\) is assumed. At the outlet constant pressure, \(p_0\) is applied. On the cylinder walls and channel top and bottom walls are used no-slip conditions for velocity and standard OF wall functions for the turbulent kinetic energy, the turbulent dissipation, the specific rate of dissipation and the turbulent viscosity.

2.3 Static Case

The quasi-steady-state simulation in a rigid cylinder array without any flexibly-mounted rod is done to select the main modelling parameters such as turbulence model, cell size, boundary conditions etc. Based on the comparison with experimentally measured pressure drop in the channel with rigid rod bundle, the standard \(k-\varepsilon \) turbulence model was used to attain the turbulence closure in RANS calculations.

The SIMPLE algorithm is used to realise the pressure-velocity coupling. Flow fields of a converged quasi-static case are used as initial conditions for time-dependent simulations.

3 Metamodeling Approach

Computational Fluid Dynamics modelling is time-consuming, so the number of calculated cases should be kept to a minimum. Metamodels can be an effective way to reduce the number of CFD simulations at the same time allowing the analysis of the system parameters impact.

3.1 Sampling Plan

The first step to build the metamodel is to create a sampling plan. The plan defines points in the design space where the response values of the CFD simulations are obtained to construct the approximate model. The space-filling by Latin hypercube sampling (LHS) is done. LHS is uniform in the entire space and on projected axes and can be generated for any number of points [7]. Mean Square Error is chosen as a space-filling criterion because of its suitability for second-order polynomial approximations [8].

Based on the number of weighted quadratic polynomial model coefficients, three-factors Mean Square Error LHS plan is to build from 16 sample points (see in Fig. 2). Sixteen plan points are also used for the two-factors plan.

3.2 Approximation

As concludes Madsen et al. [3], the presence of some numerical noise in CFD results (due to the complexity of the numerical modelling) is practically inevitable. Therefore, the second-order polynomial (3) is used as the response surface because of its robustness to numerical noise [9].

where \(\beta \) is the coefficient of a polynomial, m is the number of the sampling points.

3.3 Model Fitting and Validation

The fit of the metamodel can be evaluated by using one of the standard measures: adjusted coefficient of determination, \(R^2\) (for more information see [10]). If the model fits perfect, the \(R^2\) is equal to one.

Leave-one-out cross-validation error estimation approach is applied to remove necessary to do additional computational simulations for the metamodel validation and based on the study of Meckesheimer et al. [1]. A sigma cross-validation percentage error (4) is used to avoid the prediction error overestimation [11].

where \(\hat{f}_{-i}\) is the predicted response without point i (\(i=1,2,...,n\)). It is assumed that \(\sigma _{cr\%}\) should be less than \(10\%\).

4 Results and Discussion

Three parameters of the flexibly-mounted TC were examined to investigate the possibility to detect failures of the rods using a fast simulation tool. Initially, the influence of 30\(\%\) variations of the rod mass m, 70\(\%\) change of the support damping coefficient c, and 10\(\%\) variations of the support stiffness coefficient k was analysed. In the second case, the influence of 10\(\%\) variations of the mass and the stiffness was studied.

4.1 Calculations of Response Values

Based on sampling plan, it was numerically modelled 16 cases with different combinations of the rod mass, stiffness and damping coefficients. The simulations were parallelised on a cluster to reduce computational time.

In time-dependent cases, the pressure-velocity coupling is realised with PIMPLE algorithm. The maximum Courant number is set to 0.5 for calculations with Unsteady RANS. At the same time, the time step was chosen to correspond at least 500 steps per oscillation period. Suggested time step resolution is from 100 steps per cycle [12], and thereby the step should be small enough not to affect the results.

Depending on initial conditions (m, k and c values) in the three-factor design are observed two extreme positions of the oscillating cylinder: stability at a non-zero position and flutter instability with a maximum amplitude (10\(\%\) of d) under the influence of the fluid flow. In two-factor case, the variation range is reduced to avoid non-oscillatory scenarios.

In all cases the coefficients k and c in both TC movement directions (x and y) are equivalents. Time responses of the flexibly-mounted cylinder TC in both extreme scenarios are shown in Fig. 3a and b. The main oscillations are observed in the perpendicular (y) direction to the flow. The amplitudes in the y-direction can be till ten times larger than in x-direction in analysed cases. As it is expected, the equilibrium point in the parallel direction (x-axis) is shifted towards the flow direction. A typical example of the TC trajectory can be seen in Fig. 3c. Quasi-stationary oscillations are observed after an initial period.

Computed frequencies of TC quasi-stationary vibrations is near the natural frequency of the rod. Therefore it can be guessed that in this case the behaviour of the oscillation system mainly is dictated by the left side of the differential Eq. (1). TC velocity is small compared to the flow velocity, so the main impact on oscillations is a coefficient proportional to TC displacement.

4.2 Analysis of Input Value Impact

The response surface approximation is applied to investigate how the variations of design parameters influence oscillation amplitudes and frequencies of the flexibly-mounted cylinder.

Three-Factors Case. In the three parameter case, the variation range of factor values is different. Values of damping coefficient have large variations (70\(\%\)). The TC mass change is moderate (30\(\%\)), and values of the stiffness coefficient vary only in 10\(\%\) range.

The leave-one-out cross validation percentage error, \(\sigma _{cr\%}\) of oscillation amplitude in the parallel, a1 and the perpendicular, a2 direction to the flow and oscillation frequencies in both directions, f1 and f2 is calculated to validate the metamodel. It was found that \(\sigma _{cr\%}=6.24\) for a1, 10.37 for a2, 3.22 for f1 and 4.68 for f2. It is seen that the response of amplitudes has higher error compared with frequencies, especially of the perpendicular oscillation amplitude which is larger than \(10\%\). It can be guessed that narrower range of design parameters variation excluding values that cause non-zero position stability (see Fig. 3b) could improve the accuracy of the metamodel. In three-parameters case, the response of frequencies is used for future analysis.

The graphical approach is used to analyse how various values of the mass, the stiffness and the damping impact the oscillation frequencies. Pareto charts show the influence of the variation of a parameter individually and the combination of design variables as well.

The influence graph of the frequency in a flow direction (see the left plot in Fig. 4) shows that significant impact on oscillation frequency is the coefficient of the support stiffness. The cylinder mass and damping coefficient effect on frequency is negligible. The oscillation frequency perpendicular to the flow (see the right plot in Fig. 4) is more sensitive to the mass, including cross-member with stiffness (\(m \cdot k\)), although the stiffness is still a decisive factor.

Analytical solution of the linear differential equation (1) shows that TC has damped approximately ten times slower comparing to OF results. It can be speculated that reasons for a damping difference are the closely-packed bundle geometry as well fluid-induced damping. More investigations should be needed to find a definite conclusion.

Two-Factors Case. The series of calculations with two design variables has been done as well. In this case, the cylinder mass and the support stiffness is varied in the same range (10\(\%\)). The damping coefficient is kept unchanged. The non-oscillatory regime is avoided.

Cross-validation percentage errors, \(\sigma _{cr\%}\), of the response values in the two-parameters case are as follow: 1.95 for a1, 6.17 for a2, 2.93 for f1 and 4.54 for f2. Reducing the variation range of design variables has made it possible to reduce the error of the model response.

Predicted response surface of amplitudes in parallel and perpendicular direction is illustrated in Fig. 5. For parallel oscillations \(R^2\) is 0.967 and for an amplitude in perpendicular direction \(R^2=0.995\).

Pareto plots of the mass and the stiffness influence on oscillation amplitude, a2 and the frequency, f2 in the perpendicular direction to the flow are shown in Fig. 6.

From Fig. 6 follows that the mass has the main influence on the amplitude and the frequency in the case when 10\(\%\) variations of design variables is allowed. The stiffness impact is smaller especially on the amplitude, although cross-members have significant influence.

Influence analysis of three- and two-factors designs show that metamodeling approach could be useful to detect the rod failures which are related to the mass reduction or support stiffness changes. More investigation of damping influence is needed.

5 Conclusions

In the present work, a metamodel-based approach was developed to analyse tube bundle behaviour in cross-flow due to a single failed rod. It is assumed that the rod failure can describe by variations of the oscillating mass, the support stiffness and damping. The impact of three design variables on vibrating rod amplitude and frequency has been investigated.

Three-factors (mass, stiffness and damping) and two-factors (mass and stiffness) metamodels were developed. Cross-validation error of the three-factors metamodel of amplitudes at given variations of design variables is quite hight. The error can be reduced narrowing the range of variables. It is realised in the two-variable case.

The metamodels gave further insights into how the design variables influence responses. Analysis of influence graphs of the three-factors design with different ranges of factor variations shows that major impact on oscillation frequencies of the flexibly-supported cylinder is the stiffness coefficient. Perpendicular to the flow, oscillations are influenced by the rod mass also. Comparison of simulations and the analytical solution of the second-order linear oscillator equation shows that fluid damping has a more significant impact on the system behaviour than solid-induced damping at given initial conditions.

Pareto plots of the two-factors metamodel show that the oscillating mass has a more significant impact as stiffness on the vibration amplitudes and frequencies of the flexible cylinder. Future investigation of the effects of the parameter variation range on responses is needed.

The first estimation shows that changes of oscillating mass and support stiffness can be detected using metamodel approach and it could be useful for monitoring of the system.

References

Meckesheimer, M., Booker, A.J., Barton, R.R., Simpson, T.W.: Computationally inexpensive metamodel assessment strategies. AIAA J. 40(10), 2053–2060 (2002). https://doi.org/10.2514/2.1538

Braatz, A.L., Hisken, H.: Response surfaces for advanced consequence models: two approaches. J. Loss Prevent. Proc. Ind. 49, 683–699 (2017). https://doi.org/10.1016/j.jlp.2017.02.007

Madsen, J.I., Shyy, W., Haftka, T.R.: Response surface techniques for diffuser shape optimization. AIAA J. 38(9), 1512–1518 (2000). https://doi.org/10.2514/2.1160

Viana, F.A.C.: A tutorial on Latin Hypercube design of experiments. Qual. Reliab. Engng. Int. 32(5), 1975–1985 (2016). https://doi.org/10.1002/qre.1924

Forrester, A.I.J., Keane, A.J.: Recent advances in surrogate-based optimization. Prog. Aerosp. Sci. 45(1–3), 50–79 (2009). https://doi.org/10.1016/j.paerosci.2008.11.001

Weaver, D.S., El-Kashlan, M.: On the number of tube rows required to study cross-flow induced vibrations in tube banks. J. of Sound Vibr. 75, 265–273 (1981). https://doi.org/10.1016/0022-460X(81)90344-8

Sessarego, M., Ramos-García, N., Yang, H., Shen, W.Z.: Aerodynamic wind-turbine rotor design using surrogate modeling and three-dimensional viscous inviscid interaction technique. Renew. Energy 93, 620–635 (2016). https://doi.org/10.1016/j.renene.2016.03.027

Auzins, J.: Direct optimization of experimental design. In: 10th AIAA/ISSMO Multidisciplinary Analysis and Optimization Conference, No 2004-4578. AIAA, Albany (2004). https://doi.org/10.2514/6.2004-4578

Jin, R., Chen, W., Simpson, T.: Comparative studies of metamodelling techniques under multiple modelling criteria. Struct. Multidisc. Optim. 23(1), 1–13 (2001). https://doi.org/10.1007/s00158-001-0160-4

Kleijnen, J.P.C., Sargent, R.G.: A methodology for fitting and validating metamodels in simulation. Eur. J. Oper. Res. 120(1), 14–29 (2000). https://doi.org/10.1016/S0377-2217(98)00392-0

Kalnins, K., Auzins, J., Rikards, R.: A fast simulation procedure for ribbed composite structures with material degradation. Mech. Com. Mat. 43(3), 225–232 (2007). https://doi.org/10.1007/s11029-007-0022-2

Hassan, M., Gerber, A., Omar, H.: Numerical estimation of fluidelastic instability in tube arrays. J. Press. Vessel Technol. 132(4), 04130 (2010). https://doi.org/10.1115/1.4002112

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Upnere, S., Auzins, J., Jekabsons, N. (2019). Metamodel-Based Analysis of Cross-Flow-Induced Vibrations. In: Abdel Wahab, M. (eds) Proceedings of the 1st International Conference on Numerical Modelling in Engineering . NME 2018. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-13-2273-0_14

Download citation

DOI: https://doi.org/10.1007/978-981-13-2273-0_14

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-2272-3

Online ISBN: 978-981-13-2273-0

eBook Packages: EngineeringEngineering (R0)