Abstract

In this study, a series of laboratory tests is conducted to examine the characteristics of mixtures composed of glass beads (GB) and polyurethane beads (PB) in different size ratios (sr = D50-GB/D50-PB). Specimens are prepared in the same relative density but in various weight ratios between GB and PB called polyurethane content, PC (= WPB/WMixture = 0, 0.5, 1.0, 2.0, and 5.0%). Small-strain shear modulus Gmax is estimated by the shear wave velocity measured by bender elements installed in an oedometer cell with various confinements under K0-loading condition. The normalized shear modulus (G/Gmax) is also measured by a resonant column test. It is found that the behavior of mixtures could be divided into two regions as the contact control and the stress control by a value of “stress threshold” that decreases with an increase in PC due to the large deformation of polyurethane particles. Additionally, with the participation of PB, the mixtures experience a sudden rise in Λ factor incorporated with a small value of ζ exponent in the Gmax = Λ(σv/1 kPa)ζ at polyurethane content, PC ≈ 0.5–2%, indicating the optimum packing and minimum sensitivity to confining pressure of the mixture. Although PB works as a low stiffness material, they play an important role to enhance inter-particle contact behaviors, resulting in an increase of stiffness degradation at low stress range. However, the deformation of PB at high confinement causes a reduction in G/Gmax curves.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Binary material mixtures generally consist of the large grains and fines or of different stiffness particles. The behaviors of the binary mixtures composed of sands and plastic/non-plastic fines have been attracted enormous interests in recent years [2, 9, 10, 13, 16]. Previous studies revealed that the inclusion of fine particles significantly effects on the engineering characteristics of unreinforced sand grains [3, 5, 13]. Additionally, adding of plastic fines into the sand leads to transitional engineering behaviors in compressibility [9, 10], and in shear modulus and damping ratio [1, 7]. In most above researches, clean sands were used as the host-rigid particle without considering the shape effect, however, particle shape could also significantly affect properties of soils [4, 8].

In this study, comprehensive laboratory experiments were performed to explore the effect of plastic grains on the engineering behavior of rigid-host particle by using polyurethane (PB) and glass bead (GB). The experimental study including materials, sample preparation, devices, and test procedures will be firstly under commanded. The compressibility and dynamic properties of the mixtures are investigated with polyurethane content (PC) and size ratio (sr) between two particles.

2 Experimental Study

2.1 Materials

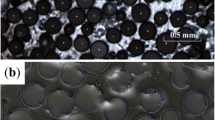

Two different sizes of glass beads (GB100 and GB400) purchased from Doosung Chemis Corporation were selected as the host rigid particles in this study. Median particle size (D50) of GB100 and GB400 are 0.08 mm and 0.23 mm, respectively. Polyurethane bead (B&K MEDIA company) with D50 = 0.08 mm was used as the plastic particle. The size ratios (sr = D50-GB/D50-PB) are 1.0 and 2.8 for GB100 and GB400, respectively. Table 1 shows the fundamental properties of GB and PB.

2.2 Sample Preparation and Testing Program

Table 2 shows the testing program in this study. Pre-determined amounts of PB were mixed with GB to form the mixtures with various polyurethane contents (PC = weight of polyurethane/total weight) = 0, 0.5, 1.0, 2.0 and 5.0%. Specific gravities (Gs) of mixtures were then evaluated based on PC, and extreme void ratios (i.e. emax and emin) were measured according to ASTM D4253 and D4254 as listed in Table 2.

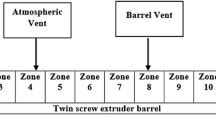

2.3 Zero-Lateral Strain Compression Tests with Shear Wave Velocity Measurements

A zero-lateral strain oedometer cell equipped with bender elements was used to evaluate the compressibility and to measure shear wave velocity (Vs) of the mixture with varying sr and PC in this study (Fig. 1). Well-mixed specimens were carefully scooped into the cell and then slightly tamped to obtain predetermined initial relative density (Dr) of ~60%. Prepared samples were applied vertical effective stresses ranging from 7 to 448 kPa. Settlements and shear wave signals were measured at the end of each loading step by an LVTD and a pair of bender elements installed in the top cap and the bottom plate of the oedometer cell [6, 11].

2.4 Resonant Column Test

In this study, shear moduli (G) with shear strains were measured by using a fix-based resonant column device (Fig. 2). Samples were prepared into a membrane with a diameter of 50 mm and fixed height of 110 mm to get the relative density Dr = ~60%. Isotropic stresses of 100, 200, and 300 kPa were applied.

3 Experimental Result

3.1 Compressibility of GB-PB Mixtures

The compressibility of specimens can be expressed in term of the constrained modulus (M), which is defined as the amount of stress induced a unit vertical strain at each loading step. Figure 3(a) illustrates the measured constrained modulus for GB100 mixtures. As shown in Fig. 3(a), the specimen with PC = 1% shows largest M values in tested stress ranges and the mixture of PC = 5% shows smallest values of M in tested PC ranges. To emphasis on the effect of the polyurethane inclusion, normalized constrained modulus (Mmixture/Mpure GB) was plotted as a function of the average effective stress in Fig. 3(b) for GB100. At low stress level, mixtures with PC = 0.5%, 1%, and 2% are experienced higher M values than pure glass bead specimen, however, at high stress range, all mixtures are exhibited a similar M value. It could be attributed to the enhancement of the contact behavior due to the inclusion of PB. At low stress, the inclusion of PB helps to increase the inter-particle contacts, resulting in increasing in M. However, at high stress level, the reduction in M is observed due to the high deformation of PB in the mixture. The mixture with 1% PC shows highest “stress threshold”, which is defined as stress value when Mmixture/Mpure GB = 1, and it gradually reduce in 0.5%, 2% PC specimens (Fig. 3(b)).

3.2 Shear Wave Velocity (Vs) and Small Strain Shear Modulus (Gmax)

The stress dependent behavior of shear wave velocity can be expressed by a power equation [10, 14] as:

where α [m/s] factor is a shear wave velocity of tested specimen at unity effective stress; and β exponent indicates the stress sensitivity of Vs. The empirically measured α and β plotted in Fig. 4(a) are well fitted with the empirical equation proposed in [12] for different geo-materials.

The stress-dependent behavior of Gmax can be expressed as:

where Λ factor expresses Gmax at 1 kPa confinement, which is controlled by packing condition including contact behavior, material properties, and coordination number; and ζ exponent shows the sensitivity of Gmax on stress, which affected by size, shape, and structure of particles [10, 14]. The experimentally determinced Λ factor and ζ exponent are plotted as a function of PC in Fig. 4(b). In this study, the optimum polyurethane content (PC*) is defined as the ratio at which mixtures exhibit highest Λ factor with lowest ζ exponent, representing the optimum packing of the mixture [1]. PC* for GB100 and for GB400 mixtures were defined at 0.5% and 2%, respectively.

3.3 Shear Modulus Degradation (G/Gmax)

Typical G/Gmax curves for mixture of GB400 - 1%PC are plotted in Fig. 5(a) and they are well matched with the Ramberg-Osgood (R.O) model. Similar to clean sands, G/Gmax increases with increasing in the confining pressure, regardless of shear strains. Figure 5(b) (c), and (d) illustrate the shear modulus degradations of GB400 with the inclusion of PB at different confining stresses of 100 kPa, 200 kPa, and 300 kPa, respectively. When the mixtures were compressed with low confining stress (i.e. 100 kPa) as shown in Fig. 5(b), G/Gmax increases with increasing in the PC under same shear strain level because of the enhancing in contact behaviors due to the inclusion of PB in mixtures. The evolutions of contact behavior could be clearly observed at high strain levels in specimens with 1%, 2%, and 5% PC. When confining stress increases, G/Gmax curves for different PC mixtures are converged into a single trend (Fig. 5(c) and (d)). Also, normalize shear modulus curves of mixtures with higher PC exhibited more reduction at high stress ranges due to large deformations by the PB inclusion.

4 Conclusion

A series of laboratory experiments were performed to investigate the characteristics of the mixtures with rigid-host (GB) and soft particles (PB). An instrumented oedometer cell was implemented to evaluate the compressibility and Gmax, and resonant column tests were performed to explore the shear modulus degradation of mixtures. It is found that the participation of PB shows significant influences on both of compressibility and dynamic properties of the mixtures due to the enhancement of the contact behavior between GB. Behavior of mixtures could be separated into two categories as the contact controlled behavior and stress controlled behavior by the stress threshold. Optimum polyurethane contents (PC* = 1% and 2% for GB100 and GB400, respectively) are observed at which mixtures experienced the optimum packing condition, resulting in an increase both of the constrained modulus (M) and small strain shear modulus (Gmax). It was also observed that the inclusion of PB in mixture results in an increase in the elastic threshold strain of the mixture at low confinement. The transition from contact control to stress control behaviors at high confinement leads to the reductions in both constrained modulus and shear modulus degradation in mixtures. Since the polyurethane bead is a high damping material, this study would provide a new idea for an energy absorbed layer or seismic base isolation application under the dynamic loading.

References

Brara, A., Brara, A., Daouadji, A., Bali, A., Mostafa Daya, E.: Dynamic properties of dense sand-rubber mixtures with small particles size ratio. Eur. J. Environ. Civ. Eng. 21, 1065–1079 (2017)

Carraro, J.A.H., Prezzi, M., Salgado, R.: Shear strength and stiffness of sands containing plastic or nonplastic fines. J. Geotech. Geoenviron. Eng. 135, 1167–1178 (2009)

Chien, L.-K., Oh, Y.-N., Chang, C.-H.: Effects of fines content on liquefaction strength and dynamic settlement of reclaimed soil. Can. Geotech. J. 39, 254–265 (2002)

Cho, G.-C., Dodds, J., Santamarina, J.C.: Particle shape effects on packing density, stiffness, and strength: natural and crushed sands. J. Geotech. Geoenviron. Eng. 132, 591–602 (2006)

Choo, H., Burns, S.E.: Shear wave velocity of granular mixtures of silica particles as a function of finer fraction, size ratios and void ratios. Granular Matter 17, 567–578 (2015)

Lee, C., Lee, J.S., Lee, W., Cho, T.H.: Experiment setup for shear wave and electrical resistance measurements in an oedometer. Geotech. Test. J. 31, 149–156 (2008)

Lee, C., Shin, H., Lee, J.-S.: Behavior of sand–rubber particle mixtures: experimental observations and numerical simulations. Int. J. Numer. Anal. Methods Geomech. 38, 1651–1663 (2014)

Lee, C., Suh, H.S., Yoon, B., Yun, T.S.: Particle shape effect on thermal conductivity and shear wave velocity in sands. Acta Geotech. 12, 615–625 (2017)

Lee, C., Truong, Q.H., Lee, W., Lee, J.-S.: Characteristics of rubber-sand particle mixtures according to size ratio. J. Mater. Civ. Eng. 22, 323–331 (2010)

Lee, J.-S., Dodds, J., Santamarina, J.C.: Behavior of rigid-soft particle mixtures. J. Mater. Civ. Eng. 19, 179–184 (2007)

Lee, J.-S., Santamarina, J.C.: Bender elements: performance and signal interpretation. J. Geotech. Geoenviron. Eng. 131, 1063–1070 (2005)

Lee, J.-S., Seo, S.-Y., Lee, C.: Geotechnical and geophysical characteristics of muskeg samples from Alberta, Canada. Eng. Geol. 195, 135–141 (2015)

Liu, N., Mitchell, J.K.: Influence of nonplastic fines on shear wave velocity-based assessment of liquefaction. J. Geotech. Geoenviron. Eng. 132, 1091–1097 (2006)

Santamarina, J.C., Klein, K.A., Fam, M.A.: Soils and Waves: Particulate Materials Behavior, Characterization and Process Monitoring. Wiley, New York (2001)

Vollenberg, P.H.T., Heikens, D.: Particle size dependence of the Young’s modulus of filled polymers: 1. Preliminary Exp. Polym. 30, 1656–1662 (1989)

Wichtmann, T., Navarrete Hernández, M.A., Triantafyllidis, T.: On the influence of a non-cohesive fines content on small strain stiffness, modulus degradation and damping of quartz sand. Soil Dyn. Earthq. Eng. 69, 103–114 (2015)

Zhou, S., Wu, L., Sun, J., Shen, W.: The change of the properties of acrylic-based polyurethane via addition of nano-silica. Prog. Org. Coat. 45, 33–42 (2002)

Acknowledgments

This work was supported by the Korea Institute of Energy Technology Evaluation and Planning (KETEP) and the Ministry of Trade, Industry & Energy (MOTIE) of the Republic of Korea (No. 20161520101130), by the National Research Foundation of Korea (NRF) grant funded by the Korea government

(MSIP) (No. NRF-2017R1C1B2004036), and by National Emergency Management Agency (NEMA) as Disaster Prevention Safety Human resource development Project.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Van Ngo, L., Choi, W., Do, T.T., Lee, C. (2018). Characteristics of Glass-Polyurethane Beads Mixtures as Function of Weight Ratios: Experimental Approaches. In: Zhou, A., Tao, J., Gu, X., Hu, L. (eds) Proceedings of GeoShanghai 2018 International Conference: Fundamentals of Soil Behaviours. GSIC 2018. Springer, Singapore. https://doi.org/10.1007/978-981-13-0125-4_6

Download citation

DOI: https://doi.org/10.1007/978-981-13-0125-4_6

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-0124-7

Online ISBN: 978-981-13-0125-4

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)