Abstract

It is believed that there is a strong link between raw material exploitation and lithic technology. The raw materials play an important role in imposing special technology to hunter gatherers for adapting themselves to their environment. The Zagros region with complex topography, as an island of moisture and the rainfall, provided sufficient food, water and raw material resources. In this paper, we focus on southern Zagros where the compromise between technological needs and the raw material resources in the Dasht-e Rostam-Basht region, led us to propose a model of “optimization of mobility, technological strategies and land use. This model examines this hypothesis that the residents of the region during their seasonal movements for following migratory preys adopted the lamellar technology of the Rostamian in order to minimize time and energy costs associated with raw material procurement and transport. Testing this model in the southern Zagros was based on the techno-typological analysis of the lithic assemblages from the survey sites in the Dasht-e Rostam-Basht region and the stratified lithic assemblages from the Ghār-e Boof Cave.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

It is widely accepted that the lithic raw material resources have great influence on the mobility of the Palaeolithic hunter-gatherers and the communication between these groups (Fisher and Eriksen 2002). The needed stone raw material is provided either by directly exploitation or indirectly by exchanging with the other groups (Blades 2001). Therefore, raw material economy, lithic technology and mobility strategies are closely related (Miller 1997). There is a strong link between raw material exploitation and lithic technology. In relation to mobility and land use patterns, raw materials play the essential role of an economic bridge between technology and the subsistence adaptations by imposing the ways foragers use the landscape and develop their lifestyle (Kuhn 1995). Therefore, stone raw material procurement and economy must be considered in a broader context of hunter gatherers subsistence and settlement systems (Fisher and Eriksen 2002).

In this paper the study of raw material economy involves with (1) availability of the raw material, (2) raw material procurement strategies, (3) preparation and reduction and (4) selection of especial technologies in order to reach to a tool form appropriate to subsistence strategies in the southern Zagros Mountains of Iran .

To date the study of Palaeolithic raw material economies on the Iranian Plateau is limited to few case studies in the west central Zagros Mountains (e.g. Heydari 2004; Biglari 2007). Some scholars believe that the raw material resources in the Zagros suffered from constraints, which highly influenced the lithic technology and typology (see Dibble 1984; Baumler and Speth 1993). However, the new data on the raw material sources proved that it was not the pervasive issue throughout the Zagros (Heydari-Guran and Ghasidian 2012; Ghasidian and Heydari-Guran 2012; Heydari 2004; Biglari 2007). In his analysis, Biglari argues the influence of using local and non-local raw materials in adoption of different core reduction technologies and selecting tool blanks among the Middle Palaeolithic assemblage from Do-Ashkaft cave of west central Zagros Mountains (Biglari 2007). There, the elaborated retouched tools are preferably made on the better quality non-local raw material, however the local raw material used expediently and not so often among the retouched tools (Biglari 2007).

Throughout the Zagros no large raw material work shop has been observed during Upper Palaeolithic (UP) (Ghasidian and Heydari-Guran 2012). On the contrary, during Middle Palaeolithic, there are some indications on the quarry workshop sites including Chakhmaq li (Heydari-Guran and Ghasidian 2004) and Bagherabad (Ghasidian and Heydari-Guran 2012).

Recent studies on the UP assemblages from the Zagros show that this period encompasses major socioeconomic and cultural changes in the subsistence strategies and settlement patterns resulting in more cultural variability than once thought (Ghasidian 2014).

The Zagros region with complex topography rises from the surrounding deserts of Iraq and Iran as an island of moisture and the rainfall has been always sufficient to support food and water resources (Heydari-Guran 2015). It is divided into four macro zones of the northern, west central, central and southern (Heydari-Guran 2015). Each of these macro zones offers different ecosystems that yields different techno-complexes among the UP of the Zagros (Ghasidian 2012a; Ghasidian et al. 2017). This variability is partly reflected in the lithic assemblages namely Baradostian (Solecki 1963; Hole and Flannery 1967; Olszewski 1993; Shidrang 2015), Zagros Aurignacian (Olszewski and Dibble 1994, 2006; Otte et al. 2007, 2012) and the Rostamian (Ghasidian 2014) presenting different techno-typological characteristics. The Baradostian is documented as flake based industry with a focus on flake blank tools (Solecki 1963; Olszewski 1993). The laminar débitage especially the bladelets appeared at the late phase of the UP or late Baradostian which are considered as prototypes of geometric microliths during Epipaleolithic or Zarzian (Hole and Flannery 1967). Reconsideration of the Baradostian led some scholars to conclude that the especial core reduction, different kinds of burins and scrapers , as main tool types, are reminiscent of the Aurignacian as documented in Europe . Therefore, they prefer to use the term Zagros Aurignacian instead of Baradostian (Olszewski and Dibble 1994, 2006; Otte et al. 2007, 2012). The Baradostian and/or Zagros Aurignacian lithic industries are documented in the northern and west central Zagros Mountains. However, in the southern Zagros the UP industries show different techno-typological characteristics. Here the Rostamian cultural group, named after the Dasht-e Rostam -Basht region, is focused on the bladelet production (Ghasidian 2012b, 2014). This pattern is seen in selection of tool blanks as well. The Rostamian documents one of the oldest bladelet production during UP throughout the Zagros and the Iranian Plateau . The bladelet production starts around 41 kyr cal. bp. and lasted through the UP (Ghasidian 2012b, 2014).

In this paper we try to illuminate the role of procurement and use of lithic raw material s in the context of broader patterns of technological change in the Rostamian early UP of the Dasht-e Rostam-Basht region of the southern Zagros. Based on the compromise between technological needs and the raw material resources in the Dasht-e Rostam-Basht region, we propose a model of “optimization of mobility , technological strategies and land use (OMTSLU)” (sensu Brantingham 2003). This model examines this hypothesis that the residents of the region during their seasonal movements for following migratory preys adopted the lamellar technology of the Rostamian in order to minimize time and energy costs associated with raw material procurement and transport. Testing the model OMTSLU in the southern Zagros was based on the techno-typological analysis of the lithic assemblages from the survey sites in the Dasht-e Rostam-Basht region (Heydari-Guran 2014) and the stratified lithic assemblages from the Ghār-e Boof Cave (Ghasidian 2014). The study of raw material economy among the UP sites of the Dasht-e Rostam-Basht region is significant in a) understanding the raw material impacts on the lithic reduction and organization of technology, b) reconstructing the size and form of the territories of the Dasht-e Rostam-Basht region occupants.

The data extracted from this study will provide answers to the following questions:

-

1.

How much could the quality and quantity of the raw materials in the region affect the knapping techniques, reduction intensity and provision of the tools?

-

2.

How was the raw material procurement controlled in the settlement and social systems of the early UP inhabitants of the Ghār-e Boof and the Dasht-e Rostam-Basht region?

-

3.

How much can raw material distributions on the Dasht-e Rostam-Basht region reflect the range and organization of hunter-gatherer mobility?

Both chaîne opératoire and attribute analysis approaches employed in the study of technology and typology of the stratified lithic assemblages from Ghār-e Boof cave and the other UP assemblages from the surveyed sites in the Dasht-e Rostam-Basht region.

2 Palaeolithic Research in the Dasht-e Rostam-Basht Region

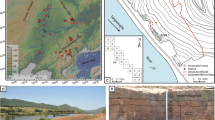

Dasht-e Rostam -Basht consists of a highly seasonal region with arid and semi-arid typical Mediterranean climate located in the southwestern Zagros Mountains of Iran . The research area is divided into several smaller areas of Dasht-e Rostam plains I and II, Yagheh Sangar Rostam pass and Khanahmad , which altogether covers an area of around 500 km2 (Fig. 11.1). The region consists of rough, steep and karstic mountains and several relatively small flat intermountain plains which are connected to each other by natural passes, rivers and seasonal streams (Heydari-Guran 2014) (Fig. 11.2).

The survey in the Dasht-e Rostam-Basht region was undertaken during 2004 through 2007 along the rim of the mountains (Heydari et al. 2004; Conard et al. 2006, 2007a, b; Heydari-Guran 2014). Most areas , especially rich in caves and rockshelters, were surveyed extensively and almost all visible caves and rockshelters were checked (Heydari-Guran 2014). The survey documented 109 caves and rockshelters and two open air sites associated with UP lithic artefacts in 13 microhabitat areas (Table 11.1). At the time of survey and collecting lithic artefacts, some sites yielded high number of lithics that required a systematic method of collecting artefacts with help of grids and measurement instruments (Heydari-Guran 2014, p. 88). For evaluating the results from survey and recover the stratified and dated Palaeolithic data, during 2006 and 2007 a cave site in the Yagheh Sangar Rostam pass has been excavated (Conard et al. 2006, 2007a, b).

Ghār-e Boof Cave is located in the Yagheh Sangar Rostam pass where two plains of Rostam I and II are connected to each other (Figs. 11.1 and 11.3). Most of the UP caves and rockshelters of the Dasht-e Rostam-Basht region are located in this corridor. An area of 18m2 was excavated and in some parts reached to the depth of 230 cm (Ghasidian 2014). A total number of 37,658 lithic artefacts have been unearthed during these two seasons all assigned to UP (Conard et al. 2007a, b; Ghasidian 2014). The UP assemblage from Ghār-e Boof comes from four archaeological horizons (AHs) of I through IV. Since the AHs I and II (including sub horizons IIa and IIb) still contain the mixture of UP lithics and the historical pottery sherds, here we include the lithics from AH III (including sub AHs IIIa, IIIb) through IV.

The radiocarbon dating points from AH III and IV place Ghār-e Boof Cave between 35 kyr cal BP and 42 kyr cal. BP in the early UP of the southern Zagros Mountains. The samples come from AH III through IV from depths ranging between 600 and 482 cm (Ghasidian 2014, p. 62, Becerra-Valdivia et al. 2017) (Table 11.2).

3 Lithic Raw Material Sources in the Dasht-e Rostam-Basht Region

From the early stages of the survey in the area, we found out most of the lithic artefacts are made of two identical types of stone raw materials . Searching for raw material sources resulted into the discovery of two main chert sources which were dominant raw materials among the lithic assemblages of the Ghār-e Boof cave and the other UP sites of the region (Table 11.1). One of these two sources is found in a secondary context while the other is in a primary context. The former is embedded in the Fahliyan river therefore is called here ‘Fahliyani chert’, and the latter is the in situ source in the Khanahmad habitat area and therefore is called ‘Khanahmadi chert ’. Here the description of each raw material type is based on the macroscopic characteristics of each type including texture grain size, colour, any impurities, cortex etc. as follow:

3.1 Fahliyani Chert

The Fahliyani chert source is a secondary deposition composed of pebbles about 5–10 cm in diameter (Fig. 11.4) which are only found in Fahliyan river bed within the study region. The pebbles have fractured and cracked exteriors which are the result of crashing with other pebbles in the water over a long time. These pebbles are well rounded, which indicates that the Fahliyan River transported them over long distances. According to geological and hydrological maps, these stones are probably moving in different tributaries of the Fahliyan River which pass from the radiolarite belt of Neyriz exposed in the high Zagros Mountain zone around 250 km northeast of the Dasht-e Rostam -Basht region (Ghasidian 2014). Since the Fahliyan riverbed covers a large area (25 km length and averagely 800 m width), the availability and abundance of the Fahliyan cherts are remarkably high in the Dasht-e Rostam-Basht region (Heydari-Guran 2014). The most abundant raw material type of Fahliyani is a radiolarian chert that occurs in a spectrum of warm colours, from yellow to red, and in a variety of textures, from coarse to medium to fine-grained. Although Fahliyani pebbles mostly have fine texture, knapping them was difficult, since they encompass hitting and pressure caused by being a long time in the river from the primary context until the time of procurement by the knappers. In some cases, removing only a thin layer of cortex was not enough for decortication and for the beginning of the reduction process because many of the impacts extend deeply into the raw material structure (Fig. 11.5). Therefore the preparation and decortication of these pieces is done by removing thicker preparation blanks (Ghasidian 2014, p. 107).

Fahliyani chert pebble (After Ghasidian 2014)

Fahliyani chert showing cracks and impurities (After Ghasidian 2014)

3.2 Khanahmadi Chert

The Khanahmadi chert belongs to a geological folded formation close to the microhabitat area of Khanahmad and composed of thin layers of radiolarite and carbonate rocks , which are mixed together as banded layers. Unfortunately, at the time of survey it was not possible to make an outline of the geographical boundary of the Khanahmadi chert distribution in the region and therefore we located the only visible area that this chert layer has exposed. It is a tabular form of chert which is mostly fine grained in texture, although, like Fahliyani, the medium and coarse-grained textures are also present but not so often used among the lithic assemblages. Generally, the Khanahmadi chert blocks are larger in volume than the Fahliyani. The chert layers in the Khanahmadi material are formed between limestone layers which are firmly attached to the chert layer making it difficult to separate. Often the reduction occurred to first remove this limestone layer to get into the chert to begin with the reduction (Ghasidian 2014, p. 108). Although the Khanahmadi chert is fine in texture, the banding limestone-chert layers sometimes produced cracks and ridges inside the material caused the piece to break apart during knapping (Ghasidian 2014). This frequent cracking and breaking led to the higher abundance of angular debris among the Khanahmadi material (Ghasidian et al. 2009) despite that most of the preparation of the raw material took place at the chert quarry. Fig. 11.6 shows a sample of Fahliyani and Khanahmadi cherts.

A sample of Fahliyani and Khanahmadi chert (After Ghasidian 2014)

3.3 Other Stone Raw Materials

Although in a small portion, several other raw material types are present among the UP lithic artefacts of this region including dolomite , chalcedony and quartz (Heydari-Guran 2014). Dolomite is abundant in and around the Dasht-e Rostam -Basht region as large blocks. Due to their abundance and hefty size, the pieces formed from the local dolomite are larger than the other two chert types.

Chalcedony and quartz comprise the other prevalent types of utilized raw materials at the Dasht-e Rostam-Basht region sites. However, their sources are presently unknown and are considered as imported material (Heydari-Guran 2014). A single artefact made on schist is also present among the Ghār-e Boof cave assemblage and was probably imported to the site (Ghasidian 2014, p. 110).

4 Raw Material Economy in the Ghār-e Boof Cave

Since the strata from Ghār-e Boof cave show a time depth of around 7 kyr, in the analysis and comparisons of the assemblage of each stratum, it was important to note any probable change through time. Therefore, each techno-typological variability, revealed from particular temporal contexts, was documented in order to see any economic variability across space. A close comparison of these stratified material with the survey assemblages from the Dasht-e Rostam-Basht region have been undertaken in order to have a complete view on the raw material economy during early UP in this part of the southern Zagros .

All assemblages from the UP sequence at Ghār-e Boof Cave (AHs III to IV) are characterized by strong emphasis on the production of bladelets from single platform cores using direct soft stone hammer percussion (Ghasidian 2014). Almost all cores throughout the stratigraphy are bladelet cores. The blades and flakes from Ghār-e Boof show a high degree of cortex or technical characteristics which relates them to the core preparation and rejuvenation pieces.

Despite duration of 7 kyr of the UP sequence, the technological and typological characteristics of the assemblages remain relatively homogeneous. Bladelets are the main blanks for tools throughout the sequence and represent in different variants of retouch. The tool classes throughout the sequence stay the same although the frequency of them changes from AHs III-IV. The radiocarbon dates show that Ghār-e Boof contains one of the oldest UP assemblage specialized in bladelet production throughout the Iranian Plateau . This specialized bladelet industry was introduced as a new cultural tradition of the “Rostamian ” named after the Dasht-e Rostam where the cave is located (Ghasidian 2014).

For the UP sites of the Dasht-e Rostam-Basht region the raw materials used are divided into two zones of raw materials (according to zoning system of Féblot-Augustins 1997 and Geneste 1989): zone 1, sources up to 5 km and zone 2, sources between 5 and 40 km far from the site.

Based on this zoning model , for Ghār-e Boof cave the Fahliyani chert is located in the first zone which is located in an area around the site at a distance of less than 6 km, and as the second zone the Khanahmadi chert is located around 20 km far from the cave and can be considered as imported raw material. This zoning is flexible for the other sites of the Dasht-e Rostam-Basht region based on their distance to these raw material resources (Heydari-Guran 2014; Ghasidian 2014) (Fig. 11.7).

Map of Dasht-e Rostam-Basht region showing the distribution of raw material in each microhabitat area (After Heydari-Guran 2014)

The dominant raw material among the whole lithic artefacts from the Ghār-e Boof is the Fahliyani chert (Fig. 11.8). It is the same through all AHs (Table 11.3). In the study of the lithic economy in the Ghār-e Boof, AH III and IV have been considered, since there is no mixture of Palaeolithic and non-Palaeolithic materials has been observed. Each stratum has been analysed separately and then comparison has been made between the strata. Each Assemblage has been divided generally into six major categories of cores, tools, flakes, blades , bladelets and debris including angular debris, small and micro-débitage .

4.1 AH III

This AH includes the major number of lithic artefacts throughout the stratigraphy . AH III itself is divided into two sub-horizons of IIIa and IIIb. In AH III the dominant raw material used is local Fahliyani chert which is considered as zone 1 (Tables 11.4 and 11.5). Due to their small size, the Fahliyani pebbles are easily transportable with less cost of energy. All stages of the chaîne opératoire are present. Although the Fahliyani raw material, in all technological categories, comprises the majority, it reduced among the tools to around half (55.4%) of the whole tool assemblage. This raw material appears in different grain size (fine to coarse). Since the whole assemblage is focused on producing bladelets , fine-grained chert is the most frequent (Table 11.6). The high number of cortical flakes and blades and the debris indicates the high reduction of Fahliyani chert in the site from the first stages of preparation until the tool production. The tools on the preparation and rejuvenation flakes and blades especially cortical pieces are frequent among the Fahliyani chert . Four Fahliyani cobbles without any modification are among the assemblage indicating that the whole process of reduction from core preparation to tool production occurred at the site.

The second frequent raw material is Khanahmadi chert is considered as the second zone of around 20 km far from Ghār-e Boof cave.

Due to the special formation of this chert between limestone layers, the knappers had to knapp the fine-grained chert at the outcrop and import it to the site. They mostly imported the fine-grained parts of the raw material. In all technological categories, this raw material keeps around 1/3 of the whole raw materials (Tables 11.4 and 11.5). The pattern of using fine textured raw material is also seen among the Khanahmadi raw material. In some tools the fine and coarse texture are joined together because of the tabular nature of the raw material. In these cases, it was observed that the retouched edges or active part of the tool was chosen on the fine grained part. The tools on coarse grained Khanahmadi chert compose only around 3% (Table 11.6).

There is no core other than Fahliyani or Khanahmadi raw materials. Flakes, blades and bladelets comprise a small number among the raw material category of “other”, the same with debris (Tables 11.4 and 11.5). A total number of 24 tools made of other raw material types including mostly chalcedony (19 pieces). The tools on chalcedony compose of bladelet blanks and are consistence with the rest of the assemblage. But based on the weight of the raw materials, surprisingly the tools under the “other” category compose around 25% of the whole tool assemblage of AH III, since there are 2 heavy duty tools made on dolomite and schist of unknown raw material source among the assemblage. These pieces are different tool types which were imported to the site as finished forms. There is no débitage or debris related into these raw materials (schist and dolomite) among the whole lithic assemblage of AH III.

AH IIIa as a sub-horizon of the AH III, comprises the same pattern of raw material economy as observed in AH III. Fahliyani chert is the dominant raw material type especially the fine grained variant (Tables 11.4 and 11.5). More than 80% of the cores are made on Fahliyani chert. This number is getting smaller in the other technological categories. Among the tools this number reaches to around 40% which is less than the AH III. The high number of debris among the Fahliyani is in proportion to the cores and débitage indicating the intensive reduction of this raw material in the site. The fine texture Fahliyani chert was preferred among the tools especially among the retouched laminar pieces (Table 11.7). It is the same among the Khanahmadi chert as the second most frequent raw material. The coarse-grained variant of this raw material is totally absent among the tools. Other kinds of raw material comprise a very small number among the flakes and bladelets and are totally absent among the blades and debris. But this category other, comprises a large number among the tools based on the weight. However, there are only 4 tools in this category including 2 small retouched blades made on chalcedony and 2 large retouched flakes made on dolomite which are imported to and not manufactured at the site.

The following AH IIIb shows more use of Khanahmadi chert but still the Fahliyani has the priority (Tables 11.4 and 11.5). However, the use of other kinds of raw material seems to be minimal among the débitage and tools and they are totally absent among the debris. The Fahliyani fine-grained texture comprise the majority of the tools and Khanahmadi fine grained is the second majority. There are two small end scrapers on the chalcedony which have a fine texture (Table 11.8).

4.2 AH IV

Although most of the cores are made on Fahliyani chert and only around 3% are on Khanahmadi chert, the relatively high numbers of débitage (including flake, blades , bladelets and tools) among Khanahmadi chert in AH IV compares to the small number of cores, indicates an intensive reduction of this raw material in this AH. Only the fine-textured variant of these two raw materials were used. The other kinds of raw material, including chalcedony , compose a small number among the whole technological categories (they are totally absent among the flakes) and among the tools (Table 11.9). In AH IV, despite the time depth of around 7 kyr, still the same pattern of raw material economy observed among the lithics. This issue is mostly due to the fact that raw material procurement as well as both technological and typological aspects remained almost the same throughout the stratigraphy .

5 Comparisons

5.1 Technology

The Rostamian lithic assemblage of Ghār-e Boof cave from AH III through AH IV shows a high degree of standardization which is closely related to the raw material procurement and the reduction patterns that the knappers had in mind. The size characteristics of this production is influenced by the factors including the knapping technique, abundance of lithic raw material available and the size and shape of this raw material (Andrefsky 1998, p. 100). The lithic assemblages from Ghār-e Boof cave are homogeneous because of the focus on the production of bladelets through all AHs using soft stone hammer percussion (Ghasidian 2014, p. 199). The bladelets mostly have twisted profiles and made from single platform bladelet cores . They were also produced from flakes. They are mostly cortical pieces that were struck during the first stages of core preparation and are analogous to the carinated burins . Most of the cores on flakes occur in AH III and considered nearly one third of the cores in the entire assemblage from this AH. The number of these cores decreased in AH IIIa downwards and by the AH IV there is only one core on a flake remaining. These cores occur on both kinds of raw materials of Fahliyani and Khanahmadi. Almost all cores, regardless of the raw material type and blank (pebble or flake) have laminar (mostly bladelet) negative scars (Fig. 11.9) which are consistence with the débitage .

Because of the different nature of the Fahliyani and Khanahmadi raw materials, the first preparation of the cores is different. Among the Fahliyani cores the shape of the original raw material pebbles facilitates the desired form for bladelet production. However, the tabular nature of the Khanahmadi imposed more preparation especially in the places where two texture of fine and coarse come together. It was tried to remove the coarse grained part to get a ridge, instead of crest, in order to produce twisted bladelets . The cores from both kinds of raw materials treated the same in the process of bladelet production and have the same way of rejuvenation. The rejuvenation was limited into faceting with small flakes rather than striking a core tablet . The homogeneity of the lithics is repeated in each AH and sub-AH with only minor differences usually in the number of pieces in different technological categories rather than the technique and means of reduction. This indicates that the lithic reduction in Ghār-e Boof cave follows a single chaîne opératoire through all Palaeolithic strata regardless of the raw material type (Ghasidian 2014, p. 194).

The physical characteristics of the Fahliyan river pebbles allowed the inhabitants of Ghār-e Boof cave to easily import them to the site, where whole reduction sequences occurred at the site. The easy procurement of Fahliyani imposed more production of lithic artefacts from this raw material. Therefore, the inhabitants of Ghār-e Boof cave did not have to travel far to access raw material and they were well aware that they had little to no need of recycling their tools or cores made from this material. In the case of Khanahmadi chert , the relatively vast distance separating the site from this chert source forced the knappers to do most of the initial preparation of the blocks directly at the raw material outcrop.

5.2 Typology

In all AHs and sub-AHs, where the flakes and blades used as blanks, they compose of the core preparation elements. These pieces normally show laminar negatives on their dorsal scars. As observed among the débitage , the bladelets , as the main products, also comprise the main tool blanks throughout the Palaeolithic strata and in all raw material types. Among the tools, the Rostam bladelets are considered as the best developed tool type in Ghār-e Boof cave due to their blank morphology and their retouch arrangement. They occur on fine grained raw material types and usually retouched on the dorsal side with semi-abrupt to abrupt retouches (Ghasidian 2014, p. 196). This tool type also serves as a characteristic tool among other UP sites in the Dasht-e Rostam -Basht region. The Rostam bladelets together with points (=Arjeneh points ) are the most well-developed tool types in Ghār-e Boof cave. The Rostam bladelets are often smaller and twisted (97% altogether in all AHs) and the Arjeneh points typically appear on the non-twisted bladelets. Having straight profile may be due to the projectile function of these points since they could be used as hunting weapons (Hole personal communications May 2016, Hole and Flannery 1967). In general, they are reminiscent of the el-Wad points , where el-Wad is a general term for the elongated points that have various retouch patterns and types (Bergman 2003).

In sum, throughout the Palaeolithic strata in Ghār-e Boof cave, aside from the Rostam bladelets and Arjeneh points which were produced in advance with a pre-planned template, the other tool types appear to be expediently made and show the opportunistic use of the blank and tool type for fulfilling immediate needs (Ghasidian 2014, p. 198) (Fig. 11.10).

6 Raw Material Economy among the Survey Sites

During survey in the Dasht-e Rostam -Basht region , it was observed that the type of raw material procured and used by early UP residents of the region is highly depended on the distance of the sites to the location of the sources (Heydari-Guran 2014, p. 122). The more the site is closer to one of the raw material sources, the more use of that raw material is observed among the lithic assemblage (Fig. 11.7). Therefore, two spatial zones for raw material context are defined for the UP sites of the Dasht-e Rostam-Basht region based on the accessibility to each raw material sources of Fahliyani or Khanahmadi. The general pattern shows the highly focus on the procurement of the local raw material source. Table 11.1 shows the percentages of two groups of stone raw materials used in the Dasht-e Rostam-Basht region. These percentages change moderately depending on how close are the microhabitat areas to the Fahliyan River or Khanahmadi sources. For example, more than 98% of the lithics from the Zir Du microhabitat area, which is located just on the right bank of Fahliyan River, are made on the Fahliyani and the remaining are made of Khanahmadi cherts . In opposition, the highest percentage of Khanahmadi chert was used among the UP sites of the Shiv microhabitat area, where 79% of the lithics made on Khanahmadi chert (Table 11.1). Meanwhile the sites which are located approximately between these two raw materials sources like the complex sites of the Sukhteh microhabitat area, the percentage of both raw material types shows almost equal (Fig. 11.7, Table 11.1).

The area between sites around Khanahmadi outcrop and the Fahliyan River is composed of rugged topographic conditions which made access to the Fahliyani chert source difficult. This terrain difficulty had great influence on the raw material procurement in the Dasht-e Rostam-Basht region (Heydari-Guran 2014). Therefore, using local raw material helped to minimize the costs of time and energy.

The UP assemblages throughout the Dasht-e Rostam-Basht region show a homogenous lithic industry focusing on bladelet production. Almost all cores are platform bladelet cores. The preparation of the striking platform was simply done through the removal of one or two primary flakes (Ghasidian et al. 2009, p. 134). In all assemblages, most of the cores were discarded after arriving at a highly exhausted state mostly caused by hinged fracture. In many cases among the cores made of Khanahmadi raw material, exhausting the cores occurred due to the irregularities of the raw material. Although the cores are specialized for bladelet production, the recovery of small number of bladelets compared to the flakes among the débitage groups at the time of survey is due to their small size which could have easily been washed away. As was observed among the sites of these 13 microhabitat areas and among the stratified lithics of Ghār-e Boof, flakes are struck only for the reason of preparation and rejuvenation of the cores. The latter is easily recognizable according to the dorsal laminar negatives. Well-developed flake production is nearly absent (Ghasidian 2014). The poor recovery of the bladelets is also observed among the tools. Here the most abundant tools are different kinds of retouched flakes. They are mostly on the same typological traits as the expedient tools of Ghār-e Boof are. When the retouched bladelets exist among the assemblages, they are mostly Rostam type bladelets.

In sum, the UP artefacts of Dasht-e Rostam-Basht region show a high degree of standardization based on the technological and typological characteristics. All 13 microhabitat areas provided lithic assemblages with the same technological and typological traits as observed among the lithic artefacts of Ghār-e Boof cave . Therefore, it can be concluded that based on the radiocarbon dates provided on the stratified material of Ghār-e Boof, these artefacts are dated back to over 42 kyr cal. bp. The core reduction process, the concentration on the bladelet production out of these cores and the presence of the Rostam type bladelets as the main tool type throughout these microhabitat areas confirm the expansion of the Rostamian tradition throughout the Dasht-e Rostam-Basht region (Ghasidian 2014; Heydari-Guran 2014).

7 Discussion and Conclusion

Throughout the region, from plains of Dasht-e Rostam I to Dasht-e Rostam II and the Yagheh Sangar Rostam pass which relates these two plains, because of the geomorphological characteristics of the region, numerous caves and rockshelters were formed in the karstic system of the region. This characteristic along with relatively easy access to the permanent water and raw material resources and the location of these sites along the seasonal migration route of animals allowed the early UP hunter-gatherers to use each of these shelters during season of following the game herds. Each shelter site in the region provided evidences of human occupation and provided excellent residential camps for the hunter gatherer groups. Therefore, we see a homogenous pattern of subsistence, land use and raw material procurement and lithic techno-typological characteristics throughout the Dasht-e Rostam-Basht region.

Depending highly on the raw material from first zone, as observed among the Dasht-e Rostam-Basht region sites, shows that the stone raw material was gathered and transported by hunter-gatherers beside their other activities, without significant travel only for the sake of searching for raw material (Binford 1979).

The adoption of the Rostamian tradition, consists of constant production of bladelets and their associated modifications, at Ghār-e Boof cave and other UP assemblages of the Dasht-e Rostam-Basht region are viewed as a response of the early UP populations to their raw material and subsistence resources. The pattern of raw material procurement, preferring first zone, has been observed among all of the UP sites throughout the Dasht-e Rostam-Basht region, including Ghār-e Boof cave. This issue, along with the shared lithic characteristics, indicates movements and migration of the hunter-gatherers with the same cultural tradition from site to site within the region. Hence the high mobility of the hunter-gatherers of the Dasht-e Rostam-Basht region is manifested in two issues: (1) by using all available spaces (caves and rockshelters) in the entire region, and (2) in the homogenous lithic assemblages and their common special lithic features throughout the region. These patterns are seen in the plains of Marvdasht and Arsanjan (Rosenberg 1988; Ikeda 1979; Ghasidian 2014). These plains are geographically connected to each other, although located in different elevations (Heydari-Guran 2014), and are 150 and 200 km crow flies far from the Dasht-e Rostam-Basht region. We hypothesize that the hunter gatherers of this part of the southern Zagros probably during winter lived in the Dasht-e Rostam-Basht region and moved to the high elevated regions like Marvdasht and Arsanjan intermountain plains during dry season. The strong seasonality in the Zagros mountains caused the movements of the animals from lower elevated areas to higher and vice versa throughout the year. Dasht-e Rostam-Basht as a part of the southern Zagros, has high amount of rainfall during winter has been served as an ideal grazing land attracted medium- and large-sized games, such as cattle, deer , onager, goat , sheep and gazelle (Heydari-Guran 2014, p. 140). Obviously, these traits attracted the early modern humans as well. During this same time of the year, both vegetation and game were easily exploitable (Heydari-Guran 2014). As the game would pass through the valleys of the Dasht-e Rostam-Basht region, the hunter-gatherers would utilize the shelter sites in the region in order to obtain profitable vantage points of the migrating game below in the valleys. Pursuing game caused the high intra-regional migration. A consequence of heightened mobility is that the hunter-gatherers needed to limit their lithic assemblage to the small-sized lithics in order to increase the overall transport capacity. Among highly mobile groups, the tools assume a greater range of uses: they are less specialized and more practical and multi-functional (Shott 1986). Although the region contains two rich raw material sources of Fahliyani and Khanahmadi, still the lithic reduction occurred intensively on both raw material types among Ghār-e Boof and other UP assemblages from the region. This reduction intensity is considered as an implication of more active mobile groups (Blades 2001). Different retouch patterns on bladelets provided several possibilities for maximizing the use of these tools for different tasks also in the form of hafting and composite tools among these tool types for maximizing their use-life. In most cases, the cores were highly reduced for bladelet production: they provided bladelets until the volume of the core was exhausted. Using other blanks for producing expedient tools can also be considered as a point of intensity in tool production despite the locally available raw material. These typological characteristics indicate the high flexibility among the tools, showing the range of applications (Shott 1986).

Based on the environmental characteristics of the Dasht-e Rostam-Basht region including topography, strong seasonality and effective temperature , the hunter-gatherers were highly mobile (Heydari-Guran 2014, p. 140). Applying this to raw material procurement and reduction, we see a restricted set of local raw material resources as well as special technological sets identifying the inhabitants of Dasht-e Rostam-Basht region in a closed social network. This issue indicates the minimum exchange of raw material and knapping experience between the hunter-gatherers of the Dasht-e Rostam-Basht region and the other UP populations in other parts of the Zagros Mountains of Iran . According to OMTSLU model, the adoption of lamellar technology as main product in the Rostamian cultural group in this region is a response to the issue of minimization of the costs associated with raw material procurement and transport for the seasonal residential moves of the residents of the region to following migratory prey. It proves that the Rostamian techno-complex is founded basically on the economic issues and the need to create a balance between the quality of the available raw material and the lithic reduction technology for more effective use in exploitation of subsistence resources and the highly mobile nature of their lives. Therefore, the lithic assemblages here are considered as strong cultural remarks for the UP inhabitants of the region. On the whole Dasht-e Rostam-Basht region , there is a great emphasizing on opportunistic use of the local raw material as decreasing time and energy costs . Instead of using other non-local raw materials, hunter gatherers of the Dasht-e Rostam-Basht region were keener to adapt their knapping technique with available resources.

References

Andrefsky WJ (1998) Lithics, macroscopic approaches to analysis. Cambridge University Press, Cambridge

Baumler MF, Speth JD (1993) A Middle Paleolithic assemblage from Kunji cave, Iran. In: Olszewski D, Dibble H (eds) The Paleolithic prehistory of the Zagros-Taurus. The University Museum, University of Pennsylvania, Philadelphia, pp 1–73

Becerra-Valdivia L,Douka K, Comeskey D, Bazgir B, Conard NJ, Marean CW, Ollé A, Otte M,Tumung L, Zeid Mi, Higham TFG, (2017) Chronometric investigations of the Middle to Upper Paleolithic transition in the Zagros Mountains using AMS radiocarbon dating and Bayesian age modelling. J Hum Evol 109:57–69

Bergman CA (2003) Twisted débitage and the Levantine Aurignacian problem. In: Goring-Morris AN, Belfer-Cohen A (eds) More than meets the eyes, studies on Upper Paleolithic diversity in the Near East. Oxbow books, Oxford, pp 185–195

Biglari F (2007) Approvisionnement et utilisation des matières premières au Paléolithique moyen dans la plaine de Kermanshah (Iran): le cas de la Grotte Do-Ashkaft. In: Moncel MH, Moigne A, Arzarello M, Peretto C (eds) Aires ‘approvisionnement en matières premières et aires d’approvisionnement en ressources alimentaires Approche intégrée des comportements, Workshop 23, XV Congrès UISPP, Lisbonne, 5. BAR international series 1725. Oxford University, Oxford, pp 227–239

Binford LR (1979) Organization and formation processes: looking at curated technologies. J Anthropol Res 35:255–273

Blades BS (2001) Aurignacian lithic economy, ecological perspectives from southwestern France. Kluwer Academic/Plenum Publishers, New York

Brantingham PJ (2003) A neutral model of stone raw material procurement. Am Antiq 68(3):487–509

Conard NJ, Ghasidian E, Heydari S, Zeidee M (2006) Report on the 2005 survey of the Tübingen-Iranian Stone Age Research Project in the provinces of Esfahan, Fars and Kohgiluyeh-Boyerahmad. In: Azarnoush M (ed) Archaeological reports 5. The Iranian Center for Archaeological Research, Tehran, pp 9–34

Conard NJ, Ghasidian E, Heydari S, Naderi R, Zeidee M (2007a) The 2006 season of the Tübingen-Iranian Stone Age Research Project in the provinces of Fars and Markazi. In: Fazeli H (ed) 9th annual report of archaeological organisation. ICAR. Iranian Center for Archaeological Research, Tehran, pp 43–67

Conard NJ, Ghasidian E, Heydari-Guran S, Naderi R, Zeidee M (2007b) The 2007 season of the Tübingen-Iranian Stone Age Research Project in Dasht-e Rostam, Fars Province. Unpublished field report. Iranian Center for Archaeological Research, Tehran

Dibble HL (1984) The Mousterian industry from Bisitun Cave (Iran). Paléorient 10(2):23–34

Féblot-Augustins J (1997) Middle and Upper Paleolithic raw material transfers in western and Central Europe: assessing the pace of change. J Middle Atlantic Archaeol 13:57–90

Fisher LE, Eriksen BV (2002) Lithic raw material economy in late glacial and early postglacial western Europe, introduction. In: Fisher LE, Eriksen BV (eds) Lithic raw material economy in late glacial and early postglacial western Europe. BAR international series 1093. Archeopress, Oxford, pp 1–6

Geneste JM (1989) Economie des resources lithiques dans Mousterien du sud-ouest de la France. In: Patou M, Freeman LG (eds) L’Homme de Néandertal 6, la subsistance. ERAUL33. Université de Liège, Liège, pp 75–97

Ghasidian E (2012a) The Rostamian tradition and the Upper Palaeolithic of the Zagros Mountains. In: Hasanzadeh Y, Miri S (eds) Eighty years of Iranian archaeology. Nashr-e Pazineh and National Museum of Iran, Tehran, pp 59–78 (In Persian)

Ghasidian E (2012b) The Upper Palaeolithic of Iran and its place among the South-western Asia. In: Fahimi H, Alizadeh K (eds) Namvarnameh, papers in honor of Masoud Azarnoush. Nashr-e Iran Negar, Tehran, pp 129–141 (In Persian)

Ghasidian E (2014) The Early Upper Paleolithic at Ghār-e Boof Cave; a reconstruction of cultural tradition in the southern Zagros Mountains of Iran. Kerns Verlag, Tübingen

Ghasidian E, Heydari-Guran S (2012) Report on the 2009 survey on the caves and rockshelters of Eslamabad, Sar Pol Zahab and Qasr-e Shirin; Kermanshah district. Iranian Cultural Heritage and Tourism Organization in Kermanshah, Kermanshah (In Persian)

Ghasidian E, Azadi A, Heydari S, Conard NJ (2009) Late Paleolithic cultural traditions in the Basht Region of the Southern Zagros of Iran. In: Otte M, Biglari F, Jaubert J (eds) Iran Paleolithic/Le Paléolithique d’Iran. Proceedings of the XV World Congress UISPP, Lisbonne, 4–9 Sept 06. BAR international series 1968. Archaeopress, Oxford, pp 125–140

Ghasidian E, Bretzke K, Conard NJ (2017) Excavations at Ghār-e Boof in the Fars Province of Iran and its bearing on models for the evolution of the Upper Palaeolithic in the Zagros Mountains. J Anthropol Archaeol 47:33–49

Heydari S (2004) Rohmaterialvorkommen für Stein in Iran Einige Fallstudien. In: Stöllner T, Slotta R, Vatandoust A (eds) Persiens antike Pracht. Bergbau Museum, Bochum, pp 124–129

Heydari S, Azadi A, Ghasidian E (2004) Paleolithic survey in Southwestern Zagros, Basht Valley. Unpublished manuscript. Iranian Center for Archaeological research, Tehran (in Parsi)

Heydari-Guran S (2014) Paleolithic landscapes of Iran. BAR international series 2586. BAR Publishing, Oxford

Heydari-Guran S (2015) Tracking upper Pleistocene human dispersals into the Iranian Plateau: a geoarchaeological model. In: Sanz N (ed) Human origin sites and the world heritage convention in Eurasia. HEADS 4, vol 1. UNESCO publication, Mexico, pp 40–53

Heydari-Guran S, Ghasidian E (2004) Geoarchaeological research in Takht-e Soleyman, travertine context according to new archaeological findings of the late Pleistocene. In: Azarnoush M (ed) Second congress of archaeology of north-west; Urmia. ICAR, Tehran, pp 27–44 (In Persian)

Heydari-Guran S, Ghasidian E (2012) Report on the 2009 survey on the caves and rockshelters of Kermanshah, Dalahoo and Gilan-e Gharb; Kermanshah district. Iranian Cultural Heritage and Tourism Organization in Kermanshah, Kermanshah (In Persian)

Hole F, Flannery K (1967) The prehistory of southwestern Iran: a preliminary report. Proc Prehist Soc 33:147–206

Ikeda J (1979) Preliminary report of an archaeological survey in Arsanjan area, Fars Province, Iran, 1977. Kyoto University, Kyoto

Kuhn SL (1995) Mousterian lithic technology; an ecological perspective. Princeton University Press, Princeton

Miller R (1997) Variability in lithic assemblages across space: differential responses to raw material context. Notae Praehistoricae 17:53–62

Olszewski DI (1993) The Late Baradostian occupation at Warwasi rockshelter, Iran. In: Olszewski D, Dibble H (eds) The Paleolithic prehistory of the Zagros-Taurus. The University Museum, University of Pennsylvania, Philadelphia, pp 186–206

Olszewski DI, Dibble HL (1994) The Zagros Aurignacian. Curr Anthropol 35(1):68–75

Olszewski DI, Dibble HL (2006) To be or not to be Aurignacian: the Zagros Upper Paleolithic. In: Bar-Yosef O, Zilhão J (eds) Towards a definition of the Aurignacian Proceedings of the Symposium held in Lisbon, Portugal, June 25–30, 2002. Instituto Português de Arqueologia Lisboa, Lisbon, pp 355–373

Otte M, Biglari F, Flas D, Shidrang S, Zwyns N, Mashkour M, Naderi R, Mohaseb A, Hashemi N, Darvish J, Radu V (2007) The Aurignacian in the Zagros region: new research at Yafteh Cave, Lorestan, Iran. Antiquity 81:82–96

Otte M, Shidrang S, Flass D (2012) The Aurignacian of the Yafteh Cave and its context (2005-2008 excavations). ERAUL 132. Université de Liège, Liège

Rosenberg M (1988) Paleolithic settlement pattern in the Marv Dasht, Fars Province, Iran. Unpublished Ph.D. dissertation. University of Pennsylvania

Shidrang S (2015) The early Upper Paleolithic of Zagros: Techno-typological assessment of three Baradostian lithic assemblages from Khar Cave (Ghar-e Khar), Yafteh Cave and Pa-Sangar Rockshelter in the Central Zagros, Iran. Unpublished Ph.D. dissertation. Université de Bordeaux

Shott M (1986) Technological organization and settlement mobility: an ethnographic examination. J Anthropol Res 42(1):15–51

Solecki RS (1963) Prehistory in Shanidar Valley northern Iraq. Science 139(1551):179–193

Acknowledgement

The authors are grateful to the university of Tübingen and the Iranian Centre for Archaeological Research. Special thanks go to profs. Nishiaki and Akazawa for making this publication possible and the anonymous reviewers of this paper.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Ghasidian, E., Heydari-Guran, S. (2018). Upper Palaeolithic Raw Material Economy in the Southern Zagros Mountains of Iran. In: Nishiaki, Y., Akazawa, T. (eds) The Middle and Upper Paleolithic Archeology of the Levant and Beyond. Replacement of Neanderthals by Modern Humans Series. Springer, Singapore. https://doi.org/10.1007/978-981-10-6826-3_11

Download citation

DOI: https://doi.org/10.1007/978-981-10-6826-3_11

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-6825-6

Online ISBN: 978-981-10-6826-3

eBook Packages: Social SciencesSocial Sciences (R0)