Abstract

Like most geotechnical materials, frozen clay is a kind of multiphase particulate composite, which makes the mechanical properties and behaviors show great uncertainty and randomness, for that reason, it is more rational to investigate constitutive relationship of frozen soil using a probabilistic approach rather than a deterministic approach. This research cites previous uniaxial experimental data and theoretical results of two kinds of permafrost for the three temperature conditions. Based on Mohr-Coulomb failure criterion of geotechnical materials and rock damage model, a new statistical damage constitutive model considering the effect of damage threshold is introduced. Finally, through a series of fitting analysis and compared with previous models, it turns out that the new model proposed by this paper can be better close to the test results and reflect the characteristics of deformation for both the warm frozen clay and warm ice-rich frozen clay. Particularly in the elastic stage and the post-peak stage, the experimental and theoretical curves are much closer.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Frozen clay naturally formed in the cold region such as Tibetan, Greenland and Northern Canada, which refers to all kinds of rocks and soils contains ice below 0 °C and contains at least the following components: soil, ice, liquids, and gases. As is well known, the mechanical properties of most of the geotechnical materials and artificial composites change very little by the temperature. But, the frozen clay discussed in this paper differs from other similar materials, because of the different mechanical properties between ice and liquid and they convert to each other easily with the temperature changes (Ladanyi 2004). Many important projects are being built in such environment, for example, the Qinghai-Tibetan Railway, almost half of which is built on warm frozen permafrost (Cheng 2003). Here, ‘warm frozen permafrost ‘ indicates that the temperature of ground is a little high, the range is about from 0 to −1.5 °C yearly. ‘ice-rich’ means that the ice content is a little high, it is about 25% or more. Due to the need of economic construction, more and more building project will be built in cold area. Therefore, the engineering mechanical properties of frozen clay causes many researchers’ attention, and some experiments were taken (Ladanyi 2004).

As the melting point of ice is 0 °C, it make the production of frozen soil samples very difficult. But, there still exist some successful experiments on this subject. E.g, by field experiment, Ma discovered that a small pressure applied on warm ice-rich frozen soil would result in huge deformation (Ma 2006), the explanation of this phenomenon can also explain the major reason of uneven subsidence setting and lots of fissures along the roadbed of the QTR for the past decade. Besides, the relationship between strengths and water contents is also studied, the compressive strength of this kind of clay decrease linearly with the temperature increase. As a matter of fact, there are many defects randomly distributed in these samples of water-bearing clay. Any deterministic approach may be improper to be adopt in the research of constitutive relationships of them. In the study of Lai et al. (Lai 2008), a mass of uniaxial tests were taken, at three temperatures. Large numbers of stress-strain curves and experiment data were obtained. Then, they introduced the statistical theory and continuous damage theory into the research. Three distribution functions were substituted into the constitutive model to fit the experiment data. After comparison, this model proved to be well in describing the whole stress-strain process, and the Weibull distribution was best in three distribution functions. Li, et al. put forward an optimized model (Li 2009), which was first introduced by Krajcinovic et al. (Krajcinovic and Silva 2012), which regarded the micro-element strength as stochastic variable. In their study, Failure criterions are used to decide if the micro-element is damaged. It turned out that Li’s theory results is more suitable to the fit the test data than Lai’s. But in their models, damage produced as soon as load began to increase. Both of them did not take the linear elastic stage of deformation into account. Li, et al. introduced the damage threshold for the first time when they study the stress-strain curves of rock which has not been used in soil, results better than previous research were obtained (Li 2012). In this study on frozen clay, the influences of soil damage threshold is also taken into account. A new measurement method more suitable to the micro-element strength of soil is established. Through further research, this research aimed at reflecting the linear elastic deformation characteristics of warm frozen soil in the low stress levels. Results shows that the new model is closer to the test results than models of by Lai et al. and Li et al. (Lai 2008; Li 2009).

2 The Establishment of Statistical Damage Constituted Model

In this paper, based on the results of Lai et al. and Li et al., a new model is induced by considering the damage threshold (Lai 2008; Li 2009).

At present, the statistical damage theory has been successfully applied to the simulation of rock and soil deformation process, one of the key is to establishment of damage model. In accordance with the strain equivalence assumption of Lemaitre (Lemaitre and Chaboche 1970), the stress-strain relationship can be written as:

The above expression can also be written as:

Where \( \sigma_{i} \) is the macro nominal positive stress; \( \sigma_{i}^{{\prime }} \) is microscopic stress on undamaged elements or effective normal stress;\( E^{{\prime }} \) and \( E \) denote the macro nominal elastic tensor and undamaged part; \( D \) is the damage factor, its definition is:

where \( N \) denotes all element, and \( N_{t} \) denotes the number of damaged element.

Equation (2) can also be written as the following form for the uniaxial compression case:

2.1 The Change Rule of the Damage Factor

For the purpose of getting the better stress-strain model of warm frozen clay (WFC, frozen content below 25% in permafrost) and warm ice-rich frozen clay (WIRFC, ice content of more than 25% of frozen soil), it is necessary to discuss the change rule of rock damage variable based on the experimental data, so the value of damage factor can be understand. First of all, Eq. (2) can be transformed in the form of the expression below:

Then, substitute the experiment data given by previous experiment of Lai et al. into Eq. (5). So it is easy to calculate the corresponding damage factor \( D \) with any mathematical software. Thus, the \( D - \varepsilon_{1} \) curves of different specimens can be plot, it can be seen from Fig. 1 that:

-

(1)

When the axial deformation is small, the damage factor changes in the lack of regularity, sometimes \( D \) is less than 0, this is obviously not in the reasonable value range (\( 0 \ll D \ll 1 \)). When the deformation is quite small, the specimen is in a linear elastic state and doesn’t produce damage. In this stage, \( D \) should be constant to 0. This suggests that the effect of damage threshold has very important practical significance.

-

(2)

Followed by deformation increases, the damage factor or stress levels increase from 0 to nearly 1. Because when the deformation or stress exceeds a certain value, the material begins to yield to produce damage, and increases with deformation or stress levels, the damage degree of WFC increase either.

-

(3)

For specimens under different temperature, the damage threshold is also different, and different ice and water content has also big influence. Of course, these difference nature is caused by the role of water and ice, besides, temperature is an important external cause.

In a word, damage threshold is exist here. Before the threshold (i.e. the linear elastic phase), no damage is produced with deformation, the damage does not begin to produce until the threshold, and it is closely related to temperature. Hence, the new damage evolution model of WFC must be able to reflect the above-mentioned damage evolution rules and characteristics.

2.2 The Establishment of Model Considering the Effect of Damage Threshold

There are different ways to establish the damage evolution model, among them the statistical theory is a relatively successful method, and the key lies in the reasonable measurement of micro-element strength. Lai et al. (Lai 2008) proposed the measurement of micro-element strength by axial strain, good results have been achieved. However, the micro-element strength of soil is not simply determined by the deformation size of a certain direction, but rather with the stress state. Li et al. adopt Mohr - Coulomb failure criterion to describe the micro-element strength (Li 2009), which is able to reflect the effect of stress state, and is more reasonable. The Mohr-Coulomb failure criterion is;

where \( {\text{c}}_{\text{f}} \) and \( {\upvarphi }_{\text{f}} \) denotes the cohesion and internal friction angle corresponding to the yield stress. ‘\( F^{{{\prime \prime }}} \)’ is a more rational choice to express the microcosmic element strength than \( \varepsilon_{1} \), but still flawed. Equation (6) indicates that the damage begins to occur at the moment of loading. In fact, the damage of WFC is not the case, it begins happen only when the stress reaches a certain level. For this reason, a definition of \( {\text{F}} \) is proposed in this paper:

where \( k_{0}^{{\prime }} \) means the threshold of a sample begins to produce damage.

Compare Eq. (6) with Eq. (7), it indicates that an initial constant must be deducted by ‘\( F^{{\prime }} \)’. The damage does not start to produce until \( F^{{\prime }} > 0 \). When \( F^{{\prime }} \le 0 \), material is in the linear elastic deformation stage, and the damage variable is 0. The new definition of \( F \) not only reflects the damage threshold problem, but also gives a reasonable point for the starting point of damage. For the convenience of calculation, both sides of Eq. (7) are divide by ‘\( 1 - \sin \varphi \)’. The final soil failure strength is obtained.

where:\( \alpha = \frac{{1 + \sin \varphi_{f} }}{{1 - \sin \varphi_{f} }} \) , \( k_{0} { = }k_{0}^{{\prime }} /(1 - \sin \varphi ) \) is constant.

The following equations are obtained by simultaneous Eqs. (2) and (8):

Assuming that \( F \) obeys Weibull distribution, the new model is established:

where \( F_{0} \) and \( m \) are both unknown parameters.

Substituting Eq. (10) into (2), we have:

Equation (11) represents the new constitutive model under triaxial loading condition. In the case of uniaxial loading, Eq. (11) can be written as:

2.3 The Parameter Determination Method

Determination of parameters (\( E \), \( F_{0} \), \( m \) and \( k_{0} \)) is one of the critical process to obtain complete model. There exists two main methods. Below is the regression method to determine these parameters by the stress-strain curves of tests.

-

(1)

For the determination of \( E \), the linear regression method is used, based on the data on the elastic stage of tests. This step is relatively simple to operate, and the calculation process is omitted for space limitation.

-

(2)

Substitute \( E \), \( \sigma_{1} \), \( \sigma_{3} \) and \( \varepsilon_{1} \) into Eq. (5), the damage variable \( D \) is obtained. when \( D = 0 \) and at the moment begins to increase (\( D \) value of the inflection point), substitute the corresponding strain \( \varepsilon_{1,D = 0} \) and stress \( \sigma_{1,D = 0} \), \( \sigma_{3} \) into Eq. (9), the solution of \( k_{0} \) is as follows:

$$ k_{0} = \frac{{E\varepsilon_{1,D = 0} (\sigma_{1,D = 0} - \alpha \sigma_{3} )}}{{\sigma_{1,D = 0} - 2\mu \sigma_{3} }} $$(13)where \( \upvarepsilon_{{1,{\text{D}} = 0}} \) and \( \upsigma_{{1,{\text{D}} = 0}} \) are the corresponding strain and stress at the inflection point of \( D \).

-

(3)

Using the nonlinear regression method, the experiment data corresponding to \( D > 0 \) are fitted by the first formula of Eq. (11) to obtain \( F_{0} \) and \( m \).

Through the above analysis, the model parameters \( E \), \( F_{0} \), \( m \) and \( k_{0} \) are determined.

3 Case Analysis and Discussion

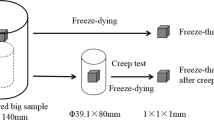

This paper cites the experimental data of Lai et al. (Lai 2008), In their study, two groups of specimens (as displayed in Fig. 1 (a, b), one group is WFC, the other one is WIRFC) were made from clay and different amount of water, respectively 17.6% and 30.0% of total mass, which was randomly distributed in the specimens. In three different conditions (the temperature were, respectively −0.5 °C, −1.0 °C and − 2.0 °C), 50 samples for each group were prepared for uniaxial compression test by a MTS low temperature testing machine. Detailed experimental information can be obtained by consulting their paper.

Based on the above experiments data, the parameters \( E \), \( F_{0} \), m and \( k_{0} \) are got through numerical calculation. Substitute these parameters in to Eqs. (11) or (12), so the new model considering the damage threshold for specimen under each condition is able to be obtained. To prove consistency and exactness of the new model of this study, this section select 12 representative test curves to be compared to the new model and previous models used in frozen clays.

3.1 Analysis for WFC

Figures 3, 4 and 5 show the test data at three different temperature. After comparison through numerical analysis, the new model shows a big advantage, especially in the elastic stage, the experimental and new theoretical curves are much closed. At the peak of the curves, the new model does not perform as well as the original model, but errors are in the acceptable range. In the stage after the peak, the new model is much better, and is significantly closer to the experimental data. Overall, the new model considering damage threshold is a finer choice to describe the constitutive model of warm frozen clay than other original theories. Moreover, we also discover that for warm frozen clay, the higher the temperature, the smaller the elastic modulus and strength, which has been found by some previous researchers (Haynes 1978). The parameters of three models are listed in Table 1.

3.2 Analysis for WIRFC

Figures 6, 7 and 8 shows the experimental and theoretical constitutive curves at three different temperature. We can see that each model is able to describe constitutive relationship of them under uniaxial condition, reason for that is the damage threshold is zero in these six cases. However, Figs. 7(b) and 8(a, b) demonstrates that the test curves is little different from those curves of original models, the new one can be much more closed to the test data on the curve. All these curves illustrate that the constitutive model of this kind of clay is ideal elastic-plastic, we can also come to this conclusion from Fig. 2(b). In general, the new model is a finer choice to present constitutive model of WIRFC than other original theories, although the advantage is not obvious. The parameters of the three models are listed in Table 1.

Considering the threshold value for the rock damage problem is more realistic than the method without considering the threshold value, because when the load is very small, the specimen is only elastically deformed without damage. Only when the load reaches a certain degree, the crack begins to develop and develop. Through the above analysis, it is not difficult to find that the model of this paper is not only realistic in the damage mechanism, but also fit the experimental data better for both WFC and WIRFC.

4 Conclusion and Discussions

Due to the complex structures and components of WFC and WIRFC, their mechanical properties and behavior show great undeterminancy, the probability method is more logical to explore the constitutive relationship of them. This paper establishes a new model considering effect of damage threshold. In order to test the correctness of this new model, a mass of test data of different condition for the two kinds of frozen clay obtained by previous researchers and two theoretical models deduced by previous scholar are cited (Lai 2008; Li 2009). Firstly, the thresholds were calculated by analyzing the experimental data, and then through the non-linear fitting method, we can see that the theoretical curve agrees well with the experimental data after taking the damage threshold into consideration. After comparison with the previous studies, the new model of this paper can better fit the experimental data. Particularly in the elastic stage and post-peak stage, the experimental and theoretical curves are much closed. Besides, the model established in this paper can be applied to triaxial condition theoretically, but further experiments are needed to support it.

More or less, the statistical distribution function has its limitation, it can’t fit the post-yield stage of experiment curves well. The new model presented in this study is not able to performance the constitutive behavior of the frozen clay at this stage precisely either and can only be closer to the experiment value numerically, the results shows better than previous models. It still deserves further study to explain the post-yield mechanical properties of this clay. In summary, despite the shortcomings, results shows that the model proposed by this paper is more appropriate for warm frozen soil.

References

Cheng, G.D.: Construction of Qinghai-Tibetan railway with cooled roadbed. China Railway Sci. 24(3), 1–4 (2003). doi:10.3321/j.issn:1001-4632.2003.03.001

Haynes, F.D.: Strength and deformation of frozen silt. In: Proceedings 3rd International Conference on Permafrost, Edmonton, Alberta, vol. 1, pp. 656–716. National Research Council of Canada, Ottawa (1978)

Krajcinovic, D., Silva, M.A.G.: Statistical aspects of the continuous damage theory. Int. J. Solids Struct. 18(7), 551–562 (2012). doi:10.1016/0020-7683(82)90039-7

Ladanyi, B., Andersland, O.B.: Frozen Ground Engineering, 2nd edn. ASCE, pp. 656–716 (2004)

Lai, Y.M., Li, S.Y., Qi, J.L., Chang, X.X.: Strength distribution of warm frozen clay and its stochastic damage constitutive model. Cold Reg. Sci. Technol. 53(2), 200–215 (2008). doi:10.1016/j.coldregions.2007.11.001

Lemaitre, J., Chaboche, J.L.: Mechanics of Solid Materials. Cambridge University Press, London (1970)

Li, S.Y., Lai, Y.M., Zhang, S.J.: An improved statistical damage constitutive model for warm frozen clay based on Mohr-Coulomb criterion. Cold Reg. Sci. Technol. 57(2), 154–159 (2009). doi:10.1016/j.coldregions.2009.02.010

Li, X., Cao, W.G., Su, Y.H.: A statistical damage constitutive model for softening behavior of rocks. Eng. Geol. 143–144(2012), 1–17 (2012). doi:10.1016/j.enggeo.2012.05.005

Ma, X.J.: Research on strength and creep of warm and ice-rich frozen soil (in Chinese), A Dissertation Submitted to Graduate School of Chinese Academy of Sciences for the Degree of Master, Lanzhou (2006)

Acknowledgements

The authors would like to thank Natural Science Foundation of Jiangsu Province of China (BK20141067) for their financial support.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Nature Singapore Pte Ltd. and Zhejiang University Press

About this paper

Cite this paper

Xu, H., Geng, H., Chen, X., Bai, Z. (2018). Statistical Damage Constitutive Model for Warm Frozen Clay Considering Effect of Damage Threshold. In: Chen, R., Zheng, G., Ou, C. (eds) Proceedings of the 2nd International Symposium on Asia Urban GeoEngineering. Springer Series in Geomechanics and Geoengineering. Springer, Singapore. https://doi.org/10.1007/978-981-10-6632-0_7

Download citation

DOI: https://doi.org/10.1007/978-981-10-6632-0_7

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-6631-3

Online ISBN: 978-981-10-6632-0

eBook Packages: EngineeringEngineering (R0)