Abstract

Pyrolysis is the foremost thermal conversion process that can be successfully used to transform biomaterials into a value-added product. The estimated biodegradable portion is prominent and denotes as 60% from total waste generation in Asian developing countries. There have been several studies on exploring the pyrolysis of complex organic fraction of municipal solid waste (MSW) streams as a sustainable MSW management technique. The objective of this research was to evaluate physicochemical characteristics of MSW biochar (MSW-BC) produced from organic MSW to observe its potential for landfill contaminant removal with case studies from Sri Lanka. Biochar was pyrolyzed from the MSW in an onsite pyrolyzer. For physicochemical properties of biochar, pH, point of zero charge, electrical conductivity, proximate analysis, ultimate analysis, heavy metal composition, bioavailable heavy metal composition and BET surface area were acquired. In addition, surface functional groups and structural identification were determined by FTIR analysis and scanning electron microscopy (SEM) analysis, respectively. Adsorption capacities for the pollutants (benzene and toluene) were examined by batch sorption experiments. Furthermore, sorption isotherms were fitted using non-linear models for better understanding of the sorption capacities of the materials. Ultimate analysis data suggested high-temperature pyrolysis of MSW. Further, low values for both H/C and polarity index depict the strongly carbonized and highly aromatic structure in BC. Additionally, FTIR suggested a loss of labile, aliphatic compounds and functional groups during pyrolysis and the formation of more recalcitrant, aromatic constituents, whereas BET and SEM data revealed a well-developed porous structure and surface properties, which indicates MSW-BC to be a potential sorbent. Further, the reported total and bioavailable heavy metal content was low in MSW-BC; hence, it can be easily mixed with compost and used as a fertilizer. At the same time, MSW-BC will potentially be used to remediate heavy metals in the landfill leachate. Therefore, MSW-BC shows high potential to be used as a material to remediate contaminants simultaneously that minimizes MSW volume. Thus, conversion of MSW to BC and chemical and thermal modification of MSW-BC would allow effective engineering to optimize their properties as a potential material in landfill covers and permeable reactive barriers and integrate in leachate treatment techniques.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Most of the developing countries utilize landfills as final disposal technique since landfills are considered as the simplest, cheapest and most cost-effective method of disposing of waste (Barrett and Lawlor 1995). However, the improper solid waste management (SWM) practices generate severe threats on the environment. Therefore, current interventions are aiming to use different technological application to produce sustainable value-added products from waste. Pyrolysis can be considered as an alternative to the conventional SWM methods such as incineration, landfills, bioreactors, aerobic/anaerobic digestion, open-air burning and composting (Serio et al. 2001), which can also produce value-added products from waste. Pyrolysis process has the capability to generate large number of components such as char, tar (oil) and gas during the thermal degradation process (Fagbemi et al. 2001),while reducing the amount of solid waste present (Onyango 2014; Malkow 2004). Literature revealed that the primary objective of the pyrolysis process is the transformation of waste biomass to physically and biologically stable components such as solids, liquids and gases (Roy 1988). The municipal solid waste biochar (MSW-BC) is such value-added product produced from MSW through pyrolysis process.

The temperature gradient, waste composition, catalyst involvement and activation agents are significant factors which influence physical and chemical properties of MSW-BC. Even though various pyrolysis methods are available, the slow pyrolysis is more effective for production of MSW-BC since the properties of MSW-BC that resulted from slow pyrolysis process are remarkable (Chen et al. 2014; Zornoza et al. 2016). The cellulosic portion of MSW tends to gain significant attention as an adsorbent (Bernardo et al. 2012; Sharypov et al. 2002). Thermo-gravimetric studies revealed that the properties of the final product are different based on the degradation pattern of different fibres (lignin, cellulose and hemicellulose), pyrolysis temperatures and nature of the raw material (Yang et al. 2007; Zhou et al. 2013). The properties of BC are closely related to the waste composition and its conditions. If the waste bulk is rich with paper-like materials, the ash content of the BC can be high, whereas plastics and industrial wastes derived BC consist of both toxic compounds and ash (Van Zwieten et al. 2010; Enders et al. 2012). Therefore, the BC produced from industrial wastes, polythene and plastic like compounds will be rich with toxic gases and xenobiotic compounds (i.e., benzene derivatives, polycyclic aromatic compounds). The elemental composition of the lignocelluloses in the BC is the portion that contributes to the efficient sorption process (Venderbosch and Prins 2010).

Therefore, this study discusses the characteristics of BC, transformed from organic material of MSW in the Gohagoda landfill site, Kandy, Sri Lanka, to understand the potential of waste to be reused and recycled and at the same time the potential determination for pollution remediation via a material for capping and leachate treatment.

2 Materials and Methodology

2.1 Biochar Production and Characterization

The segregated organic fraction of the MSW obtained from the dumpsite at Gohagoda, Kandy, Sri Lanka, has been used for producing MSW-BC. Pyrolysis was performed in batch reactor built in Gohagoda dumpsite under slow pyrolysis. The furnace temperature was controlled in 450 °C for pyrolysis reaction and the holding time was 30 min. Proximate, ultimate and heavy metal analysis was conducted (muffle furnace Nabertherm N17/HR, Germen, Vario MAX CN, elementar, Germany; Perkin elmer Optima 4300 DV ICP-OES, USA). At the same time, chemical and physical characterization including pH, Electrical conductivity (EC), Cation exchange capacity (CEC), and point of zero charge (pHzpc) and surface characteristics based on BET, FTIR, etc. have been conducted for MSW-BC.

2.2 Case Studies

Humic acids (HAs) are dissolved organic compounds (DOCs), and toluene and benzene are volatile organic compounds (VOCs) which cannot easily be removed by conventional landfill leachate treatment methods.

At first, the preselected amount of MSW-BC was added to each amber colour bottle. The solution pH was managed at the range of 2-9 by addition of either 0.1 M HCl or NaOH. Equilibrated concentration of each supernatant was passed through the 0.45 μm membranes. Then, samples were analysed for HA by using UV spectrophotometer (UV-160A Shimadzu) at 254 nm wavelength. For sorption experiments, the dosage selected was 0.5 g/L.

2.2.1 VOC Adsorption (Benzene and Toluene)

The batch sorption technique was employed for interaction identification on MSW-BC and VOCs. The sorbent dosages (1–10 g/L) were investigated and best suited 1 g/L combination was used for further analysis. For benzene and toluene as sorbate, different concentrations (30–300 μg/L) were investigated for isotherm experiments, whereas kinetics were evaluated at initial concentration of 50 μg/L for different time intervals (0.5, 1, 2, 4, 12, 18 and 24 h). Non-linear curve fitting was employed for mechanism determination. Quantitative analysis of benzene and toluene was performed using static headspace equipped gas chromatography-coupled mass spectrometer (Shimadzu GCMS 2010 ultra).

3 Results and Discussion

3.1 General Nature of MSW-BC

Table 1 shows the respective char yield and temperature programme of previous studies with MSW. The yield results can be supported to biomaterial composition where high amount of mass loss under the pyrolysis temperature of 450 °C. During pyrolysis process, the fixed-carbon content of MSW-BC is higher than that of sludge pyrolysis, and MSW shows effective char preparation (Chen et al. 2014). Similar characters of high amount of ash content readily available via pyrolysis in MSW as same as all other literature were observed due to processed biomaterials like paper waste. This ash composition helps to create alkaline nature that facilitate the metal removal ability of MSW-BC (Agrafioti et al. 2014).

3.2 Proximate Results

The thermal degradation resulted disappearances of functional groups which belong to cellulose and hemicelluloses and dehydrogenation of hydroxyl groups due to the higher temperature (Zhang et al. 2015). After the pyrolysis of fibres at high temperature, the results were 46.5% of high-degree fixed-carbon content and 15.6% of ash content (Sørum et al. 2001). The fixed carbon of 63% present indicates moderate pyrolysis temperature of MSW-BC which discloses the fixed aromatic formation during pyrolysis and helps to improve hydrophobicity and exhibit the organic adsorption (Jin et al. 2014; Agarwal et al. 2015). The present study shows 46% fixed-carbon content which depicts high-temperature pyrolysis which can easily be used for organic adsorption. Table 2 shows the proximate results of the MSW-BC from Gohagoda, Sri Lanka.

3.3 Ultimate and Elemental Results

The analytical results for the MSW-BC are presented in Table 2. Ultimate analysis demonstrates low O/C molar ratio of the char and that corroborates the high temperature resulted MSW-BC. Pyrolysis temperature on organic compound adsorption can be distinguished according to Bornemann et al. (2007), and it shows the high-temperature-derived BC favourable for organic compound adsorption. The value of (N + O)/C is closer to 0.2 and compatible on literature and may sorb considerable amount of nutrients like sugars (Zai-ming et al. 2013). Even though, still retain a significant proportion of the polar surfaces in BC. Therefore, non-polar surfaces absorb weakly polar substances, whereas polar groups enrich polar adsorption. However, polar substances in MSW-BC are able to associate with the soil colonization and microbial formation (Liu et al. 2015) and that helps to development of effective cover material amendment with BC (Sadasivam and Reddy 2015; Liu et al. 2015).

The concentration of total and available heavy metal on the MSW-BC and total heavy metal in municipal solid waste and sewage sludge BC is represented in Table 2. Compared to the other MSW-BCs, the amount of heavy metal content is very low in the present MSW-BC (Jin et al. 2014; Chen et al. 2014; Liu et al. 2014a). Higher toxic As and Cd are not detected in MSW-BC , and that condition is favourable for field-level application. Therefore, potential utilization of MSW-BC as sorbent can be implemented without any constraint on the environment.

3.4 pH, Electrical Conductivity and Potentiometric Titration

The electrical conductivity and pH of the MSW-BC are listed in Table 2. Higher pyrolytic temperature further implies the less functional groups specially in acidic groups such as carboxylic and phenolics. At the same time, increment of basic groups can be seen due to separation of alkali salts from organic fraction (Mukherjee et al. 2011). The pHzpc was found to be 6.7 for the MSW-BC. The pHzpc denotes where the MSW-BC pH is neutral. Beyond pH 6.7, the MSW-BC can be used for cationic sorption, while it suits for anion removal at high pH than 7. If the solution pH exceeds the pzc of char, the surface charge of the BC will be positive (Essandoh et al. 2015). Potentiometric titration window is shown in Fig. 1.

3.5 Surface Characterization

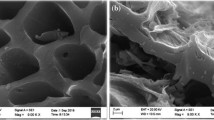

The surface properties of the BC are expressed in Table 3. Visualization of deep porous holes in MSW-BC became more prominent. The MSW-BC exhibits substantial porous structure development as well as void establishment (Li et al. 2015). MSW literature revealed that the higher surface is requirement for metal removal from MSW-BC which requires modification and activation. However, the present study exhibited higher surface area for MSW-BC without modification. Similar surface area for the medium temperature-generated BC was observed for azo dye removal from cellulosic MSW study (Agarwal et al. 2015). There was significant improvement of BET surface area (108.47 m2g−1) for derived MSW-BC. The FTIR spectra (Fig. 2) illustrated the appearance of MSW-BC surface functional groups with the aromatic cycles indicating the ability of a material which can perform surface complexation. Previous studies elaborated the involvement of surface functional groups for cationic metal ion adsorption that is an important mechanism for MSW-BC (Jin et al. 2014). The peaks at wave numbers 3442 and 1034 show the surface carbon structures; those structures consist of functional groups such as OH− and aromatic rings. Literature reveal that the MSW-BC have an ability to provide π electron and potentially bond heavy metals (Chen et al. 2014). Therefore, literature suggests the potential of MSW-BC in moderate temperature for adsorption of more organics due to carbonization as well as cations by functionality.

3.6 Case Studies

3.6.1 HA Adsorption

Although BC itself contributes to HA, still it has the potential of adsorbing more into its structure. Sorption capacities of the HA into BSW-BC were evaluated at different pHs, and it was observed that the adsorption was higher in acidic region while lower in alkaline region. The maximum sorption (40.36 mg/g) was observed at pH 5–6. Major functional groups in HA as carboxylic and phenolics may release the OH− at low pH facilitating hydrophobic adsorption with negatively charged MSW-BC surface. At high pH, these anionic species may dissociate and compete with aqueous OH− to occupy the active BC sites (Omri et al. 2014).

3.6.2 VOC Adsorption

For benzene and toluene, respectively, pH 9.0 and 8.3 were favourable for adsorption, whereas highest adsorption at 24 h reaction time on pH 9.0 and 8.3 was recorded as 85.4 and 87.0% (42.7, 43.5 μg/g), respectively, for benzene and toluene. Freundlich fitting could explain isotherm data with good accuracy for both benzene and toluene (R 2 = 0.955, 0.988). Besides, recorded maximum adsorption capacity was about 218.2 and 257.7 μg/g for benzene and toluene. Hence, a heterogeneous process involved with physisorption between sorbate molecule in aqueous media and sorbent surface can be suggested as the benzene and toluene removal mechanism.

4 Conclusions

The segregated cellulose fraction from MSW is rather effective for production of BC. Moreover, the MSW-BC properties seemed to be well fitted on pollution removal through different mechanisms such as ion exchange, complication and precipitation. Therefore, the production of BC from MSW through slow pyrolysis process is a sustainable approach for landfill improvement due to the net benefit towards greener environment through pollution removal.

By the case studies and literature, possible conclusions can be made for MSW-BC as a potential sorbent for the removal of HA, dye, heavy metals, pesticides and BTEX like benzene and toluene from the contaminated water sources. However, more research should be undertaken to understand the change in the environmental conditions on the desorption of pollutants. Hence, the MSW-BC can be considered as a value-added material from MSW which has a wide range of applications for environmental remediation. At the same time, MSW can be recycled and reused to remediate its own pollutants while reducing the volume of waste by producing MSW-BC.

References

Agarwal M, Tardio J, Mohan SV (2015) Pyrolysis biochar from cellulosic municipal solid waste as adsorbent for azo dye removal: equilibrium isotherms and kinetics analysis. Int J Environ Sci Dev 6:67

Agrafioti E, Kalderis D, Diamadopoulos E (2014) Arsenic and chromium removal from water using biochars derived from rice husk, organic solid wastes and sewage sludge. J Environ Manag 133:309–314

Ateş F, Miskolczi N, Borsodi N (2013) Comparison of real waste (MSW and MPW) pyrolysis in batch reactor over different catalysts. Part I: product yields, gas and pyrolysis oil properties. Bioresour Technol 133:443–454

Barrett A, Lawlor J (1995) The economics of solid waste management in Ireland, Economic and Social Research Institute (ESRI)

Bernardo M, Lapa N, Gonçalves M, Mendes B, Pinto F, Fonseca I, Lopes H (2012) Physico-chemical properties of chars obtained in the co-pyrolysis of waste mixtures. J Hazard Mater 219:196–202

Bornemann LC, Kookana RS, Welp G (2007) Differential sorption behaviour of aromatic hydrocarbons on charcoals prepared at different temperatures from grass and wood. Chemosphere 67:1033–1042

Buah W, Cunliffe A, Williams P (2007) Characterization of products from the pyrolysis of municipal solid waste. Process Saf Environ Prot 85:450–457

Chen T, Zhang Y, Wang H, Lu W, Zhou Z, Zhang Y, Ren L (2014) Influence of pyrolysis temperature on characteristics and heavy metal adsorptive performance of biochar derived from municipal sewage sludge. Bioresour Technol 164:47–54

Enders A, Hanley K, Whitman T, Joseph S, Lehmann J (2012) Characterization of biochars to evaluate recalcitrance and agronomic performance. Bioresour Technol 114:644–653

Essandoh M, Kunwar B, Pittman CU, Mohan D, Mlsna T (2015) Sorptive removal of salicylic acid and ibuprofen from aqueous solutions using pine wood fast pyrolysis biochar. Chem Eng J 265:219–227

Fagbemi L, Khezami L, Capart R (2001) Pyrolysis products from different biomasses: application to the thermal cracking of tar. Appl Energy 69:293–306

He M, Xiao B, Liu S, Hu Z, Guo X, Luo S, Yang F (2010) Syngas production from pyrolysis of municipal solid waste (MSW) with dolomite as downstream catalysts. J Anal Appl Pyrolysis 87:181–187

Jin H, Capareda S, Chang Z, Gao J, Xu Y, Zhang J (2014) Biochar pyrolytically produced from municipal solid wastes for aqueous as (V) removal: adsorption property and its improvement with KOH activation. Bioresour Technol 169:622–629

Kabir MJ, Chowdhury AA, Rasul MG (2015) Pyrolysis of municipal green waste: a modelling, simulation and experimental analysis. Energies 8:7522–7541

Li G, Shen B, Wang Y, Yue S, Xi Y, An M, Ren K (2015) Comparative study of element mercury removal by three bio-chars from various solid wastes. Fuel 145:189–195

Liu T, Liu B, Zhang W (2014a) Nutrients and heavy metals in biochar produced by sewage sludge pyrolysis: Its application in soil amendment. Polish J Environ Stud 23:271–276

Liu T, Liu B, Zhang W (2014b) Nutrients and heavy metals in biochar produced by sewage sludge pyrolysis: its application in soil amendment. Pol J Environ Stud 23:271–275

Liu G, Xie M, Zhang S (2015) Effect of organic fraction of municipal solid waste (OFMSW)-based biochar on organic carbon mineralization in a dry land soil. J Mater Cycles Waste Manag 1–10

Malkow T (2004) Novel and innovative pyrolysis and gasification technologies for energy efficient and environmentally sound MSW disposal. Waste Manag 24:53–79

Mukherjee A, Zimmerman A, Harris W (2011) Surface chemistry variations among a series of laboratory-produced biochars. Geoderma 163:247–255

Omri A, Benzina M, Trabelsi W, Ammar N (2014) Adsorptive removal of humic acid on activated carbon prepared from almond shell: approach for the treatment of industrial phosphoric acid solution. Desalin Water Treat 52:2241–2252

Onyango D (2014) Pyrolysis: an alternative technology for municipal solid waste management. Scientific conference proceedings

Phan AN, Ryu C, Sharifi VN, Swithenbank J (2008) Characterisation of slow pyrolysis products from segregated wastes for energy production. J Anal Appl Pyrolysis 81:65–71

Roy G (1988) Municipal solid waste recycle-an economic proposition for a developing nation

Sadasivam BY, Reddy KR (2015) Adsorption and transport of methane in landfill cover soil amended with waste-wood biochars. J Environ Manag 158:11–23

Serio MA, Kroo E, Bassilakis R, Wójtowicz MA, Suuberg EM (2001) A prototype pyrolyzer for solid waste resource recovery in space. SAE Technical Paper

Sharypov V, Marin N, Beregovtsova N, Baryshnikov S, Kuznetsov B, Cebolla V, Weber J (2002) Co-pyrolysis of wood biomass and synthetic polymer mixtures. Part I: influence of experimental conditions on the evolution of solids, liquids and gases. J Anal Appl Pyrolysis 64:15–28

Sørum L, Grønli MG, Hustad JE (2001) Pyrolysis characteristics and kinetics of municipal solid wastes. Fuel 80:1217–1227

Van Zwieten L, Kimber S, Morris S, Chan K, Downie A, Rust J, Joseph S, Cowie A (2010) Effects of biochar from slow pyrolysis of papermill waste on agronomic performance and soil fertility. Plant Soil 327:235–246

Velghe I, Carleer R, Yperman J, Schreurs S (2011) Study of the pyrolysis of municipal solid waste for the production of valuable products. J Anal Appl Pyrolysis 92:366–375

Venderbosch R, Prins W (2010) Fast pyrolysis technology development. Biofuels Bioprod Biorefin 4:178

Yang H, Yan R, Chen H, Lee DH, Zheng C (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86:1781–1788

Yuan H, Wang Y, Kobayashi N, Zhao D, Xing S (2015) Study of fuel properties of torrefied municipal solid waste. Energy Fuel 29:4976–4980

Zai-Ming C, Bao-Liang C, Dan-Dan Z (2013) Composition and sorption properties of rice-straw derived biochars. Acta Sci Circumst 33:9–19

Zhang J, Liu J, Liu R (2015) Effects of pyrolysis temperature and heating time on biochar obtained from the pyrolysis of straw and lignosulfonate. Bioresour Technology 176:288–291

Zhou H, Long Y, Meng A, Li Q, Zhang Y (2013) The pyrolysis simulation of five biomass species by hemi-cellulose, cellulose and lignin based on thermogravimetric curves. Thermochim Acta 566:36–43

Zornoza R, Moreno-Barriga F, Acosta J, Muñoz M, Faz A (2016) Stability, nutrient availability and hydrophobicity of biochars derived from manure, crop residues, and municipal solid waste for their use as soil amendments. Chemosphere 144:122–130

Acknowledgements

Equipment and financial supports from the JICA-JST SATREPS grant and NRC 15-24 are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Jayawardhana, Y., Kumarathilaka, P., Mayakaduwa, S., Weerasundara, L., Bandara, T., Vithanage, M. (2018). Characteristics of Municipal Solid Waste Biochar: Its Potential to be Used in Environmental Remediation. In: Ghosh, S. (eds) Utilization and Management of Bioresources. Springer, Singapore. https://doi.org/10.1007/978-981-10-5349-8_20

Download citation

DOI: https://doi.org/10.1007/978-981-10-5349-8_20

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-5348-1

Online ISBN: 978-981-10-5349-8

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)