Abstract

The presence of dark swirls or rings in luminescence image of a solar cell is usually caused by oxygen precipitate during fabrication of a solar cell. This is not desirable as it could cause a drop in efficiency of the cell. An application of gray level co-occurrence matrix (GLCM) is presented to detect such dark swirls or rings in both photoluminescence (PL) and electroluminescence (EL) images. It was found that the energy values calculated from a GLCM has a good separation between defective and non-defective images. A threshold was established based on the energy values and was then used to perform classification. Experiments have shown that this method provides a good result with minimal under-rejection and over-rejection rate for both PL and EL.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Since the advent of luminescence techniques such as photoluminescence (PL) [7] and electroluminescence (EL) [3], defects in crystalline silicon solar cells that were previously invisible to the naked eye can now be observed with the presence of certain distinct patterns in the captured image.

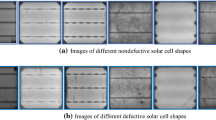

One such defect is the appearance of dark swirls or rings in PL and EL images of monocrystalline silicon solar cells as shown in Fig. 1. This phenomenon is caused by the formation of oxygen precipitation in a monocrystalline silicon wafer that was used to fabricate the solar cell [6]. Although oxygen is one of the main impurities in silicon and cannot be avoided during crystal growth [1], the formation of oxygen precipitates can be minimised by controlling the thermal treatment process during solar cell fabrication [2]. The presence of oxygen precipitates in solar cells is not desirable as it could cause a drop in efficiency [5].

Solar cell manufacturers are increasingly demanding automated machine vision systems in a production line to detect defects and the capability to automatically detect dark swirls or rings in luminescence images is not an exception. Haunschild et al. defined a specific circle to cover the largest extension of rings in their study and the presence of swirls or rings is defined by the ratio of the luminescence signal between the inside and outside of the circle [5]. However this approach will fail should the dark swirls or rings cover the entire solar cell or being too faint although it still can be identified by a human observer.

We have found that the swirls or rings can vary greatly in terms of size and gray level intensity as shown in Fig. 2. It is also difficult to define the edges of the swirls or rings as there are no clear boundaries between defective and non-defective areas. However, the presence of swirls or rings in both PL and EL images will create a distinct circular texture in contrast to the homogeneous nature of a non-defective solar cell. Texture analysis has not been used to classify this defect so far. Therefore, we propose to use the gray-level co-occurrence matrix (GLCM) [4] method in the attempt to distinguish defective and non-defective cells.

2 Methodology

2.1 Gray-Level Co-occurrence Matrix

Given that the texture of swirls or rings in PL and EL images is circular in nature, it is useful to use a statistical approach such as GLCM to provide information about the relative position of neighbouring pixels in an image. Haralick [4] proposed 14 statistical features that can be extracted from GLCM. The most relevant feature in the interest of dark swirls or rings in luminescence images was determined to be energy, also called the “uniformity” measure. Energy is calculated as follows:

where width is width of the GLCM, i and j are the horizontal and vertical pixel coordinates respectively while \(c_{ij}\) the matrix value in i and j coordinate. It should be noted that the energy value calculated in this study is the mean of the four different directions of GLCM at \(0^{\circ }\), \(90^{\circ }\), \(45^{\circ }\) and \(135^{\circ }\).

2.2 Energy Value Threshold

A set of 25 PL images of monocrystalline solar cells containing dark swirls or rings along with another set of 25 non-defective cells was studied. It was found that the cells containing dark swirls or rings will return a high energy value while non-defective cells will have a lower energy value. The details are summarised in Table 1.

It was discovered that there is a good separation between the energy values of defective and non-defective cells, therefore a threshold value T of 0.45000 which represents a value slightly below the lowest energy value for defective cells while still being much higher than the highest energy value of a non-defective cell can then be set. This threshold can then be used for classification as follows:

where a Boolean value of 1 is returned if the cell is defective and 0 if it’s non-defective.

3 Experimental Results

3.1 Photoluminescence Images

A dataset containing 100 PL images of known defective cells and another with 1500 PL images of known non-defective cells was tested against the algorithm. The result of this experiment is tabulated in Table 2.

This experiment has shown that by using the energy values calculated from a GLCM, the algorithm is capable of separating defective and non-defective samples with minimal under-rejection and over-rejection rates, even for dark swirls or rings that cover the entire cell.

As a comparison with previous methods that calculates the ratio of luminescence intensity inside and outside of a predefined circle; most defective cells within this sample set will be under-rejected as they contain dark swirls or rings that cover the entire cell.

Further investigation into the one particular cell that was under-rejected shows that the dark ring was atypically homogeneous in texture and therefore has a low energy value as shown in Fig. 3a. Meanwhile, over-rejected cells has shown that certain noises that could be present in a cell can cause the calculated energy level from a GLCM to increase beyond the threshold. An example of such a cell is shown in Fig. 3b. Nevertheless, the under-rejection and over-rejection rate suggests that the occurrences of such cells are relatively low.

3.2 Electroluminescence Images

The experiment was repeated with the same sample set but with EL images instead. However it should be noted that the threshold value T was adjusted slightly higher as EL images contain higher energy values for both defective and non-defective samples. Nevertheless, the ratio of average energy values for defective and non-defective samples still remains the same. The result of this experiment is tabulated in Table 3.

The results of the experiment were almost identical, with marginally more over-rejection. This experiment has shown that the proposed method also works in exactly the same way with EL images as well.

4 Conclusion

The results of this study shows that the energy value calculated from a GLCM can be effectively used to detect the presence of dark swirls or rings in both PL and EL images of a solar cell. There is a good separation of energy values between images of defective and non-defective cells and by using a threshold; they can be easily separated with minimal under-rejection and over-rejection.

References

Borghesi A, Pivac B, Sassella A, Stella A (1995) Oxygen precipitation in silicon. J Appl Phys 77(9)

Chen L, Yu X, Chen P, Wang P, Gu X, Lu J, Yang D (2011) Effect of oxygen precipitation on the performance of czochralski silicon solar cells. Sol Energy Mater Sol Cells 95(11):3148–3151

Fuyuki T, Kitiyanan A (2009) Photographic diagnosis of crystalline silicon solar cells utilizing electroluminescence. Appl Phys A 96(1):189–196

Haralick R, Shanmugam K, Dinstein I (1973) Textural features for image classification. Syst Man Cybern IEEE Trans SMC-3(6):610–621

Haunschild J, Reis IE, Geilker J, Rein S (2011) Detecting efficiency-limiting defects in czochralski-grown silicon wafers in solar cell production using photoluminescence imaging. Phys Status Solidi RRL 5(5–6):199–201

Liu P, Luo C, Chen L, Deng H, Zhou R, Ma Z, Zhang L, Deng L. (2015) The influencing factors and formation mechanism of the dark ring of monocrystal silicon cells. In: Semiconductor Technology International Conference (CSTIC), China. pp. 1–3

Trupke T, Bardos RA, Schubert MC, Warta W (2006) Photoluminescence imaging of silicon wafers. Appl Phys Lett 89(4):044107

Acknowledgments

This work has been supported by the Collaborative Research in Engineering, Science and Technology (CREST), grant 304/PELECT/6050264/C121.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer Science+Business Media Singapore

About this paper

Cite this paper

Teo, T.W., Abdullah, M.Z. (2017). Detection of Oxygen Precipitate Dark Rings in Solar Cell Luminescence Using Gray Level Co-occurrence Matrix. In: Ibrahim, H., Iqbal, S., Teoh, S., Mustaffa, M. (eds) 9th International Conference on Robotic, Vision, Signal Processing and Power Applications. Lecture Notes in Electrical Engineering, vol 398. Springer, Singapore. https://doi.org/10.1007/978-981-10-1721-6_33

Download citation

DOI: https://doi.org/10.1007/978-981-10-1721-6_33

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-1719-3

Online ISBN: 978-981-10-1721-6

eBook Packages: EngineeringEngineering (R0)