Abstract

China is presently undergoing an intensive industrialisation. As the world’s largest emerging economy, energy efficiency is expected to play a critical role in China’s ever-rising demand for energy. Based on factual overviews and numerical analysis, this chapter presents an in-depth investigation into the effectiveness of policies announced or implemented in recent decades targeted at energy conservation in energy-intensive manufacturing sectors. It highlights nine energy-intensive sectors that achieved major improvements in their energy technology efficiency efforts. Under the umbrella of the 11th Five-Year Plan, the success of these sectors’ energy-saving efforts reflects the effectiveness of China’s energy conservation policies. The Chinese government has introduced various measures to reduce the road transport sector’s demand for energy and its greenhouse gas (GHG) emissions: by implementing fuel economy standards, and by promoting advanced energy-efficient vehicles and alternative fuels. Coal-based energy-saving technologies, especially industrial furnace technologies, are critical for China’s near and medium-term energy-saving goals, which include the improvement of the direct technical efficiency for power generation, iron and steel production, non-ferrous products production, and non-metal mineral products production. In the long run, renewable energy development and expanding the railway transport system are the most effective ways to reduce China’s energy use and GHG emissions. Its road vehicles are projected to consume 370–520 million metric tons of oil and produce 1.6–2.0 billion tons of GHGs by 2050. Fuel economy standards could reduce oil consumption and GHGs by 34–35 %.

Dr. Libo Wu, Professor, School of Economics, Fudan University, China; Email: wulibo@fudan.edu.cn.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

4.1 Introduction

In the last two decades of the 20th century, the intensity of China’s energy use fell rapidly at a rate unparalleled by any other country at a similar stage of industrialisation. Internally, the dramatic expansion of labour-intensive industries allowed for the substitution of cheap labour to energy inputs and provided market-based incentives for energy conservation. Decomposition analysis focusing on Chinese industrial energy use has showed such substitutions (Zhang 2003; Wu et al. 2005, 2006). Externally, the Chinese government has implemented various policies and programmes to monitor industrial energy use, disseminate energy conservation information and services, stimulate energy technology renewal, promote investment in innovation and improve energy management capabilities (Sinton et al. 1998, 1999; Sinton/Fridley 2000; Wang et al. 1995). Energy consumption in China has accelerated since 2001 and surpassed GDP growth in 2003 and 2004. As a result, the long-lasting decline of energy intensity ended—the annual decreasing rate of energy intensity was –4.02 % in the 1980s and –6.30 % in the 1990s. However, this reversed to 0.36 % in the first five years of the 21st century (see Fig. 4.1).

Concerned about energy security, ever-rising energy costs, climate risks and environmental degradation, the Chinese government enacted the 20 % energy intensity reduction target in the 11th FYP. Following this challenging goal, central and regional governments took various political, technical, industrial and fiscal measures to facilitate the energy conservation activities of stakeholders. From 2006 to 2010, China’s energy use per unit of economic output fell by 19.06 % (State Council 2011). In the 12th FYP covering 2011–2015, the Chinese government announced that energy intensity is to decline by 16 % and carbon intensity by 18 %. All these targets are further disaggregated to each province by the National Development and Reform Commission (NDRC).

Along with these mandatory energy conservation and carbon emission reduction targets, energy-intensive sectors were forced to get rid of a number of energy technologies and in the meantime, utilise new energy-saving technologies recommended by the national government. Given the intensive industrialisation and motorisation taking place in China, can these command-and-control policies work effectively to completely change the ever-rising energy consumption pattern? This chapter will addresses this question by clarifying the energy consumption scale as well as the structural and efficiency dynamics in the Chinese industrial sector, and examine the relevant policy implications Furthermore, by introducing a new portfolio of energy-saving technologies into the I-Dream model, this chapter also provides some simulation results with respect to the contribution of these technologies to low-carbon emissions reduction targets in the long run.

The accelerated pace of industrialisation, urbanisation and motorisation accounts for most of China’s energy use. Figure 4.2 shows that during the past decade, the contribution of the manufacturing sectors to incremental energy use experienced an inverted-U curve. It was 55.31 % in 2000, peaked at 67.95 % in 2004, and then declined to 43.2 % in 2010. The transportation sector, together with the power generation sector, accounted for a greater portion of the incremental energy use over the same period.

Is the above structural transformation mainly due to the command-and-control policy since the 11th FYP? Alternatively, is there an intrinsic mechanism also playing a significant role in driving the change? How does one rate the energy efficiency performance of the Chinese industrial sector, especially the energy-intensive sectors before and after strong political interventions? What are the likely contributions of energy conservation technologies to long-term energy conservation and carbon emissions reductions in China? This chapter employs numerical analysis to determine the relative importance of the driving forces of industrial energy use, and discusses the policies that China is implementing to reduce energy and their effects on the industrial energy use.

4.2 Energy Efficiency Analysis in China’s Manufacturing Sector

4.2.1 Overview of Energy Conservation Policies in the Recent Decades

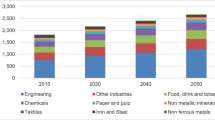

In the late 1990s, energy consumption in China’s manufacturing industries declined greatly, contributing to the slowdown of total energy use (see Fig. 4.1). Since 2000, however, energy use in manufacturing industries rebounded to become the dominant forces driving the rising energy demand. In 2005, nine energy-intensive sectors accounted for 96.2 % of total manufacturing industrial energy use, 78.2 % of total industrial energy use and 55.9 % of total final energy consumption, but their gross output was just 44.0 % of the manufacturing total and 41.4 % of the industrial total. Energy-intensive sectors were also the main sources of environmental pollutants, such as SOx, NOx and suspended particulates. These facts pointed to the urgent need to slow the scale of expansion of energy-intensive sectors, to improve their energy efficiency and to adjust product production methods.

In the 11th FYP, the Chinese government announced a comprehensive energy intensity reduction target and put the energy-intensive sectors at the centre of energy conservation. However, this did not hinder the rapid expansion of energy-intensive sectors in the initial stages of its implementation. Regional goals for economic growth and large sunk costs made it difficult to slow the overall scale of energy-intensive sectors in the short term. Efficiency improvement, by reducing energy input per unit of output, became more critical to counteract expansion (Zhou et al. 2010; Price et al. 2011). In order to strengthen the effectiveness of the energy conservation movement, the State Council, the National Development and Reform Commission (NDRC) and other responsible ministries and administrations announced and implemented various policies. The following section examines all these policies and measures over the 11th FYP period and the beginning year of the 12th FYP.

It is clear that the governance focus was on the energy-intensive sectors, with special attention to the 1,000 large-scale enterprises.

4.2.1.1 Strengthening the Energy Conservation Technology Diffusion

The Chinese government has organised a large amount of specific funding for energy conservation and emissions reduction. The funding system mainly serves as a public subsidy to improve the cost efficiency of the 10 key energy-saving projects. The NDRC published the 10 Key Energy Saving Projects Guidelines and the Ministry of Science and Technology published the National Technology Policy Outline on Energy Conservation to instruct the technology transformation and innovation directions. Any energy conservation project approved by the authorised expert committee can receive RMB 200–300 per ton of standard coal for the energy-saving units. In the National Technology Policy Outline for Comprehensive Resource Utilisation, technologies aimed at improving life cycle energy efficiency are introduced, and systematic change presently carries more importance as compared to end-of-pipeline management. Specifically, 3R (reduce, reuse and recycle) principles are strongly recommended for application in the production processes; hence less energy is consumed and less pollutants are emitted when producing the same amount for outputs.

4.2.1.2 Strengthening the Capability-Building for Key Enterprises, Regional Government and Professional Third Parties

Capability-building policies have been widely implemented over the past decades to develop the energy auditing, monitoring and statistical system. In 2005, the rule of reporting energy use per unit of GDP was established. The National Administration of Statistics and NDRC announced the energy conservation performance of each province regularly. During the 11th FYP, energy management capability-building projects were mainly focussed on the 1,000 key energy-intensive enterprises. A regular reporting system is now well developed among these enterprises (Dai/Zhou 2008; Zhou et al. 2010). In 2010, policies aimed at the state-owned key enterprises and medium and small-scale enterprises were also announced.

4.2.1.3 Phasing Out Technologies and Industries with Energy-Exhausting and Outdated Production Capacity

In addition to the technology innovation and capability-building, the Chinese government is taking strong measures to phase out outdated production capacities in energy-intensive sectors. Small-scale plants with outdated production capacity (from power generation, coal-mining and processing, coking production, ferroalloy production, calcium carbide production, iron and steel production, cement and plate glass production, fibre and clothing production) are on the agenda to be removed. While there are many critics of intervention in the market, there are some people in regional governments who are supportive of this policy. It is reported that over the period of the 11th FYP, China phased out 76,825 MW of power generation capacity, 120 million tonnes of pig iron production capacity, 72 million tons of steel production capacity and 370 million tons of cement production capacity.

How do we evaluate the effects of the above policies with respect to their effectiveness and efficiency? Looking at the energy use situation in 2010, we find that the gross output contribution of energy-intensive sectors to total manufacturing and industrial energy use declined by 2.2 % compared to 2005 levels. However, their share in total manufacturing energy use, total industrial energy use and total final energy consumption declined slightly by 0.2–0.5 %. Further analysis is needed to clarify the relative importance of the factors driving the inelastic energy demand of energy-intensive sectors and to determine the correct policy orientation and rationale of the 12th FYP target.

4.3 Scale, Structure and Efficiency Dynamics of Energy Use in China’s Manufacturing Sector

4.3.1 Brief Model Description

By applying the basic logarithmic mean divisia index (LMDI) decomposition techniques developed by Wu et al. (2005), this chapter analyses the energy consumption of China’s manufacturing sectors. With our focus on energy-intensive sectors, we include such sectors and take the other manufacturing sectors as a whole. We thus put forward this model to examine concerns about the dominant energy-intensive sectors users, and define the following KAYA type equation as the basis for decomposition model:

Then, the final format of the decomposition model can be depicted as the following equation:

We use the time series data from 1994 to 2010, while sectoral energy consumption, gross output (current price) and added value (current price) data until 2007 can be taken directly from the National Statistical Yearbook and Energy Statistical Yearbook (NBS 1993–2011). We use the yearly sectoral PPI index as a deflator to derive the constant price. Since 2007, the Administration of Statistics has only released the year-on-year growth rate and annual compound growth rate for sectoral added value. We estimate the constant price added value of 2008–2010 by taking 2007 as the base year.

4.3.2 Model Result and Discussion

4.3.2.1 The Relative Importance of Various Factors to Energy Consumption Change in the Manufacturing Sectors

The decomposition model indicates that during the past decades, especially during the 11th FYP, energy consumption in China’s manufacturing sectors has decelerated and even stabilised (see Fig. 4.3). This transition is not mainly due to the slowdown in economic growth, but because of energy efficiency improvements. In fact, with the exception of the crisis year of 2008, total output expansion has always played a dominant role in driving up energy use. Energy efficiency improvement acts as an opposite force pushing down energy use. However, since their scale could not match that of output expansion at the beginning of this century, the net outcome of industrial energy use soared substantially. The imbalance was reduced in 2003, and energy efficiency improvements have been a considerable source of dampening expansion since that time.

The Plan for National Economic and Social Development plays a central role in guiding the direction of policymaking in China. A comparison across the 9th, 10th and 11th FYP (Fig. 4.3) indicates the importance of energy efficiency improvements as they became more pronounced in the 11th FYP; while the scale of change for economic output did not alter for each five-year period. Therefore, this study illustrates that policies towards energy efficiency improvement in the industrial sectors, especially the energy-intensive sectors in the 11th FYP did not reverse the internal economic growth trends but added substantially to overall energy efficiency improvement.

4.3.2.2 Relative Importance of Factors to Energy Consumption Change in Various Energy-Intensive Sectors

Figure 4.4 illustrates some interesting findings generated by the sectoral analyses. For most of the energy-intensive sector, excluding the power generation sector, the total energy efficiency improvement was spectacular in the 11th FYP. Furthermore, energy technology innovation, the phasing out of outdated small-scale production capacity, and improved managerial policies contributed to considerable efficiency improvement, which effectively counteracted expansion. In particular, energy efficiency improvement in the raw chemical product industry, smelting and processing of ferrous industry, non-chemical mineral products industry, and paper-making industry successfully outperformed the economic growth that brought about noticeable shrinkage in overall energy use.

However, it is noted that the pace of energy efficiency improvement in the power generation sector is becoming less. This is clearly indicated in Fig. 4.4. During the past decade, the gross coal consumption rate for fossil-fired power plants declined by 11.85 %, but the absolute amount is still 8.9 % higher than the average level of Japan in 2010. The structure of the power generation source is the main factor hampering the overall thermal power efficiency improvement. In 2008, coal consumption still accounted for 89.3 % of China power generation, while in Japan, only 27.6 % of thermal power was based on coal with 23.6 % from natural gas and 30.7 % from nuclear power. This means that while there is still some technical space for overall efficiency improvement in fossil-fired power plants, more efforts are needed to facilitate less dependence on fossil fuels.

4.3.2.3 Relative Importance of Various Sectors to Energy Consumption Change

As indicated in Fig. 4.5, the abnormal increase in the manufacturing sector’s energy use over the 11th FYP period was driven manly by the smelting and processing of the ferrous metal sector, non-metal mineral products sector, and raw chemical materials and product sector.

Chinese production of steel and pig iron, cement, synthetic ammonia and alkaline increased rapidly during the past decade. China has been the largest producer of pig iron in the world this century and its consumption of it continues to increase. In the past decade, pig iron production rose by 342 %, whereas the global production increased by less than 50 %. Therefore, China’s production accounted for 46.39 % of the world’s total in 2010 and was about two times the sum of Japan, US, Germany, Russia and India. Given the fact that the comparable energy consumption for steel in China was still higher than that in Japan by 1.4 % in 2000 and 10.95 % in 2010, China’s dramatically expanding ferrous industry should make energy conservation its key priority. Over the past decade, China contributed more than 90 % to the world incremental cement production. The energy efficiency of cement production in China was lower than Japan’s by 44 % in 2000 and 22.8 % in 2010, respectively. Therefore, the cement production sector should also make more efforts to reduce its energy use.

4.4 Modelling Technological Development in Energy-Intensive Sectors in a Low-Carbon Economy: A Shanghai Case Study

4.4.1 Model Introduction

In recent years, the low-carbon transformation of China has been further accelerated by domestic environmental degradation, energy security concerns and rising costs of energy use. Energy-intensive sectors are playing central roles in this process by utilising more energy-saving and emissions reduction technologies. Furthermore, the Chinese government regularly provides recommendations for technologies to guide the direction of innovation and remove inefficient production capacities.

This chapter examines how energy-intensive sectors can choose an optimised technological roadmap under different scenarios of energy conservation and emissions reduction targets. It will go on to illustrate the scenario analysis results of the Shanghai model: differing from previous studies, this model modifies the commonly utilised energy technology portfolio of the TIMEs model by introducing a series of energy conservation technologies recommended by the Chinese government. Therefore, the analysis results are capable of capturing energy technology innovations since the 11th FYP in all of the energy-intensive sectors.

4.4.1.1 Development of the Reference Energy System

The basic structure of our Shanghai TIMES model can be referred to in Wu (2010). This model establishes a reference energy system (RES) containing 10 energy processing technologies, 15 power and heat generation technologies, 100 industrial technologies, 9 residential technologies, 9 service technologies and 31 transport technologies. In order to clarify the competitiveness of newly recommended technologies by the Chinese government, this model is further modified to add 21 key conservation technologies in the “ten major energy conservation projects implementation planning” (NDRC 2011). Since this chapter’s focus is on energy-intensive sectors, these 21 technologies are identified as new energy-use technologies in iron and steel, construction materials, petro-chemical products and non-ferrous metal products industries. The following figure illustrates some special modification to the reference energy system (RES) by introducing detailed technology choices into energy-intensive sectors regarding their energy use (Fig. 4.6).

4.4.1.2 Parameters and Main Assumptions

The second step consists of inputting data for all the parameters of energy commodities and technologies into the model. These parameters are composed of resource supply curves, demand projections, dynamically evolving technology costs and other relevant parameters.

The resource supply curves are based on current energy prices and IEA forecasts (see Table 4.1). This model assumes the domestic energy prices in China will change in line with the global energy prices after 2020.

Demand projections are based on historical energy demand in Shanghai from 2000–09. The compounded annual growth rates (CAGR) of different energy demands are computed across all demand sectors from 2005–09 to estimate the energy demand in 2010. As the growth rate of all demand devices will not remain at such a high level in the future, we assume the CAGR will decrease by half every 10 years in each sector. By estimating the CAGR of energy demands during 2010–20, 2020–30, 2030–40 and 2040–50, the model can extrapolate the energy demands of all the milestone years from 2010–50 (Table 4.2).

Technology costs comprise the investment cost, the fixed O&MFootnote 1 cost and the variable O&M cost of each energy technology. As TIMES is a technology-rich model which minimises the total cost of the energy system, these cost data are very important to modelling. The investment cost data comes mainly from official statistics and our field surveys, while the O&M cost data is estimated by setting an appropriate ratio compared to the investment cost data.

Other relevant parameters include conversion efficiency, technology life, residual capacity and emission factor. These parameters are estimated by referring to relevant OECD data and making some adjustments according to the technological conditions in China.

4.4.1.3 Scenario Settings

In this chapter, one base scenario as a benchmark scenario and three low-carbon scenarios (namely LC1, LC2 and LC3) are set to analyse the technological development pattern of the economy.

Base scenario is a business-as-usual scenario which includes legislated policy measures as of 2010. However, no future policies or measures would be enacted to reduce energy use or CO2 emissions.

LC1 scenario is a low-carbon scenario involving a low level of emissions restrictions. At the Copenhagen Meeting in 2009, the Chinese government promised to reduce carbon emissions per unit of GDP by 40–45 % in 2020 from 2005 levels. Shanghai, a vanguard city for a low-carbon economy, is expected to do better than the whole country in achieving these emissions targets. It is estimated that Shanghai will reduce its carbon emissions per unit of GDP by 50 % in 2020 from its 2005 level. Additionally, with structural upgrades to its economy, Shanghai will likely reduce its carbon emissions per unit of GDP by 65 % in 2030 from the 2005 base. China should ideally assume absolute quantitative control of its carbon emissions by 2040, while Shanghai is expected to retain its CO2 emissions at its 2030 levels. By 2050, Shanghai is likely to further reduce its CO2 emissions by 10 % from its 2040 level.

LC2 scenario is a low-carbon scenario involving a medium level of emissions restrictions. Shanghai is expected to decrease its carbon emissions per unit of GDP by 55 % in 2020 from the 2005 base. Then, by 2030, Shanghai is likely to quickly assume absolute quantitative control of carbon emissions by limiting CO2 emissions growth to no more than 40 % from the 2020 base. By 2040, Shanghai is expected to retain its CO2 emissions to 2030 levels, and by 2050, it appears set to further reduce its CO2 emissions by 10 % from the 2040 base.

LC3 scenario is a low-carbon scenario involving a high level of emissions restrictions. Shanghai is likely to reduce its carbon emissions per unit of GDP by 60 % in 2020 from the 2005 base. Then, by 2030, Shanghai is expected to assume quantitative control of its carbon emissions by limiting CO2 emissions growth to no more than 30 % from the 2020 base. By 2040, Shanghai will likely retain its CO2 emissions at its 2030 level, and by 2050, it is expected to further reduce its CO2 emissions by 10 % from the 2040 base.

4.4.1.4 Core Scenario Results

In Fig. 4.7, the bars in four different colours represent the amount of CO2 emissions from 2000–50 in four respective scenarios, and the lines denote the development of CO2 emissions per unit of GDP.

4.4.1.5 Overall Results

As shown, in the base scenario, Shanghai’s CO2 emissions will increase dramatically from 153,634 kt in 2000 to 1,292,529 kt in 2050. However, as the economy develops, the carbon emissions per unit of GDP will decline rapidly from 32.20 kt per 100 million yuan in 2000 to only 5.26 kt per 100 million yuan in 2050. In the LC1, LC2 and LC3 scenarios, CO2 emissions in 2050 will drop sharply from 1,292,529 to 836,127 kt, 697,120 kt and 575,400 kt, respectively. Meanwhile, the carbon emissions per unit of GDP will also decline to 3.40 kt, 2.84 kt and 2.34 kt per 100 million yuan, respectively.

In the Shanghai TIMES model, CO2 emissions come from six sectors, namely: power generation, energy processing, industrial, residential, services and transport. Breaking down the sources of carbon emissions across these sectors, we find that most of the CO2 emissions are produced by the industrial and power generation sectors.

In the base scenario, the power generation sector contributed 56 % of CO2 emissions in the whole energy system of 2000. This is expected to grow steadily to 70 % by 2030 and then remain constant until 2050. The industrial sector produces the second largest proportion of carbon emissions, which is likely to decline from 36 % in 2000 to 23 % by 2050.

In the LC1 scenario, the proportion of carbon emissions in the power generation sector shrinks a little during the 2020–50 period compared with that of the base scenario. This is because a more stringent carbon restriction requires this sector to use more decarbonised technologies such as wind power or solar power. The proportion of the industrial sector keeps a premium of 2–4 ppt higher than that in the Base Scenario during the 2020–40 period. However, it suddenly drops by 6 ppt in 2050 after the economy assumes absolute quantitative control of carbon emissions in 2040. Others, including the residential, services and transport sectors, mildly expand their proportions after 2010. By comparing Figs. 4.8 and 4.9, one can conclude that the power generation sector has the largest potential in carbon reduction at the initial stage of decarbonisation. But when the economy assumes absolute quantitative control over carbon emissions, a significant change will occur within the industrial sector. Section 4.3 will further examine what is happening in this sector.

In the LC2 scenario, it is observed that the power generation sector produces high carbon emissions by 2020 (Fig. 4.10). But as the economy assumes absolute quantitative control over carbon emissions by 2030, the industrial sector becomes the vanguard sector to decarbonise as the proportion of this sector’s emissions drops significantly from 32 % in 2020 to 18 % in 2050. However, other sectors have almost doubled their proportion of emissions during the 2010–50 period.

In the LC3 scenario, the carbon emissions sources have witnessed a more significant structural change as the power generation and industrial sectors produce higher proportions of emissions (Fig. 4.11). For example, most strikingly, the transport sector’s emissions increase from 3 % in 2010 to 10 % in 2050. The expansion of the other three sectors’ emissions is mainly due to the relatively lower contribution of their emissions as a whole and little room for technological decarbonisation at the current rate of innovation progress.

4.4.2 Power Generation Sector

The power generation sector has the largest potential to reduce carbon emissions as it contributes the largest proportion of emissions among all the sectors. With improvements to government policies concerning carbon restrictions, the power generation sector currently uses more green energy to produce electricity.

In the base scenario, the coal-fired power plants dominate the power generation sector, with 86.1 % of electricity produced by coal technologies in 2000 (Fig. 4.12). Traditional coal technology will be gradually replaced by coal IGCC after 2020. By 2050, all coal technologies are expected to generate 96.7 % of China’s electricity. As the availability of fossil fuels become scarcer, such a development pattern is not sustainable.

In the LC1 scenario, coal technologies will stop growing after 2030, and start to decrease by 2040 as the Chinese economy assumes quantitative control of carbon emissions (Fig. 4.13). By 2050, coal technologies will likely produce only 47.0 % of electricity while wind and CHP will contribute to 38.6 and 14.3 %, respectively, of electricity in the power generation sector. This means that wind power technology will be applied on a large scale after 2030. As Shanghai is geographically located near the sea, we expect that offshore wind power technology will be the most prospective technology to support the decarbonisation progress of the economy.

In the LC2 scenario, the power generation sector will be further decarbonised as coal technologies will account for only 31.5 % of electricity produced (Fig. 4.14). Wind and CHP will in turn contribute to 41.6 and 19.1 % of electricity, respectively. Notably, the economy will start to use solar power after 2040, and solar power generation will likely account for 8.0 % of electricity produced by 2050.

In the LC3 scenario, renewable technologies will produce more than half of the electricity produced in the power generation sector (Fig. 4.15). The application of such a high proportion of renewable technologies will create supply shocks to the grid system, and thus hasten the urgency to develop energy storage technology to offset the uncertainty of renewable technologies.

4.4.3 Industrial Sector

Figures 4.16, 4.17, 4.18 and 4.19 show the energy consumption structure of the industrial sector in all four scenarios. The structural changes occurring in this sector reflect a distinct pattern of decarbonisation. As carbon restrictions become more and more stringent across the low-carbon scenarios, the proportion of coal technologies in 2050 drops sharply from 36 % in the base scenario to 13, 4 and 0 % in LC1, LC2 and LC3 scenarios, respectively. Another notable change is that heat technologies account for 32, 42 and 46 % of all energy consumption in LC1, LC2 and LC3 scenarios, respectively, while in the base scenario only 7 % of energy consumption is produced from heat technologies.

As discussed in Sect. 4.1, when the Chinese economy assumes absolute quantitative control of carbon emissions, the industrial sector will reduce its carbon emissions significantly. This is done by eliminating more coal technologies and using cleaner technologies such as electricity and heat in the industrial sector. Electricity technologies are already expected to contribute to about one-third of energy consumption in the base scenario by 2050. But why will the proportion of heat technologies grow so fast under the low-carbon scenarios? First, only electricity and heat technologies do not produce carbon emissions. Second, electricity is largely produced by coal-fired power plants, while heat is produced by CHP using a large proportion of natural gas which is less carbon-intensive than coal. In addition, using more renewables to produce electricity is more costly than using current CHP technology to produce heat, thus making heat technologies more favourable than electricity technologies in efforts to meet stringent carbon emission restrictions.

4.5 Conclusions

In the early years of the 12th FYP, the Chinese government released a series of policies for further energy conservation and emissions reduction. Following the 1,000 Intensive Enterprises Energy Conservation Project, 10,000 enterprises were included in the energy monitoring and auditing system. A decline in international exports and slowdown of economic growth in domestic markets have also dramatically reduced the demand for energy-intensive goods, and resulted in the problem of over-production in these sectors. The updated list detailing the phasing out of outdated production capacity in energy-intensive sectors was thus approved despite great pressure for economic recovery (MOIIT 2012).

In light of the results and predictions discussed throughout this chapter, continuity and consistency in China’s energy conservation scheme can be safely expected for the next decade. Industrial structure upgrades and technology innovation are regarded as the two underpinnings of the country’s energy conservation efforts to achieve systematic optimisation of the energy system in the long term.

This chapter presents a TIMES model and three low-carbon scenarios are applied to analyse the technological development of Shanghai in a low-carbon economy. Giving insights into the energy system of Shanghai, one base scenario and three low-carbon scenarios with different CO2 emission restrictions are set to observe the kinds of changes that would take place in a low-carbon economy. By comparing the emissions structure among different sectors and analysing the energy consumption source of each sector, we reach the following conclusions which present us with a development pattern of a low-carbon economy in view of technological advancement or replacement.

Among all the sectors in Shanghai’s energy system, the power generation sector has the largest potential for carbon reduction at the initial stage of decarbonisation. However, when the economy assumes absolute quantitative control of carbon emissions by the industrial sector will become a vanguard to reduce CO2 emission by facilitating technological reforms.

The decarbonisation of the power generation sector is accomplished mainly by cutting down the proportion of coal-related technologies and using more renewable technologies. In the LC3 scenario, the most stringent low-carbon scenario, more than half of all electricity is produced by wind and solar power. Such a high proportion of renewable technologies applied will create supply shocks to the grid system. Therefore, the development of energy storage technology is urgently needed to offset the uncertainty of renewable technologies.

Significant changes have occurred in the energy consumption structure of China’s industrial sector as its economy further reduces its carbon emissions. The large proportion of coal technologies used in the base scenario will gradually be replaced by more clean technologies such as electricity and heat technologies in low-carbon scenarios. It is noted that the proportion of heat technologies expands extremely fast from the LC1 to LC3 scenarios, chiefly due to the fact that using more renewables in producing electricity is more costly than using current CHP technology to produce heat.

Notes

- 1.

O&M cost represents the operation and maintenance cost of an energy technology. For example, in a coal-fired power plant, the fixed O&M cost includes the salaries of employees and the repair fees of power equipment, while the variable O&M cost implies the cost of electricity and some fuel oil associated with the use of the power plant.

References

Alfstad, T. (2005) “Development of a Least Cost Energy Supply Model for the SADC Region”. Master thesis, University of Cape Town.

Chen, W. (2005) “The Costs of Mitigating Carbon Emissions in China: Findings from China MARKAL-MACRO Modeling”. Energy Policy 33, 7: 885–96.

Chen, W. and Z. Wu (2001) “Use MARKAL Model to Study the Future Sustainable Energy Development Strategy in China”. Journal of Tsinghua University (Science and Technology) 41, 12: 103–6 (in Chinese).

Chen, W. and Z. Wu (2002) “China’s Future Policies to Control SO2 and CO2”. Journal of Tsinghua University (Science and Technology) 42, 10: 1320–3. (in Chinese).

Chen, W., P. Gao and J. He (2004) “Use MARKAL-MACRO Model to Study the Impact of Carbon Emission on Chinese Energy System”. Journal of Tsinghua University (Science and Technology) 44, 3: 342–6. (in Chinese).

Chen, W., Z. Wu, J. He et al. (2007) “Carbon Emission Control Strategies for China: A Comparative Study with Partial and General Equilibrium Versions of the China MARKAL Model”. Energy 32, 1: 59–72.

Chen, W., J. Liu, L. Ma et al. (2009) “Role for Carbon Capture and Storage in China”. Energy Procedia 1, 1: 4209–16.

Dagoumas, A.S. and T.S. Barker (2010) “Pathways to a Low-Carbon Economy for the UK with the Macro-Econometric E3MG Model”. Energy Policy 38, 6: 3067–77.

Delaquil, P, W. Chen and E.D. Larson (2003) “Modeling China’s Energy Future”. Energy for Sustainable Development 7, 4: 40–56.

Gielen, D. and C. Chen (2001) “The CO2 Emission Reduction Benefits of Chinese Energy Policies and Environmental Policies: A Case Study for Shanghai, period 1995–2020”. Ecological Economics 39: 257–70.

Hainoun, A., M. Seif Aldin and S. Almoustafa (2010) “Formulating an Optimal Long-Term Energy Supply Strategy for Syria using MESSAGE Model”. Energy Policy 38: 1701–14.

Kannan, R. (2009) “Uncertainties in Key Low Carbon Power Generation Technologies: Implication for UK Decarbonisation Targets”. Applied Energy 86, 10: 1873–86.

Makela, J. (2000) “Development of an Energy System Model of the Nordic Electricity Production System”. Master thesis, Helsinki University of Technology, 2000.

Manne, A., R. Mendelsohn and R. Richels (1995) “MERGE: A Model for Evaluating Regional and Global Effects of GHG Reduction Policies”. Energy Policy 23, 1: 17–34.

Sands, R.D. (2004) “Dynamics of Carbon Abatement in the Second Generation Model”. Energy Economics 26, 4: 721–38.

Song, H.-J., S. Lee, S. Maken, S.-W. Ahn et al. (2007) “Environmental and Economic Assessment of the Chemical Absorption Process in Korea using the LEAP Model”. Energy Policy 35, 10: 5109–16.

Wu, Z., P. Delaquil, E.D. Larson et al. (2001) “Future Implications of China’s Energy-Technology Choices: Summary of a Report to the Working Group on Energy Strategies and Technologies”. Energy for Sustainable Development 5, 4: 19–31.

Zhang, Z.X. (2003) “Why Did the Energy Intensity Fall in China’s Industrial Sector in the 1990s? The Relative Importance of Structural Change and Intensity Change”. Energy Economics 25, 6: 625–38.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Appendix

Rights and permissions

Copyright information

© 2016 The Author(s)

About this chapter

Cite this chapter

Wu, L. (2016). Efficiency Improvement in China’s Energy-Intensive Industries and Their Contributions to Carbon Emission Reduction Targets. In: Su, B., Thomson, E. (eds) China's Energy Efficiency and Conservation. SpringerBriefs in Environment, Security, Development and Peace, vol 30. Springer, Singapore. https://doi.org/10.1007/978-981-10-0737-8_4

Download citation

DOI: https://doi.org/10.1007/978-981-10-0737-8_4

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-0735-4

Online ISBN: 978-981-10-0737-8

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)