Abstract

Insulated conductive molecules, in which the π-conjugated compounds are covered by a cyclic protective sheath, have attracted considerable attention because of their potential applicability in next-generation molecular electronic devices. New methods of synthesizing three-dimensionally insulated π-conjugated molecules through the polymerization of insulated π-conjugated molecules as monomers are summarized. The obtained insulated molecular wires are highly soluble in organic solvents and have a high coverage ratio, rigidity, and photoluminescence efficiency; further, they show high charge mobility, even in the solid state. This chapter also highlights a new type of molecular wiring method based on the polymerization or copolymerization of an insulated π-conjugated monomer between nanosized electrodes.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Insulated molecular wires

- Molecular electronic device

- Rotaxane

- Polyrotaxane

- Permethylated cyclodextrin

- Charge mobility

- Molecular wiring

6.1 Introduction

Inorganic semiconductor materials such as silicon are still major players in the fabrication of electronic devices in our modern information society. Computer innovations based on the integration of silicon semiconductors have greatly facilitated the expansion of our knowledge base, which in turn has significantly influenced our daily activities. However, the miniaturization of these systems is approaching fundamental limits due to the continuing decrease in feature size (Moore’s law) [1]. Therefore, the development of innovative new devices using materials other than silicon is necessary for the continued advancement of these systems. The field of molecular electronics is the most promising area for further innovation in information technology [2, 3]. In molecular electronics, each functionalized molecule has the potential to behave as a single device, such as a switch, socket, memory, light emitter, diode [4], sensor, transistor [5], or photoelectric cell [6], which enables extensive integration and miniaturization [7]. To realize such molecular electronics, various functionalized molecules must be wired in between electrodes with nanosized gaps, in an efficient and dense fashion. Therefore, the development of techniques for the synthesis of definite-structure molecular wiring materials with appropriate functional groups and the development of an effective molecular wiring method are eagerly anticipated. In this context, this chapter focuses on the following: (1) the synthesis of functionalized insulated molecular wires possessing high linearity, rigidity, stability, and high charge mobility and (2) the establishment of wiring methods utilizing organic reactions such as cross-coupling or polymerization reaction in between nanosized gaps (Fig. 6.1).

6.2 Synthesis of Three-Dimensionally Insulated Molecular Wires

6.2.1 Synthesis of Cyclodextrin-Based Insulated Molecular Wires

Organic semiconductor materials mainly made of carbon π-conjugated polymers, known as plastics that conduct electricity, have drawn attention because of their advantage in being more suitable than low-molecular organic compounds. Printing technology such as inkjet printing and rotary press can be used in their fabrication, so π-conjugated polymers are expected to reduce production cost. However, their charge mobilities, a parameter for carrier transport property, have not been comparable to those of silicon-based inorganic semiconductor materials. This is the biggest challenge in developing high-polymer materials for semiconductors, and the development of such materials with high charge mobility is being eagerly awaited. As one of the methods to solve these, research is actively conducted for insulating the conductive π-conjugated polymer chain one by one with insulation synthesizing chemically, as though a coated conductor wire is created [8–10]. This insulation reduces the interaction between the π-conjugated chains, and it is expected to provide stability to the conjugated chain along with improvement in solubility, fluorescence characteristics, and charge mobility characteristics of the conjugated chain. The synthetic method for insulated π-conjugated polymer (insulated molecular wire) is broadly classified into the method of sterically introducing bulky side chain to the π-conjugated polymer chain [11] and method of insulating the polymer chain three-dimensionally with cyclic molecules such as cyclodextrin (CD) [12] or cyclophane [13]. The former can impart solubility to the π-conjugated polymer chain, by sterically linking the bulky dendrimers with covalent bonds as the side chain and preventing contact between the π-conjugated polymer chains. Moreover, the constituent units of the insulated π-conjugated polymer synthesized by this method are unique, and the structural regularity is extremely high. The latter using the comparatively weak interactions of hydrophilic–hydrophobic interactions or coordination can efficiently coat the main chain three-dimensionally with cyclic compounds. This chapter explains the overview of the synthesis method for cyclodextrin-based insulated molecular wires and the physical properties.

It is known that water-soluble cyclic molecules capture organic molecules with hydrophilic–hydrophobic interactions forming rotaxanes (inclusion complexes) in water. Among these, water-soluble CD derivatives are easily available at low cost, and they are widely used as insulation molecules (host molecules) of various organic compounds. There are two methods for synthesizing insulated molecular wires using CD: the first method is to form polyrotaxane by inclusion of multiple CDs in the π-conjugated polymer chain and the second method is to form by the inclusion of π-conjugated monomer molecule in CD and the subsequent polymerization reaction.

Harada et al. were able to form polyrotaxane by stirring polyethylene glycol and CD in water and were successful in synthesizing molecular necklace [14, 15] and molecular tube [16]. Ito et al. found that insulated π-conjugated polymers with a pseudo-polyrotaxane structure are formed below 275 K by stirring the conductive polymer polyaniline and β-CD using N-methyl-2-pyrrolidinone (NMP) as the solvent [17–19]. This molecular wire dissociates into polyaniline and β-CD at 275 K or more. Moreover, even when cross-linked molecular tubes between CDs are used instead of CD, the polymer enters the tube holes and provides the same insulated π-conjugated polymer chain. The same technique, as will be explained later, has been applied to the insulated π-conjugated polymer chain synthesis of conductive polymers such as polythiophene. When polyaniline insulated molecular wires were placed on a microelectrode substrate having 100–200 nm electrode gap, with platinum as the electrode metal and thermal oxide film on the insulating substrate, using scanning probe microscope (SPM)-based lithography, the resistance was above a few TΩ when measured in vacuum. Moreover, the resistance value was approximately 47 KΩ and conductivity 4 × 10−2 S cm−1 with the doping of the polyaniline chain. This value is comparable to the conductivity 10−1 S cm−1 of polyaniline in the bulk state [20].

Anderson et al. succeeded in the synthesis of water-soluble insulated π-conjugated polymers with the copolymerization reaction of pseudo-rotaxane monomer, obtained by the inclusion of π-conjugated monomer chain with boronic acid reaction points at both ends to CD in water and dihalides having a water-soluble functional group under the Suzuki–Miyaura coupling reaction conditions [21]. In this method, since it is carried out by sterically adding a bulky monohalide as a polymerization terminator, the molecular wire is obtained as a polyrotaxane structure having a stopper portion at both ends (Fig. 6.2); hence, the CD does not fall off. Since the feature of this method is to synthesize the π-conjugated chain using a polymerization reaction, it is possible to synthesize insulated molecular wires with different π-conjugated chains using monomers with various π-conjugated structures [22–24]. The resulting molecular wires show high fluorescence quantum yield compared to the corresponding π-conjugated polymers without insulation. That is, the respective π-conjugated polymer chains in the excited state exist independently because of the insulation, and this is considered to be due to the suppression of energy transfer between the chains.

6.2.2 Synthesis of Permethylated Cyclodextrin-Based Insulated Molecular Wires

Polyrotaxane insulated molecular wires are cyclic compounds containing π-conjugated polymer that can move relatively freely and can be moved along the main polymer chain. However, this shuttling may reduce the solubility of the polyrotaxane itself in addition to frequent aggregation of cyclic compounds leading the formation of π-conjugated part without insulation. Moreover, its poor structural regularity is an unfavorable factor for application to molecular electronics where synthesis of identical molecules with good reproducibility is required. Furthermore, when CD is used, ionic insulated π-conjugated polymers are formed due to the CD hydroxyl group, and removal of water molecules and salts influencing the conductivity are the issues faced when developing a device. Development of a nonionic π-conjugated polymer synthesis method with structural regularity and solubility which retains the properties of the π-conjugated polymer that is the main chain while achieving a high insulation for the main chain is required for the realization of molecular electronics using π-conjugated polymers.

One method to satisfy these requirements is to use permethylated cyclodextrin as a macrocycles for the synthesis of insulated molecular wire instead of native cyclodextrin. The methylation of all the hydroxyl groups of cyclodextrin provides permethylated cyclodextrin which has deeper vacancy and higher solubility in organic solvents as compared to the native cyclodextrin. New synthetic route to organic-soluble insulated molecular wires is shown in Fig. 6.3. The self-inclusion of guest-branched permethylated cyclodextrin forms pseudo-rotaxane [25], which is capped with a stopper molecule to afford a linked [2]rotaxane ([1]rotaxane). Polymerization sites are introduced at both ends of this rotaxane to form a fixed [2]rotaxane monomer. Then, this monomer is polymerized to afford π-conjugated polyrotaxane as an organic-soluble insulated molecular wire [26].

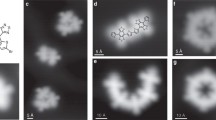

Crystals of fixed [2]rotaxane were grown from a mixture of DMSO and H2O. The X-ray structure is shown in Fig. 6.4. It is clear that the permethylated cyclodextrin is displaced from the center of the guest moiety, and the main axis of the guest exhibits a slight torsion.

To decrease the number of reaction steps and increase coverage, a simple methodology for the synthesis of regioregular insulated molecular wires by polymerization of pseudo-linked [3]rotaxane monomer 2 by sequential intramolecular self-inclusion of a phenylene ethynylene oligomer with two permethylated cyclodextrins was developed (Fig. 6.5) [27, 28]. In order to examine the covering effect of permethylated cyclodextrin, an uncovered polymer 3 was also synthesized as a reference by the polymerization of 1 in a lipophilic solution (CH2Cl2) instead of a hydrophilic solution (1:1 CH3OH:H2O) [29]. The absolute quantum yields of 3 and 4 were determined using a calibrated integrating sphere system. The fluorescence quantum yields of 4 revealed that its fluorescence efficiency was better than that of 3, particularly in the solid state.

Figure 6.6a shows polarized optical micrographs of 4 in concentrated CHCl3 solutions. It should be noted that 4 forms a cholesteric phase, as confirmed from its indisputably clear fingerprint texture, while 3 forms only an isotropic liquid even at high concentrations. The observed cholesteric phase can be attributed to the presence of permethylated cyclodextrin in 4 since a nematic LC phase should be observed if a polymer chain threads through achiral macrocycles. This is the first report of the formation of a cholesteric LC phase whose chirality originates from the inclusion of a polymer main chain into the permethylated cyclodextrin cavity. The morphology of 4 was investigated by performing AFM experiments using cleaved mica substrates (Fig. 6.6b). Highly dilute solutions of high-molecular-weight 4 that was separated by GPC (gel permeation chromatography) were used to avoid the aggregation of individual assemblies. From the AFM image and a section analysis, the expected average contour length and height of the polymer chains were determined to be ∼200 nm and ∼1.5 nm, which is equal to the outer diameter of the free permethylated cyclodextrin calculated using the CPK model.

(a) Polarized optical micrographs of 4 in CHCl3 solution, (b) tapping-mode AFM topographic image of 4 on a mica substrate [29]

6.2.3 Synthesis of Insulated Molecular Wires with High Charge Mobility

To increase the effective conjugation length in the core molecules, polyrotaxane 5, with only a poly(phenylene ethynylene) (PPE) backbone, was synthesized by the Sonogashira copolymerization of 2 with 1,4-diiodobenzene (Fig. 6.7).

The kinetic traces of the transient conductivity and optical absorption of 5 upon irradiation by UV light (355 nm) were examined. For the quantitative analysis of photogenerated charge carriers, N,N-bis(2,5-di-tert-butylphenyl)-3,4,9,10-pery-lenedicarboximide (PDCI) was used as an electron acceptor because of its high extinction coefficient in the radical anion form (ε-PDCI•− = 7.4 × 104 cm−1 · mol−1 · dm3). The excellent correlation between the two transients clearly suggests that the positive charge on the π-conjugated core of the molecules in 5 contributed to the high conductivity of this compound over the entire time range. It is noteworthy that the minimum value of anisotropic hole mobility (μ+) in the core estimated from the maximum value of the quantum yield of charge carriers (ϕ) (3.4 × 10−4) was 0.5 cm2 V−1•s−1. This is the first report of the formation of an almost perfectly insulated organic semiconductor wire in which the hole mobility along the π-conjugated polymer chain is extremely high and is comparable to that of amorphous silicon [30, 31]. To achieve much higher charge mobilities in the polymer chain, a new strategy to achieve efficient charge hopping has been developed by regularly localizing polymer molecular orbitals to achieve an ideal orbital alignment and, at the same time, by equalizing energy strength and making use of thermal energy. To test this theory, defect-free insulated molecular wires with meta-junctioned poly(phenylene ethynylene) as the backbone units were synthesized to equalize the distance and molecular orbital levels between the hopping sites. Rewardingly, the twisted insulated molecular wire exhibited a higher intramolecular charge mobility (2.1 cm2 V−1s −1 is the first time that intramolecular charge mobility above 1 cm2 V−1s −1 has been achieved as charge carrier hopping processes in π-conjugated polymers) along the designed π-conjugated polymer chain compared with that of the corresponding linear wire (Fig. 6.8). This was probably because uncontrolled structural deformations owing to rotation and fluctuation in linear π-conjugated polymers will result in widely distributed orbital levels, which should be disadvantageous for charge mobility via hopping processes. On the other hand, meta-junction units regularly break the orbital delocalization resulting in a narrow distribution of the orbital levels, which should be suitable for efficient charge hopping processes, like in the crystal structure of pentacene (Fig. 6.9). Interestingly, when the length of the insulated para-segments in the twisted insulated molecular wire was increased to ten phenylene ethynylene units, an intramolecular charge mobility of 8.5 cm2 V−1s−1 was obtained [32]. It was determined that an increase in the planarity of the meta-junctioned systems with an increase in the number of phenylene ethynylene units plays an important role in the enhancement of the charge mobility, and the longer para-segments also enhance the charge mobility via a coherent charge transport process. It is important to note that the value of 8.5 cm2 V−1s−1 for intramolecular charge mobility in the cross-boundary range of hopping and band transport is comparable to the highest value in amorphous silicon (1–10 cm2 V−1s−1). The application of this technology to π-conjugated polymer backbones will lead to the possible creation of π-conjugated polymers with higher charge exchange. Insulated π-conjugated polymers are expected to be used as organic semiconductor materials and wires in molecular devices.

6.2.4 Synthesis of Functionalized Insulated Molecular Wires

For use as wiring materials, molecular wires must satisfy two requirements: (I) compatible processability resulting from high solubility and defined molecular structure and (II) appropriate material properties such as high linearity, rigidity, and, in particular, high conductivity. As described above, the synthesis of insulated molecular wires which adequately satisfied properties (I) and (II) was developed; in these wires, the conjugated moieties were isolated through insulation using CD derivatives [33, 34]. However, it is not necessary for molecular wiring materials to strictly mimic their conventional inorganic counterparts. In other words, molecular wires that contain stimuli-responsive units in their polymer chains are expected to perform as higher-order nanodevices owing to their functionalities; i.e., electrodes connected to functionalized molecular wires could exhibit not only conductivity but also physical property change by external stimuli. In order to synthesize functionalized insulated molecular wires by copolymerization of insulated monomer with various functionalized monomers, the insulated OPE 6 as a monomer having a fixed [3]rotaxane structure in the organic solvents was employed. The synthesis of defect-free insulated poly(phenylene ethynylene) (PPE) was executed via Sonogashira copolymerization of 6 with 1,4-diiodobenzene in the presence of a catalytic amount of Pd2(dba)3 and PPh3 in the organic medium (THF/Et3N = 2/1). This method was subsequently applied to the synthesis of functionalized insulated molecular wires 7a–e by Sonogashira copolymerization of 6 with functionalized dihalides having a tetrathiafulvalene (TTF) unit as a redox group, a porphyrin unit as a metal ion-sensing group, and an azobenzene or diarylethene unit as a photoswitching group (Fig. 6.10) [35].

A significant fluorescence enhancement in response to oxidation was observed for the insulated molecular 7b wire bearing tetrathiafulvalene units as compared with the corresponding uninsulated molecular wire. The porphyrin insulated molecular wire 7c switches conductivity in response to variation of the coordinated metal ion and to the absence or presence of a metal ion. The insulated monomer unit prevents the π-stacking of the conjugated main chains, even in the solid phase, leading to prolongation of the lifetime of the charged radicals on the conjugated backbone through blockage of the charge recombination processes. Conformational changes of the azobenzene insulated molecular wire 7d in response to sequential irradiation with UV and visible light were clearly observed by AFM measurements and are believed to result because encapsulation of the π-conjugated polymer chains precludes a high degree of aggregation through a decrease in the strong interactions between the π-conjugated chains.

6.2.5 Synthesis of Insulated Metallopolymers

Over the past few decades, many scientists have focused on the integrated property of molecular wires and metal elements, and the synthesis and properties of conjugated metallowires have gained considerable importance [36–40]. The transition metal complexes are directly inserted into their conjugated main chains producing interesting phosphorescent [41, 42], magnetic [43, 44], and redox behaviors [45, 46] in addition to the reversibility derived from d-electrons or coordination bonding [47]. In conjugated metallowires, transition metal complexes strongly affect π-conjugation because they are placed in between the conjugated wire backbones [48]. Further, conjugated metallowires promise higher-order, unique functionalized materials that have novel properties combined with those of the conventional π-conjugated materials. However, the unique electronic properties of the metal complexes are known to decrease their solubility because of metal–metal interactions and the polycation state. Typical metallowires have very low solubility and can exist only as solids in their crystal packing state [39]. The limitations of conjugated metallowires render their usage as practical functionalized materials difficult. Overcoming these drawbacks can produce highly functionalized materials with excellent physical properties and high processability, such as wet processing. In recent decades, a number of insulated conjugated metallowires have been successfully synthesized and interesting properties have been reported. In addition to the conventional features derived from π-conjugation and transition metals, their insulated structures can compensate for solubility, a disadvantage in conventional metallowires, and enhance their stability and functionalities, such as sensing and luminescence.

Schanze et al. demonstrated the effect of insulation on the phosphorescent behavior of platinum acetylide wires 8 because of its bulky side chains [49] (Fig. 6.11). Launay et al. reported an insulation behavior of metallowire 9a bearing coordination bonds, wherein bulky Ru(II) porphyrins on the outer edges, closely connected by short bridging ligands, exhibited an insulation effect, as the interactions between the oxidant and the polymer backbone consisting of metals and bridging ligands were inhibited [50]. These results indicated the protective effects of other reagents or interactions on the metallowires. A coordinative metallowire 9b composed of Ag(I)–pyridyl bonds covered with dendrons, displaying depolymerization by the cleavage of the coordination bonds, was reported, unusual to the nature of the coordinative metallowire [51]. Lee et al. reported an insulated metallowire 9c with Ag(I)–pyridyl bonds that showed interconversion between the gel and the nematic phases, triggered by an external solvent system through weak interactions of the exposed Ag(I) ions [52]. These wires were significantly affected by the external environment, peculiar to the nature of coordination bonds.

Liu et al. reported the first coordinative metallowire with conjugated chains insulated by cyclic molecules (Fig. 6.12) [53]. The host–guest inclusion complex between β-CD and 4,4′-bipyridine, based on hydrophilic–hydrophobic interactions in water, was then subjected to coordination polymerization with one equivalent of NiCl2·6H2O to form an insulated metallowire 10a with pyridyl–metal coordination bonds. The effect of the various types of cyclodextrins, metals, and counter-anions on the insulated metallowires was reported [54]. They demonstrated that the counter-anion sensing for chloride by the metallowires 10b was attributed to the limited space between the CDs that disturbed the coordination between the Co(II) ions and water [55]. Li and coworkers reported another functionalized material using Liu’s strategy [56]. The color of the solution of the modified Ag nanoparticles with the inclusion complex in water was selectively changed to a metallowire 10c by Yb(III) among seven other lanthanide ions owing to its small ionic radius. Shinkai et al. reported a Tb(III)-based insulated metallowire 11 with carboxylate–metal coordination bonds, as a chiral sensing material, estimated to stem from the steric repulsion of D/L-tartaric acids around Tb(III) ions induced by the chiral α-CDs [57].

6.2.5.1 Synthesis of Solid-State Phosphorescence Insulated Metallopolymers

Transition metal complexes have gained importance as components for light-emitting diodes (LEDs) [41, 58, 59] and in optical sensing [60, 61] and bio-imaging [62] devices because of their highly effective and long-wavelength phosphorescence at room temperature. In the solid state, they are expected to produce higher-density phosphorescent materials, which will display brighter emissions per unit volume than their dilute counterparts [63]. However, their desirable phosphorescence in the solid state decreases or changes drastically [64, 65] as a result of their indiscriminate molecular interactions with adjacent molecules [66]. Therefore, they exhibit high performance only under highly dilute conditions (such as in a matrix with a very low doping concentration). Several examples of exceptional solid-state phosphorescence have been achieved through the adequate control of molecular arrangements or the inhibition of undesirable molecular interactions in crystalline systems [67–69]. However, the simple concentration of diluted phosphorescent materials cannot increase their emission densities, but rather can lead to unpredictable changes in emission behavior [70–73]. As practical device materials, polymers are of interest owing to their high processability and thermodynamic stability as compared with low-molecular-weight materials. However, their intrinsic disorder in the solid state, which is due to their high degrees of freedom, makes it difficult to organize a well-ordered structure, such as in the crystalline solid state. For this reason, applications of phosphorescent polymer materials have been limited to highly diluted systems, which are usually formed by doping a polymer matrix or through copolymerization with a low mixing ratio [74]. Thus, to achieve high-density phosphorescence in polymer solid materials, two contradictory requirements must be simultaneously satisfied: (i) a higher concentration for brighter emission and (ii) a lower concentration to inhibit molecular interactions. Nevertheless, because of their potential application in solid-state phosphorescent polymer devices, the development of such materials has been eagerly pursued; the insights obtained would contribute to progress in the field of device science. By using macrocycles for higher-order inhibition, only the desired area of a polymer chain can be covered, without any interstitial space, to achieve higher-density phosphorescence. In 2014, poly(phenylene ethynylene) (PPE), covered with permethylated cyclodextrin, omnidirectionally insulated metallopolymers composed of platinum acetylide, and oligoPE as the polymer backbone was synthesized (Fig. 6.13) [75, 76]. Two unprecedented cyclic insulation effects on the phosphorescence behavior of the metallopolymers are described: (i) the cyclic insulation enhances phosphorescence and (ii) identical phosphorescence behaviors are observed in the high-density solid state as well as in dilute solution. The uninsulated platinum acetylide polymer 12 was synthesized by copper-catalyzed transmetalation of 1 with trans-PtCl2(PEt3)2 in a hydrophobic solvent (piperidine). The corresponding insulated polymer 13 was obtained from the same monomers in the hydrophilic solvent, MeOH/H2O (2:1), from insulated complex 2. To examine the effects of the cyclic insulation area and PE units, insulated polymer 14 was also synthesized from 6 bearing different oligoPE units. As expected, 13 displays a strong orange emission. In contrast, uninsulated polymer 12, which exhibited phosphorescence in dilute solution, shows very weak phosphorescence in the solid state, despite its bulky permethylated cyclodextrin side chains which cover the polymer backbone (Fig. 6.13). These results indicate that the insulation in polymer 13 prevents interactions with adjacent molecules, even in the solid state, achieving high-density phosphorescence. Because 13 also tolerated oxygen, as described above, it even exhibits phosphorescence in the solid state under an air atmosphere. In contrast, despite its insulation, 14 does not show any phosphorescence in the solid state, but only fluorescence. The triplet-state quenching observed in the polymer 14 solid should be caused by intermolecular interactions, similar to the case of 12, because 14 also displayed phosphorescence in dilute solution. Higher-order inclusion effects were observed on the phosphorescence behavior of platinum acetylide polymers fully covered with permethylated cyclodextrins. To our knowledge, this is an unprecedented example which integrates the features of phosphorescence and rotaxane structure. Complete three-dimensional insulation generated almost identical phosphorescence emission behaviors in solid systems as in dilute solutions because of protection from all interactions. Moreover, such insulation also led to oxygen tolerance: phosphorescence was observed under an air atmosphere in the solid state. This is the first example of the unimolecular phosphorescence of a polymer material in the high-density solid state.

Emission spectra of polymer solids of 12 (red), 13 (blue), and 14 (green) under degassed conditions (excitation: 405 nm) [76]

6.2.5.2 Synthesis of One-Dimensional Insulated Coordination Polymers

One-dimensional coordination polymers containing transition metals, which combine the advantages of organic insulated molecular wires mentioned above, with those of transition metal complexes have recently received much attention [77]. They are expected to form wiring materials with novel properties including (1) various characteristics derived from the transition metal complexes such as redox behavior and triplet-state properties and (2) enhanced processability such as recyclability and self-healing through reversible monomer–polymer interconversion brought on by the reversible nature of the non-covalent bonds as opposed to covalently bonded molecular wires. Insulated molecular wire 17 displayed novel processability as a result of its non-covalent bonding motif that was synthesized through the coordination polymerization of Ru(II) porphyrin complex 16 with insulated bridging ligand 15 having well-defined structures [78]. A remarkable property of coordination polymer 17 is its interconversion between monomer and polymer states under certain conditions due to the reversibility of its coordinate bonds (Fig. 6.14). Carbon monoxide (CO) underwent ligand exchange with the pyridyl groups on Ru(II) porphyrin complexes of 17, because of its stronger coordination ability, thereby yielding monomers 15 and 16. The resulting monomeric porphyrin complex was expected to subsequently release CO upon UV irradiation to reform 17. Although 17 was stable in toluene/EtOH even at 55 °C, decomplexation into monomers 15 and 16 occurred with 1 atm of CO, as confirmed by size-exclusion chromatography. Recomplexation of the air-stable monomers could subsequently be induced by UV irradiation of the resulting solution. The degree of polymerization after recomplexation was perfectly consistent with that before decomplexation. Thus, in spite of the stability of 17 and its monomeric components under normal conditions, monomer-to-polymer interconversion could be induced under specific conditions, i.e., either 1 atm of CO or UV irradiation. This property is unique to metal-containing molecular wires bearing coordinate bonds and may be applied in molecular wiring applications such as recycling and self-healing of wiring materials, in addition to as sensory materials for CO.

Schematic and SEC monitoring of polymer–monomer interconversion (eluent: THF) [78]

6.3 The Establishment of Wiring Methods Utilizing Organic Reactions Between Nanosized Gaps

The fabrication of molecular devices that use organic molecules, such as π-conjugate polymers and DNA, and carbon compounds, such as carbon nanotubes, as wiring materials is currently being widely studied [79, 80]. Three types of single molecular junction methods have been reported thus far: the break junction method, which is the connection of conjugated molecules via sulfur in the nanogap formed by bending a thin line made of gold; the electrostatic orientation method, which establishes a connection between DNA-coated nanoelectrodes using an electric field; and the junction method, which involves the vacuum deposition of carbon nanotubes over nanoelectrodes (though the probability of achieving a junction is low with this method). Many problems exist with such physical wiring methods including the low obtained current values, extremely low reproducibility, and small number of molecular line connection. A method for connecting conjugated molecules using a thiol group on both ends of the nanoelectrodes, by forming gold and sulfur bonds, with chemisorption of thiol groups on gold has been used for this purpose. However, there are issues, such as low probability and reproducibility of line connections because of (i) poor bonded sections reacting on the same electrodes (because the directionality and linearity of the conjugated chains are low), (ii) aggregation of conjugated chains due to π–π interactions, and (iii) occupation of chemisorption sites by heteroatomic species before a bridge can be formed; low transfer efficiency due to electron hopping between conjugated chains; and difficulty in fabricating nanoelectrodes with identical gaps (because conjugated chains corresponding to the electrode distance must be synthesized) [81, 82]. This research will make molecular junctions that do not rely on the distance between electrodes possible, by performing synthesis reactions in the nanospace between them. This buildup method involves the assembly of conjugated molecular units that are shielded from the electrode surfaces. In other words, there will be no need to fabricate or synthesize nanoelectrodes and wiring molecules of the same lengths. It will become possible to perform wiring simultaneously and with greater numbers of conjugated molecules than conventional methods because molecular junctions will be formed by chemical reactions. High conductivity is expected because charge transfers should only occur within conjugated chains, because the chains are shielded and no aggregations should develop between them. Furthermore, applications for practical electrically conductive luminescent materials are expected, because the conductivity and fluorescence quantum yield will increase because of the independent nature of the conjugated polymer chains. The application of spin coating or inkjet methods, which are cheap manufacturing processes, will be possible because the materials are soluble in most organic solvents.

In 2006, Taniguchi et al. developed a new wiring method for fabricating nanosized photoswitching devices (Fig. 6.15) [83]. In this process, electrodes with nanosized gaps were sequentially dipped into a solution of benzenethiol possessing a reactive site, immersed into a solution of wiring molecules, and finally exposed to a solution of functional molecules; the three molecules were then connected via a transition metal-catalyzed cross-coupling reaction. The key to the success of this method lies in the use of CD-based π-conjugated polyrotaxane as the wiring molecule to maintain structural linearity and isolate the π-conjugated polymer chain.

However, this “buildup” method was limited because the synthesis of molecular wires with defined lengths and the fabrication of nanosized electrodes of appropriate lengths were elaborate processes. Therefore, it would be ideal to develop a new wiring method that would be independent of the lengths of the molecular wires and the gaps [84]. To overcome these issues, attempts were made to wire between the nanogaps by polymerizing the insulated monomer 6, which was characterized by excellent organic solubility and a high coverage ratio and linearity (Fig. 6.16) [85]. Nanosized electrodes with a 20 nm gap were fabricated via electron beam lithography and a lift-off process, using a silicon dioxide layer and gold/titanium electrodes. The fabricated electrode was then dipped into 4 mM 1,2-bis(4-ethynylphenyl)diselenide 18 in dichloromethane to form a Au–Se bond by chemical adsorption, which could serve as a reaction site. After washing with dichloromethane, the surface-modified nanosized electrode was placed in a dichloromethane solution of 3 and stirred for 2 days under Hay coupling conditions to elongate the π-conjugated chain from the surface of the nanosized electrodes, followed by washing. GPC analysis of the solution after the wiring reaction showed that 3 disappeared completely and confirmed that the insulated molecular wires 7 had formed. The electric current was 8 pA for 1 V. These results clearly demonstrated that molecular wiring was achieved using this polymerization method. To evaluate the covering effect of the insulated conjugated monomer, the same wiring method was performed using the uninsulated monomer and five nanosized electrodes. Although GPC analysis of the solution after the wiring reaction confirmed that the uninsulated polymer had formed, none of the electrodes exhibited current values over the measurement limit.

This result indicated that the molecular wiring efficiency using the uninsulated monomer was much less efficient than that with the insulated monomer, which maintains structural linearity and isolation of the π-conjugated moiety. This difference was probably due to the high degree of π–π interactions or flexibility of the former, leading to low-molecular wiring efficiency by aggregation and bending. As shown in Fig. 6.17, a newly developed wiring technique between the nanogaps to fabricate a nano-optical switching device has been developed by copolymerizing the insulated monomer with the photochromic molecule. The resultant electrode was dipped into a solution of 18 to fabricate the modified nanosized electrode with surface polymerization sites. After washing, the electrode was placed in a solution of 6 and diiododiarylethene, which was stirred for 2 days under Sonogashira copolymerization conditions, to form connections between the electrodes and, under ultraviolet irradiation, to drive the photochromic diarylethene segments into the ring-closing state. GPC analysis of the solution after the wiring reaction confirmed that 11 had formed. To confirm the connection of each molecule by this copolymerization wiring method, electric conduction between the electrodes was measured. The initial electric current was 80 nA for 1 V (ON state). Irradiation of the molecules with visible light required to drive the photochromic diarylethene residues into the ring-opening state (OFF state), and then UV radiation required to switch them into the ring-closing state (ON state). The electric current in molecular wire 11 ⊂ nanogap decreased to 45 nA for 1 V under visible light, but increased to 70 nA for 1 V under ultraviolet radiation, indicating a reversible switching property with light. The observed switching behavior strongly supported the assertion of binding of the molecules between the nanosized electrodes, affording molecular wiring by our newly developed technique to fabricate photoswitching nanodevices.

6.4 Summary and Conclusions

This chapter highlights a new method for synthesizing insulated molecular wires through the polymerization of structurally defined permethylated cyclodextrin-based rotaxane monomers. The insulated molecular wires thus formed have a high coverage ratio, rigidity, and PL efficiency and showed high charge mobility in the solid state; further, they are readily soluble in a variety of organic solvents. There was significant fluorescence and phosphorescence enhancement in the insulated molecular wires, especially in the solid state, which suggests that encapsulation of the π-conjugated polymer chains by permethylated cyclodextrin is essential to attain efficient fluorescence properties. A cholesteric LC phase was observed for polyrotaxanes because of the polymer’s high rigidity and structure featuring a π-conjugated polymer chain threaded through chiral macrocycles. A highly insulated organic semiconductor wire in the solid state was demonstrated with hole mobility along the π-conjugated polymer chain achieving close to that of amorphous silicon. The thus-formed polyrotaxane structure prevents π-stacking of the conjugated main chains even in the solid phase, leading to prolongation of the lifetime of charged radicals on the conjugated backbone by blocking the charge recombination processes.

This chapter also highlights a new type of molecular wiring method based on the polymerization or copolymerization of an insulated π-conjugated monomer between nanosized electrodes. Measuring the conductivity of π-conjugated polymers has thus far been either impossible or difficult, because of hopping conduction between neighboring conjugated chains. Taking conductivity measurements of singly conjugated chains will be possible, because using our wiring method will produce π-conjugated chains that are independent of their environment. This is expected to clarify the electrical conduction mechanisms of π-conjugated polymers, which has been considered difficult until now. The proposed research is a unique concept of the applicant, and as such, no studies that are similar to this are being conducted elsewhere.

This research is expected to drastically reduce manufacturing costs. It is also expected to be environmentally friendly and to make a contribution to green innovation because petroleum products are used instead of rare elements, such as Ge or Ir, which are currently used for highly integrated devices. To successfully make molecular electronics, it is important to gain access to synthesize single π-conjugated polymers with metal terminals and understand the behavior of their electrons.

Once the our fabrication method of molecular electronics are established, quantities of single molecule devices can be fabricated in a solution process at lower cost and with higher reproducibility than the conventional physical methods, which involve top-down fine processing technology and require expensive equipment. This technology for innovative nanosized molecular electronics is expected to overcome “Moore’s law” and dramatically change industry and society. Currently large amounts of energy are required to prepare integrated circuits by photon and electron beam lithography in clean rooms. The proposed method would offer immense energy-saving effects by preparing molecular electronics in comparatively inexpensive chemical reactors. This method would be advantageous for mass production, because molecular devices, prepared by the assembly of molecular elements, could be prepared in the order of moles.

References

Moore GE (1985) Electron Mag 38:114

Jalabert A, Amara A, Clermidy F (2008) Molecular electronics materials devices and applications. Springer, Berlin

Petty MC (2007) Molecular electronics from principles to practice. Wiley, Chichester

Pope M, Kallmann HP, Magnate P (1963) J Chem Phys 38:2042

Kudo K, Yamashina M, Moriizumi T (1984) Jpn J Appl Phys 23:130

Tang CW (1986) Appl Phys Lett 48:183

Forrest SR (2004) Nature 428:9113

Wenz G (2009) Inclusion polymers. Springer, Berlin

Frampton MJ, Anderson HL (2007) Angew Chem Int Ed 46:1028

Pan C, Zhao C, Takeuchi M, Sugiyasu K (2015) Chem Asian J 10:1820–1835

Schlüter AD, Rabe JP (2000) Angew Chem Int Ed 39:864

Wenz G, Han B-H, Müller A (2006) Chem Rev 106:782

Sleiman H, Baxter P, Lehn J-M, Rissanen K (1995) J Chem Soc Chem Commun 715

Harada A, Kamachi M (1990) Macromolecules 23:2823–2824

Harada A, Li J, Kamachi M (1992) Nature 356:325

Harada A, Li J, Kamachi M (1992) Nature 364:516

Yoshida K, Shimomura T, Ito K, Hayakawa R (1999) Langmuir 15:910

Akai T, Abe T, Shimomura T, Ito K (2001) Jpn J Appl Phys 40:L1327

Shimomura T, Akai T, Abe T, Ito K (2002) J Chem Phys 116:1753

Shimomura T, Akai T, Fujimori M, Heike S, Hashizume T, Ito K (2005) Synth Met 153:497

Taylor PN, O’Connell MJ, McNeill LA, Hall MJ, Aplin RT, Anderson HL (2000) Angew Chem Int Ed 39:3456

Michels JJ, O’Connell MJ, Taylor PN, Wilson JS, Cacialli F, Anderson HL (2003) Chem Eur J 9:6167

Cacialli F, Wilson JS, Michels JJ, Daniel C, Silva C, Friend RH, Severin N, Samorì P, Rabe JP, O’Connell MJ, Taylor PN, Anderson HL (2002) Nat Mater 1:160

Terao J, Tang A, Michels JJ, Krivokapic A, Anderson HL (2004) Chem Commun 56

Tsuda S, Terao J, Kambe N (2009) Chem Lett 38:76

Terao J, Tsuda S, Tanaka Y, Okoshi K, Fujihara T, Tsuji Y, Kambe N (2009) J Am Chem Soc 131:16004

Tsuda S, Terao J, Tsurui K, Kambe N (2009) Chem Lett 38:190

Tsuda S, Terao J, Tanaka Y, Maekawa T, Kambe N (2009) Tetrahedron Lett 50:1146

Terao J, Tanaka Y, Tsuda S, Kambe N, Taniguchi M, Kawai T, Saeki A, Seki S (2009) J Am Chem Soc 131:18046

Terao J, Ikai K, Kambe N, Seki S, Saeki A, Ohkoshi K, Fujihara T, Tsuji Y (2011) Chem Commun 47:6816–6818

Terao J, Kimura K, Seki S, Fujihara T, Tsuji Y (2012) Chem Commun 48:1577

Terao J, Wadahama A, Matono A, Tada T, Watanabe S, Seki S, Fujihara T, Tsuji Y (2013) Nat Commun 4:1691

Terao J (2011) Chem Rec 11:269

Terao J (2011) Polym Chem 2:2444

Terao J, Homma K, Konoshima Y, Imoto R, Masai H, Matsuda W, Seki S, Fujihara T, Tsuji Y (2014) Chem Commun 50:658

Wong W-Y, Ho C-L (2010) Acc Chem Res 43:1246

Wild A, Winter A, Schlütter F, Schubert US (2011) Chem Soc Rev 40:1459

Mas-Ballesté R, Gómez-Herrero J, Zamora F (2010) Chem Soc Rev 39:4220

Leong WL, Vittal JJ (2011) Chem Rev 111:688

Koepf M, Chérioux F, Wytko JA, Weiss J (2012) Coord Chem Rev 256:2872

Evans RC, Douglas P, Winscom CJ (2006) Coord Chem Rev 250:2093

Zhao Q, Li F, Huang C (2010) Chem Soc Rev 39:3007

Dul M-C, Pardo E, Lescouëzec R, Journaux Y, Ferrando-Soria J, Ruiz-García R, Cano J, Julve M, Lloret F, Cangussu D, Pereira CLM, Stumpf HO, Pasán J, Ruiz-Pérez C (2010) Coord Chem Rev 254:2281

Bodenthin Y, Schwarz G, Tomkowicz Z, Lommel M, Geue T, Hasse W, Möhwald H, Pietsch U, Kurth DG (2009) Coord Chem Rev 253:2414

Nijhuis CA, Ravoo BJ, Huskens J, Reinhoudt DN (2007) Coord Chem Rev 251:1761

Tam AY, Yam VW (2013) Chem Soc Rev 42:1540

Burnworth M, Tang L, Kumpfer JR, Duncan AJ, Beyer FL, Fiore GL, Rowan SJ, Weder C (2011) Nature 472:334

Ho C-L, Wong W-Y (2011) Coord Chem Rev 255:2469

Zhao X, Cardolaccia T, Farley RT, Abboud KA, Schanze KS (2005) Inorg Chem 44:2619

Marvaud V, Launay JP (1993) Inorg Chem 32:1376

Tokuhisa H, Kanesato M (2005) Langmuir 21:9728

Kim H-J, Jung E-Y, Jin LY, Lee M (2008) Macromolecules 41:6066

Liu Y, Zhao Y-L, Zhang H-Y, Song H-B (2003) Angew Chem Int Ed 42:3260

Yang Y-W, Chen Y, Liu Y (2006) Inorg Chem 45:3014

Zhao Y-L, Zhang H-Y, Guo D-S, Liu Y (2006) Chem Mater 18:4423

Han C, Zhang L, Li H (2009) Chem Commun 3545

Yoshida D, Tsuchiya Y, Noguchi T, Yamamoto T, Dawn A, Shinkai S (2013) Chem Eur J 19:15485

Costa RD, Ortí E, Bolink HJ, Monti F, Accorsi G, Armaroli N (2012) Angew Chem Int Ed 51:8178

Xiao L, Chen Z, Jiaxiu BQ, Luo J, Kong S, Gong Q, Kido J (2011) Adv Mater 23:926

Ma D-L, Ma VP, Chan DS, Leung KH, He HZ, Leung CH (2012) Coord Chem Rev 256:3087

Liu Z, He W, Guo Z (2013) Chem Soc Rev 42:1568

Mou X, Wu Y, Liu S, Shi M, Liu X, Wang C, Sun S, Zhao Q, Zhou X, Huang W (2011) J Mater Chem 21:13951

Baggaley E, Weinstein JA, Williams JAG (2012) Coord Chem Rev 256:1762

Zhu YC, Zhou L, Li HY, Xu QL, Teng MY, Zheng YX, Zuo JL, Zhang HJ, You XZ (2011) Adv Mater 23:4041

Juliá F, Bautista D, Fernández-Hernández JM, González-Herrero P (2014) Chem Sci 5:1875

Wagner PJ, Hammond GS (1968) In: Noyes WA Jr, Hammond G, Pitts JN Jr (eds) Advances in photochemistry, vol 5. Interscience Publishers, New York

Hong Y, Lam JWY, Tang BZ (2011) Chem Soc Rev 40:5361

Komiya N, Okada M, Fukumoto K, Jomori D, Naota T (2011) J Am Chem Soc 133:6493

Bolton O, Lee K, Kim HJ, Lin KY, Kim J (2011) Nat Chem 3:205

Lo SC, Harding RE, Shipley CP, Stevenson SG, Burn PL, Samuel IDW (2009) J Am Chem Soc 131:16681

Lo SC, Male NAH, Markham JPJ, Magennis SW, Burn PL, Salata OV, Sammuel IDW (2002) Adv Mater 14:975

Kim JJ, You Y, Park YS, Kim JJ, Park SY (2009) J Mater Chem 19:8347

Tang MC, Tsang DPK, Chen MMY, Wong KMC, Yam VWW (2013) Angew Chem Int Ed 52:446

Gong S, Yang C, Qin J (2012) Chem Soc Rev 41:4797

Terao J, Masai H, Fujihara T, Tsuji Y (2012) Chem Lett 41:652

Masai H, Terao J, Makuta S, Tachibana Y, Fujihara T, Tsuji Y (2014) J Am Chem Soc 136:14714

Masai H, Terao J, Tsuji Y (2014) Tetrahedron Lett 55:4035

Masai H, Terao J, Seki S, Nakashima S, Kiguchi M, Okoshi K, Fujihara T, Tsuji Y (2014) J Am Chem Soc 136:1742

Tao NJ (2006) Nat Nanotechol 1:173

Jalabert A, Amara A, Clermidy F (2008) Molecular electronics materials devices and applications. Springer, New York

Tang J, Wang Y, Klare JE, Tulevski GS, Wind SJ, Nuckolls C (2007) Angew Chem Int Ed 46:3892

Kiguchi M, Nakashima S, Tada T, Watanabe S, Tsuda S, Tsuji Y, Terao J (2012) Small 8:726

Taniguchi M, Nojima Y, Yokota K, Terao J, Sato K, Kambe N, Kawai T (2006) J Am Chem Soc 128:15062

Meng F, Hervault Y–M, Shao Q, Hu B, Norel L, Rigaut S, Chen X (2014) Nat Commun 5:3023

Terao J, Homma K, Konoshima Y, Taniguchi M, Kimoto Y, Horikawa M, Naito Y, Fujihara T, Tsuji Y (2014) Bull Chem Soc Jpn 87:871

Acknowledgments

I greatly acknowledge the experimental and intellectual contribution of my coworkers listed in the references that have made possible the research described herein.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer Science+Business Media Singapore

About this chapter

Cite this chapter

Terao, J. (2016). Synthesis and Physical Properties of Three-Dimensionally Insulated Molecular Wires. In: Kiguchi, M. (eds) Single-Molecule Electronics. Springer, Singapore. https://doi.org/10.1007/978-981-10-0724-8_6

Download citation

DOI: https://doi.org/10.1007/978-981-10-0724-8_6

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-0723-1

Online ISBN: 978-981-10-0724-8

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)