Abstract

Oil-insulated transformer is the main source of power substation fire. It is important therefore to investigate the fire suppression of transformer oil pool fires. Experiments were conducted in a 3 × 3 × 3 m room to study the transformer oil pool fire suppression by water mist. The square pool fire with dimensions of 17, 25, and 30 cm and a downward-directed single-injector nozzle with operating pressures of 1.0, 2.5, and 4 MPa were considered in the experiments. The flame shape during water mist application was recorded by a video camera. The temperature, CO concentration, and flame thermal radiation were measured to evaluate the fire suppression process by water mist. The results show that the flame would be intensified due to the injection of water mist at the initial period, and the intensification phenomenon is related to the fire size and the injection pressure of water mist system. The flame intensification occurred obviously under low injection pressure and large-size fire conditions. In addition, the fire extinguishment time increases with the decrease of the injection pressure and the increase of pool size. The results of this work would be valuable for optimizing the water mist system in the application of transformer substation fire suppression.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

With the development of social economy and electricity industry, the coverage of transformer substations expanded incrementally, and oil-immersed transformer played an essential part in large transformer substations. The fire risk of transformer oil fire has been increased due to overheat, leaking out, etc. The damage and loss of transformer oil fire are extremely very large, due to the fire releasing lots of heat and toxic gases [1, 2]. So it is important and necessary to study the protection and suppression technologies for transformer oil fire.

Water mist being considered as a clean and efficient fire-extinguishing agent has been widely studied and applied [3–8]. Especially, water mist systems have been proven to be effective in suppressing transformer fires in certain situations [9]. Fire suppression using water mist is a complex problem, which involves several combined physical phenomena [10, 11]. The main effects usually observed in water mist action are gas-phase cooling, oxygen displacement, fuel vapor dilution, and wetting and cooling of the fuel surface [12]. Wang et al. [13] conducted tests with kerosene, alcohol, and heptane pool fires and found that in the cases of heptane and ethanol pool fires, water mist suppressed and extinguished them quickly through cooling and oxygen displacement. But in the case of kerosene, combustion was enhanced at the beginning of water mist application due to impediment of soot particles, evaporation expansion, and the chain reactions. The studies about water spray suppression and intensification of high-flash-point hydrocarbon pool fires by Ho [14] indicated that flame intensification occurred to the mineral seal oil and cooking oil pool fires, which are class IIIB liquids with a flash point at or above 93 °C. Cong et al. [15] investigated extinction limit of diesel pool fire and found that the fuel surface cooling is the dominant mechanism at extinction limit and fire intensification was dependent on the effective water flux and the plume-spray thrust ratio.

However, the suppression of transformer oil pool fire by water mist has been seldom studied. So experimental study on water mist suppression of transformer oil pool fire was conducted. The results would provide some guidance for water mist applied on transformer substation facilities.

2 Experimental Apparatus and Materials

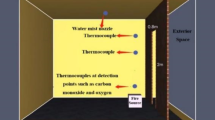

The schematic diagram of the experimental apparatus is shown in Fig. 92.1. A downward-pointing solid-cone water mist nozzle was installed 2.0 m above the fuel pan. The flame and plume temperatures were measured with seven K-type thermocouples with bead diameters of 1 mm and a resolution of 0.1 °C, which are located between 0.0 m and 1.05 m above the fuel pan with an interval of 0.15 m. A radiative heat flux meter was installed 0.45 m above the fuel pan and at a horizontal distance of 0.6 m from the center of the fuel pan. The flue gas analyzer to measure the CO concentration was installed 1.05 m above the fuel pan and at a horizontal distance of 0.25 m from the center of the fuel pan. An electric balance with sampling intervals of 0.1 s and a resolution of 0.01 g was positioned below the fuel pan to measure the mass loss rate without water mist. The square pool fires with dimensions of 17, 25, and 30 cm were tested in the experiments. The 25# transformer oil was used as the fuel and whose properties can be seen in Table 92.1.

Because the transformer oil is a high-flash-point hydrocarbon fuel, it is not easy to be ignited, so a small amount of N-heptane fuel was used to ignite it. The experimental test cases were shown in Table 92.2. In each test, the water mist activated after the fuel pre-burn for about 120 s.

3 Water Mist Characteristics

Water mist was discharged from a single fluid-type nozzle prototype with seven heads made of stainless steel. Only the downward head was used in the experiments. The diameter of the orifice is 0.8 mm. The droplet size and velocity were obtained by a PDA (phase Doppler anemometry) system at the cross section 1.0 m away from the nozzle exit. Typical droplet size distribution at the radial locations of 0 cm and 15 cm under an injection pressure of 1.2 MPa is shown in Fig. 92.2. The droplet velocity distribution is shown in Fig. 92.3, and it shows that the mean velocities of U-, V-, and W-direction are 3.82, 0.77, and 0.86 m/s, respectively. Its other characteristics can be seen in Table 92.3.

4 Results and Discussion

4.1 Transformer Oil Fire Without Water Mist

The transformer oil fire combustion and flame characteristics were measured. Figure 92.4 shows the typical temporal evolution of temperature measured above the fuel pan of a 25 × 25 cm pool fire, and it can be seen that the maximum flame temperature is about 770 °C. For about 120 s after the fuel ignited, the burning was almost kept in the steady state. So in the latter cases with application of water mist, the activation time of water mist system was also at this time.

Figure 92.5a–c shows the temporal evolution of mass loss rate, CO concentration, and radiative heat flux for different pool fires without water mist. It can be seen that the mass loss rate, smoke production, and thermal radiation from transformer oil fire have large difference for fires with different pool size, i.e., the larger the pool size is, the higher the CO concentration and the radiative heat flux would be.

4.2 Fire Suppression and Flame Intensification with Water Mist

The fire suppression or flame intensification phenomenon occurred for different fire sizes and water mist work pressures. Figure 92.6 shows the results of experiment for fire extinguishment time. It can be seen that for pool fire with a dimension of 30 cm and water mist injection pressure of 1.0 MPa, the fire suppression was failed, while the others were successful. The fire extinguishment time increased with the increase of the pool size as well as the decrease of the injection pressure of water mist.

For the cases of fire suppression, the flame size and behavior after water mist activation were affected by the injection pressure. Figure 92.7 shows the flame image of 25 cm pool fire. For an injection pressure of 1.0 MPa, as shown in Fig. 92.7a, the flame sizes are always suppressed by the water mist through the whole fire extinction process. But for 4.0 MPa case, the flame size enlarged rapidly at the initial period of water mist injection, as shown in Fig. 92.7b, especially in lateral direction, which may be also deemed as a flame intensification, although the fire extinction time is short. Figures 92.8 and 92.9 show the temporal evolution of temperature and radiative heat flux for the fire under different injection pressures. Since the thermocouple trees were put at the centerline of flame plume above the fuel pan, the temperature shows no clear increase after water mist activation (shown in Fig. 92.8), although the flame intensification occurred. From Fig. 92.9, it can be seen that the radiative heat flux suddenly increased as soon as the water mist activated. The reason for the slight flame intensification is that the air entrainment was enhanced and the flame was deflected due to the high velocity of mist droplets. So the enlargement of flame by water mist should be avoided even though fire can be suppressed.

For the failed case of fire extinction, the flame was usually intensified due to water mist activation. To the relative large pool size of 30 cm and relative small spray injection pressure of 1 MPa, the flame intensification obviously occurred which is mainly due to the spray-induced oil splattering. In the observation, oil splash phenomenon was very obvious, and the flame height increased largely after water mist activation, as shown in Fig. 92.10a. Similarly, from Fig. 92.10b, it can be seen that the flame temperatures all increased first after water mist activation and fluctuated at relative high temperature. Figure 92.11 shows the radiative heat flux and CO concentration for 30 cm pool fire under different water mist injection pressures. Figure 92.11a shows that the flame intensification can be reflected by the variation of radiative heat flux and for the large injection pressure, the flame intensification also occurs due to the enlargement of flame in lateral direction. From Fig. 92.11b, it can be seen that the CO concentration increased slightly when water mist activated. But for the failed case, it increased largely due to the incomplete combustion by water mist.

From the above results, it can be seen that for larger pool fire and lower injection pressure water mist, the flame intensification occurred easily. So the flame intensification phenomenon in the practical water mist system applied on the transformer oil fire should be avoided. In addition, the appropriate water mist characteristic should be carefully selected for suppressing transformer oil fire.

5 Conclusions

The experiments about transformer oil fire suppression by water mist have been conducted. The following conclusions can be drawn:

-

1.

Fire extinguishment time increased with the increase of pool size and the decrease of injection pressure of water mist system.

-

2.

The flame size and behavior of transformer fire after water mist activation are related to the pool size and water mist injection pressure. With small injection pressure, the flame size would be enlarged obviously.

-

3.

Strong flame intensification phenomenon occurred to large pool size fire and low injection pressure of water mist system. All of the flame height, CO concentration, and radiative heat flux increased as the intensification phenomenon occurred.

-

4.

Appropriate water mist characteristics should be carefully optimized for suppressing transformer oil like liquid pool fires.

References

Petersen A, Blanc R, Carrander K et al (2012) Guide for transformer fire safety practices, Working Group A2.33

Duarte D (2012) Aspects of transformer fires in Brazil. Open J Saf Sci Technol 2:63–74

Gupta M, Pasi A, Ray A, Kale SR (2013) An experimental study of the effects of water mist characteristics on pool fire suppression. Exp Thermal Fluid Sci 44:768–778

Huang X, Wang XS, Liao GX (2011) Characterization of an effervescent atomization water mist nozzle and its fire suppression tests. Proc Combust Inst 33:2573–2579

Husted BP, Petersson P, Lund I, Holmstedt G (2009) Comparison of PIV and PDA droplet velocity measurement techniques on two high-pressure water mist nozzles. Fire Saf J 44:1030–1045

Mawhinney JR, Richardson JK (1997) A review of water mist fire suppression research and development. Fire Technol 1:54–90

Wang XS, Liao GX, Yao B, Fan WC, Wu XP (2001) Preliminary study on the interaction of water mist with pool fires. J Fire Sci 19:45–61

Wang XS, Zhao XD, Zhang Y, Cai X, Gu R, Xu HL, Liao GX (2009) Experimental study on the interaction of a water drop impacting on hot liquid surfaces. J Fire Sci 27:545–559

Bureau, Hydroelectric Research and Technical Services Group (2005) FIST 3-32, Transformer fire protection

Grant G, Brenton J, Drysdale D (2000) Fire suppression by water sprays. Fire Saf J 26:79–130

Liu Z, Kim AK (2000) Review of water mist fire suppression systems—fundamental studies. J Fire Prot Eng 10:32–50

Mawhinney JR, Back GG (2002) Water mist fire suppression systems. In: SFPE Handbook of fire protection engineering, pp 4.311–4.337

Wang XS, Liao GX, Qin J, Fan WC (2002) Experimental study on the effectiveness of the extinction of a pool fire with water mist. J Fire Sci 20:279–295

Ho San-Ping (2003). Water spray suppression and intensification of high flash point hydrocarbon pool fires, doctoral thesis. Worcester Polytechnic Institute

Cong BH, Liao GX, Huang Z (2009) Extinction limit of diesel pool fires suppressed by water mist. J Fire Sci 27:5–26

Acknowledgment

The authors appreciate the Natural Science Foundation of China (Grant No. 51323010), the Fundamental Research Funds for the Central Universities (WK23200000035), and the Anhui Provincial Natural Science Foundation (Grant No. 1408085MKL95).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer Science+Business Media Singapore

About this paper

Cite this paper

Zhu, P., Wang, X., Wang, Z., Cong, H., Ni, X. (2017). Experimental Study on Transformer Oil Pool Fire Suppression by Water Mist. In: Harada, K., Matsuyama, K., Himoto, K., Nakamura, Y., Wakatsuki, K. (eds) Fire Science and Technology 2015. Springer, Singapore. https://doi.org/10.1007/978-981-10-0376-9_92

Download citation

DOI: https://doi.org/10.1007/978-981-10-0376-9_92

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-0375-2

Online ISBN: 978-981-10-0376-9

eBook Packages: EngineeringEngineering (R0)