Abstract

A major target of strategies toward a more sustainable resource use must be to find ways of remaining within the planetary boundaries, not only by reducing overall resource use but also through keeping within the system what we are already using. This makes it necessary to take a systemic perspective and look at the whole life cycle of joint product systems, raw material inputs, and respective emissions. Knowing and understanding the dynamics of material stocks and flows may be a first step toward managing them. In the context of society, this approach is known as socioeconomic metabolism and is increasingly applied especially in regional and urban contexts. Here, we introduce material flow analysis as a possible method for constructing and evaluating material and energy flows to gain an insight into the flows of specific substances within the anthropogenic system. We show the main characteristics and applications as well as possible limitations of such a modeling approach and conclude with implications for a further development of such methods to enable a shift from analysis to assessment and strategy building that reflects sustainability principles and goes beyond efficiency.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Material flow analysis

- Socioeconomic metabolism

- Industrial ecology

- Life cycle assessment

- Stocks and flows

1 Society’s Dependency on Materials: Avoiding End-of-Pipe Solutions

Issues of current and future raw material use and the resource needs are vital for sustainable development (Graedel and van der Voet 2010). Either the resources are actually vital, like water, or they are built into devices that make life easier or contribute to certain aspects of sustainable development (such as clean energy production devices). Take the case of smartphones and mobile computing. Far exceeding all estimations made on their future demand, worldwide mobile phone subscriptions have increased from 33.9 % in 2005 to an estimated 96.2 % in 2013 (Fig. 18.1) (ITU 2013). They have become essential components of our everyday life and fulfill vital functions, especially in developing countries, for example, in banking and the organization of health care in remote areas (cf. the VillageReach program in Malawi (VillageReach 2014)).

But this also makes us highly dependent on the availability of raw materials. Before being used or built into a device, they must be mined and refined, and measures must be taken once they are put out of use. There are, for example, more than 40 chemical elements built into a single phone (Wäger and Lang 2010), partly in such small amounts that it is next to impossible to recycle them.

The aim, therefore, must be not only to reduce the overall amount of resources we take from the Earth but also to keep those we are already using within the system. In order to minimize the amount of valuable resources being disposed of in landfills or lost through dissipation (understood as “the ‘dilution’ of materials into the technosphere or ecosphere in such a way that their recovery is made difficult or impossible” (Wäger et al. 2012)), we need to aim for an optimization of the according processes and interfaces between the various phases. In other words, we must look at the whole life cycle of a product and its raw materials. Ideally, this leads us to point at which (i) products that have reached their end-of-life stage become a stock (a mine, if you like) for new products and (ii) products that cannot be reused and recycled are compostable and therefore not producing waste and emissions.

2 Material Flows, the Socioeconomic Metabolism Concept and Industrial Ecology

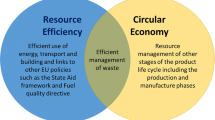

In order to achieve a level of resource consumption that remains within the planetary boundaries, it is necessary to take a systemic perspective. This includes shifting the focus from resource efficiency (i.e., from a rather static perspective) to the dynamics of flows and stocks (dynamic perspective). Knowing and understanding these material flows is an essential step toward managing them. It also allows us to identify and take into account side effects of the respective material use, not only throughout a product’s value chain but also in the broader context of human-environmental interactions.

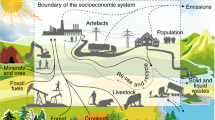

This way of looking at material flows in the context of society can be subsumed under the concept of socioeconomic metabolism. Originally derived from the biological and ecological perspective on an organism, the metabolism concept is widely used to comprehend energetic and material stocks and flows; their reactions, processes, and interrelations of and between entities; and different forms of inputs and outputs (Fischer-Kowalski 1998). Various disciplines, such as geology and anthropology, have developed this concept further, increasingly shifting its application to human society. Especially with the rise of environmental movements and society’s growing critique of economic growth in the 1960s, the metabolism of highly developed societies became a major issue and required a stronger collaboration to develop approaches that are capable of analyzing human-environmental interactions by radically crossing disciplinary boundaries of social, natural, and human sciences.

Box 18.1: Industrial Ecology

Industrial ecology - as an academic concept and a practical tool for policymakers (Gibbs and Deutz 2007) - arose in the 1990s from the idea of creating an industrial circular economy, in which industrial waste may serve as a source for others, also coining the term “industrial ecosystem” (Frosch et al. 1989).

Industrial ecology employs a metaphor that makes the idea tangible but also a little fuzzy (Graedel 1996).

The question of the practical utility of the idea of industrial ecology is consequently also a major point of critique (Gibbs and Deutz 2007). The “industry” part refers to its focus on improving industrial processes, which are a major cause of environmental disturbance, making companies the main addressees. The “ecology” part shows (i) the concept’s origin, i.e., taking natural ecosystems as a model for the design of industrial activities, as well as (ii) its intention, namely, to keep all human (industrial) action within the ecological frame that enables such action and to achieve effects of “industrial symbiosis” comparable to those found in nature (Lifset and Graedel 2002). “Industrial symbiosis engages traditionally separate industries in a collective approach to competitive advantage involving physical exchange of materials, energy, water, and/or by-products. The keys to industrial symbiosis are collaboration and the synergistic possibilities offered by geographic proximity.” (Chertow 2000)

Two prominent examples of eco-industrial parks, which apply IE principles, are:

-

Kalundborg in Denmark (Lowe 1997): See online Case Kalundborg

-

Ulsan in South Korea (Behera et al. 2012): See online Cases in South Korea

These historical developments, as well as current urbanization trends, require us to look into the functioning of our cities, i.e., human activities such as transportation, communication, living, and working (Baccini and Brunner 2012). More broadly, Kennedy et al. (2007) define it as “the sumtotal of the technical and socio-economic processes that occur in cities, resulting in growth, production of energy, and elimination of waste” (Kennedy et al. 2007).

Becoming more prevalent over the course of the last few decades, Wolman began a first holistic approach in accounting the urban metabolism of a hypothetical American city, revealing the first systemic insights on the impacts of production and consumption in 1965. Since then, a number of urban metabolism studies with varying foci have been conducted (Kennedy et al. 2011).

Comprehensive holistic overviews of urban metabolisms are not very common. Frequently, studies focus on isolated flows, depending on availability and quality of data. The example of Duvigneaud and Denayeyer-De Smet (1977) (see Fig. 18.2) illustrates one of the first analyses on energy flows within Brussels, adding the natural energy balance to the anthropogenic energy inputs. An integrative perspective is given through the assessment of carbon cycling with storage, input, and export, as it ascribes systemic flows to different sectors of buildings, transportation, humans, and vegetation from which carbon emissions originate (Kellett et al. 2013).

Informal Sankey diagram of the material and energy flow of Brussels (Duvigneaud and Denayeyer-De Smet 1977)

The focus on the spatial scale, the boundaries of the metabolism, is basic in order to define the significance, importance, and relative contribution of flows for the system and its relation to others, e.g., to global boundaries. Case studies are conducted from the household level (Cohen et al. 2005) to the neighborhood level (Kellett et al. 2013; Codoban and Kennedy 2008; Berg and Nycander 1997), and to the city level. They also relate across those scales to the respective hinterlands and regions. The hinterland fulfills a twofold role: as sink for urban waste and as source for resources and material. The work of Lenzen and Peters (2009) follows localized household consumption demands throughout Australia and reveals the upstream impacts on the hinterland of greenhouse gas emissions, water usage, and labor provision.

Given that input and output of materials happen with a certain time delay, the temporal scale also plays an important role in assessing resource flows in cities. Very young, fast-growing cities and older, slow-growing or shrinking cities differ in pace and amount of intake and output of materials and waste. This manifests, for example, in the building stock: When point in time for retrofitting of existing building stock arrives, dynamically, waste and bound resources (such as copper) are discharged and made available for future endeavors, but also require waste disposal, and consequently add on to the disadvantage of future generations. For example, the German Federal Environment Agency (Umweltbundesamt) approaches this issue with the project “Anthropogenic Stocks,” with which buildings, roads, and other facilities are inventoried to estimate future flows of material like concrete, steel, or copper. Such a model requires a dynamic material flow analysis (UBA 2012).

In order to strengthen the concept of a sustainable metabolism, it is crucial to consider the foregoing aspects in relation to the normative dimensions of the sustainability framework, including inter- and intragenerational components, as well as geographical inequalities in regions of the Global South versus the Global North. A transformative approach to reshaping resource flows into sustainable metabolisms requires broadening the conceptual basis of a current state analysis and including a sustainability appraisal.

2.1 Material Flow Analysis

One of the tools that help to better understand material flows and to assess the society’s metabolism is material flow analysis (MFA). “Material flow analysis refers to the analysis of the throughput of process chains comprising extraction or harvest, chemical transformation, manufacturing, consumption, recycling and disposal of materials.” (Bringezu and Moriguchi 2002).

The most important purpose of material flow analysis nowadays is efficiency analysis, such as in life cycle assessment (LCA), a special material analysis approach (Guinée 2002), which analyzes the impacts of products and services on the natural environment.

2.1.1 Material Flow Analysis as a Modeling Procedure

At its core, material flow analysis is a modeling process: the process of constructing and evaluating material and energy flow models. The purposes of those models are mainly insights into the flows of specific substances into the anthropogenic system, and the impacts of production, usage, and disposal of products and services on the environment, as well as the design of new production and supply networks. Regarding the metabolism concept, the modeling instrument analyzes the effects of societal institutions and processes on material and energy stocks and flows and therefore on the natural environment.

Four main modeling steps generally apply: (i) defining the goals and framing the system that is to be analyzed, (ii) informal analysis of the process chain, (iii) modeling and calculation, and (iv) evaluation of the model (cf. Bringezu and Moriguchi 2002). Core modeling steps are an informal analysis of supply chains, product life cycle, and the transformation of the conceptual model into a formal model that allows for calculating the dynamics of flows, stocks, and other metabolic indicators.

From a mathematical perspective, the step of constructing formal material flow models is the construction of a graph G = (V, E) that consists of a finite set of nodes V (in case of MFA processes) and a set of links or edges E between the nodes where the flows take place. These graphs are called flow sheets or networks. The second step is to specify the processes by defining the relationships between the input and the output flows of each process in a way that a modeling expert or computer can evaluate them to calculate formerly unknown flows within the system. A third step is to specify already known “manual” flows, for instance, the planned product output per year (reference flows in life cycle assessment, cost objects in future-oriented cost accounting), feed streams on the input side (chemical engineering), or other parameters of the model.

Figure 18.3 shows such a model with two nested loops: The production system consists of two different chemical processes (chemical reactor 1 and chemical reactor 2). The second chemical process uses a by-product of the first process as its input. The purpose of MFA is to determine all relevant flows and the process levels of the unit processes.

The modeling steps result in a system of nonlinear equations (Westerberg et al. 1979, p. 14), which (1) specify the relationships within the unit processes, (2) link the processes (connecting equations) to one another, and (3) link the manual flows or design specifications (Chen and Stadtherr 1985).

The aim of the calculation step, mainly performed by computers today, is to solve the system of nonlinear equations and to know all material and energy flows, which occur in the material flow model. The algorithms are called solvers. Different solvers can be distinguished. If we want to find future steady states of the material and energy flow system (steady-state modeling), the solver has to calculate time-independent flow rates (flows per time unit). The main problem of calculating steady states is dealing with loops. Loops are a characteristic of metabolisms, but they inhibit direct sequential calculation. Different approaches are developed to deal with loops and recycle flows: the sequential modular approach, the simultaneous modular approach, and the equation-based approach (Westerberg et al. 1979; Westerber and Piela 1994).

Another class of solutions emphasizes the dynamics of material and energy flow systems, in which the flow rates are rather time-dependent functions. Consequently, the solver has to deal with a system of (ordinary) differential equations, as in system dynamics (Hannon and Ruth 1994). This kind of analysis is called a dynamic MFA. Here, steady-state approaches cannot be applied to solve a system of (ordinary) differential equations (ODEs) as initial value problems (Finlayson 2012, p. 356). Continuous simulation and integration methods like Euler–Cauchy and Runge–Kutta 2/4 come into play.

Different evaluation methods exist, including very simple approaches like a direct evaluation through input/output balance or sophisticated impact assessment methods to estimate effects like climate change or ozone depletion. Substance flows can be visualized by splitting flows into their components (e.g., phosphorus) and with aid of Sankey diagrams.

Direct evaluation methods do not include efficiency analyses like LCA, but they may be performed as a subsequent modeling step, consisting of (1) a period-oriented material flow analysis with the purpose of providing a material and energy flow model for a given system (region (urban metabolism), supply chain, production site, etc.) and (2) a subsequent efficiency analysis, for which the period-oriented material model provides the data.

2.2 Focus and Limitations of Different Types of MFA

Because LCA is in line with generalized action orientations in our economic system (efficiency (Taylor 1911), key performance indicators, etc.) and can be combined with cost accounting, it is a very attractive instrument in the field of material flow analysis, just like carbon or water footprinting (Weidema et al. 2008).

However, such efficiency analyses do not cover all relevant metabolism core indicators (Fischer-Kowalski & Hüttler 1999), for instance, absolute stocks and flows and their dynamics. In addition to life cycle thinking, several modeling images are discussed for MFA. One of them is “verbund.” The term is used in the chemical industry as one of the most important design metaphors. The idea of the verbund, which has existed in the chemical industry for more than 100 years, becomes more and more important in other parts of our socio-technical metabolism, for instance, as an approach to regional material flow analysis. Regions are interpreted as a verbund, including production, consumption, agriculture, services, waste management, and energy supply. Chemical processes feed other chemical processes, so that ideally, no waste streams and emissions occur, making consistency and symbiosis important design principles, as new chemical processes and products must fit into the verbund.

Also, LCAs do not support insights into the interplay between stocks and flows. Relevant challenges in the field of sustainability result from the fact that, in modern societies, this interplay of stocks and flows has been changed dramatically: scarcity of raw materials, waste disposal, artificial substances in the natural environment, the concentration of carbon dioxide in the atmosphere, etc. Therefore, metaphors like verbund can be applied to broaden the horizon.

Nevertheless, the main focus of all MFA instruments is on material flows and stocks. In modern societies, material flows and stocks are extended by immaterial flows and stocks: computer-based information systems and networks. It is very difficult to model the effects of these flows on the natural environment, for instance, the carbon footprint of single emails. Direct and indirect impacts must be distinguished, and the indirect impacts of already existing infrastructures like computers and routers are very high. Often, typical examples in the field of MFA and LCA are steel, concrete, and packaging, but not services of modern computer-based communication and information infrastructures.

3 Toward Sustainable Material Flows: Further Developments and the Role of MFA for Sustainable Development

While theoretical and conceptual thoughts on material flows and their value for sustainable development are fairly strongly developed, the operationalization of sustainability principles within their tools and practical application are still rather undeveloped in parts: In order to achieve material flows that may be considered “sustainable,” we will have to shift from analysis to assessment and strategy building (Wiek et al. 2012); specifically, this means to link analytical results (what are the material flows in a given region) to sustainability principles that go beyond efficiency (what are sustainable material flows in this region).

At first sight, today’s smartphones are an example of dematerialization: They are 1 billion times more powerful as, while being only a fraction of the size of, the first computers in the 1940s, such as Konrad Zuse’s Z1, which weighed about 500 kg and consumed electric energy of 1 kWh. Still, the total material input has increased due to the fact that there are many more smartphones and computers in the world now than back then (known as rebound effect). Therefore, we have to consider total amounts, as well as developments over time, in order to achieve material use that is consistent with our planetary boundaries.

Consequently, when going into the direction of sufficiency principles, the necessity to shift from analysis to assessment clearly comes to the fore: more precisely, instead of focusing on improving existing processes (analysis), sustainability assessments would consider whether the process is actually “good.” This advancement demands more interdisciplinary work, such as tapping into social and cultural norms in order to understand and integrate questions of lifestyle and behavior change, or taking into account the possibility of applying low-tech solutions.

So far, strategies focusing purely on optimization of material flows might disregard a resilience perspective. Improvement of flows and infrastructure from an efficiency perspective should be in close interrelation with stability and resilience of the system at hand: Shocks affecting the system, such as extreme climate change events in urban areas, can severely damage dependent systems operating without any redundancies and diversity. This may result in lack of service provision, social segregation, and security issues and eventually threaten the well-being of residents.

Taking all these aspects into account will afford an increased amount of planning and management. This may include material flow management, which also replaces approaches for end-of-life waste disposal, i.e., aiming at waste reduction instead of reuse or mere disposal (Lang et al. 2006), and may be supported through national legislation and international agreements. But it also calls for improved procedures for the process of finding the best possible solutions considering regional characteristics, norms, and needs, including transdisciplinary approaches. A practical example for such a process is the BRIDGE project (see http://bridge-fp7.eu). Across several transdisciplinary case studies with Firenze (Italy), Helsinki (Finland), and Gilwice (Poland), the BRIDGE Decision Support System (DSS) aims to connect the analytical tool with a sustainability appraisal and evaluation design for urban planning interventions on the basis of both material flow data and socioeconomic criteria (Chrysoulakis et al. 2013). These are first steps toward a transformational approach and metamorphosis of the urban metabolism to broaden its conceptual basis away from a purely analytical tool but with serious chances for interdisciplinary and transdisciplinary research.

Further Reading

Ayres RU, Ayres LW (eds) (2002) A handbook of industrial ecology. Edward Elgar Publications, Cheltenham/Northampton

Baccini P, Brunner PH (2012) Metabolism of the anthroposphere: analysis, evaluation, design. MIT Press, Cambridge

Fischer-Kowalski M (1998a) Society’s metabolism – the intellectual history of material flow analysis, part I, 1860–1970. J Ind Ecol 2(1):61–78

Fischer-Kowalski M, Hüttler W (1999a) Society’s metabolism – the intellectual history of material flow analysis, Part II, 1970–1998. J Ind Ecol 2(4):107–136

Graedel TE, van der Voet E (eds) (2010) Linkages of sustainability. The MIT Press, Cambridge

Journal of Industrial Ecology (2012) Special Issue: Sustain Urban Syst 16(6): 775–715

References

Baccini P, Brunner PH (2012) Metabolism of the anthroposphere: analysis, evaluation, design. MIT Press, Cambridge

Behera SK et al (2012) Evolution of “designed” industrial symbiosis networks in the Ulsan Eco-industrial Park: “research and development into business” as the enabling framework. J Clean Prod 29–30:103–112

Berg PG, Nycander G (1997) Sustainable neighbourhoods - a qualitative model for resource management in communities. Landsc Urban Plann 39(2):117–135

Bringezu S, Moriguchi Y (2002) Material flow analysis. In: Ayres RU, Ayres LW (eds) A handbook of industrial ecology. Edward Elgar Publications, Cheltenham/Northampton, pp 79–90

Broyden CG (1965) A class of methods for solving nonlinear simultaneous equations. Math Comput 19:577–593

Chen H-S, Stadtherr MA (1985) A simultaneous-modular approach to process flowsheeting and optimization, part I: theory and implementation. AIChE J 31(11):1843–1856

Chertow MR (2000) Industrial symbiosis: literature and taxonomy. Annu Rev Energy Environ 25:313–37

Chrysoulakis N et al (2013) Sustainable urban metabolism as a link between bio-physical sciences and urban planning: the BRIDGE project. Landsc Urban Plann 112:100–117

Codoban N, Kennedy CA (2008) Metabolism of neighborhoods. J Urban Plann Dev 134(1):21–31

Cohen C, Lenzen M, Schaeffer R (2005) Energy requirements of households in Brazil. Energy Policy 33:555–562

Duvigneaud P, Denayeyer-De Smet S (1977) L’Ecosystéme Urbain Bruxellois, in Productivité en Belgique. In: Duvigneaud P, Kestemont P (eds) Traveaux de la Section Belge du Programme Biologique International, Bruxelles, pp 581–597

Erkman S (2002) The recent history of industrial ecology. In: Ayres RU, Ayres LW (eds) A handbook of industrial ecology. Edward Elgar Publications, Cheltenham/Northampton, pp 27–35

Finlayson BA (2012) Introduction to chemical engineering computing, 2nd edn. Wiley, Hoboken

Fischer-Kowalski M (1998) Society’s metabolism – the intellectual history of material flow analysis, part I, 1860–1970. J Ind Ecol 2(1):61–78

Fischer-Kowalski M, Hüttler W (1999) Society’s metabolism – the intellectual history of material flow analysis, part II, 1970–1998. J Ind Ecol 2(4):107–136

Frosch RA, Gallopoulos NE (1989) Strategies for manufacturing. Sci Am 189(3):144–152

Gibbs D, Deutz P (2007) Reflections on implementing industrial ecology through eco-industrial park development. J Clean Prod 15(17):1683–1695

Graedel TE (1996) On the concept of industrial ecology. Ann Rev Energy Environ 21:69–98

Graedel TE, van der Voet E (2010) Linkages of sustainability. MIT Press, Cambridge/London

Graedel TE et al (2012) Methodology of metal criticality determination. Environ Sci Technol 46(2):1063–1070

Guinée JB (Final ed) (2002) Handbook on life cycle assessment – operational guide to the ISO standards. Kluwer Academic Publishers, Dordrecht/Boston/London

Hannon B, Ruth M (1994) Dynamic modeling. Springer, Berlin/Heidelberg/New York

Heijungs R (1994) A generic method for the identification of options for cleaner products. Ecol Econ 10:69–81

Heijungs R, Suh S (2002) The computational structure of life cycle assessment. Kluwer Academic Publishers, Dordrecht

ITU (International Telecommunications Union) Statistics (2013) ICT facts and figures. Available at: http://www.itu.int/en/ITU-D/Statistics/Pages/stat/default.aspx. Accessed 21 Apr 2014

Kellett R, Christen A, Coops NC, van der Laan M, Crawford B, Tooke TR, Olchovski I (2013) A systems approach to carbon cycling and emissions modeling at an urban neighborhood scale. Landsc Urban Plan 110:48–58

Kennedy C, Cuddihy J, Engel-Yan J (2007) The changing metabolism of cities. J Ind Ecol 11(2):43–59

Kennedy C, Pincetl S, Bunje P (2011) The study of urban metabolism and its applications to urban planning and design. Environ Poll 159(8–9):1965–73

Lang DJ, Binder CR, Scholz RW, Schleiß K, Stäubli B (2006) Impact factors and regulatory mechanisms for material flow management: Integrating stakeholder and scientific perspectives The case of bio-waste delivery. Resour Conserv Recy 47:101–132

Lenzen M, Peters GM (2009) How city dwellers affect their resource hinterland. J Ind Ecol 14(1):73–90

Lifset R, Graedel TE (2002) Industrial ecology: goals and definitions. In: Ayres RU, Ayres LW (eds) A handbook of industrial ecology. Edward Elgar Publications, Cheltenham/Northampton, pp 3–15

Lowe EA (1997) Creating by-product resource exchanges: strategies for eco-industrial parks. J Clean Prod 5(1–2):57–65

Möller A (2000) Grundlagen stoffstrombasierter Betrieblicher Umweltinformationssysteme. Projekt Verlag, Bochum (in German)

Möller A (2004) Continuous simulation in material flow networks. In: Proceedings of the iEMSs 2004 “Complexity and Integrated Resource Management”, Osnabrueck

Möller A (2005) Dynamic material flow analysis in the life cycle assessment tool chain. In: Geldermann J, Treitz M, Schollenberger H, Rentz O (eds) Challenges for industrial production. Universitätsverlag, Karlsruhe

Reisig M (1985) Petri nets – an introduction. Springer, Berlin/Heidelberg/New York

Riebel P (1994) Core features of the ‘Einzelkosten- und Deckungsbeitragsrechnung’. Euro Account Rev 3(3):515–546

Taylor FW (1911) The principles of scientific management. Harper & Brothers Publications, New York/London

UBA 2012 What matters (2012): annual report of the Federal Environment Agency. Available at: https://www.umweltbundesamt.de/sites/default/files/medien/publikation/long/4296.pdf

VillageReach (2014) http://villagereach.org/

Wäger PA, Lang DJ (2010) Seltene Metalle – Rohstoffe für Zukunftstechnologien. Available at: http://www.satw.ch/publikationen/satwinfo/SelteneMetalle.pdf

Wäger PA et al (2012) Towards a more sustainable use of scarce metals - a review of intervention options along the metals life cycle. GAIA 21(4):300–309

Weidema B, Thrane M, Christensen P, Schmidt J, Loekke S (2008) Carbon footprint – a catalyst for life cycle assessment? J Ind Ecol 12(1):3–6

Westerberg AW, Piela PC (1994) Equational-based process modeling. Technical report. Department of Chemical Engineering and the Engineering Design Research Center - Carnegie Mellon University, Pittsburgh

Westerberg AW, Hutchinson HP, Motard RL, Winter P (1979) Process flowsheeting. Cambridge University Press, London/New York/Melbourne

Wiek A, Ness B, Brand FS, Schweizer-Ries P, Farioli F (2012) From complex systems analysis to transformational change: a comparative appraisal of sustainability science projects. Sustain Sci 7(Suppl 1):5–24

Wolman A (1965) The metabolism of cities. Sci Am 213(3):179–190

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer Science+Business Media Dordrecht

About this chapter

Cite this chapter

John, B., Möller, A., Weiser, A. (2016). Sustainable Development and Material Flows. In: Heinrichs, H., Martens, P., Michelsen, G., Wiek, A. (eds) Sustainability Science. Springer, Dordrecht. https://doi.org/10.1007/978-94-017-7242-6_18

Download citation

DOI: https://doi.org/10.1007/978-94-017-7242-6_18

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-017-7241-9

Online ISBN: 978-94-017-7242-6

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)