Abstract

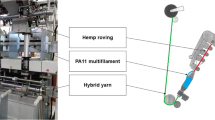

Commingled yarns are one of the possible preforms used for continuous fiber reinforced thermoplastic composites in order to solve the problem of high melt viscosity during impregnation and consolidation as the required steps for manufacturing of technical components. The preforms can be considered as‘dry’ prepregs, in which the solid resin is physically divided and more or less evenly distributed among the reinforcement fibers. Division of the polymer can be made using either powder or the fiber form. Glass fiber (GF) manufacturers (e.g. Vetrotex, France) especially took advantage of their expertise in fiber spinning to develop a commingling process for glass and thermoplastic filaments (Figure 1 (a)) [1]. In their patented one-step process, Vetrotex succeeded in producing commingled yarns with a rather uniform distribution of small glass and thermoplastic fiber bundles, a good consistency of the glass content, a wide range of the GF volume fraction (20–50 vol.%), and the price level of industrial glass composites. Polypropylene (PP) has been their first choice for achieving a good balance between versatility of performance, ease of processing, and price (tradename Twintex®). More recently, a material with PET (polyethylene-terephthalate) fibers was developed for applications needing better thermal resistance and higher strength.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Guillon, D. and Saint-John, C. (1995) Twintex®, a material for the composite industry, personal communication at IVW in 1996; see also: Proceedings of the International Conference on Composite Materials ICCM-10, Whistler, Canada, August 1995, Vol. III, (eds A. Poursartip and K. Street), Woodhead Publishing, Cambridge, UK, pp. 757–764.

Hamada, H., Maekawa, Z.I., Ikegawa, N. and Matsuo, T. (1993) Influence of the impregnating property on mechanical properties of commingled yarn composites. Polymer Composites, 14(4), 1993, 308–313.

Van West, B.P., Pipes, R.B. and Advani, S.G. (1991) The consolidation of commingled thermoplastic fabrics, Polymer Composites, 12(6), 417–427.

Svensson, N., Shishoo, R. and Gilchrist, M. (1998) Manufacturing of thermoplastic composite from commingled yarns — a review, J. Thermoplast. Composite Mater., 11, 22–56.

Mäder E., (1997) Textile preforms for tailored fibre-reinforced thermoplastics, Wiss. Z. Tech Univers. Dresden, 46, 20–26.

Cain, T.A., Wakeman, M.D., Brooks, R., Long, A. and Rudd, C.D. (1996) Isothermal consolidation of a co-mingled thermoplastic composite, in Proceedings of the European Conference on Composite Materials ECCM-7, London, UK, 1996, (ed. M. Bader), Woodhead Publishing, Cambridge, UK, pp. 57–62 and pp. 221-227.

Klinkmüller, V., Um, M.K., Steffens, M., Friedrich, K. and Kim, B.-S. (1995) A new model for impregnation mechanisms in different GF/PP commingled yarns. Appl. Comp. Mat., 1, 351–371.

Ostgathe, M., Breuer, U., Mayer, C. and Neitzel, M. (1996) Fabric reinforced thermoplastic composites — Processing and Manufacturing, in Proceedings of the European Conference on Composite Materials ECCM-7, London, UK, 1996, Vol. 1, (ed. M. Bader), Woodhead Publishing, Cambridge, UK, pp. 195–200.

Michaeli, W. and Jürs, D. (1996) Thermoplastic pull-braiding: Pultrusion profiles with braided fiber lay-up and thermoplastic matrix system (PP), Composites, 27A(1), 3–7.

Neitzel, M., Funck, R., Haupert, F., Friedrich, K. and Schwarz, W. (1994) Filament winding with thermoplastic matrices-current development and equipment, in Proceedings of the Japan International SAMPE Technical Seminar’ 94 (JISTES’94), Kyoto, Japan, July 14 and 15, 1994, (ed. N. Teranishi), SAMPE, Tokyo, pp. 149–168.

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 1999 Springer Science+Business Media Dordrecht

About this chapter

Cite this chapter

Friedrich, K. (1999). Commingled yarns and their use for composites. In: Karger-Kocsis, J. (eds) Polypropylene. Polymer Science and Technology Series, vol 2. Springer, Dordrecht. https://doi.org/10.1007/978-94-011-4421-6_12

Download citation

DOI: https://doi.org/10.1007/978-94-011-4421-6_12

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-010-5899-5

Online ISBN: 978-94-011-4421-6

eBook Packages: Springer Book Archive