Abstract

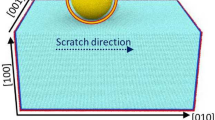

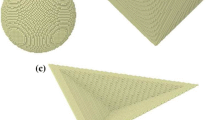

The molecular dynamics computer simulation method is used to study the indentation and scraping of a clean metal surface by a hard diamond tool. Both two and three dimensional models are considered. The embedded atom method is used to represent a metallic work material. To make connection with macroscopic continuum models, we calculate the stress field from the atomistic computer experiment. The agreement is excellent during the initial elastic indentation. However, the onset of plastic deformation occurs at a much higher yield stress in the atomistic simulations. This enhanced hardness, with shallow indentations, corresponds to the theoretical yield stress required to create dislocations and leads to a dramatic increase in specific cutting energy for small depths of cut. Remarkably, the range of plastic deformation in our three dimensional simulations is only a few lattice spacings, unlike the several hundred lattice spacings dislocations readily propagate in our two dimensional simulations. This suggests that dislocations are not a very efficient mechanism for accommodating strain at this nanometer length scale in three dimensions.

Work performed under the auspices of the U.S. Department of Energy by the Lawrence Livermore National Laboratory under contract No. W-7405-ENG-48.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Donaldson, R.R., Syn, C.K., Taylor, J.S. and Riddle, R.A. (1987) “Chip Science: A Basic Study of the Single-Point Diamond Turning Process,” Lawrence Livermore National Laboratory Report UCRL-53868–87.

Belak, J. and Stowers, I.F. (1990) “A Molecular Dynamics Model of the Orthogonal Cutting Process,” Proceedings of the 1990 Annual Meeting of the American Society of Precision Engineers, Rochester, NY, pp76–79.

Landman, U. (1991) “Computer Simulations,” These Proceedings.

Daw, M.S. and Baskes, M.I. (1984) “Embedded Atom Method: Derivation and Application to Impurities, Surfaces, and other Defects in Metals,” Phys. Rev. B 29, 6443–6453.

Holian, B.L., Voter, A.F., Wagner, N.J., Ravelo, R.I., Chen, S.P., Hoover, W.G., Hoover, C.G., Hammerberg, J.E. and Dontje, T.D. (1990) Los Alamos National Laboratory Report LA-UR-90-3566.

Oh, D.J. and Johnson, R.A. (1989) “Embedded Atom Method Model for Close-Packed Metals,” in V. Vitek and D.J. Srolovitz (eds.) Atomistic Simulation of Materials: Beyond Pair Potentials, Plenum Press, New York, pp233–238.

Pharr, G.M. and Oliver, W.C. (1989) “Nanoindentation of Silver—Relations between Hardness and Dislocation Structure,” J. Mater. Res. 4, 95–101.

McClintock, F.A. and Argon, A.S. (1966) Mechanical Behavior of Materials, Addison-Wesley Publishing, Reading.

Johnson, K.L. (1985) Contact Mechanics, Cambridge University Press, Cambridge.

Bowden, F.P. and Tabor, D. (1950) The Friction and Lubrication of Solids, Clarendon Press, Oxford.

Belak, J. (1990) Unpublished calculations. Our energy scale differs by a factor of three from that used by Holian et. al, because we take the standard Lennard-Jones model as our reference two-body potential model while Holian et. al use one third of this model. We find that both the Young’s modulus (E) and Poisson’s ratio (v) are independent of direction for the 2D triangularlattice. At T = Tmelting / 4, E ≈ 57.5 ± 2.5 ɛ/σ2 and v ≈ 0.43 ± 0.02. The shear modulus (G) depends upon the direction of shear within the crystal. However, we can define an effective isotropic shear modulus as G = E/ 2(1 + v) ≈ 20.1 ± 0.5 ɛ/σ2. The theoretical yield strength (Yt) is calculated by performing constant tension computer experiments on an initially perfect crystal. We find the system to yield at a strain of about 8 percent under an applied tension of Yt ≈ 2.4 ± 0.2 ɛ/σ2.

Belak, J, Hoover, W.G., DeGroot, A.J., and Stowers, I.F (1990) “Molecular Dynamics Modeling Applied to Indentation and Metal Cutting,” Lawrence Livermore National Laboratory release PR-16039.

Moriwaki, T. and Okuda, K. (1989) “Machinability of Copper in Ultra-Precision Micro Diamond Cutting,” Annals of CIRP 38, 115–118.

Stowers, I.F, Belak, J., Lucca, D.A., Komanduri, R., Rhorer, R.L., Moriwaki, T., Okuda, K., Ikawa, N., Shimada, S., Tanaka, H., Dow, T.A. and Drescher, J.D. (1991) “Molecular Dynamics Simulation of the Chip Formation Process in Single Crystal Copper and Comparison with Experimental Data,” Proceedings of the 1991 Annual Meeting of the American Society ofPrecision Engineers, Santa Fe, NM, pp100–103.

Shaw, M.C (1984) Metal Cutting Principles, Clarendon Press, Oxford; Backer, W.R., Marshall, E.R., and Shaw, M.C. (1952) “The Size Effect in Metal Cutting,” Trans. of ASME 74, 61.

Gane, N. and Bowden, F.P. (1968) “Microdeformation of Solids,” J. Appl. Phys. 39, 1432–1435; see also Pethica, J.B. (1991) “Mechanical Responses of Materials on the Nanometer Scale,” These Proceedings.

Suh, N.P. (1986) Tribophysics, Prentice-Hall, Englewood Cliffs, p96 and references therein.

Childs, T.H.C. (1991) Private communication; see also reference 15.

Hull, D. and Bacon, D.J. (1984) Introduction to Dislocations, Pergamon Press, Oxford.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 1992 Springer Science+Business Media Dordrecht

About this chapter

Cite this chapter

Belak, J., Stowers, I.F. (1992). The Indentation and Scraping of a Metal Surface: A Molecular Dynamics Study. In: Singer, I.L., Pollock, H.M. (eds) Fundamentals of Friction: Macroscopic and Microscopic Processes. NATO ASI Series, vol 220. Springer, Dordrecht. https://doi.org/10.1007/978-94-011-2811-7_25

Download citation

DOI: https://doi.org/10.1007/978-94-011-2811-7_25

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-010-5249-8

Online ISBN: 978-94-011-2811-7

eBook Packages: Springer Book Archive