Abstract

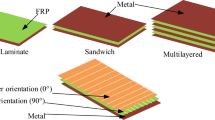

As the name Fibre Metal Laminates (FML) already suggests, they are a mixture of sheet material and fibres, bonded by an adhesive. Arall and Glare are the first and second generation FMLs respectively However, other potential variants have been developed with success as well. In the early nineties a carbon titanium laminate was developed for operating temperatures up to 300 °C, while at this moment, a glass aluminium laminate is under development for elevated temperatures up to 180 °C. As well as developing other laminates, different manufacturing processes have also been investigated. For example, a special manufacturing process for seamless tubes was successfully developed.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

M.J.L. van Tooren, J. Sinke, H.E.N. Bersee, Composties: Materials, Structures & Manufacturing Processes, Dictaat 32, Delft (NL), May 1993

T. de Boer, The development of an elevated temperature FML. Master’s thesis, Delft (NL), May 2000

J. L.M. Mensink, Thermal properties and possible space applications of Fibre Metal Laminates, Delft (NL), April 1994

C.A.J.R. Vermeeren, The application of carbon fibres in Ar all Laminates. Report LR 658, Delft (NL), September 1991

E.W. Medenblik, Enhancement of Fibre Metal Laminates for use ate elevated temperatures, Drexel University

E.W. Medenblik, Titanium fibre metal laminates, Master’s thesis, Delft (NL), January 1994

M.G. de Koos, Peek carbon fibre reinforced titanium laminates, Delft (NL), October 1990

C. Verseput, The production of seamless Fibre Metal Laminate tubes. Delft (NL), May 1994

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2001 Springer Science+Business Media Dordrecht

About this chapter

Cite this chapter

de Boer, T. (2001). Next Generation Fibre Metal Laminates. In: Vlot, A., Gunnink, J.W. (eds) Fibre Metal Laminates. Springer, Dordrecht. https://doi.org/10.1007/978-94-010-0995-9_3

Download citation

DOI: https://doi.org/10.1007/978-94-010-0995-9_3

Publisher Name: Springer, Dordrecht

Print ISBN: 978-1-4020-0391-2

Online ISBN: 978-94-010-0995-9

eBook Packages: Springer Book Archive