Abstract

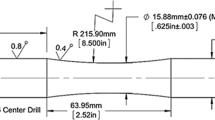

As part of a research project investigating metallographic methods of life prediction in low alloy ferritic steels, a creep testing programme is being carried out on 1%Cr-0.50025Mo steel in a simulated weld heat affected zone condition. The major creep damage mechanism in this fully bainitic material is the nucleation and growth of cavities at prior austenite grain boundaries, resulting in low ductility intergranular fracture (uniaxial failure strains are typically less than 2%). Since cavity growth is considered to be driven by the maacimum principal stress σ l, and creep deformation to be controlled by equivalent stress \(\bar \sigma \), a torsion creep test programme was initiated to quantify the effects of stress state on damage accumulation and failure. Choice of a “thin-wall” specimen to simplify comparisons between uniaxial and biaacial tests dictated the use of an inert atmosphere to combat oxidation effects. This requirement was reinforced by the use of test temperatures up to 675°C for test acceleration in order to maintain the operational creep mechanism (Cane and Townsend, 1984). Existing torsion-tension creep machines were modified to accept gas boxes and torsion testpieces with threaded ends. Methods of strain monitoring and gas sealing were adapted for torsion testing.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

BS3500: Part 3 (1969) Methods for Creep and Creep Rupture Testing of Metals. British Standards Institution, London.

Cane, B. J. (1981) Creep damage accumulation and fracture under multiaxial stresses. Advances in Fracture Research, Proc. 5th International Conference on Fracture, Cannes, 29 March-3 April 1981, Pergamon Press, Oxford, pp. 1285–93.

Cane, B. J. and Townsend, R. D. (1984) Prediction of remaining life in low alloy steels. Flow and Fracture at Elevated Temperature, ASM, Metals Park, Ohio, pp. 279–316.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 1986 Elsevier applied Science Publishers Ltd

About this chapter

Cite this chapter

Shammas, M.S., Marchant, K.D. (1986). Torsion Testing in an Inert Atmosphere. In: Gooch, D.J., How, I.M. (eds) Techniques for Multiaxial Creep Testing. Springer, Dordrecht. https://doi.org/10.1007/978-94-009-3415-3_6

Download citation

DOI: https://doi.org/10.1007/978-94-009-3415-3_6

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-010-8027-9

Online ISBN: 978-94-009-3415-3

eBook Packages: Springer Book Archive