Abstract

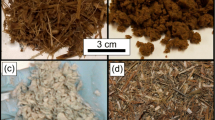

The liquefaction of biomass is discussed in this paper from the perspective of processing wood-solvent suspensions. The particular rheology of these systems, the need for solvation and the treatment of suspensions in the 10 to 30% initial solids content has led to the development of a methodology which involves thermomechanical pretreatment as a key step of the overall liquefaction process. Configuration of the pretreatment loops and their influence on defibration and solvation will be presented and discussed relative to their effects on liquefaction.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Figueroa, C, Schaleger, L.L. and Davis, H.G., “LBL Continuous Bench Scale Liquefaction Unit: Operations and Results”, Lawrence Berkeley Laboratory, Technical Information Dept., Univ. of California at Berkeley, publ. no. LBL-13709, (1982), 17 p.

Davis, H.G., “Direct Liquefaction of Biomass: Final Report and Summary of Effort 1977–1983”, prepared for the U.S. DOE, Lawrence Berkeley Laboratory, Technical Information Dept., Univ. of California at Berkeley, publ. no. LBL-16243, (1983), 92 p.

Mason, W.H., 1928, “Apparatus for and process of explosion fibration of lignocellulosic material”, U.S. Patent no. 1 655 618 (10 January 1929).

Brown, D.B. and Bender, R., “Feeding natural cellulose fiber into steam pressure vessel for manufacture of fodder from waste wood chips, straw, bagasse, etc.”; Canadian Patent no. 1 070 537 (29 January 1980).

Wayman, H., 1980, “Alcohol from cellulosics: the autohydrolysis-extraction process”, NTIS document no. conf. 8010302, US Dept. of Commerce, Springfield, VA, USA.

Eager, R.L., Mathews, J.F. and Pepper, J.M., “Continuous Reactor for the Liquefaction of Aspen”, Comptes rendus de l’atelier de travail sur la liquéfaction de la biomasse, publ. of the National Research Council of Canada, NRCC no. 23120, (1983), pp. 11–80.

White, D.H., Homaidan, A., Chehab, M., Schott, N.R., Wolf, A. and Lenyar, A., “Modified Extruder for Feeding Fine-Ground Cellulosic Slurries to Pressure Systems”, Proceedings of the 13th Biomass Ther-mochemical Conversion Contractor’s Meeting (Arlington, Virginia), U.S. DOE, (1981), pp. 576–645.

Gullichsen, J.E., “Innovations through Explorations of Fiber-Water Interactions”, Proceedings of the Marcus Wallenberg Foundation: Symposium No. 3, publ. by the Marcus Wallenberg Foundation, S-791 80, Falun (Sweden), ISSN 0282–4647, (1986), pp. 44–68.

Vanasse, C, Chornet, E. and Overend, R.P., “Liquéfaction de matières lignocellulosiques par voie organo-solvolytique”; influence des forces de cisaillement élevées sur la désaggrégation et la dépolymérisation des constituants majeurs”, rapport préparé pour le Programme de Développement en Bioénergie, Division des énergies renouvelables, Energie, Mines et Ressources Canada, Ottawa, dossier no DSS: 055V.23216–4–6202, (1986), 278 p.

Vanasse, C, Lemonnier, J.P., Eugène, D., Chornet, E. and Overend, R.P., “Pretreatment of Wood Flour Slurries Prior to Liquefaction”, The Can. J. Chem. Eng., (1988), 66, pp. 107–111.

Overend, R.P. and Chornet, E., “A unified treatment for liquefaction”, presented at the Conf. on Research in Thermochemical Biomass Conversion, May 2–6, 1988, Arizona, USA (to be published in the proceedings).

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 1988 Elsevier Science Publishers Ltd

About this chapter

Cite this chapter

Chornet, E., Vanasse, C., Lemonnier, J.P., Overend, R.P. (1988). Preparation and Processing of Medium and High Consistency Biomass Suspensions. In: Bridgwater, A.V., Kuester, J.L. (eds) Research in Thermochemical Biomass Conversion. Springer, Dordrecht. https://doi.org/10.1007/978-94-009-2737-7_58

Download citation

DOI: https://doi.org/10.1007/978-94-009-2737-7_58

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-010-7728-6

Online ISBN: 978-94-009-2737-7

eBook Packages: Springer Book Archive