Abstract

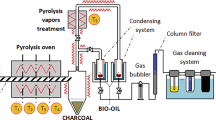

Conventional pyrolysis produces charcoal, pyrolysis oil and gas in approximately equal proportions. However fast pyrolysis has the potential for producing over 60% of an organic pyrolysis oil from biomass. The oil can be used as a low grade boiler fuel or the vapors can be converted to gasoline-like fuels.

However, fast pyrolysis requires high rates of heat transfer. Heat transfer can be greatly enhanced by pressure contact between biomass and hot solid surfaces. A “pyrolysis mill” has been developed to produce pyrolysis oil from biomass particles. Mass balance data is presented on six runs on sawdust. Yields of up to 54% of liquid have been achieved to date. Research is now in progress to optimize liquid yield and quality.

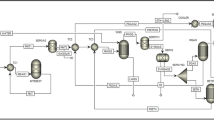

A simple model of the operation of the pyrolysis mill is presented. In the model particles fall between the millstones near the center and follow a spiral path of n turns to the edge. Rotation rate and pressure determines the residence time and degree of pyrolysis. The model predicts a mass flow of 1.7 tons/day for a 1 m diameter mill wheel, and such a mill would require a heat input of 20 kW. Multiple wheels could be used to improve the throughput.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Stern, A. J. and Harris, E. E., “Chemical Processing of Wood”, Chemical Publishing Co., New York, 1953.

Reed, T. B., Diebold, J. P. and Desrosiers, R. “Perspectives in Heat Transfer Requirements and Mechanisms for Fast Pyrolysis”, Proceedings of the Specialists Workshop on the Fast Pyrolysis of Biomass, Copper Mountain, CO., Oct. 12 1980, Solar Energy Research Institute, Golden, CO. 80401, SERI/CP-622–1096.

Lede, J., Panagopoulos, J., Li, H. Z. and Villermaux, J., “Fast Pyrolysis of Wood: Direct Measurement and Study of Ablation Rate”, Fuel 64, 1985, 1514.

Reed, T. B. and Cowdery;, C. D., “Heat Flux Requirements for Fast Pyrolysis and a New Method for Generating Biomass Vapor”, in Symposium Production Analysis and Upgrading of Oils from Biomass, Denver, CO April 5, 1987. Division of Fuel Chemistry, the American Chemical Society, Volume 32, No. 2, 1987.

Reed, T. B., Diebold, J. P., Chum, H. L., Evans, R. J. Milne, T. A. and Scahill, J. W., “Overview of Biomass Fast Pyrolysis and Catalytic Upgrading to Liquid Fuels,” in Proceedings of the American Solar Energy Society, K. W. Boer, Ed., Boulder, CO June 11, 1986.

Cowdery, C. D., “Measurement of the Mass and Energy Balance in Contact Fast Pyrolysis of Wood”, Master’s thesis, T-3459, Colorado School of Mines, Golden, CO, September 1987.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 1988 Elsevier Science Publishers Ltd

About this chapter

Cite this chapter

Reed, T.B. (1988). Contact Pyrolysis in a “Pyrolysis Mill”. In: Bridgwater, A.V., Kuester, J.L. (eds) Research in Thermochemical Biomass Conversion. Springer, Dordrecht. https://doi.org/10.1007/978-94-009-2737-7_15

Download citation

DOI: https://doi.org/10.1007/978-94-009-2737-7_15

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-010-7728-6

Online ISBN: 978-94-009-2737-7

eBook Packages: Springer Book Archive