Abstract

This chapter presents data on the nutrient management practices of Tasmanian potato growers and data from Tasmanian and other research on tuber yield and quality responses to fertilizers. Together, this information shows that most growers apply more nitrogen, phosphorus and potassium than is removed in the tubers they harvest and in many cases more than can be justified on the basis of known responses to these elements. This behavior is discussed in relation to the risks of underfertilising on the one hand and the risks of environmental and food safety impacts on the other.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

Tasmanian potato growers operate in a global marketplace and therefore are subject to economic pressures that require them to make the most efficient use of inputs including fertiliser, which can constitute as much as 30% of variable costs of production. Foreign imports of processed potato products are increasing (DPIF 2009) which puts downwards pressure on the prices offered to local farmers for their crops, while burgeoning global demand for fertiliser saw its cost more than double in 2008. While fertiliser costs have remained relatively static since, it is difficult to see the general cost–price “squeeze” on growers easing in the immediate future. In addition to increasing economic pressures, Tasmanian potato growers are also subject to growing community expectations that farming will produce safe food and have minimal impact on the natural environment. This chapter summarises the results of Tasmanian research aimed at better understanding the fertiliser needs of potatoes, how soil and plant tests can help predict these needs, and also at understanding the barriers Tasmanian farmers face in adopting more efficient management practices and complying with regulatory requirements.

2 Fertiliser Use by Tasmanian Potato Growers and Tasmanian Potato Soil Fertility

Potatoes in Tasmania are almost all grown with nitrogen (N), phosphorus (P) and potassium (K) fertiliser. Some micronutrients are occasionally applied even though there is no evidence of responses to their application (see Sect. 17.5). Macronutrients such as sulphur, calcium and magnesium have not been shown to be deficient, and they are not routinely applied in fertiliser. Most of the NPK is banded as a mix of diammonium phosphate and potassium chloride at planting, with some N also applied as urea during the growth of the crop. Potassium sulphate is not used because it is more expensive than potassium chloride and, as noted above, sulphur deficiencies have not been observed in potatoes in Tasmania.

A survey of 54 growers (about 15% of the Tasmanian industry) in 2001 (Cotching and Sparrow unpublished data) showed median N, P and K fertiliser rates in excess of 200 kg N ha−1 and 200 kg P ha−1 and almost 300 kg ha−1 for K (Table 17.1), with little difference in rates across soil types. In a separate Tasmanian study, Lisson et al. (2009) found that seven growers applied 279–442 kg N ha−1 to potatoes. The N and K rates above are not atypical of potato production elsewhere (e.g. Maier 1986 in South Australia, Hyatt et al. 2010 in Minnesota, USA), but the rates of P in Tasmania are some of the world’s highest (c.f. 40–75 kg P ha−1 in Minnesota, USA (Rosen and Bierman 2008), 80–115 kg P ha−1 in Prince Edward Island, Canada (Sanderson et al. 2003), and 30–70 kg P ha−1 in South Australia (Maier et al. 1989)), mostly because Ferrosols in Tasmania have extremely high P fixation capacity (Moody 1994, Sparrow et al. 1992), a characteristic which is also the main reason why the P fertiliser is banded at planting and not broadcast on these soils beforehand (Sparrow et al. 1992).

Extractable P and K and pH of the surveyed soils (Table 17.1) were higher in Ferrosols than in other soils because Ferrosols in Tasmania have been more intensively cropped (Cotching 1995). Tuber yields were comparable with the Tasmanian average of 49 Mg ha−1 reported in Chap. 15.

Growers presumably apply high rates of NPK because on responsive sites the potential benefits are thought to outweigh the potential risks. Based on 2010 fertiliser prices and crop returns (see footnote to Table 17.2), tuber yields have to increase only by about 5 kg per kg of N applied, 12 kg per kg of P and 6 kg per kg of K applied, to pay for the fertiliser application. An examination of published Russet Burbank N, P and K yield responses obtained in Tasmanian field trials (Sparrow and Chapman 2003a; Sparrow et al. 1992; Chapman et al. 1992), and relevant P trials on Ferrosols from Victoria, Australia (Freeman et al. 1998) shows that the break-even point where adding extra N, P or K becomes unprofitable is not reached until crop yield is very close to maximum (Table 17.2). Corresponding N, P and K fertiliser rates are also shown, and largely vindicate the grower rates shown in Table 17.1. Furthermore, break-even points are relatively insensitive to changes in potato price. For example, decreases in price of 10% only drop the yield targets by about 0.1% (data not shown).

3 Assessing the Need for Fertiliser

The targets shown in Table 17.2 only apply to responsive sites, and there is evidence in Tasmania for N and K that many sites may be non-responsive. For example, 4 of the 13 N trials described in Sparrow and Chapman (2003a) and 4 of the 8 K trials of Chapman et al. (1992) were non-responsive. How can growers tell if their site is likely to respond to fertiliser? For N, an immediate history of grass/clover (usually Lolium spp. / Trifolium spp.) pasture was associated with a lower potato crop N requirement (48 kg ha−1) compared to that of continuously cropped paddocks (193 kg ha−1) (Sparrow and Chapman 2003a), because pasture residues provided more mineral N than did residues of crops (Sparrow and Chapman 2003b). Compared with grass species, legumes as short term cover crops have been shown to provide more N to potatoes, but do not totally replace the need for N fertiliser (Porter and Sisson 1991; Honeycutt et al. 1996; Sincik et al. 2008). In Tasmania, many grass-legume pastures are grown for several years before being ploughed in (Chap. 15), and so should accumulate more N than a cover crop does. Potato crops grown after pasture may therefore need only modest rates of N, for example 50–100 kg ha−1 or sometimes none at all. The time of ploughing is important to maximise the N benefit by ensuring mineralised N is available when the potatoes need it (Griffin and Hestermann 1991, Sanderson and MacLeod 1994).

Petiole testing for nitrate-N is widely used to diagnose the N-status of potato crops (Williams and Maier 1990; Westcott et al. 1991) and has been promoted on the basis that deficient crops will benefit from supplementary N, and also that a better match between N supply and demand will improve N use efficiency. In the 2001 survey mentioned previously Tasmanian potato growers applied an average of 56 kg supplementary N ha−1 (data not shown). In Tasmania, Sparrow and Chapman (2003a) conducted 13 N experiments on Russet Burbank which confirmed the trend of decreasing petiole nitrate concentrations with crop age found elsewhere (Williams and Maier 1990, Westcott et al. 1991). However, in only one of 11 crops which responded to N at planting were yield responses to supplementary N recorded (Sparrow and Chapman 2003a). Thus, while petiole N testing may be a good diagnostic tool, overcoming a diagnosed deficiency may not be straightforward. Sparrow and Chapman (2003a) concluded that the poor response to topdressed N may be because potatoes absorb most of their N early in the life of the crop, and that later on the plant shows a greater emphasis on internal relocation of N from shoots to tubers. While the evidence for this is equivocal, there are very few published instances of split N applications outyielding equivalent rates of N applied at planting (see Sparrow and Chapman 2003a for discussion of this point).

For K, a measure of soil sodium bicarbonate-extractable K (Colwell 1963) was found to be a reliable predictor of potato responsiveness (Chapman et al. 1992), with a critical value for 95% maximum yield on Ferrosols of 400 mg K kg−1 for Russet Burbank and 350 mg kg−1 for Kennebec. For Sodosols and Tenosols the critical value of 200 mg K kg−1 derived by Maier (1986) on similar soils in South Australia is used in Tasmania.

For P, the critical extractable P value (Colwell 1963) derived by Maier et al. (1989) of 34 mg P kg−1 is used for light-textured soils in Tasmania, but the lack of a good soil calibration for P on Ferrosols, the state’s major potato growing soil, remains a limitation to good P management. The best such calibration is that of Freeman et al. (1998), who predicted a critical Olsen P (Olsen et al. 1954) value of 46 mg kg−1 for 90% maximum Russet Burbank yield on Victorian Ferrosols. However, this predicted value was beyond the range of their data. In Tasmania, 3 of 4 trials on Ferrosols high in extractable P (Colwell P 112–210 mg kg−1) did not reach maximum yield even at 240 kg P ha−1 (Sparrow et al. 1992). The results from this study and that of Freeman et al. (1998) suggest that Ferrosols may require significant P loading for potatoes not to respond to additional fertiliser P. More research on such heavily loaded soils is needed to define a calibration.

4 Potato Grower Fertiliser Practices

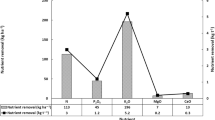

Most Tasmanian potato growers are reluctant to cut back on fertiliser because they know how responsive their crops can be, and they are unwilling to risk losing yield. Figures 17.1 and 17.2 show P and K fertiliser and soil test data and NPK balances of the Tasmanian potato crops surveyed in 2001 (Sparrow et al. 2003). Extractable K and P concentrations from individual paddocks on different soil types are plotted against grower K and P fertiliser rates for the same paddocks (Fig. 17.1). In each case, there was no relationship between soil test values and fertiliser rates, either within a soil type or across all soils. It is particularly disturbing to see that most growers on Sodosols and Tenosols appear to follow the P and K practices of their counterparts on Ferrosols despite (1) the calibrated soil tests at their disposal, (2) successful demonstrations that such high rates are not needed on these soils (Sparrow et al. 1993c) and (3) 90% of growers using soil tests (Sparrow 2009). Most growers applied more N, P and K than was removed in the tubers (Fig. 17.2), and there were obvious positive linear relationships between rates of applied NPK and nutrient balance. Mistrust of soil tests and a lack of market or regulatory signals regarding fertiliser use may be barriers to the adoption of better fertiliser practices.

Rates of fertiliser P (top) and K (bottom) applied to 54 Tasmanian potato crops in 2001 in relation to extractable P and K (Colwell 1963) in the soil (0–150 mm) (squares = Ferrosols; circles = Dermosols; triangles = Sodosols; diamonds = Tenosols)

NPK nutrient balances (kg element applied ha−1 in fertiliser – kg element removed ha−1 in tubers) of 54 Tasmanian potato fields surveyed in 2001 (squares = Ferrosols; circles = Dermosols; triangles = Sodosols; diamonds = Tenosols). Crop yields and unpublished average Tasmanian fresh tuber nutrient concentrations of 0.3% N, 0.042% P and 0.4% K were used to calculate rates of removal

It seems likely that Tasmanian vegetable growers apply more than maintenance fertiliser rates to many of their crops, not just potatoes. This is supported by a comparison of 3 populations of Tasmanian Ferrosol cropping soil test data since the 1960s (Table 17.3), which indicates a steady increase in extractable K and P. In addition, Sparrow et al. (submitted) monitored bicarbonate-extractable P (Colwell 1963) in the topsoil of 15 other cropped Tasmanian Ferrosols between 1997 and 2010 and found an average increase during this period of 69 mg kg−1. If these trends continue, Tasmanian Ferrosols may yet reach a non-responsive P status. Research to define this status will be needed. Soil pH has also increased (Table 17.3) due to the consistent use of lime for other acid-sensitive rotation crops, notably onions and poppies (e.g. Temple-Smith et al. 1983), rather than on potatoes where lime may increase the incidence and severity of common scab.

5 Micronutrients

While micronutrient fertilisers are not routinely used on Tasmanian potatoes, they are frequently marketed as “silver bullets” or potential missing links in the production chain. Copper (Cu), zinc (Zn) boron (B) and molybdenum (Mo) are sometimes applied. Tasmanian soils are very high in iron (Fe) and manganese (Mn), so these micronutrients are not normally applied. In the 1990s, the potato and fertiliser industries and government invested in micronutrient field trials for a range of Tasmanian crops including potatoes (Salardini and Sparrow 2001). Eleven trials on potatoes were conducted, seven with foliar-applied micronutrients (Cu, Zn and B), three with soil-applied micronutrients (Cu, Zn, B, Mo), and one with a combination of soil and foliar Zn application. The soil at the selected sites had low relative concentrations of one or more micronutrients as determined by either DTPA extraction for Zn and Cu, or hot water extraction for B. Micronutrients were applied as both inorganic and EDTA salts. Rates for soil and foliar application were consistent with those used in published research elsewhere.

There were no statistically significant tuber yield increases in any of the trials, and one instance of B toxicity when 4 kg B ha−1 was added to a very sandy soil. Salardini and Sparrow (2001) concluded that the micronutrient status of Tasmanian potato soils is generally adequate for potatoes, and this was borne out by petiole Zn, Cu and B concentrations surveyed as part of the study: the vast majority of these lay within the ranges considered adequate for potatoes (Salardini and Sparrow 2001). In addition, responses to some elements e.g. Zn would be expected to be small or absent because these elements are or were previously applied regularly at low rates in many fungicides.

6 Effects of Fertiliser on Tuber Quality

In addition to the effect of nutrition on tuber yield, much of the research referred to in this chapter included assessment of effects on tuber quality, including tuber size and shape, tuber number, specific gravity, hollow heart, crisp colour and bruising susceptibility. The quality responses observed included increased tuber number with applied P (Sparrow et al. 1992) and decreased specific gravity and increased yields of misshapen tubers with increasing rates of applied N (Sparrow and Chapman 2003a). However, such responses were far from universal and sometimes they depended on whether the site was yield-responsive or not. For example, Chapman et al. (1992) found that on highly K-deficient sites, specific gravity and crisp colour increased with low rates of fertiliser K, but across all sites the trend was the opposite. A general observation arising from all of this work was that applying enough fertiliser for optimum yield usually gave good tuber quality.

7 Cadmium in Potatoes

One aspect of tuber quality that has received particular attention in Tasmania and elsewhere in Australia in recent times is tuber cadmium (Cd) concentration. Cadmium is a natural impurity in rock-phosphate and therefore of P fertiliser, and accumulates both in soils to which P fertiliser is added, and in crops grown on those soils. The Australian potato and fertiliser industries supported a significant Cd research program in the 1990s. This was in response to data (Stenhouse 1991) indicating that, because of their propensity for Cd accumulation and their popularity amongst consumers, potatoes were potentially a significant source of dietary Cd in Australia, even though there has never been any evidence of Cd-related health impacts in the country. The Tasmanian research on Cd in potatoes conducted as part of the national program has a number of implications for the management of soil fertility.

Russet Burbank tuber Cd concentrations increased with rate of P fertiliser (and hence Cd in fertiliser), but only when those rates of P also increased tuber yield (Sparrow et al. 1992, 1993a). Fertiliser P rates in excess of crop needs did not further increase tuber (or petiole) Cd concentrations although they did increase petiole P concentrations (Sparrow 2000). It appears that Cd uptake at least in Russet Burbank may be related to its root growth or function more than to Cd supply. This view is supported by other work which showed that, at equivalent P rates, increasing the Cd-content of P fertiliser by 6-fold did not increase tuber Cd concentration (Sparrow et al. 1993b). On the basis of immediate Cd risk, there thus appears to be little incentive to use P fertiliser wisely, and the need to minimise soil Cd load in the longer term does not seem to be a strong influence on grower behaviour. However, the Australian fertiliser industry did respond to this need by sourcing phosphate rocks with relatively low Cd content compared with Australia’s traditional sources supplied by Christmas Island and Nauru.

The form of K fertiliser can affect tuber Cd uptake (Sparrow et al. 1994), with potassium chloride increasing uptake compared with potassium sulphate applied at the same K rate. This is because the chloride ion forms soluble chloro-cadmium complexes in the soil solution, increasing Cd availability (O’Connor et al. 1984). Switching to potassium sulphate is a short term management option that growers can use to decrease tuber Cd uptake. In 2010, potassium sulphate was about 70% more expensive than potassium chloride, so this switch would come at significant additional cost.

Cd availability is considered to decrease with increasing soil pH (Page 1981), yet field studies in Tasmania (Sparrow et al. 1993a) and South Australia (Maier et al. 1997) failed to show that lime in the short term decreased tuber Cd concentrations. However, in repeat crops grown 2 or 3 years later on the Tasmanian sites (Sparrow and Salardini 1997), tuber Cd concentrations were decreased by about 30% in the residual lime treatments. This medium term effect was attributed to the more even and deeper mixing of the lime with the soil by the harvest of the initial crop of potatoes. Lime is therefore a suitable medium to long term Cd control measure, and the pH trends in Table 17.3 indicate that use of lime by Tasmanian farmers is probably helping to control Cd uptake. However, soil pH is only one control factor, and Sparrow and Salardini (1997) found it explained only 22% of the variation in tuber Cd concentrations under controlled conditions. Moreover, at one site they also found that the previous liming increased the severity of common scab symptoms to the point of tubers being unmarketable.

A number of other strategies for minimising tuber Cd uptake were identified in other Australian research (McLaughlin 1999), including choice of cultivar, chloride content of irrigation water, addition of zinc and maintenance of soil organic matter. Fortunately, Russet Burbank, Tasmania’s most popular cultivar, is a relatively low Cd accumulator (McLaughlin et al. 1994), while Tasmania’s irrigation water is mostly low in chloride salts, and its soils relatively high in organic matter (Chapter 16).

By far the most significant outcome of the national program was that its data formed the foundation of a submission by the potato industry to the Australian government which allowed a more informed dietary risk assessment to be conducted and which resulted in the maximum allowed level for Cd in potatoes to be revised from 0.05 to 0.10 mg kg−1 (FSANZ 2010). The revised level currently accommodates virtually all Australian potatoes, including those from Tasmania. Whether that continues to be the case will depend on how well growers manage their Cd inputs and their crops.

8 Environmental Impacts of Fertiliser

While potatoes could be considered to have a potentially high environmental impact because of their high inputs, heavy cultivation and soil disturbance during harvesting, quantitative data on this impact in Tasmania is scarce. Here, recent Tasmanian research on the modelling of potential impacts of potato production on N leaching and nitrous oxide emissions is summarised.

Lisson et al. (2009) modelled nitrogen leaching and crop yield on seven cropping farms in northern Tasmania using the Agricultural Production Systems Simulator (APSIM, Keating et al. 2003). Information about farm practices (including rotation, fertiliser use and irrigation management) was collected by interviewing the farmers involved. Potatoes were part of the rotation of six of the seven farms. Other rotation crops included poppies, cereals, beans, peas and broccoli, and pasture was also grown in each rotation. The modelling approach allowed for year-to-year carry-over effects (i.e. nitrogen remaining in the soil after harvest that was available for use by the following crop or lost via leaching) and the effects of seasonal climate variability to be fully assessed.

The average N fertiliser rate for potatoes was 397 kg N ha−1, with a range of 279–480 kg N ha−1 used across the 6 farms growing potatoes. These rates were the highest of any crop and higher than the median rates found in 2001 (Table 17.1), and not surprisingly potatoes had the highest estimated N leaching over the 25 year simulation (29 kg N ha−1 year−1), four times more than estimates for other crops. Across all farms and years there was an average excess of N supplied as fertiliser over N uptake by potatoes of 89 kg ha−1. This did not include an estimate of N mineralisation from soil organic matter, which Sparrow and Chapman (2003b) measured in 13 potato paddocks from just before planting to the time of early tuber growth. They measured average mineralisation rates of 3.5 kg N ha−1 day−1 in ex-pasture paddocks and 1.2 kg N ha−1 day−1 in previously cropped paddocks. Clearly, mineralisation will add substantially to the pool of excess mineral N and the risk of N leaching.

However, while the modelling indicated that N fertiliser rate did affect N leaching loss, changes to irrigation management were much more influential. By scheduling irrigation according to crop demand (only one farmer monitored soil water content, the rest used a fixed irrigation schedule interrupted only by heavy rain), the model predicted that N leaching under potatoes on the farm with the highest loss could be cut from 53 to 6 kg N ha−1. However, reducing the N fertiliser rate from 480 to 284 kg N ha−1 only cut N leaching by a further 3 kg N ha−1. Significantly, neither changes to irrigation nor N fertiliser rates affected modelled crop yields, indicating that growers have little to lose in adopting these changes. The maximum seasonal N loss ranged up to 135 kg N ha−1, illustrating the variability in N leaching.

In their survey of Tasmanian potato grower practices, Sparrow (2009) found that only about a third of growers used some form of soil moisture monitoring. Almost half assessed soil moisture by visual inspection. Thus the savings available to the farmers through better irrigation scheduling in the modelling study would seem to be much more widely available in Tasmania. The average of the break-even N rates shown in Table 17.2, 312 kg N ha−1, is consistent with the reduced rate modelled by Lisson et al. (2009), further supporting the notion that the growers in that study were using too much N. There is a need to raise the awareness of Tasmanian potato growers to the potential for more efficient water and N use as this appears to be a win-win situation, benefiting both grower returns and environmental quality.

Nitrogen fertiliser was also found to be one the main sources of greenhouse gases (GHG) in a recent assessment of the on-farm environmental footprint of the Australian potato industry (Norton et al. 2008). This work comprised life cycle analyses (LCA, e.g. Grant and Beer 2008) of a number of regional case studies including three for processed potato production in Tasmania. On-farm practices from seed production to the delivery of the harvested crop to the factory gate were assessed. Off-site losses through leaching were included. Rate of N fertiliser use was linearly related to emissions of GHG, with estimates of its contribution ranging from 25–56% of total emissions (8–25 kg N2O ha−1) across the case studies. Other emissions came from diesel use (26–40%), agri-chemical use (4–9%), infrastructure (11–16%) and electricity (0–19%). Estimated average GHG emissions from Tasmanian potato production were 14% higher than those for onions and 95% than those for broccoli, partly because the latter crops received only 180 and 91 kg N ha−1 respectively. At a regional scale, the study found that potato production could account for about 2.5% of total agricultural GHG emissions. The rates of N fertiliser used in the LCA were those volunteered by industry experts in the case study regions. The average rate for the three Tasmanian potato case studies was 413 kg N ha−1, much higher than those for the other three potato case studies in South Australia (200 kg N ha−1), Queensland (164 kg N ha−1) and New Zealand (288 kg N ha−1). This adds further weight to the call for a re-examination of N fertiliser rates on potatoes in Tasmania.

9 Conclusion

The Tasmanian potato industry is a large user of N, P and K fertiliser. There is no evidence that other nutrients are lacking in Tasmanian potato soils. For N and P, there is a continuing tension between maximising economic returns and minimising the risk of environmental impact. The tension is driven by 1) the relatively low cost of fertiliser compared to the potential returns which encourages high application rates and 2) the current weak signals to growers about water and food quality impacts. When these signals intensify, growers may have to fertilise to a target yield closer to 95% of maximum. This would reduce fertiliser rates considerably but still allow for profitable production.

There is adequate evidence that the rates of N and K currently used are often excessive, and for N, may be leading to adverse environmental impacts. A better soil test calibration for P on Ferrosols, the main soil for potato production in Tasmania (see Chap. 15), would provide growers with a soil P target, but getting growers to adhere to such a target will require a substantial change to the current culture of high P fertiliser use.

References

Chapman KSR, Sparrow LA, Hardman PR, Wright DN, Thorp JRA (1992) Potassium nutrition of Kennebec and Russet Burbank potatoes in Tasmania: effect of soil and fertiliser potassium on yield, petiole and tuber potassium concentrations and tuber quality. Aust J Exp Agric 32:521–527

Colwell JD (1963) The estimation of the phosphorus fertilizer requirements of wheat in southern New South Wales by soil analysis. Aust J Exp Agric Anim Husbandry 3:190–197

Cotching WE (1995) A review of the challenges for long term management of krasnozems in Australia. Aust J Soil Water Conserv 8:18–27

DPIF (2009) The Tasmanian Potato Industry. Department of Primary Industries and Water, Tasmania

Freeman KL, Franz PR, de Jong RW (1998) Effect of phosphorus on the yield, quality and petiolar phosphorus concentrations of potatoes (cvv. Russet Burbank and Kennebec) grown in the krasnozem and duplex soils of Victoria. Aust J Exp Agric 38:83–93

FSANZ (2010) Australia New Zealand Food Standards Code http://www.foodstandards.gov.au/foodstandards/foodstandardscode/. Accessed 29 January 2011

Grant T, Beer T (2008) Life cycle analysis of greenhouse gas emissions from irrigated maize and their significance in the value chain. J Exp Agric 48:375–381

Griffin TS, Hestermann OB (1991) Potato response to legume and fertilizer nitrogen sources. Agron J 83:1004–1012

Honeycutt CW, Clapham WM, Leach SS (1996) Crop rotation and N fertilization effects on growth, yield and disease incidence in potato. Am Potato J 73:45–61

Hyatt CR, Venterea RT, Rosen CJ, McNearney M, Wilson ML, Dolan MS (2010) Polymer-coated urea maintains potato yields and reduces nitrous oxide emissions in a Minnesota loamy sand. Soil Sci Soc Am J 74:419–428

Isbell RF (2002) The Australian soil classification. Revised edition. CSIRO, Collingwood

Keating BA, Carberry PC, Hammer GL, Probert ME, Robertson MJ, Holzworth D, Huth NI, Hargreaves JNG, Meinke H, Hochman Z, McLean G, Verburg K, Snow V, Dimes JP, Silburn M, Wang E, Brown S, Bristow KL, Asseng S, Chapman S, McCown RL, Freebairn DM, Smith CJ (2003) An overview of APSIM, a model designed for farming systems simulation. Eur J Agron 18:267–288

Lisson S, Cotching B, Rawnsley R (2009) Assessing the risk of nutrient loss under intensive crop production in the Panatana Catchment. Final report for CERF Landscape Logic Project 4, Australian Department of Environment and Heritage. CSIRO, Hobart

Maier NA (1986) Potassium nutrition of irrigated potatoes in South Australia. 1. Effect on tuber yield and the prediction of tuber yield response by soil analysis. Aust J Exp Agric 26:717–725

Maier NA, Potock-Pacay KA, Jacka JM, Williams CMJ (1989) Effect of phosphorus fertiliser on the yield of potato tubers (Solanum tuberosum L.) and the prediction of tuber yield response by soil analysis. Aust J Exp Agric 29:419–432

Maier NA, McLaughlin MJ, Heap M, Butt M, Smart MK (1997) Effect of current season applications of calcitic lime on pH, yield and cadmium concentration of potato (Solanum tuberosum L.) tubers. Nutr Cycl Agroecosyst 47:1–12

McLaughlin MJ (1999) A national strategy to reduce cadmium in potatoes. Final Report, Project PT423, Horticultural Research and Development Corporation. CSIRO Land and Water, Glen Osmond

McLaughlin MJ, Williams CMJ, McKay A, Gunton J, Jackson K, Dowling B, Kirkham R, Partington D, Smart MK, Tiller KG (1994) Effect of potato variety on cadmium accumulation in potato tubers. Aust J Agric Res 45:1483–1495

Moody PW (1994) Chemical fertility of krasnozems: a review. Aust J Soil Res 32:1015–1041

Norton N, Hay F, Lambert S, Sparrow L, Kirkwood I (2008) Enhancing environmental sustainability in the processing potato industry in Australia Final Report Project PT07060. Horticulture Australia, Sydney

O’Connor GA, O’Connor C, Cline GR (1984) Sorption of cadmium by calcareous soils: influence of solution composition. Soil Sci Soc Am J 48:1244–1247

Olsen SR, Cole CV, Watanabe FS, Dean LA (1954) Estimation of available phosphorus in soils by extraction of sodium bicarbonate. USDA Circular 939. Washington, DC

Page AL (1981) Cadmium in soils and its accumulation by crops. In: Proceedings 3rd international conference on heavy metals in the environment, Amsterdam, September 1981. CEP Consultants, Edinburgh, pp 206–213

Porter GA, Sisson JA (1991) Response of Russet Burbank and Shepody potatoes to nitrogen fertilizer in two cropping systems. Am Potato J 68:425–443

Rosen CJ, Bierman PM (2008) Potato yield and tuber set as affected by phosphorus fertilization. Am J Potato Res 85:110–120

Salardini A, Sparrow L (2001) The trace element requirements of vegetables and poppies in Tasmania. Final Report of Project PT320 to Horticulture Australia Limited. Horticulture Australia, Sydney

Sanderson JB, MacLeod JA (1994) Soil nitrate profile and response of potatoes to fertilizer N in relation to time of incorporation of lupin (Lupinus albus). Can J Soil Sci 74:241–246

Sanderson JB, MacLeod JA, Douglas C, Coffin R, Bruulsema T (2003) Phosphorus research on potato in PEI. Acta Hortic 619:409–417

Sincik M, Turan ZM, Göksoy AT (2008) Response of potato (Solanum tuberosum L.) to green manure cover crops and nitrogen fertilization rates. Am J Potato Res 85:150–158

Soil Survey Staff (2006) Keys to soil taxonomy, 10th edition. Natural Resources Conservation Service, USDA. Washington, DC. Available at: http://www.statlab.iastate.edu/soils/keytax/

Sparrow LA (2000) Excess P fertiliser does not increase tuber cadmium concentrations in potato. In: Adams JA, Metherell AK (eds) Soil 2000: new horizons for a new century proceedings of the Australian and New Zealand Second Joint Soils Conference 3–8 December 2000, Lincoln University, NZ, vol 2 oral papers. NZ Society of Soil Science, Lincoln

Sparrow L (2009) Crop rotations. In: Kirkwood I (ed) Australian Potato Research Program Final Report to Horticulture Australia for project PT04016. Horticulture Australia, Sydney

Sparrow LA, Chapman KSR (2003a) Effects of nitrogen fertiliser on potato (Solanum tuberosum L., cv. Russet Burbank) in Tasmania. 1. Yield and quality. Aust J Exp Agric 43:631–641

Sparrow LA, Chapman KSR (2003b) Effects of nitrogen fertiliser on potato (Solanum tuberosum L., cv. Russet Burbank) in Tasmania. 2. Petiole and soil analysis. Aust J Exp Agric 43:643–650

Sparrow LA, Salardini AA (1997) Effects of residues of lime and phosphorus fertilizer on cadmium uptake and yield of potatoes and carrots. J Plant Nutr 20:1333–1349

Sparrow LA, Chapman KSR, Parsley D, Hardman PR, Cullen B (1992) Response of potatoes (Solanum tuberosum cv. Russet Burbank) to band-placed and broadcast high cadmium phosphorus fertiliser on heavily cropped krasnozems in north-western Tasmania. Aust J Exp Agric 32:113–119

Sparrow LA, Salardini AA, Bishop AC (1993a) Field studies of cadmium in potatoes (Solanum tuberosum L.). I. Effect of lime and phosphorus on cv. Russet Burbank. Aust J Agric Res 44:845–853

Sparrow LA, Salardini AA, Bishop AC (1993b) Field studies of cadmium in potatoes (Solanum tuberosum L.) II. Response of cvv. Russet Burbank and Kennebec to two double superphosphates of different cadmium concentration. Aust J Agric Res 44:855–861

Sparrow LA, Walker AR, Johnstone J, Chapman KSR (1993c) New fertiliser recommendations for potato growers on sandy soils in Tasmania’s northern midlands. In: DR Baigent (ed) Proc First ASPAC National Workshop on Soil and Plant Analysis, Ballarat, 2–4 March 1993. ASPAC, Tatura

Sparrow LA, Salardini AA, Johnstone J (1994) Field studies of cadmium in potatoes (Solanum tuberosum L.). III. Response of cv. Russet Burbank to sources of banded potassium. Aust J Agric Res 45:234–249

Sparrow LA, Cotching WE, Hawkins K (2003) Fertiliser practices of Tasmanian potato and poppy grows: do they show any relation to pre-plant soil test information? In: LD Currie and JA Hanly (eds) Tools for Nutrient and Pollutant Management: Applications to Agriculture and Environmental Quality Occasional Report No. 17 Fertilizer and Lime Research Centre, Massey University, Palmerston North, New Zealand. Massey University, Palmerston North

Stenhouse F (1991) The 1990 Australian Market Basket Survey Report. Australian Government Publishing Service, Canberra, Australia

Temple-Smith MJ, Wright DN, Laughlin JC, Hoare BJ (1983) Field responses of poppies (Papaver somniferum L) to lime application on acid krasnozems in Australia. J Agric Sci Cambridge 100:485–492

Westcott MP, Stewart VR, Lund D (1991) Critical petiole nitrate levels in potato. Agron J 83:844–850

Williams CMJ, Maier NA (1990) Determination of the nitrogen status of irrigated potato crops. I. Critical nutrient ranges for nitrate-nitrogen in petioles. J Plant Nutr 13:971–984

Acknowledgments

The author would like to thank the anonymous reviewers for their constructive comments on the manuscript.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2012 Springer Science+Business Media B.V.

About this chapter

Cite this chapter

Sparrow, L.A. (2012). Potato Nutrient Management in Tasmania, Australia. In: He, Z., Larkin, R., Honeycutt, W. (eds) Sustainable Potato Production: Global Case Studies. Springer, Dordrecht. https://doi.org/10.1007/978-94-007-4104-1_17

Download citation

DOI: https://doi.org/10.1007/978-94-007-4104-1_17

Published:

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-007-4103-4

Online ISBN: 978-94-007-4104-1

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)