Abstract

This book chapter deals with the production of biogas coupled with the use of waste effluents for microalgae biomass growth. Biogas production through anaerobic digestion of microalgae uses the whole organic content of microalgae to produce energy. Furthermore, biogas generation seems to be the least complex of the different energy conversion routes since anaerobic digestion avoids energy-intensive steps such as biomass drying and extraction. Biogas can be produced as the main product from microalgae (direct anaerobic digestion of the whole biomass) or can be a coproduct of an industry culturing microalgae for different purposes. The integration of different technologies in a biorefinery aims at maximizing benefits while reducing the environmental impact. The future of algae biorefineries would include the extraction of several components from microalgae. Waste biomass can be treated by anaerobic digestion, reducing the pollutant load while producing energy. Additionally, there is a synergy between anaerobic digestion and microalgae growth. Biogas contains a high percentage of CO2, and if it is combusted in CHP units, CH4 is converted to CO2. The digestate produced after anaerobic digestion is a liquid medium where most of the nutrients of the organic substrate are mineralized. Therefore, the two main products of anaerobic digestion could serve as sources of nutrients for microalgae growth. If the nutrient loop is closed, profitable processes can be achieved. Consequently, biofuels and high-value products would be obtained at the same time from microalgal biomass, reducing environmental impact and increasing profits.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Anaerobic Digestion

- Switch Grass

- Organic Matter Solubilization

- Hydraulic Retention Time

- Methane Production

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

Algae are aquatic organisms which obtain energy via photosynthesis. Algae capture CO2 and transform it into organic carbon. Algae comprises of two major groups – macroalgae and microalgae.

Microalgae are a diverse group of unicellular organisms with more than 30,000 known species. Although microalgae, in their strictest sense, are eukaryotes, this chapter will also consider cyanobacteria (blue-green algae), which are prokaryotes with photosynthetic capacity. In spite of the great number of species that belong to this group of living forms, only a handful are currently of commercial significance (Bruton et al. 2009).

Microalgae are attracting great interest in recent years due to their high photosynthetic efficiency, which can be as high as 5 % (Acién et al. 2012a). As a consequence, they grow faster than terrestrial plants and have a high potential for bioenergy production (Brennan and Owende 2010). Moreover, microalgae show other advantages compared to traditional energy crops such as their high CO2 consumption during their growth (Chisti 2007), their ability to grow on marginal lands, and use of marine or wastewater (Park et al. 2011). This biomass can be used for biofuel production or extraction of a wide range of value-added products. Pigments, ω-3 fatty acids, feed, food, fertilizers, and natural food colorants can be obtained from microalgal biomass (Spolaore et al. 2006; Romero García et al. 2012). The economical revenue obtained from these value-added compounds makes biofuel production from algae even more attractive. However, the current market is not yet open to high value-added products obtained from waste streams, and thus, as of today, the only recovery from this biomass can be achieved by its conversion into an energy form.

In this context, this book chapter is devoted to the production of biogas coupled with the use of waste effluents for microalgae biomass growth. Considering all available technologies producing biofuels, anaerobic digestion along with thermal liquefaction is the only conversion route that uses the whole organic content of microalgae to produce energy. Furthermore, biogas generation seems to be the least complex since anaerobic digestion avoids energy-intensive steps such as biomass drying and extraction. Therefore, AD has a higher energy efficiency compared to the other options (Sialve et al. 2009). Biogas can be produced as the main product from microalgae (direct anaerobic digestion of the whole biomass) or can be a coproduct of an industry culturing microalgae for different purposes (organic waste treatment in biorefineries) (Ramos-Suárez and Carreras 2014). Additionally, there is a synergy between anaerobic digestion and microalgae growth: (1) biogas contains a high percentage of CH4 and CO2, and if it is combusted in CHP units, CH4 is converted to CO2; (2) the digestate produced after anaerobic digestion is a liquid medium where most of the nutrients of the organic substrate are mineralized. Therefore, the two main products of anaerobic digestion (CO2 and nutrients) could serve as sources of growth enhancer for microalgae culture (Sialve et al. 2009; Uggetti et al. 2014).

2 The Anaerobic Digestion Process

Anaerobic digestion is a suitable technology for the treatment of almost all types of organic residues generated in agro-industrial processes. This technology has been shown to be environmentally friendly and cost competitive with more than 9232.7 ktoe of primary energy produced from decentralized biogas plants only in Europe during 2012–2013 (EurObserv’ER 2014).

The anaerobic digestion or biomethanation is a biological process whereby organic matter is degraded into a number of gaseous products, known as biogas, and a by-product known as digestate. This bioprocess is conducted in the absence of oxygen where degradation of organic matter is performed through a complex series of biochemical reactions that are carried out by different groups of anaerobic microorganisms.

2.1 Anaerobic Process Stages

Biochemical and microbiological studies conducted so far divide the anaerobic decomposition process into four phases or stages: (1) hydrolysis, (2) acidogenesis, (3) acetogenesis, and (4) methanogenesis. Any of these four stages can be the limiting step in terms of the overall reaction rate. Hydrolysis is usually the limiting step when dealing with complex substrates, as it is the case for some microalgal strains (Mussgnug et al. 2010). Figure 5.1 shows a diagram of the various steps involved in the anaerobic digestion process, the microorganisms involved, and intermediate products generated. The numbers indicate the bacterial population responsible for the process.

Degradation steps of anaerobic digestion process and microorganisms involved (1 fermentative bacteria, 2 hydrogen-producing acetogenic bacteria, 3 homoacetogenic bacteria, 4 hydrogenotrophic methanogenic bacteria, 5 acetoclastic methanogenic bacteria) (Source: adapted from Gujer and Zehnder (1983))

2.1.1 Hydrolysis

Out of the four stages, hydrolysis is the initial step in the anaerobic degradation of complex organic substrates. Anaerobic microorganisms can only use soluble organic matter that can pass through the cell wall, and thus, hydrolysis of organic matter is a must. The organic material mainly comprises of three basic types of macromolecules: carbohydrates, proteins, and lipids. During hydrolysis, the bacteria transform the complex organic substrates into simple soluble compounds, i.e., proteins, carbohydrates, and fats are converted to amino acids, monosaccharides, and fatty acids, respectively.

The hydrolysis of these complex molecules is carried out through the action of extracellular enzymes produced by hydrolytic microorganisms.

The rate of hydrolytic degradation of lignocellulose materials composed mainly of lignin, cellulose, and hemicellulose is so slow that it is often the limiting step of the AD process. This is because lignin is highly resistant to degradation by the anaerobic microorganisms and also affects the biodegradability of the cellulose, hemicellulose, and other carbohydrates. It is noteworthy to mention that in contrast to lignocellulosic material, microalgal biomass does not contain lignin, and therefore, their hydrolysis and overall methane production is favored.

2.1.2 Acidogenic Phase

During acidogenesis, the fermentation of soluble organic molecules takes place via facultative bacteria. The end product of this reaction includes alcohol, hydrogen, carbon dioxide, and several fatty acids like acetic acid, formic acid, propionic acid, valeric acid, lactic acid, etc. Some of the end products of this reaction like acetic acid, formic acid, and hydrogen can directly be used by the methanogenic bacteria.

The formation of one or another acid depends on the concentration of H2 produced during the digestion. When the H2 concentration in the gas produced is very low (5–50 ppm), acetic acid is preferably formed. When the H2 concentration increases, acetic acid decreases, and the fraction of long-chain acids (e.g., propionic, butyric, etc.) increases.

In this phase, also alcohols are produced. The kinetics of the process is relatively fast; the acid-producing bacteria are fast growing with minimum doubling times of 30 min.

2.1.3 Acetogenic Phase

In the third stage, known as acetogenesis, the other products of the acidogenic phase, namely, propionic acid, butyric acid, and alcohols, are transformed by acetogenic bacteria in hydrogen, carbon dioxide, and acetic acid. The small organic molecules, especially VFA (volatile fatty acids), are converted into acetic acid. The bacteria involved in this process are facultative, live in close collaboration with methanogenic bacteria, and can only survive in symbiosis with the genre that consumes hydrogen, since they are inhibited by high hydrogen concentrations (Anderson et al. 2003). These bacteria have slower growth rates than acidogenic bacteria, with minimum doubling times from 1.5 to 4 days.

2.1.4 Methanogenic Phase

This phase constitutes the final stage in which compounds such as acetic acid, hydrogen, and carbon dioxide are transformed into CH4 and CO2. Bacteria involved constitute a single group composed of several species of different shapes and cell structures. There are two main types of strictly anaerobic microorganisms, which degrade acetic acid (acetoclastic methanogenic bacteria) and those that consume hydrogen (hydrogenotrophic methanogens). The main route for methane formation is the first one, with about 70 % of the methane produced.

Acetoclastic methanogenic bacteria produce methane from acetate. They have a slow growth (minimum doubling time of 2–3 days) and are not affected by the concentration of hydrogen in the biogas. The hydrogen-consuming methanogenic bacteria produce methane from hydrogen and CO2. This reaction has a dual function in the anaerobic digestion process; on the one hand, methane is produced and, on the other, gaseous hydrogen is removed.

With high ammonia concentrations, acetate-utilizing methanogens have limited activity in methanogenesis (Hansen et al. 1998). Symptoms of limitation of acetoclastic methanogens have also been observed in anaerobic digestion of microalgae due to high ammonia concentrations (Ramos-Suárez et al. 2014b).

2.1.5 Formation of Hydrogen Sulfide

In addition to the bacteria described above, there is a group called sulfate-reducing bacteria (SRB), which are particularly important if sulfates are also present (Espinosa-Chávez et al. 2007). SRB are able to reduce sulfate to sulfide. This reaction is crucial in anaerobic digestion, since SRB can compete with methanogens and decrease the production of methane. Moreover, SRB are also able to reduce the sulfates using the hydrogen produced by the acid-forming bacteria. In this case, the hydrogen cannot be used by the methanogenic bacteria. Sulfur content of microalgae cells varies normally between 1.5 and 1.6 μg mg−1 dry weight, whereas the concentration range of sulfur (in the form of salts) in the growth media is usually in the range of grams per liter (Grobelaar 2004). Remains of growth media will probably be introduced in the digester together with microalgal biomass, increasing sulfur content and, therefore, hydrogen sulfide production. Moreover, chemicals with sulfur could be used in some extraction process, which could remain in spent biomass under digestion (Romero García et al. 2012). It is therefore important to monitor the presence of sulfates during the process, since besides affecting the methanogenesis, hydrogen sulfide is corrosive and can affect several processes and structures (Hidalgo and García 2001). In microalgal biorefineries, if biogas is supplied as carbon source, hydrogen sulfide can be inhibitory for the growth of microalgae (Kao et al. 2012a, b).

2.2 Process Parameters

Anaerobic digestion is affected by various parameters which influence the kinetics of the different reactions and the production of biogas. Those parameters affecting the digestion process include: control parameters (nutrients, temperature, pH, redox potential) and operational parameters (agitation, hydraulic retention time, organic load). Moreover, many of these parameters are used to monitor the digestion course in industrial plants.

2.2.1 pH and Alkalinity

The different groups of bacteria involved in the process have optimum activity levels around neutral pH:

-

Fermentative bacteria: 7.2–7.4

-

Acetogenic bacteria: 6.0–6.2

-

Methanogenic bacteria: 6.5–7.5

Generally, the pH of the digester should not be lower than 6.0 or higher than 8.3 (Bazara et al. 2003). If the pH of the medium is below 6.5, the activity of methanogenic acetoclastic bacteria diminishes, while at pH below 4.5, the activity ceases completely (Lema and Méndez 1997).

Organic overloading can mediate instability of the digestion process due to organic acid accumulation. A high concentration of organic acids decreases the pH, decreases methane production, and can cause reactor souring or reactor failure (Rittmann and McCarty 2001).

Alkalinity is defined as the capacity to neutralize acids (Rittmann and McCarty 2001). Bicarbonate alkalinity of at least 500–900 mg/l CaCO3 is required for a pH greater than 6.5 (Rowse 2011). In the anaerobic digestion of microalgae besides the alkalinity caused by the carbonate-bicarbonate equilibrium, ammonia produced from protein degradation plays an important role increasing the buffer capacity.

2.2.2 Redox Potential

Methanogenic bacteria are strict anaerobes; therefore, their tolerance to changes in the redox potential is lower than other microorganisms involved in the digestion process. In pure cultures, methanogens require a redox potential of at least −350 mV to ensure the strongly reduced environment that these bacteria need for optimal activity (Anderson et al. 2003).

2.2.3 Temperature

Methanogenic microorganisms are extremely sensitive to temperature changes. There are three temperature ranges: (1) psychrophilic (5–20 °C), (2) mesophilic (25–45 °C, with the optimum of 30–37 °C; above 40 °C can cause denaturation of the enzymes), and (3) thermophilic (45–65 °C, being the optimum 55–60 °C) (Anderson et al. 2003). At the industrial level, it is common to find mesophilic (35–40 °C) and thermophilic digesters (55–60 °C). Stability decreases with increasing temperature, as a consequence of higher accumulation of VFA, greater toxicity of ammonium, an increased sensitivity to temperature changes, and foam and odor problems (Parkin and Owen 1986).

Specific methane production rates are 50–100 % higher for thermophilic anaerobic digestion than for mesophilic anaerobic digestion (Rittmann and McCarty 2001). In the anaerobic degradation of microalgae, the use of higher temperatures sometimes leads to higher methane yields (Golueke et al. 1957). Other studies showed a decrease in the methane yield (Samson and LeDuy 1986). Whereas Golueke et al. (1957) suggested a higher rate of degradation of algal cells due to the increased temperature, the latter study pointed to an increase of ammonia sensitivity with increasing temperatures due to a shift to the unionized form of ammonium.

2.2.4 Nutrients

The main nutrients required for growth of microorganisms are carbon, nitrogen, and phosphorus. Also, a series of mineral elements such as sulfur, potassium, sodium, calcium, magnesium, and iron should be present at trace levels. Carbon is the main power source for bacteria and the main component of biogas. This carbon comes mainly from carbohydrates contained in the biomass degraded.

On the other hand, nitrogen is a major source for the synthesis of proteins. Nitrogen deficiency disables bacteria to metabolize the carbon, which would lead to a reduced efficacy in the degradation. Conversely, if there is an excess of nitrogen, its accumulation in the form of NH3 (ammonia) is toxic to anaerobic microorganisms.

Therefore, the C/N ratio of the substrate is a key indicator of digestibility and potential methane yield of the biomass (substrate) to be degraded. This value is specific to each substrate, and in the case of microalgae, it depends on the species and the cultivation process (Sialve et al. 2009). Optimal C/N ratio for anaerobic digestion is between 10 and 30, and it depends on operational conditions, substrate composition, and microorganism acclimation to a particular substrate (Chen et al. 2008; Pagés Díaz et al. 2011). Microalgae, due to their high protein content, show normally a low C/N ratio which could be detrimental for the anaerobic digestion process (Sialve et al. 2009).

2.2.5 Inhibitors

The anaerobic digestion process can be inhibited by the presence of toxics in the system which affects the development of bacterial activity. Furthermore, the threshold toxicity concentration of specific compounds (ammonium, sulfide, volatile fatty acids, etc.) depends also on other parameters such as temperature or pH. Out of the anaerobic microorganisms, methanogenic bacteria are generally the most sensitive although generally all groups of microorganisms involved in the process are affected.

2.2.6 Mixing

Mixing aims at facilitating mass transfer processes and preventing dead zones and insufficient contact between organic matter and microorganisms. Mixing increases the kinetics of the anaerobic digestion process by accelerating the biological conversion. Additionally, mixing allows uniform heating of the reactor (Tchobanoglous et al. 2003).

Mixing can be provided mechanically through conventional impellers rotating immersed within the digester at low speed, pneumatical recirculation by injecting biogas via spargers at the bottom of the digester (Tchobanoglous et al. 2003), or by recycling the effluent at the bottom of the digester.

2.2.7 Retention Time

The retention time defines the time that the substrate is in contact with the active biomass within the digester. In digesters without biomass retention mechanisms (e.g., CSTR), the retention time is equivalent to the hydraulic retention time (HRT). HRT is defined as the average amount of time one reactor volume of actively digesting sludge stays within the reactor. HRT can be calculated with the following equation:

where:

-

HRT = hydraulic retention time (d)

-

V = volume of reactor (m3)

-

Q = influent flow rate (m3/d)

Anaerobic reactors should be designed with sufficient retention time to allow an effective volatile solid conversion to biogas and the development of methanogenic populations (Vesilind 1998; Parkin and Owen 1986). In this context, there are digesters (e.g., fluidized bed reactors, membrane reactors) where the solid retention time (SRT) is increased by means of biomass retention mechanisms which separate the liquid and the solid streams. These digesters are normally used for the treatment of high volumes of wastewater with low solid content. Although not applied yet, these types of digesters could be used for degrading highly diluted microalgal biomass.

2.2.8 Organic Loading Rate (OLR)

The organic loading rate (OLR) is defined as the mass of volatile solids added each day per reactor volume (Vesilind 1998) or the amount of BOD or COD applied to the reactor volume per day (Tchobanoglous et al. 2003). Organic loading rate is related to the hydraulic retention time by the following equation:

where:

-

OLR = organic loading rate (kg VS m−3 d−1)

-

Q = volumetric flow rate (m3 d−1)

-

CVS = concentration of volatile solids in the substrate (kg VS m−3)

-

V digester = reactor volume (m3)

-

HRT = hydraulic retention time (days)

OLR thus depends on the waste composition and the retention time. It is one of the parameters commonly used to characterize the treating capacity of anaerobic digesters.

According to Rittmann and McCarty (2001), the recommended rate of organic loading for high-rate anaerobic digestion is 1.6–4.8 kg VSS m−3 d−1, and the recommended organic loading rate for low-rate anaerobic digestion (digestion with no heat and no mixing) is 0.5–1.6 kg VSS m−3 d−1. Vesilind (1998) recommended that the peak organic loading rate for high-rate anaerobic digestion should be 1.9–2.5 kgVS m−3 d−1. These values can vary for different substrates and digesters. If the loading rate is too high for the system conditions, methanogenesis can become inhibited by organic overloading. Therefore, organic loading rate should be set in a conservative way.

2.3 Biogas Recovery and Use

Biogas is mainly composed of methane and carbon dioxide. The energetic value of biogas (between 20 and 25 MJ m−3) is determined by the concentration of methane in the biogas (Werner et al. 1989). Besides methane and carbon dioxide, biogas contains other minor constituents such as water vapor (H2O), hydrogen sulfide (H2S), ammonia (NH3), hydrogen (H2), and nitrogen (N2). Additionally, some traces of volatile organic compounds (e.g., siloxanes, mercaptans, terpenes) can be present in biogas produced in landfills but are rarely produced in agro-industrial applications (Rasi 2009). Biogas composition affects the possibilities for its use, since the methane concentration determines the LHV of the fuel. Moreover, high concentrations of some of these trace components may impede the use of biogas for certain energetic purposes.

Biogas can be used practically for the same energy applications developed for natural gas. Nowadays, the applications of greatest interest (see Fig. 5.2) are (1) heat by direct combustion, (2) power generation in engines, (3) power generation in engines with heat recovery (cogeneration), (4) integration in natural gas grid, and (5) fuel for vehicles. Nevertheless, the most common ones are direct combustion for heat and power generation with cogeneration engines. However, there is a growing interest in other alternatives such as its application as motor fuel and its integration into the natural gas grid (AEBIOM 2009).

Therefore, depending on the application in which biogas is used, a different degree of cleaning is required. Biogas purification systems are based on different techniques (chemical, physical, biological) and are normally designed for the removal of a single component. In agro-industrial biogas plants, the minor constituents that require removal include water vapor, carbon dioxide, and hydrogen sulfide, depending on their concentration and the intended application. Commercial techniques for hydrogen sulfide removal include iron sponges, activated carbon, micro-aeration (inside digester), water scrubbing, chemical absorption, biological filters, and membranes. Whereas for CO2 removal, the following techniques are available in the market: physical and chemical absorption, water scrubbing, pressure swing adsorption (PSA), vacuum swing adsorption (VSA), membrane separation, and cryogenic separation.

Microalgae cultures can be used for biogas purification by fixing CO2 and sulfur in their biomass. Although this option is still under study and no commercial systems based on this technology exists, biogas purification with microalgae could show some benefits compared to the other techniques, such as no use of chemicals, production of a valuable product (microalgal biomass) or additional energy (if biomass is digested), and simultaneous removal of CO2, H2S, and other compounds. This option will be further discussed in this chapter.

2.4 The Digestate

The anaerobic digestion process produces a by-product commonly known as digestate. It is a mixture of stabilized influent and microbial biomass. For a certain substrate, the type of digester and the operation parameters determine the properties of the digestate. As already mentioned, during the anaerobic process, part of the organic matter is converted into methane; therefore, the organic content of the digestate is lower than in the influent. The reduction of the C/N is beneficial when the end product is intended for agricultural purposes.

The agricultural valorization of digestates focuses mainly on two aspects: the direct use of the digestate as fertilizer and solid–liquid separation and further usage of the solid fraction for the preparation of high value-added fertilizers through composting and the use the liquid fraction as a liquid fertilizer.

The fertilizer value of the digestate depends mainly on the nutrient concentration of the degraded substrate. During the digestion process, organic carbon is converted to methane and carbon dioxide, whereas most of the nutrients that were associated to organic molecules are mineralized and remain in the digestate. For instance, organic nitrogen is converted to ammonia nitrogen, whereas total nitrogen remains virtually unchanged (some ammonia will be found in the gas phase). Therefore, the digestate exhibits a great fertilizer value and could be used for the growth of terrestrial crops and also for microalgae cultures, as it will be further discussed in this chapter.

3 Biogas Production from Microalgae

3.1 Introduction

The initial studies on anaerobic digestion of microalgae are from the end of the 1950s (Golueke et al. 1957; Golueke and Oswald 1959). In their very first work published, Golueke et al. (1957) observed the difficulties that the anaerobic degradation of microalgal biomass (Scenedesmus and Chlorella) could entail, both in mesophilic and thermophilic range. Authors inferred three possible reasons: (1) low C/N ratio, (2) ability of algae to survive in the digester, and (3) resistance of algae cell wall to bacterial attack.

Gunnison and Alexander (1975a) worked to understand the resistance of microalgae to bacterial attack under natural conditions. The main conclusion of their study was that the composition of microalgal cell wall is a decisive factor for this resistance. Afterwards, the same authors analyzed the constituents of the cell wall of some microalgal species that showed an effective resistance to bacterial degradation (Gunnison and Alexander 1975b). In many species (e.g., Staurastrum sp., Pediastrum duplex, and Fischerella muscicola), complex carbohydrates supported high resistance to bacterial attack and decomposition. Considering these results, research conducted in the recent years has pursued different goals:

-

Coupling anaerobic digestion to microalgal growth units for clean energy production

-

Application of pretreatments to break microalgal cell walls in order to enhance biodegradation and consequently biogas production potential

-

Co-digestion of microalgal biomass with high C/N substrates in order to balance nutrients and to enhance microbial activity

-

Anaerobic digestion of microalgal residues produced after the extraction of high-value products, as waste treatment process in a biorefinery

3.2 Microalgae as Energy Crop

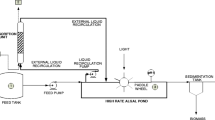

The literature on the direct use of microalgal biomass for biogas production is to some extent scarce. However, in the recent years, a new approach is emerging: the use of microalgae grown in wastewater for direct biogas production. In this case, the energy savings generated by replacing the traditional wastewater treatment processes by microalgae-based treatments make the cultivation process profitable, and the use of mixed algal-bacterial populations for biogas production adds to even higher energy gains. There are important R&D projects trying to implement this concept at medium and industrial scale with encouraging results to date (e.g., All-Gas project, led by Aqualia: http://www.all-gas.eu/).

Different microalgae species have been assessed for methane production. Microalgae assessed in the different studies include chlorophytes or green microalgae (Chlorella sp., Scenedesmus sp. Chlamydomonas reinhardtii, Dunaliella salina, Monoraphidium sp.), cyanobacteriae (Arthrospira platensis, Oscillatoria sp., Spirulina maxima), euglenoids (Euglena graciliis), and haptophytes (Isochrysis galbana) (Golueke et al. 1957; Golueke and Oswald 1959; Samson and LeDuy 1986; Varel et al. 1988; Mussgnug et al. 2010; Ras et al. 2011; Hernández et al. 2013; Prajapati et al.; 2014a; Tran et al. 2014; Mottet et al. 2014; Santos et al. 2014). The results are reported to be influenced by operational parameters and experimental conditions of each study (e.g., batch or continuous tests, temperature, hydraulic retention time, organic loading rate), but they provide an insight into intra- and interspecies variability in methane potential of microalgae (see Fig. 5.3 for a comparative evaluation of some of these results).

Mesophilic methane yield of the different species ranged from 139.7 ± 0.9 LCH4 kgVS−1 for Scenedesmus sp. (Tran et al. 2014; Ramos-Suárez et al. 2014a) to 387 LCH4 kgVS−1 for Chlamydomonas reinhardtii (Mussgnug et al. 2010) or 446.8 LCH4 kgVS−1 for an algal sludge mainly composed of Scenedesmus, Chlorella, Euglena, and Oscillatoria (Golueke and Oswald 1959), the latter at thermophilic digestion (45 °C).

From all these studies, the main conclusion that can be drawn is that biodegradability, and therefore methane potential production, is species and strain specific (Mussgnug et al. 2010; Prajapati et al. 2014a). Moreover, within the same species, this potential could change depending on the culture growing method, or more specifically, on the nutrients supplied to the culture during its growth which determine its biochemical composition and, therefore, its methane production potential (Hernández et al. 2013).

It has been concluded, that biodegradability is mainly conditioned by the presence or absence of a cell wall composed of complex polymers, hardly biodegradable, that impede the degradation of intracellular organic molecules by microorganisms (Mussgnug et al. 2010).

Another drawback for an optimum anaerobic degradation of microalgae is the high content of nitrogen and low C/N ratio of this biomass. The major fraction of microalgae cultured without nutrient limitation is protein (Rebolloso Fuentes et al. 2000), which could be up to 60 % (Mahdy et al. 2014a). During anaerobic digestion, proteins are degraded and ammonium is produced. If ammonium concentration reaches important levels, microorganisms could be inhibited reducing or even stopping biogas production (Samson and LeDuy 1986). In literature, a wide range of ammonia inhibition thresholds are shown (from 1.7 to 14 g L−1 being the necessary concentration to cause a 50 % reduction in methane production). The inhibiting concentration could change with differences in substrates, inocula, environmental conditions (temperature and pH), and acclimation period (Chen et al. 2008).

Additionally, for marine species, salinity could also play an important role, as high salinity levels can diminish anaerobic digestion performance. Mottet et al. (2014) showed that salinity could be counteracted by means of adapted or acclimated inoculum, which could withstand high salinity levels yielding similar methane as low-salinity-level microalgae.

3.2.1 Enhancement of Methane Yields

3.2.1.1 Pretreatments for Microalgal Biomass

Algae consist of complex organic matter which implies a difficult enzymatic hydrolysis and hence limits the efficiency of anaerobic digestion. The limited hydrolysis is due to the biomass features such as biochemical composition and cell wall characteristics of the different microalgae strains. One of the approaches followed for enhancing methane production is the pretreatment of microalgae biomass. This approach enhances the hydrolysis rate of microalgae during anaerobic digestion by facilitating cell wall disruption. In this sense, organic matter contained in microalgal biomass becomes readily available for anaerobic microorganisms, and therefore, methane production and productivity increase. Pretreatments to open up the cell wall structure have been widely studied in activated sludge and lignocellulosic biomass; however, there is not enough information regarding the effect of those pretreatments on microalgae. Even though microalgae does not contain lignin which renders this substrate easier to degrade than lignocellulosic substrates, microalgal biomass contains some other compounds, such as algaenans and sporopollenin, which confer the cell wall a high resistance to bacterial attack (Burczyk and Dworzanski 1988).

3.2.1.1.1 Pretreatment Features: Organic Matter Solubilization and Structural Changes

The pretreatments applied to microalgal biomass prior to anaerobic digestion results in different changes in biomass structure and organic matter solubilization. By these means, microalgae biomass suffers changes which ultimately lead to methane production enhancement.

Traditionally, the organic matter solubilized upon pretreatment of activated sludge has been directly correlated to methane yield enhancement (Bougrier et al. 2005). Opposite to activated sludge, a parameter that can be used as an indicator of methane yield enhancement after pretreatment is lacking. As mentioned above, pretreatments employed for activated sludge are being adapted for microalgae biomass, and therefore, the first indicator followed was soluble COD increase after pretreatments. Nevertheless, this attempt has shown that microalgae biomass behaves differently than other biomasses upon pretreatments and no direct linkage exists (González-Fernández et al. 2012a; Alzate et al. 2012). In the constant search of finding a key indicator, proteins and carbohydrates have been also studied. These two macromolecules have been pointed out as potential indicators since microalgae biomass is mainly composed of these components (González-Fernández et al. 2010; Mendez et al. 2014a). In this sense, these macromolecules are main components, but what is indeed causing the low hydrolysis of these substrates in anaerobic digestion is the composition of the cell walls. It is important to understand the chemical composition of the targeted microalgal cell wall. C. vulgaris is one of the most commonly studied microalgae, and as reported in historical literature, it has a cellulose-based cell wall (Loos and Meindl 1984), but the latest studies are showing that this may not be correct (Gerken et al. 2013; Kim et al. 2014). By taking a closer look into carbohydrates, Mendez et al. (2014a) were able to identify a close relationship between carbohydrate solubilization and methane production enhancement after thermal pretreatment. Nevertheless, when trying to reproduce this trend in different microalgae strains, the results indicated that the overall fraction of carbohydrates was not a proper indicator (Mendez et al. 2014b). It can be thus concluded that the carbohydrate fraction itself cannot be used for this purpose, but study on the different carbohydrates that constitute the microalgae cell wall deserves further investigation. More specifically, uronic acids, neutral sugars, and amino sugars have been identified in the microalgae cell wall (Cheng et al. 2015). Studies have always claimed that this microalga possesses a carbohydrate-based cell wall mainly composed of cellulose and hemicellulose (González-Fernández et al. 2012b). Nevertheless, lately, few investigations have pointed out that this might not be true. For instance, Kim et al. (2014) used cellulases to hydrolyze C. vulgaris cell wall and the results were not as expected. Their investigation revealed that cellulase and amylase did not have any effect on cell wall disruption. To verify which enzyme would be more efficient for cell wall degradation, they tested pectinase, cellulase, amylase, xylanase, β-glucosidase, chitinase, lysozyme, and sulfatase. Their results confirmed that only pectinase had a significant effect on the degradation of polysaccharides from the cell wall of C. vulgaris. Similarly, another recent publication reached the same conclusion. It seems likely that C. vulgaris does not have a cellulose rigid cell wall, but rather uronic acids and amino sugars are conferring this microalgae its hardness (Gerken et al. 2013). At this point, it seems of relevant importance to characterize the carbohydrate fractions released upon pretreatments in order to gain insights on the effect that this disruption method has on the microalgae cell wall.

Proteins have been studied to a minor extent than carbohydrates. One of the main reasons for this limited information on proteins is related to the fact that proteins are weaker macromolecules than carbohydrates, and thus, upon pretreatments, proteins are quite often converted into other polymers and therefore not quantified in the soluble phase (Mendez et al. 2013). The low solubilization of proteins has been attributed to the occurrence of Maillard reaction. In this context, the available reducing sugars and amino acids reacted leading to the formation of complex molecules. Maillard reaction course is strongly affected by factors such as temperature, heating duration, water content, pH, and amino acid to sugar ratio. In this study, the low solubilization of proteins recorded was attributed to this type of reaction taking place when proteins and carbohydrates are soluble at high temperatures. As proteins react with reducing sugars, the amount of carbohydrates and proteins solubilized was indeed higher than the determined value. Nevertheless, the polymerization of the solubilized macromolecules reduced their solubility.

Microalgal cell walls have been reported to contain 10–30 % protein (Burczyk et al. 1999; Blumreisinger et al. 1983). The presence of proteins in the cell wall cannot be neglected since this polymer may also be responsible of the low anaerobic digestibility of microalgae. This macromolecular fraction has been pointed out as the polymer limiting the anaerobic digestion of other biomasses such as activated and primary sludge (Mottet et al. 2010; Miron et al. 2000). Lately, studies focusing on enzymatic hydrolysis of microalgae cell wall have elucidated the relevance of cell wall proteins for biogas production purposes. In this context, Mahdy et al. (2014a) tested two enzymatic cocktails, namely, carbohydrase and protease, which resulted in high hydrolysis efficiencies rendering almost all the particulate carbohydrates and proteins available in soluble phase. When subjecting carbohydrase and protease hydrolyzed biomass to anaerobic digestion, methane production was greatly enhanced for biomass pretreated with proteases. The importance of proteins for biogas production has been evidenced in chlorophyta, namely, Chlorella sp. and Scenedesmus sp. (Mahdy et al. 2015). Proteins frequently reported on microalgae cell wall conferring rigidity belong to the glycoprotein family (Voigt et al. 2014). Glycoproteins themselves are not difficult to digest but their linkage can be of great importance. For instance, Chlamydomonas reinhardtii exhibiting glycoproteins is a substrate easy to digest (Mahdy et al. 2014a), while Scenedesmus is probably one of the most difficult microalgae to degrade. In this latter one, glycoproteins are cross-linked via carbohydrate side chains and not via transglutaminase-dependent reactions or peroxidase-catalyzed isodityrosine formation as it happens in C. reinhardtii (Voigt et al. 2014).

The other change that is observed during microalgae pretreatments is the formation of aggregates upon cell wall disruption. Particle size distribution shifts to higher particle diameters when applying temperatures greater than 80 °C or when subjecting the microalgae biomass to ultrasound pretreatment at high energy levels (Ometto et al. 2014; González-Fernández et al. 2012c). The reason for this increased diameter has been attributed to the release of intracellular material. Some other evidences of cell wall disruption during pretreatments have been provided microscopically. Change in structural integrity or breakdown of microalgal cells are not detected under normal microscopic observation. However, cell wall disruption has been proved by using dyes, such as Sytox green (González-Fernández et al. 2012a), or through transmission electron microscopy (Passos and Ferrer 2014). These two methods are useful to fully ascertain that organic matter released during the different pretreatment is intracellular and not due to the exopolymers attached to the cell wall. In this context, Sytox green dyes the cell when the wall is disrupted; on the other hand, if only extracellular organic matter is released, microalgal cells would not be stained. Transmission electron microscopy has been also confirmed as a helpful tool to identify structural changes occurring upon microalgae cell wall pretreatments. During thermal hydrolysis, the cell wall are expanded and partially disaggregated inside the cell boundaries, while cell turgidity is less evident after enzymatic hydrolysis (Ometto et al. 2014). Authors attributed this less distorted cell structure after enzymatic hydrolysis to the degradation of specific cell wall components. FT-IR spectra of raw and pretreated microalgae biomass has also been used widely for obtaining information of chemical and structural changes in different biomasses (Monlau et al. 2012; Salehian et al. 2013). When applied to microalgal biomass, the intensity of peaks related to the bond C–O–C of polysaccharides diminishes at increasing temperatures, and also changes in the fingerprint regions of amide band (proteins) were registered during thermal pretreatment (Mendez et al. 2014a). Therefore, infrared spectra can support qualitative changes of the biomass upon pretreatment but not quantitative because the changes in peak intensity are too low to determine structural changes.

As it can be seen, the need of finding an indicator to elucidate whether the cell wall was damaged or not during biomass pretreatment has been successfully achieved during this last decade of research. Nevertheless, no clear indicator that can be related to methane production enhancement after biomass pretreatment has been provided. Most likely, the reason for this is the different cell wall composition and matrix linkage of the microalgae studied. However, the last decade of intensive research on microalgae biomass has shown a wide range of efficient pretreatments for biogas production. Most of the pretreatments studied recently are done through thermal, physical, or chemical means.

3.2.1.1.2 Thermal Pretreatments

Thermal pretreatments affect weak hydrogen bonds when mild temperatures (below 100 °C) are applied while complex carbohydrates solubilizes when higher temperatures are employed (González-Fernández et al. 2012a; Garrote et al. 1999). Mild temperatures of 50 °C when applied to microalgal biomass resulted in organic matter solubilization (Mahdy et al. 2014b). Carbohydrate solubilization recorded for Chlorella sp. was 15 and 32 % for Scenedesmus sp. Despite the organic matter release, methane yield of these biomasses did not increase significantly (Mahdy et al. 2014b; Passos et al. 2013). The almost negligible increase in methane yield was attributed to the fact that the organic matter solubilization was probably mediated by exopolymer released during the pretreatment rather than by cell wall breakage. At higher temperatures of around 90 °C, Scenedesmus biomass is disrupted after 30 min, and methane production is doubled (González-Fernández et al. 2012a). At this point, it should be stressed out that Scenedesmus is probably one of the most difficult microalgae to digest (Mussgnug et al. 2010). Similarly, out of the three mild temperatures tested on Nannochloropsis oculata, at 30, 60, and 90 °C for 4 h, an enhancement in methane yield of 41 % was recorded at 90 °C compared to the raw biomass (Marsolek et al. 2014). This was due to the organic matter solubilization registered after thermal treatment (40 %). In the same range, 32 % methane yield enhancement was registered after the thermal treatment at low temperature (60 °C for approximately 4 h) of a microalgal mixture of Pediastrum sp. and Micractinium sp. where 11 % organic matter was solubilized after the pretreatment (Kinnunen et al. 2014). Interestingly, these authors also reported the effect of freeze-thawing the biomass. This pretreatment resulted in 18 % organic matter solubilization but double methane yield. It can thus be confirmed that organic matter solubilization is a too general parameter, and the chemical composition of the different organic matter solubilized is crucial for methane production. This fact has also been confirmed by other authors. The different pretreatments and different pretreatment conditions differently affect microalgal biomass disruption, and thus, different disruption mechanisms lead to different chemical compositions of organic matter that ultimately determine the methane yield achievable by these pretreated substrates (González-Fernández et al. 2012a; Ometto et al. 2014). Overall, it may be hypothesized that this range of temperatures (around 100 °C) would be enough to open up all microalgae cell walls and make their organic material available for anaerobic microorganisms.

When evaluating higher temperatures, carbohydrate solubilization prevails over proteins (Mendez et al. 2013). This investigation dealt with Chlorella vulgaris subjected to 120 °C for 20 min, and 40 min resulted in 4- and 4.5-fold carbohydrate content in the soluble phase, respectively. Even though the differences attained were low, this had a major effect on the methane yield achieved. While biomass subjected to 120 °C for 20 min increased methane yield by 30 %, the biomass heated for 40 min doubled the methane production. Similarly, Cho et al. (2013b) reported a methane yield enhancement of 20 % together with 30 % organic matter solubilization when pretreating a microalgae mixture (70 % Chlorella sp. and 30 % Scenedesmus sp.) at 120 °C for 30 min with regard to 336 LCH4 kgVS−1 achieved by the raw biomass. These enhancements decreased to 14 % and 4 % when the mixture was pretreated at 80 and 50 °C, respectively. Nevertheless, as pointed out before, these enhancements are strain specific due to the differences in their cell wall and biochemical composition. In this manner, applying the same pretreatment to Scenedesmus sp. biomass supported an enhancement of 21–27 % (Mendez et al. 2014b). Even though carbohydrate profile for Scenedesmus biomass showed solubilization pattern similar to Chlorella biomass, the methane yield enhancement was lower for Scenedesmus than the observed value for Chlorella biomass. These results could be attributed to the high strength of Scenedesmus cell wall. In the case of saline biomass, thermal pretreatment at 120 °C for 2 h has been tested on Nannochloropsis salina (Schwede et al. 2013a). This investigation did not follow the organic matter solubilization, but authors observed a twofold increase in methane yield. The same enhancement was observed in semicontinuously operated reactors; however, the absolute methane yield values were diminished by half. In this sense, pretreated biomass digested in batch assay provided methane yield of 570 L kgVS−1, while the digestion in continuous mode mediated 270 L kgVS−1. The reason for such a decrease was attributed to the high ammonium and salt concentration in the feedstock which ultimately led to volatile fatty acid accumulation.

Moving upwards to higher temperatures in the range of 140–180 °C (applied for 10 min) increased the carbohydrate content in the soluble phase by four- to sixfold, while protein solubilization was enhanced by one- to twofold (Mendez et al. 2014a). Concomitantly with the enhanced carbohydrates solubilization, methane yield was improved by 1.4–1.6-fold in comparison to that of the raw Chlorella biomass. Ometto et al. (2014) also studied high temperatures in the range of 120–165 °C. Their results showed an organic matter solubilization of around 40 % when applying temperature at 165 °C for Scenedesmus obliquus and Chlorella sorokiniana. Despite the fact that the organic matter solubilization was similar, the methane yield in the case of Scenedesmus obliquus was enhanced by 200 % and for Chlorella sorokiniana by 100 % in comparison to the raw biomass (88 and 118 LCH4 kgVS−1, respectively). Within the high temperature range, high-pressure thermal hydrolysis (170 °C at 800 KPa) as pretreatment for Scenedesmus hydrolysis has been also tested (Keymer et al. 2013). These conditions of temperature and pressure were maintained for 30 min and resulted in 11-fold organic matter solubilization and 81 % increase in methane yield over that of raw algae (150 LCH4 kgVS−1).

3.2.1.1.3 Chemical Pretreatments

Chemical pretreatments have been studied to a lesser extent due to the need to readjust the pH changes prior to feeding into the reactor and associated chemical cost. The positive effect of acid catalysts in thermal pretreatment on other substrates, such as lignocellulose, has been confirmed. Thermo-acid pretreatment clearly affects the cell wall by solubilizing polymers, thus favoring anaerobic microbial degradation. This pretreatment, for instance, has been proven particularly efficient in solubilizing microalgae carbohydrates (Mendez et al. 2013). Treating Chlorella vulgaris at 120 °C for 40 min at pH 2 increased carbohydrates in the soluble phase by sevenfold, while the acid addition alone provided only 2.3-fold increase. Proteins were also solubilized; however, their conversion into other complex molecules made the quantification impossible. With regard to methane yield of this thermo-acid pretreatment, the higher solubilization of carbohydrates did not support an enhanced methane yield compared to only the thermally treated biomass. Thermally pretreated biomass yielded 267.7 LCH4 kg COD−1, while when this pretreatment was combined with pH reduction, methane yield reached 228.6 LCH4 kgCOD−1. Chemical supplementation combined with this temperature hindered the methane production, probably mediated by unidentified side product released during the pretreatment.

In case of lignocellulosic biomass, alkali addition disrupts the lignin structure and breaks the linkage between lignin and other cell wall carbohydrates. This feature does not affect microalgal biomass since these substrates are lignin-free. Nevertheless, alkali pretreatment enlarges the surface area of cellulose by biomass swelling and reduces cellulose crystallinity by cleavage of carbohydrate glycosidic bonds (Hsu 1996). Alkali pretreatment at pH 10 and temperature of 120 °C led to an increase of proteins in the soluble phase by 1.7- and 1.9-fold when pretreating Chlorella vulgaris biomass for 20 and 40 min, respectively (Mendez et al. 2013). Under this alkali scenario, carbohydrates were solubilized in a similar fashion like the thermal pretreatment which did not involve chemicals. Thermo-alkali pretreatment reported slightly higher values on methane yield than that observed for thermo-acidic pretreatment. Methane yield was reportedly enhanced by 1.73-fold when a combination of 120 °C for 40 min and pH 10 was used as pretreatment, while for the raw biomass, it was 139 LCH4 kgCOD−1 only.

Carbohydrate solubilization is also reported when pretreatment involves lower temperatures (50 °C), in addition to alkali (Mahdy et al. 2014b). The solubilization of polymer is strain specific. For C. vulgaris, it ranged from 1 to 18 %, while for Scenedesmus sp., it was 15–44 %. Once again, even though the organic matter solubilization was higher for Scenedesmus, methane yield enhancement was higher for C. vulgaris. The reason for that was attributed to the nature of carbohydrates solubilized. This study showed low methane production enhancement under this conditions (approximately 15 % when biomass was pretreated with 5 % w/w NaOH). This low enhancement was ascribed to the fact that the organic matter solubilization was probably mediated by exopolymers released during the pretreatment rather than those from within the cell. When alkali pretreatment was performed over a mixture of microalgae (70 % Chlorella sp. and 30 % Scenedesmus sp.) without heating, only 5 % organic matter solubilization was observed at pH 9 and 11, while this value increased up to 21 % at pH 13 (Cho et al. 2013b). Nevertheless, pH 11 and 13 negatively affected methane production and inhibited the process. Subjecting the biomass to pH 9 provided only a slight enhancement. It can be thus concluded that alkali pretreatment of microalgal biomass is not a promising method.

Overall, acidic pretreatments increased the carbohydrates released into the medium while under alkaline conditions; proteins were solubilized to a greater extent. The drawback of using concentrated chemicals includes material corrosion and formation of by-products that could result in inhibition of digestion (Monlau et al. 2014).

3.2.1.1.4 Physical Pretreatment

Physical pretreatment involves the reduction of particle size and increase in surface/volume ratio available for hydrolysis. Within this category, microwave and ultrasound are the most commonly used methodologies. Microwave pretreatment involves boiling of water using microwave radiation. This process resulted in cell hydrolysis and structural changes in proteins (Park et al. 2010). Microwave pretreatment (900 W for 3 min having specific energy of 70,000 kJ kg VS−1) has been tested on a mixture of microalgae, and the results on methane yield were not significant (Passos et al. 2014a). Minor increase in methane yield was attributed to the possible cell wall damage, but since lysis did not occur, any significant increase in yield was precluded. However, it remains to be seen if this pretreatment has strain specificity. For application of ultrasound to microalgal biomass, literature is more extensive. As a matter of fact, a detailed review on the effect of this pretreatment on different biomasses, including microalgae, is available (González-Fernández et al. 2014). Ultrasound consists of elastic waves with frequency range between 20 kHz and 1 GHz. Bubbles are formed in the liquid and filled with the liquid’s vapor and dissolved gases. Above a critical value of local pressure, the bubbles implode violently, producing powerful hydromechanical shear forces in the liquid medium surrounding them. On micro scale, the cavitation process produces temperature of around 5000 °C and pressure of 50 MPa for microseconds (Suslick 1990). Ultrasound pretreatment has also been proven as an effective pretreatment for two of the most robust microalgae, Chlorella vulgaris and Scenedesmus obliquus. When subjecting Scenedesmus obliquus to different levels of ultrasound energy, the results showed methane production at a twofold higher level on lower ultrasound levels (35.5 MJ kg−1 TS−1) and a fourfold level when applying higher energy levels (76.5–130 MJ kgTS−1) (González-Fernández et al. 2012b). The highest energy supplied (100–130 MJ kgTS−1) almost doubled the methane production for the untreated S. obliquus (51 LCH4 kgVS−1). This enhancement is similar to that observed for thermal pretreatment of this biomass, and therefore, due to lower energy requirements of thermal application, this latter one might be a preferable pretreatment (González-Fernández et al. 2012a). Ometto et al. (2014) compared the effect of ultrasound on three photosynthetic microorganisms, namely, C. vulgaris, S. obliquus, and A. maxima. This investigation showed that the microalgae C. vulgaris provided the highest methane yield enhancement (44 % in comparison to the raw biomass which attained 169 LCH4 kgVS−1) when the biomass was subjected to 35 MJ kgTS−1. In the case of A. maxima, 82 % organic matter solubilization and 33 % methane yield enhancement were observed, regardless of the increase in power output applied (from 0.35 up to 35 MJ kgTS−1). This was due to the fact that A. maxima has a weaker cell wall compared to other microalgae, and therefore, even the lowest energy level applied provided the very high solubilization and methane yield achievable out of this biomass. On the other hand, when applying a specific energy of 32 MJ kgTS−1 to a microalgal mixture composed of Monoraphidium sp., Stigeoclonium sp., and the diatoms Nitzschia sp. and Amphora sp., the methane yield enhancement was 11 % (raw biomass exhibited 148 LCH4 kgVS−1) (Passos et al. 2014b). This low enhancement was attributed to the presence of diatoms which have a silica-based cell wall which is only slightly degradable. Methane yield increased by 33 % after subjecting this biomass mixture to 67.2 MJ kgTS−1; nevertheless, the authors have also pointed out that the preliminary energy assessment indicated that the energy input was higher than the extra energy produced. The general conclusion that can be pointed out of the ultrasound pretreatment studies confirms that the thermal pretreatments can be more effective than ultrasound in enhancing microalgae digestibility (González-Fernández et al. 2012b; Cho et al. 2013b; Ometto et al. 2014).

3.2.1.1.5 Enzymatic Hydrolysis

For enzymatic hydrolysis, the correct choice of enzymes is crucial for a successful pretreatment. So far, very little work has been done on the effect of enzymatic hydrolysis of microalgae for methane production purposes (Miao et al. 2013; Ciudad et al. 2014). Cell wall enzymatic pretreatment may not be useful for biofuel production only but also for value-added products that can be extracted from this biomass. It is of high importance to understand the chemical composition of the targeted microalgae cell wall. Enzymatic pretreatment precludes the formation of inhibiting by-products. The overall process cost of enzymatic hydrolysis may be lower than thermochemical hydrolysis as it avoids corrosion of the container and requires mild temperature. Likewise, enzymes can be produced naturally by a wide range of bacteria and fungi.

As mentioned above, the cell wall composition is one of the key parameters. Chlorella vulgaris is probably one of the most studied microalgae, but the composition of its cell wall is still not clear. Some studies have claimed that this microalga possesses a carbohydrate-based cell wall mainly composed of cellulose and hemicellulose. Nevertheless, lately, few investigations have pointed out that this might not be true (Kim et al. 2014). It seems likely that C. vulgaris does not have a rigid cell wall because of cellulose, but uronic acids and amino sugars are conferring this microalgal cell wall its hardness (Gerken et al. 2013). Therefore, enzymatic hydrolysis may be extremely useful to gain insights on cell wall composition.

The addition of carbohydrase and protease mediated high carbohydrate and proteins solubilization (86–96 %) when applied on Chlamydomonas reinhardtii and Chlorella vulgaris (Mahdy et al. 2014a). Out of these two biocatalytic cocktails, protease addition was more beneficial for biogas production. In the case of C. reinhardtii, protease addition increased methane production by 1.17-fold in comparison to the raw biomass (263 LCH4 kgCOD−1). This enhancement was low due to the inherent high biodegradability of this biomass. On the other hand, hydrolyzed C. vulgaris mediated an enhancement of 51 % compared to the raw biomass (190 LCH4 kgCOD−1). In order to optimize the protease dosage, results were tested by decreasing dosages. This attempt resulted in diminished hydrolysis efficiency concomitantly with decreased methane yield enhancement (Mahdy et al. 2014c). Thus, the optimum protease dosage was set at 0.585 AU g DW−1. This dose was tested at increasing biomass loads to elucidate whether the viscosity of the broth was affecting the hydrolysis. The results indicated that this dose can be employed up to 65 g TS L−1 without markedly affecting the hydrolysis efficiency or the methane yield enhancement. At this point, it should be stressed out that proteases are released under biomass storage. Using some other biocatalyst cocktails, Ometto et al. (2014) tested a mixture of endoglucanase and cellulase and a mixture of esterase and protease in two microalgae and one cyanobacterium. Their results showed that the first mixture was better to hydrolyze Scenedesmus obliquus and increased methane yield by 5.6-fold, while the enhancement in the case of Chlorella vulgaris was decreased by 3.15-fold. The second mixture of enzymes provided an enhancement in methane yield of 3.9- and 3.2-fold for S. obliquus and C. vulgaris, respectively. In the case of the cyanobacterium Arthrospira maxima, no significant differences were attained between the two cocktails; thereby, both of them provided a biogas yield increase of approximately eightfold.

Only one study is available in the recent literature concerning the use of noncommercial enzymes for hydrolyzing microalgae biomass. In this context, marine bacteria with cellulolytic capacity (mainly exhibiting endoglucanase activity) were tested on Nannochloropsis gaditana (Muñoz et al. 2014). After 25 days of digestion, methane yield was enhanced by 2.5-fold compared to the raw biomass (109 LCH4 kgVSS−1). For commercial cocktails which are mostly active at 50 °C, these authors also pointed out that the activities of these enzymes were maximum at 30 °C. Thereby, it can be inferred that energy costs can be decreased due to moderate requirement of temperature. Once identified, the most appropriate enzyme (or a cocktail) which is able to disrupt a broad range of microalgae strain may be produced in situ.

3.2.1.2 Co-digestion

Due to the high nitrogen content, microalgal biomass is characterized by a low C/N ratio. Co-digestion aims to increase the C/N ratio of the substrate introduced into the digester in order to balance nutrients. Different substrates rich in carbon could be combined with microalgal biomass thereby increasing the C/N ratio up to levels close to the optimum for anaerobic digestion, which oscillates between 10 and 30 (Pagés Díaz et al. 2011). The reason for such wide optimum C/N ratio is that it depends on several factors such as the chemical composition of the digested substrate, temperature of the process, and adaptation of the microorganisms to high levels of potentially inhibitory compounds, such as nitrogen (Chen et al. 2008).

Algae could potentially be integrated in a wastewater treatment plant and combine the benefits of nutrient removal, energy production, and CO2 sequestration. Recently, a study was conducted to evaluate the potential of microalgae biomass as co-substrate for anaerobic digestion of primary and secondary sludge, thereby increasing the methane production and improving the energy balance of the whole process (Mahdy et al. 2014d).

Co-digestion with different substrates has been tested with different microalgae species such as Spirulina maxima (Samson and LeDuy 1983), Arthrospira platensis (El-Mashad 2013), Scenedesmus sp. (Yen and Brune 2007; González-Fernández et al. 2011; Ramos-Suárez et al. 2014a), Chlorella sp. (Yen and Brune 2007; Ehimen et al. 2009, 2011; González-Fernández et al. 2011; Wang et al. 2013; Park et al. 2013), Nannochloropsis salina (Park and Li 2012; Schwede et al. 2013b), Microcystis sp. (Zhong et al. 2012, 2013; Zhao and Ruan 2013), Isochrysis galbana, and Selenastrum capricornutum (Caporgno et al. 2015). In turn, co-substrates employed are diverse, mostly rich in carbon (sewage sludge, peat hydrolyzate, paper residues, glycerin, waste fat and oils, kitchen wastes, corn straw, switch grass, and prickley pear) and in once case a substrate rich in nitrogen: swine manure.

Most of these studies showed a positive effect when co-digesting microalgal biomass. Yen and Brune (2007) observed an increase in methane production and an improvement in the kinetics of degradation when co-digesting Scenedesmus and Chlorella with paper residues. Besides the beneficial effects of the balance of nutrients and alkalinity, they found an increase in the activity of cellulase when paper residues were added to the digesters together with microalgal sludge. The cellulase activity registered mediated a better degradation of Scenedesmus and Chlorella cell wall, and thus, the anaerobic biodegradability of these substrates was improved. Methane yield of microalgal sludge digested alone (C/N= 6.7) was 143.2 LCH4 kgVS−1, whereas a mixture composed of 40 % algal sludge and 60 % paper residues in VS basis (C/N= 22.6) increased methane yield by 124 %. On the other hand, Wang et al. (2013) suggested that the increase in the biodegradability of Chlorella when it was co-digested with activated sludge was consequence of the high quantity and diversity of microorganisms in the sludge that aided in the hydrolysis of microalgal cell wall.

However, not all the studies have shown positive results. González-Fernández et al. (2011) co-digested Chlorella vulgaris and Scenedesmus obliquus with swine manure expecting microalgae to act as a carbon source to improve the digestion of swine manure. Although the cell walls of both species are rich in carbon, their complexity impeded the degradation and the methane production decreased. A decrease in methane production was also observed when Spirulina platensis was co-digested with switch grass (El-Mashad 2013). According to the author, the high lignin content of switch grass was the cause of this reduction even though C/N ratio was higher.

Ammonia produced by nitrogen degradation increased the buffer capacity of the digestion system. Therefore, microalgae could be used as co-substrate of easily degradable energy crops, increasing the organic loading rates (OLR) achievable. Schwede et al. (2013b) observed that the addition of Nannochloropsis salina to maize silage in a continuous digestion process facilitated the increase in organic loading rates to higher levels than in the monodigestion of maize silage. Similarly, Ramos-Suárez et al. (2014a) reached OLR as high as 5.33 gVS L−1 d−1 (HRT of 15 days) in the co-digestion of Scenedesmus sp. and O. maxima with a methane yield of 307.8 L kgVS−1.

Considering the different studies concerning co-digestion of microalgal biomass, it seems that the addition of carbon-rich substrates enhanced the digestion process and an increase in the methane production along with an improvement in the kinetics of degradation. However, each co-substrate needs to be studied separately, since the increase in the C/N ratio cannot be used as a sole indicator of the process performance (Table 5.1).

3.3 Anaerobic Digestion in Microalgae Biorefineries

Definitely, there is a great potential in microalgae for biofuel production, but the truth is that nowadays microalgal biofuels are far from being economically viable. In this regard, the upper limit value of biomass production cost has been agreed at 0.5 US$ kg−1 (Acién et al. 2014), although Chisti (2012) suggested a production cost of 0.25 US$ kg−1 for algal fuels to be competitive with petroleum-derived fuel.

Production cost estimates vary widely from study to study due to the lack of industrial plants working at full capacity and a defined technology (Acién et al. 2014). Chisti (2007) estimated production costs of 2.95 US$ kg−1 and 3.80 US$ kg−1, respectively, for PBRs and raceways, assuming free carbon dioxide and a facility with an annual biomass production of 100 tons. Acién et al. (2012b) estimated production cost of 69 € kg−1 for a 3 m3 tubular PBR facility producing Scenedesmus almeriensis. Authors indicated that by a simplification of the production system and due to economics of scale, increasing annual biomass production up to 200 tons year−1 (1570 m3 of PBRs) could reduce production costs to 12.6 € kg−1, still far away from the upper limit mentioned above. Other authors (Norsker et al. 2011) estimated production costs of microalgae in closed tubular PBRs, flat panels, and raceways to be 4.15, 4.95, and 5.96 € kg−1, respectively, and stated that optimizing production conditions could reduce production costs to 0.68 € kg−1.

In any case, microalgae production costs need to be reduced to meet requirements of the energy market (Acién et al. 2012b). Microalgae industry is expected to keep growing in the near term for the nutraceutical, pharmaceutical, cosmetic, food, and feed industries, whereas fertilizers, bioremediation, and chemical demands are also future applications of interest. If several compounds and products are obtained from microalgae at the same time, the economics of production would improve substantially. It has to be taken into account that all these products have higher market prices than biofuels, and therefore, the production of the latter can be expected to be as a marginal case at the end of a production line. Whatever the compound/s to be extracted or product/s to be produced from microalgae, it is expected that in the large scale this activity would produce great amount of organic residues that would require appropriate treatment (Ramos-Suárez and Carreras 2014).

Anaerobic digestion can be used in a biorefinery concept, as the appropriate process with huge synergistic possibilities for energy generation with microalgae culture. The coupling of anaerobic digestion to the extraction of proteins from microalgae could improve the economics of the process by the generation of renewable energy, the recycling of the digestate as growth medium (Uggetti et al. 2014), and the use of raw biogas or combusted biogas as carbon source (Douškova et al. 2010).

3.3.1 Organic Waste Treatment and Clean Energy Production

The first goal of anaerobic digestion in any biorefinery is the treatment of the organic waste and the production of clean energy in form of biogas, and in the case of microalgal biorefineries, this is not different. In this regard, different options have been assessed up to now, although available literature is pretty scarce.

As already mentioned in this chapter, the major fraction of microalgae grown without nutrient limitation is protein (Rebolloso Fuentes et al. 2000). Therefore, if the goal of a biorefinery is to use most of the generated biomass, protein should be leveraged properly. After the extraction of proteins, the residual biomass could be converted into biogas. Furthermore, the digestion process is improved due to the disruption of the cell wall prior to protein extraction and the increase in the C/N ratio (Ramos-Suárez and Carreras 2014). In their study with Scenedesmus biomass digested in CSTR, Ramos-Suárez et al. (2014b) observed an increase in the biodegradability and biogas yield in amino acid-extracted residual biomass similar to that observed after thermal and thermochemical pretreatments by other authors. Biogas yield of Scenedesmus residual biomass increased up to 409 Lbiogas kgVS−1 (71 %CH4) with a digester efficiency of 1084 LCH4 m−3 digester d−1 at and OLR of 3.85 gVS L−1 d−1 and 20 days of HRT.

Several authors have pointed anaerobic digestion as a convenient supplemental process to biodiesel production from microalgae (Sialve et al. 2009; Chisti 2007), since the produced biogas could serve the electrical and thermal energy necessary to run the biodiesel production process. In this regard, different studies have assessed the combination of lipid extraction from microalgae and subsequent anaerobic digestion of lipid-extracted residual biomass.

Two studies assessed methane potential of Chlorella biomass both in batch and continuous mode and after different lipid extraction methods (Ehimen et al. 2009, 2011). A reduction in methane potential was observed when lipid-extracted biomass was digested, although kinetics of the process was improved. The decrease in the methane production was a consequence of the extraction of the lipid fraction, which yields higher methane than proteins and carbohydrates (Sialve et al. 2009). It is important to note the solvent used during the extraction method since it can remain the residual biomass and affect the microorganisms. In fact, it has been demonstrated that the extraction of lipids with a chloroform-methanol mixture in the conventional lipid extraction process can inhibit the process (Ehimen et al. 2009). Contrarily to the results observed by Ehimen et al. (2009), other studies have shown that the lipid extraction could benefit a subsequent digestion of the residues compared to raw biomass. An increase in methane yield for Scenedesmus and Nannochloropsis gaditana lipid-extracted biomass has been observed. For Scenedesmus biomass, increases of 33.3 and 51.3 % have been observed after lipid extraction (Keymer et al. 2013; Ramos-Suárez and Carreras 2014), whereas for Nannochloropsis gaditana, a slight increase of 10 % was observed (Alzate et al. 2014). Results obtained suggest that the increase or decrease of methane potential is dictated by the specie under digestion. In species with resistant cell walls, such as Scenedesmus, the rupture of the cell wall is enough to produce a significant increase in the methane production compared to that obtained from raw biomass, even though lipids are extracted from the biomass.

Although major part of the research on this field is focused on the use of lipid- or protein-extracted residual biomass, the ideal biorefinery would use all precious components in a multistep extraction before introducing residues in an anaerobic digester. Lipids and amino acids could be extracted in sequential processes; afterward, residues could be used for biogas production. Moreover, sugars or other high-value products depending on the species could also be extracted. However, the sequential application of different extraction processes is difficult due to the intensive processes used. Normally, the extraction of certain component causes the loss or degradation of the other components, preventing further use of generated residual biomass. Researchers in the University of Almería (Spain) are working currently in the development of multipurpose extraction process (see Fig. 5.4), minimizing residues but using them for anaerobic digestion as a final step to produce biogas and digestate which could be used as fertilizer (Fernández Sevilla 2014).

3.3.2 Closing the Nutrient Loop

As already said, the two main products of anaerobic digestion are biogas and the digestate. Biogas is formed mainly by methane and carbon dioxide, although it has typically other minor components such as water vapor, hydrogen sulfide, ammonia, hydrogen, and nitrogen. On the other hand, the digestate is an aqueous sludge where almost all nutrients remain in a mineralized form, therefore being used as biofertilizer and/or soil amendment. Both products could be used for microalgae culture, the first as carbon source for their autotrophic growth and the second as growth medium, supplying the necessary mineral nutrients for microalgae growth. Possibilities for their use are described in this section.

3.3.2.1 Biogas Upgrading

There are two possibilities for biogas to be used by microalgae (see Fig. 5.5): (1) biogas upgrading by microalgae to produce methane-enriched biogas and subsequent use of methane-enriched biogas in different applications which can provide additional CO2 for microalgae culture and (2) supplying the flue gases produced after the combustion of biogas in traditional CHP engines or boilers to microalgae cultures.

Based on these two basic combinations, different additional processes could be included. For instance, in Fig. 5.5a, instead of using the upgraded biogas in CHP units or boilers, biogas could be further upgraded to be used as vehicle fuels, in fuel cells, or to be injected in natural gas grids. Additionally, in both schemes, cultivated microalgae could be introduced in the anaerobic digester as co-substrate to increase biogas production. The use of flue gases as carbon source in microalgae cultures has been extensively studied and will not be covered in this chapter, where we will focus on biogas upgrading by microalgae.

The need of biogas purification depends on the application in which it is being used, as shown in Fig. 5.2. Hydrogen sulfide and carbon dioxide removal technologies are widely applied in biogas plants all over the world, with different existing options based on chemical, physical, or biological methods.

If microalgae are used for biogas upgrading, the technology needs to be competitive with the existing technologies in the market. Table 5.2 shows a comparison between the main technologies used nowadays for biogas purification. Microalgae show potential in biogas purification at farm scale although capital costs are high compared to other low-cost technologies such as iron sponge, activated carbon, iron chloride addition to substrate, and microareation. Moreover, it is the only technology that has the potential for simultaneous removal of H2S and CO2.

The main benefits of microalgal purification over the other technologies are:

-

Effective absorption of CO2 in the form of biomass.

-

Generation of microalgal biomass which can be further marketed.

-

Microalgal biomass could be used as co-substrate increasing biogas production.

-

No residues are produced and no chemicals are used.

-

The digestate could be also used as growth medium, removing nitrogen and phosphorous

Microalgal biogas purification is a new technology, poorly developed, that even has some uncertainties that will be important to determine the feasibility of the process. Besides the factors influencing microalgal growth in any conventional culture system (light, mineral nutrients, temperature, pH, mass transfer capacity), if biogas is used as carbon source, some additional factors come into play.

Biogas composition influences purification efficiency according to three factors: (1) CH4 concentration, (2) CO2 concentration, and (3) H2S concentration. Another important point that limits the efficiency of the system is the oxygen concentration in the upgraded biogas.

3.3.2.1.1 Methane Concentration